I've had it in open backed tweeters. Then again it's probably not breakup but just a reflection or resonance in the air gap.

If the tweeter is not shielded from the pressure in the box due to the bass driver and this will produce inter-modulation distortion through the cone of the former unit.

At low frequencies there is a lot more air pressure inside the box than on the outside which is a set up where you don't want panels to vibrate making matters worse when cone break up arises. With reflex enclosures the internal air pressure can be regulated by flaring the ports - the same principle can be used for the inside of the hole for the speaker unit.The box internals have nothing to do with cone break-up at say 3-5 kHz, neither does chamfering.

Jbrunner - who did the experiments with the PM180 and his original thread https://techtalk.parts-express.com/forum/tech-talk-forum/61859-scan-speek-4-for-49-cents used DAP Alex Plus Clear claulk. I know he experimented with different adhesives and settled on this one.This has worked well in the past. Of course the people telling us how well this works, would never tell us what they actually use for glue. Here's an example of a very good result:

https://techtalk.parts-express.com/forum/tech-talk-forum/66754-how-to-train-your-pm180-8

The box internals have nothing to do with cone break-up at say 3-5 kHz, neither does chamfering.

Yes, cone resonance is a problem by itself, but 3-5" midrange drivers are very sensitive to cavity resonances at roughly 1-2 kHz frequency range without chamfering

http://www.troelsgravesen.dk/chamfer.htm

Despite the forum's prompt to start a new thread, I thought it made more sense to post this here where some other experiments have been posted. I sliced an SB16PFCR25-8 in a similar pattern to the revelator. I used DAP Alex Plus with Silicone Clear caulk. Because it was clear I could see light through the cone and wasn't sure if there was air leakage so I put some black Dynaflex caulk on the back just to make sure there was no air leak. I put a little bit of gloss Modge Podge on the cone and quickly wiped it off - not trying to add damping but just to make my ugly glue-job look better.

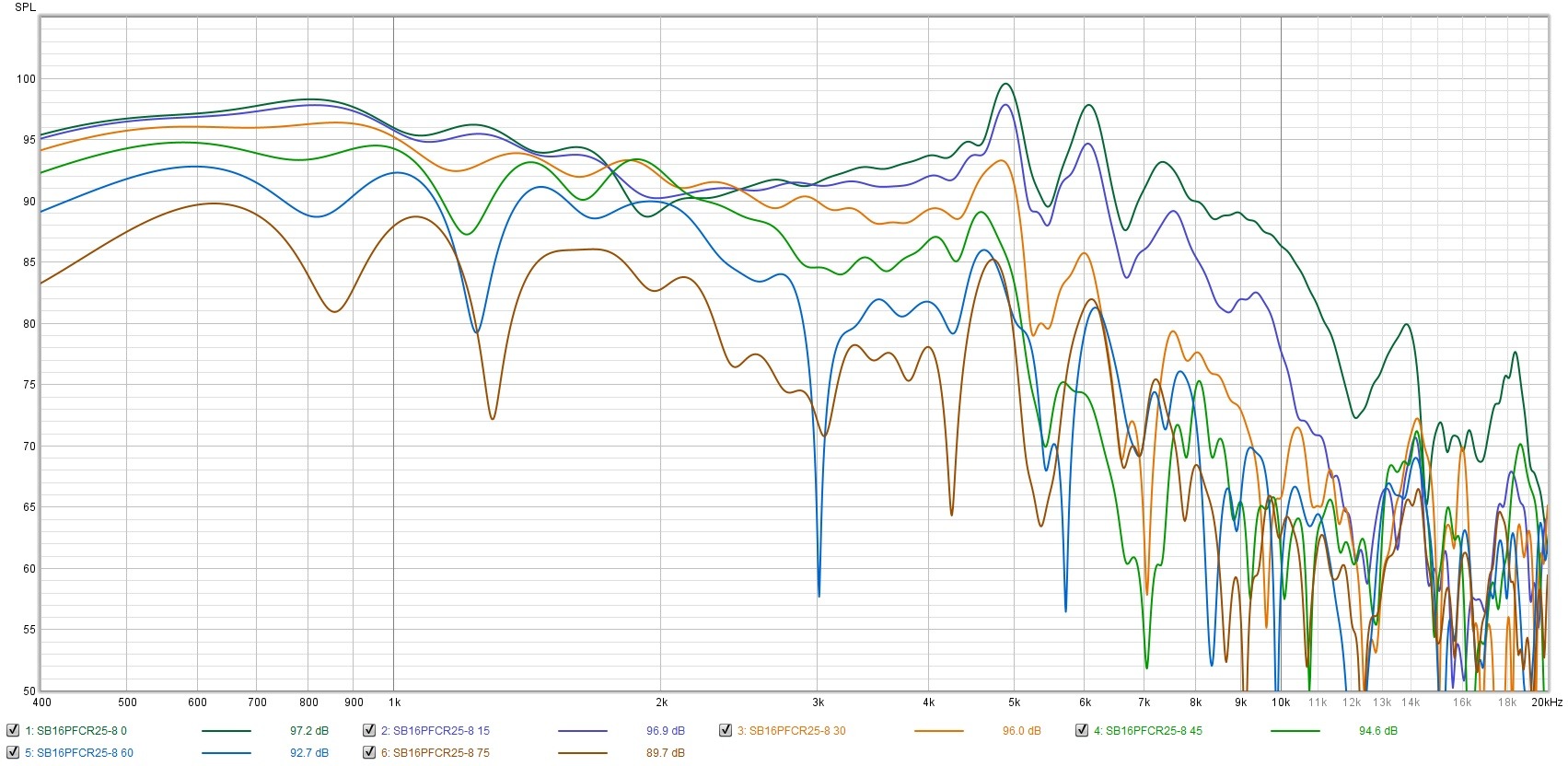

Here is the stock driver from 0 to 75 degrees (15 degree increments)

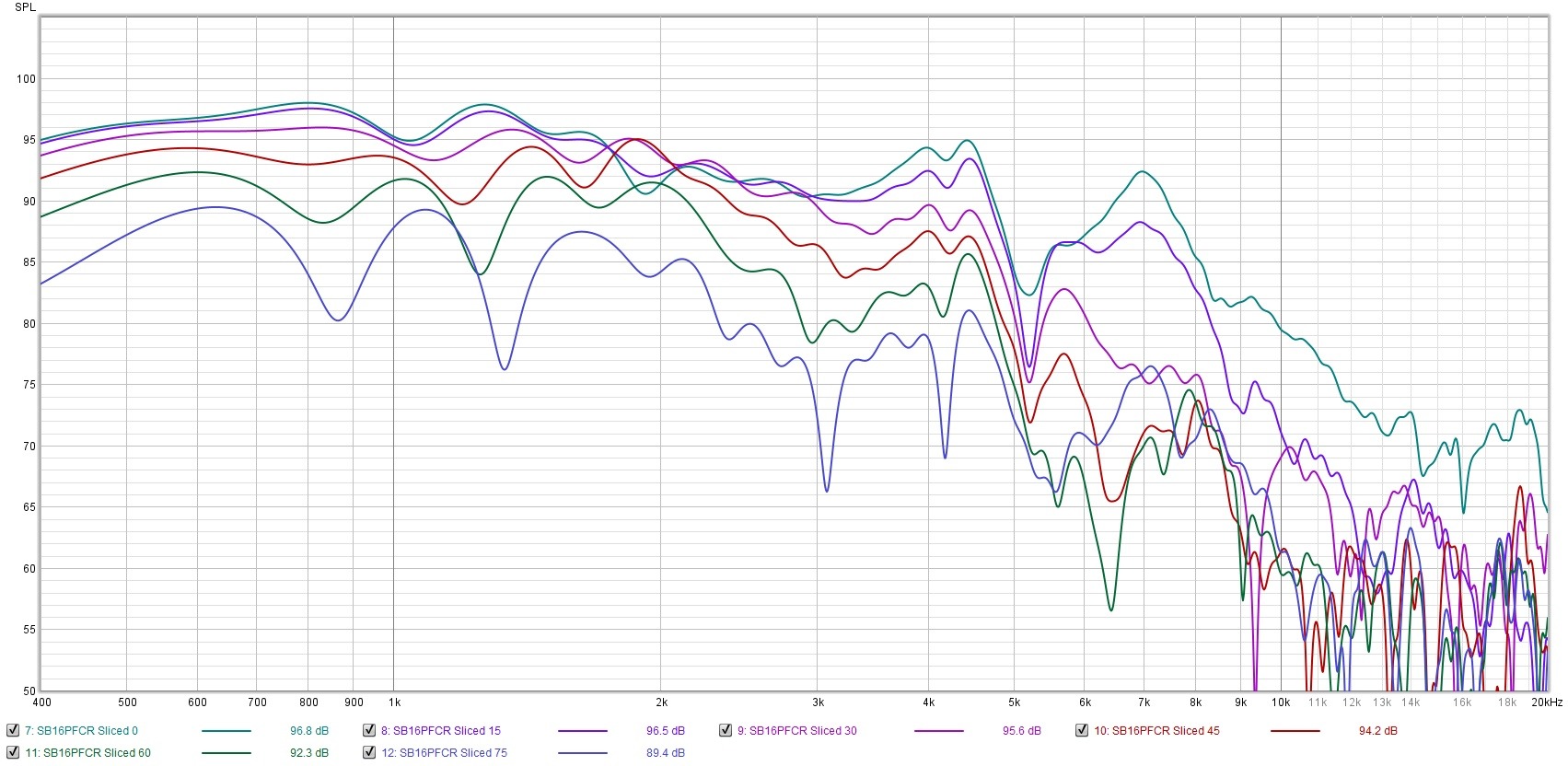

And here is the modified driver - greatly reducing the cone breakup at 5Khz and 6Khz

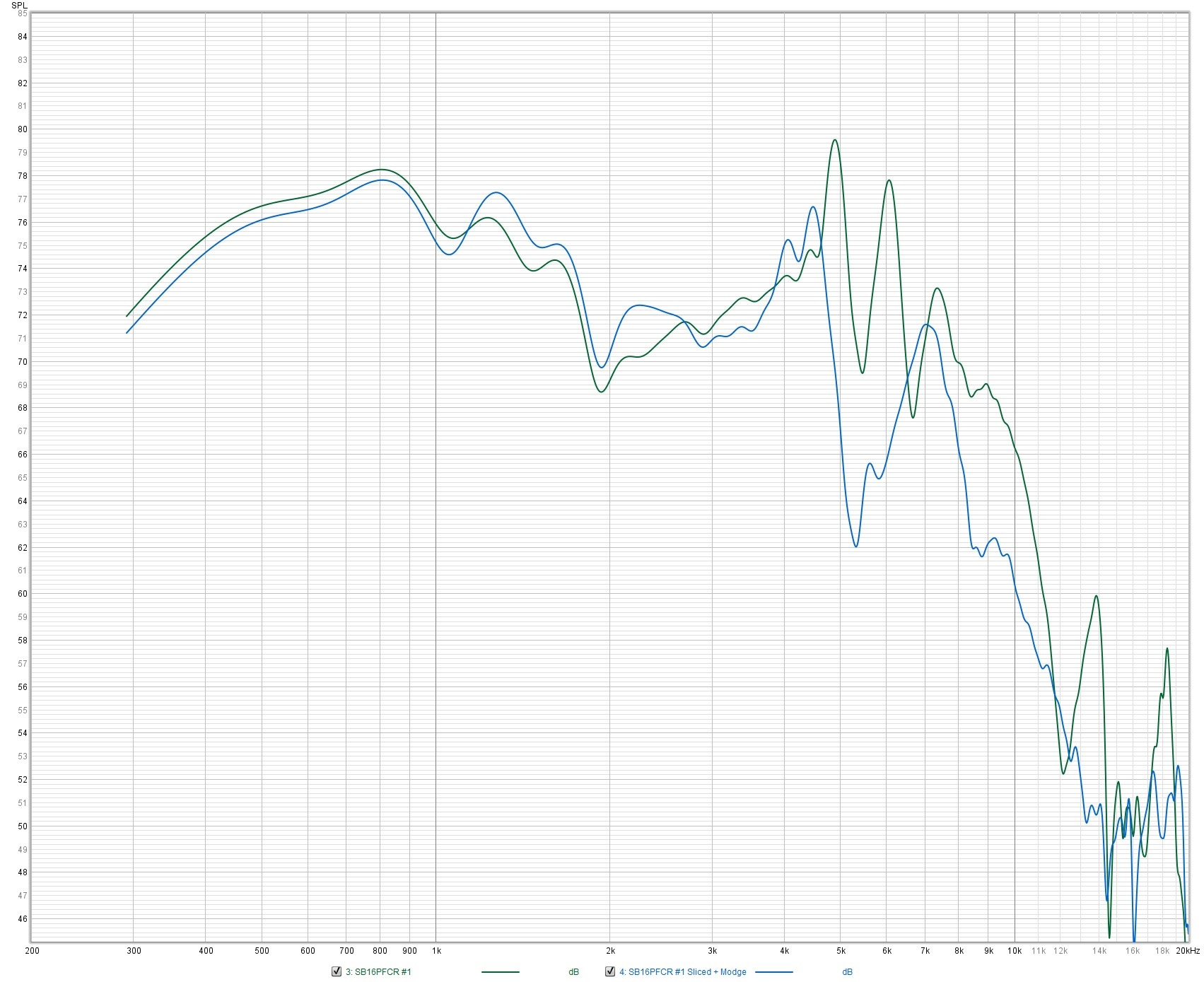

On-axis SPL of stock cone vs sliced cone

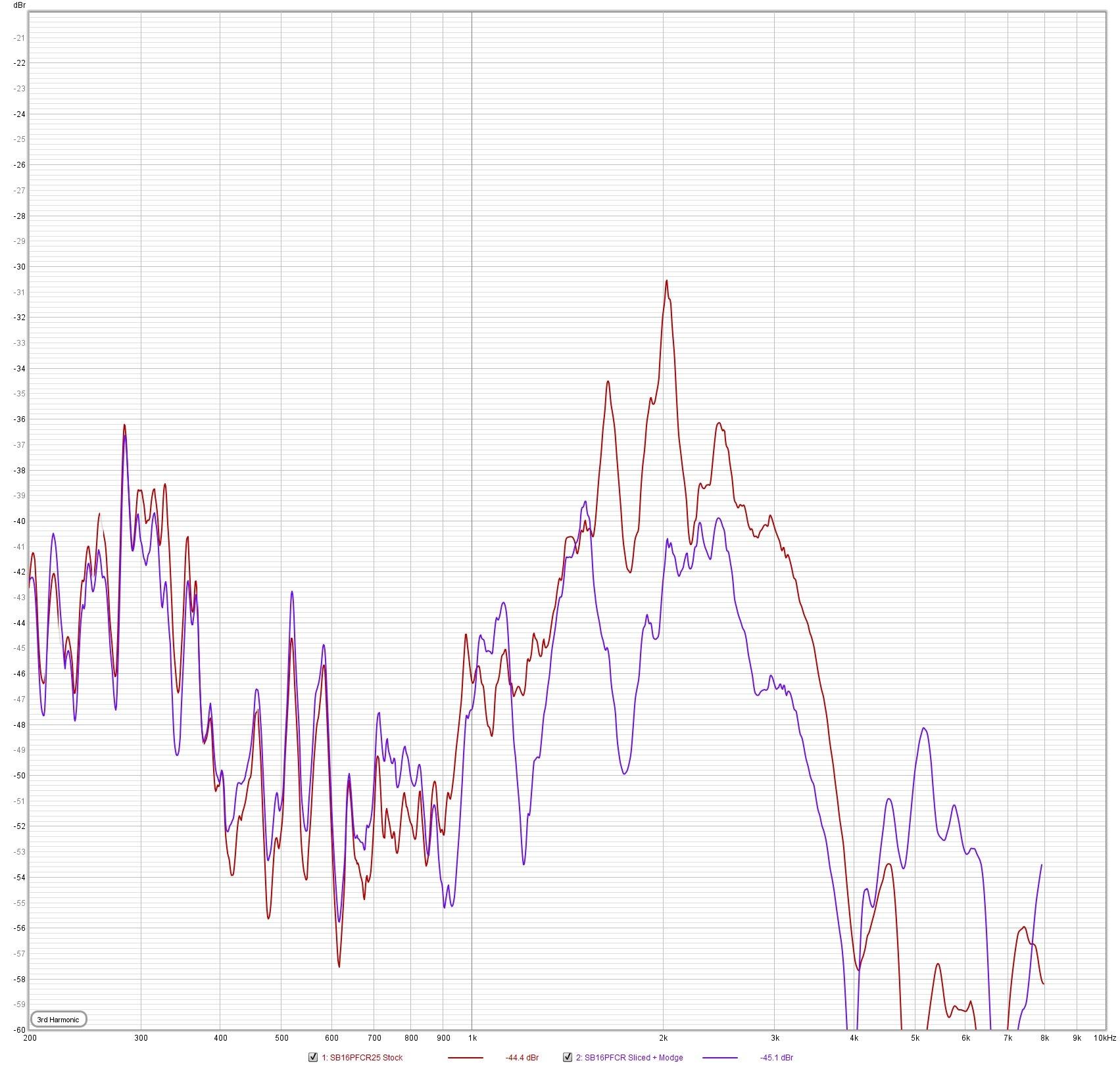

Here is 3rd order distortion of the stock cone vs the sliced cone

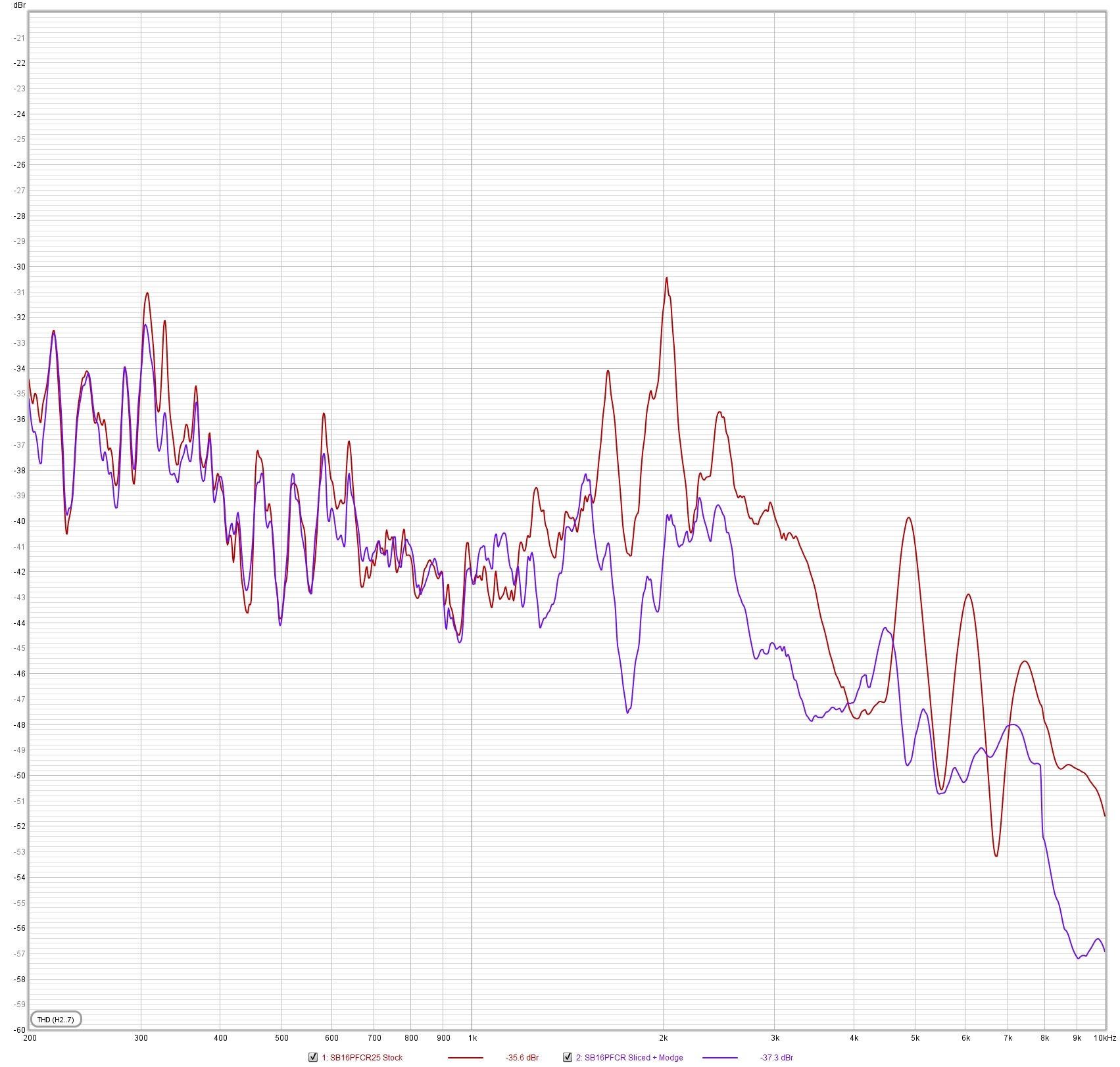

Here is THD of stock cone vs sliced cone

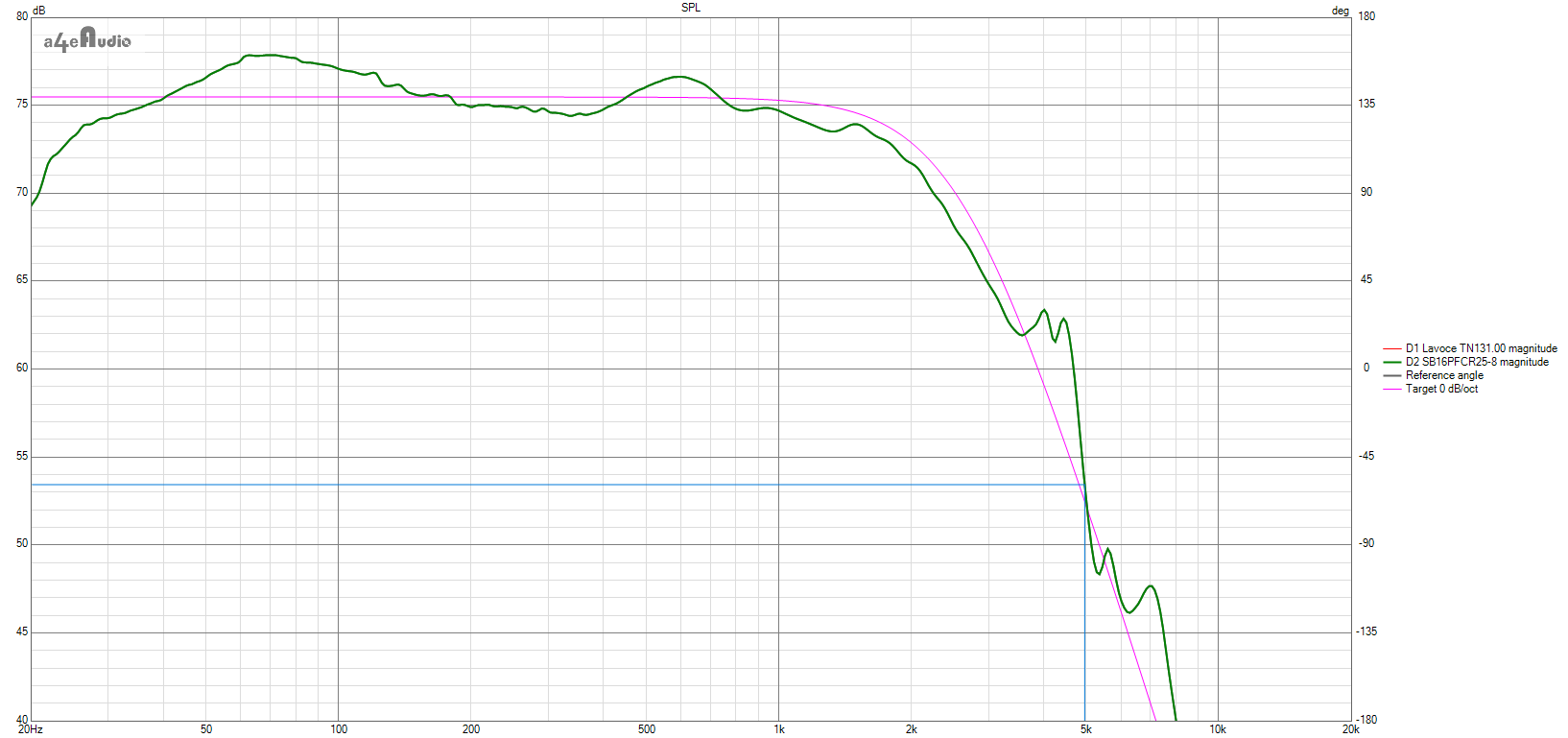

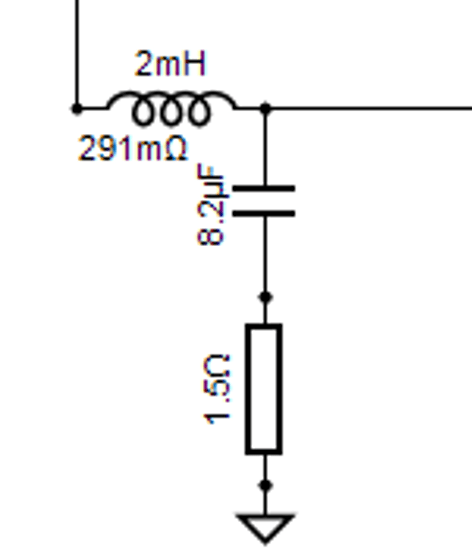

Here is the woofer with a LR4 acoustic crossover in place

Here is the stock driver from 0 to 75 degrees (15 degree increments)

And here is the modified driver - greatly reducing the cone breakup at 5Khz and 6Khz

On-axis SPL of stock cone vs sliced cone

Here is 3rd order distortion of the stock cone vs the sliced cone

Here is THD of stock cone vs sliced cone

Here is the woofer with a LR4 acoustic crossover in place

Attachments

Nice work! Note that Revelator at al, use 5 slices for pentagonal symmetry, which prevents even order (mirror symmetry) drum head vibration modes. Could use 7 but too many more and it approximates a round even cone. You used 10 slices - which is even number. It might have been better at 9 or 7.

It makes me wonder why I had very little change with my similar experiment. I guess the varnish I used was too stiff or perhaps some cone materials benefit more .

I always felt the 16PFCRs sounded very good in stock form. The ones I tested only had mild breakup around 4 - 5k, which was easy to tame by treating the surround junction with viscoelastic coating ie. tub and tile bathroom caulk (not silicone RTV). Otherwise this driver sounds as good as some $50 - $75 Seas stuff I've used before. Its a nice 2 way midbass which sounds very lively and engaging. Its just a little wimpy in the power handling department for my tastes, but great as a dedicated cone mid in OB.

I'm currently re-coning a set of PRV 6MR500-NDY and adding a phase plug. This driver has some significant breakup modes up top, but sounds really nice as a high efficiency midrange, so I'm trying to tame it up top and use a more shallow xover. Alot of junk comes from the sizzle added by the flimsy dustcap, hence I'm using a phase plug instead in hopes of also killing the pole cavity resonance.

I'm currently re-coning a set of PRV 6MR500-NDY and adding a phase plug. This driver has some significant breakup modes up top, but sounds really nice as a high efficiency midrange, so I'm trying to tame it up top and use a more shallow xover. Alot of junk comes from the sizzle added by the flimsy dustcap, hence I'm using a phase plug instead in hopes of also killing the pole cavity resonance.

The Scanspeak 15M/4531K Revelator 5.5" Midrange pictured on Madisound has 10 slices along with the two on the dust cap.Nice work! Note that Revelator at al, use 5 slices for pentagonal symmetry, which prevents even order (mirror symmetry) drum head vibration modes.

https://www.madisoundspeakerstore.com/approx-5-midrange/scanspeak-15m/4531k-revelator-5.5-midrange/

Seems we have a new member with @Tenson 🙂

https://www.diyaudio.com/community/threads/some-speaker-driver-measurements.317632/post-7483104

https://www.diyaudio.com/community/threads/some-speaker-driver-measurements.317632/post-7483104

Nice result! Will you make a pair, it would be cool to see consistency.

The "On-axis SPL of stock cone vs sliced cone" in the post above was my woofer #1, here is the same for woofer #2

Here were the two stock (un-modified) woofers before I started.

Here is an actual speaker with a Lavoce TN131.00 tweeter, taken to InDIYana 2023 and Parts Expresss SDC2023.

This is the speaker, but the tweeter changed to a Peerless XT25SC40 since then. Ash Burl veneer and a DIY waveguide using a Yonico table edge router bit.

My objective conclusions: Slicing a paper cone woofer can reduce the cone breakup significantly as well as lower distortion.

Practical conclusion: This is mostly above the crossover. Reducing the cone breakup definitely makes designing the crossover easier, but its not clear that I couldn't get to the same place with more or different components.

Subjective conclusions: None. These sound good, but so do the stock SB16PFC woofers and I did not build a pair with stock woofers and a pair with sliced woofers to blind A-B test them.

But it was fun and I learned some things. And, oh yeah, this was just practice so that when I slice my Dayton PM180's I don't mess them up, as they were more expensive.

Maybe I'm missing something here but is it not the aim of a speaker cone to act in a pistonic way? If so, where does weakening the cone by slicing it achieve this?

The trick would be to keep the pistonic motion but dampen motion once the cone breaks up (non-pistonically).

I can see where that would be a good thing, but judging by the FR curves, these are far from pistonic. (Depending on frequency reached). So would it not be better to experiment with ways to make it more pistonic within the required range first?

That's true if we knew the behaviour before compared to after the cuts. There seem far more speaker cones made without cuts rather than with them.That would be a question to be asked to the scan speak development labs ...

- Home

- Loudspeakers

- Multi-Way

- I sliced my speaker cone!