Well then. Still remains the capability to comprehend and/or interpret the outcomes.

Best regards!

Best regards!

I tried something similar on a PA130-8.

https://www.diyaudio.com/community/threads/the-daytonator-pa130-8x.279043/

Slicing should be done in odd number like 5 to avoid reflection symmetry. The cones of TC9FD and SS 10F are pentagonal shaped even (glued on a circular surround) and this helps flatten the breakup peaks. Revelator has 5 slices. Use of flexible glue like RTV will probably dramatically change things.

A phase plug and its shape seems to have a bigger impact. In the end I added a coaxial tweeter to where the dustcap was.

https://www.diyaudio.com/community/threads/the-daytonator-pa130-8x.279043/

Slicing should be done in odd number like 5 to avoid reflection symmetry. The cones of TC9FD and SS 10F are pentagonal shaped even (glued on a circular surround) and this helps flatten the breakup peaks. Revelator has 5 slices. Use of flexible glue like RTV will probably dramatically change things.

A phase plug and its shape seems to have a bigger impact. In the end I added a coaxial tweeter to where the dustcap was.

Depends on the varnish. Spar is softer than hard. Poly softer than Spar.The varnish is pretty flexible even when cured. https://photos.app.goo.gl/t6DFPtA3uZkCc5r36

When removing dust caps, one must consider the pole piece venting and if you are creating a place to whistle.

Just being clear, all varnish is not the same. Not everyone is a woodworker and knows these things.

To add confusion, satin and flat has fillers that may change it a little.

To add confusion, satin and flat has fillers that may change it a little.

It might have been a better approach to find a couple of cheap speakers to use as guinea pigs if you want to experiment with doping or slicing cones. Years ago I tried doping cones of my speakers which had Phillips 20 cm paper cones - this after seeing a kit using these with a different crossover network and reportedly using carpet glue as the dopant. I did not like the result however in hindsight I should have applied the glue diluted with water in multiple coats.I have used artist "dope" on some cones and to great effect on the dust caps ( aluminum) of my FE 85's Of course doping adds mass, so it has a lot of effects. I played with some cheap Silver Flute and some Mark drivers for various mode management hacks. Good success adding phase plugs. Not so much on the cones. If you have access to laser inferomerty and can test to see the modes, them knowing what to attack may be easier. People like Scan Speak can and do. There were several papers to AES on this subject in the '70's. Go search the AES archives.

Going wayback, I remember thin balsa strips set in RTV on some cheap cone. I figured out, I should just buy a better driver. A 5K breakup is better handled by selecting an appropriate crossover. If you have used many Dayton RS drivers, you have had to master that. I did want a lower Fs on one aluminum driver and a coating of fabric paint around the edge did help a little as I could use a shallow but lower crossover.

Tenson, Poly is used on car bushings by kiddie racers who don't know better as it is stiffer than rubber giving better control, and slick enough to last a little while. NOT because it has any dampening features. It has a little more shock absorbing than metal in a real race car, and way too much for a street car. There are a few places where it works OK, TC rods and sway bar end bushings for example. One will get around the track on FAT a lot quicker if they used the poly bushing money for an hour of professional instruction.

Since then I have tried ladies nail varnish on paper cones by that process. That did no harm because I did not push the boundaries. Talking of boundaries by slicing the cone you could have tried narrow strips of removable painters tape on the back of the cone.

It looks a little flatter than original between 1.5 and just over 3kHz range where the ear is sensitive. This might work better depending where the crossover to a tweeter is placed. Cosmetically you could have done a tidier job, possibly with some suitable material glued or adhesive tapes across the cuts at the back of the cone. Maybe you should buy some cheap speakers to use as guinea pigs. I recently used removable painters masking tape to stabilise the disc drive of a CD player. I had bought this at an op shop and worked well for a while but started skipping. Opening it up I found that a cover to clamp the disc was not there. The movement of the motor did not affect the effectiveness of the tape.I was curious about the effect of slicing and coating a speaker cone in a similar way ScanSpeak do.

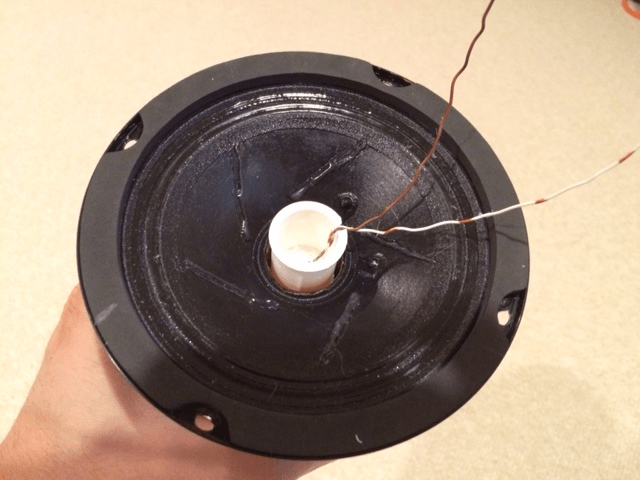

So here you go. Original driver, measured 80dB @ 30cm (at least according to my phone SPL meter).

View attachment 1008539

View attachment 1008538

Now we slice and varnish! Varnish used was two part Sayerlack TLL3097.

View attachment 1008541

View attachment 1008542

View attachment 1008544

View attachment 1008545

View attachment 1008546

I'm amazed the results are so damn similar before and after such brutal slaughter of the driver!

Thank you! Your experiment proves very well that anyone who advocates such treatment simply spreads snake oil BS, unless he's in need for an ugly looking driver.

This has worked well in the past. Of course the people telling us how well this works, would never tell us what they actually use for glue. Here's an example of a very good result:

https://techtalk.parts-express.com/forum/tech-talk-forum/66754-how-to-train-your-pm180-8

This rabbit hole led me to the archived pages of Mark McKenzie. He even used to post on this forum, but I can hardly find a single image of anything he ever created.

http://web.archive.org/web/20200129121454/http://madspeaker.com/page2.html

Older archives have a crafts section on his site, but it's quite useless since like all such "archived" sites the images are all gone.

Does anything of Mark remain?

http://web.archive.org/web/20200129121454/http://madspeaker.com/page2.html

Older archives have a crafts section on his site, but it's quite useless since like all such "archived" sites the images are all gone.

Does anything of Mark remain?

Just my 2C on some points mentioned here.

Electrical filtering. Its possible to entirely 'notch' out resonances on-axis from a driver but the tendency to 'ring' is still there in the driver assembly. Resonances will remain apparent in the harmonic distortion behaviour of the driver. I might notch out a peak at 5khz, but the cone will still show a higher 2nd harmonic at 2.5khz (2.5khz *2).

Doping or driver modifications can damp breakup and the associated harmonic excitation, but we will usually do this at expense of top end response tha ks to increase in weight or reduction in material stiffness. A loss in SPL will also be associated with increased mass. Its easy just to shift problems around in frequency and 'Q' but not actually fix anything.

Phase plugs can do a lot to improve both on and off-axis response. However they do not alter the total energy output at a specific frequency. They do redistribute the energy over space (dispersion angle). Like electrical filters, they do not change structural resonances or their tendancy for harmonic excitation. Generally phase plugs are used to equalise path lengths, or inhibit interference between, more than one sound source such as two sections of a cone that are moving out of phase due to resonant modes or mass imbalance.

I'd estimate most resonant breakup in cones is largely down to reflection of the sound wave as it travels from the center of the cone to the outer rim and encounters a sudden change of material density (I.e. the cone does not continue forever, it stops at the outer edge) this causes the wave to reflect back towards the center of the cone and interference with the next part of the sound wave. Messy behaviour ensues. The rubber / foam / paper surround job is to damp that high frequency energy when it reaches the edge of the cone, while also not limiting the general linear motion of the cone. There are also circular resonance modes that set up around the rim.

The combination of all these factors gets mighty complex, so a bit of practicle experimentation with a specific case is certainly worth trying and doesn't necessarily apply to every other case.

Electrical filtering. Its possible to entirely 'notch' out resonances on-axis from a driver but the tendency to 'ring' is still there in the driver assembly. Resonances will remain apparent in the harmonic distortion behaviour of the driver. I might notch out a peak at 5khz, but the cone will still show a higher 2nd harmonic at 2.5khz (2.5khz *2).

Doping or driver modifications can damp breakup and the associated harmonic excitation, but we will usually do this at expense of top end response tha ks to increase in weight or reduction in material stiffness. A loss in SPL will also be associated with increased mass. Its easy just to shift problems around in frequency and 'Q' but not actually fix anything.

Phase plugs can do a lot to improve both on and off-axis response. However they do not alter the total energy output at a specific frequency. They do redistribute the energy over space (dispersion angle). Like electrical filters, they do not change structural resonances or their tendancy for harmonic excitation. Generally phase plugs are used to equalise path lengths, or inhibit interference between, more than one sound source such as two sections of a cone that are moving out of phase due to resonant modes or mass imbalance.

I'd estimate most resonant breakup in cones is largely down to reflection of the sound wave as it travels from the center of the cone to the outer rim and encounters a sudden change of material density (I.e. the cone does not continue forever, it stops at the outer edge) this causes the wave to reflect back towards the center of the cone and interference with the next part of the sound wave. Messy behaviour ensues. The rubber / foam / paper surround job is to damp that high frequency energy when it reaches the edge of the cone, while also not limiting the general linear motion of the cone. There are also circular resonance modes that set up around the rim.

The combination of all these factors gets mighty complex, so a bit of practicle experimentation with a specific case is certainly worth trying and doesn't necessarily apply to every other case.

What you say matches my understanding and is also similar to the points made my McKenzie in the examples paper in the link I gave, I suggest you read that as it is highly relevant. Unfortunately there are very few pictures extant of McKenzie's work. It almost seems deliberate.

Mark McKenzie together with a certain Spangler wrote an AudioXpress article (around 2002 or so) about drastic improvements of a 3" TangBand polyconed FR driver. The surgery involved replacement of the -ringing- dustcap by a carefully tailored and shaped phase plug/diffuser, stabilization of the inside of the rubber surround by the well known "ring of glue" technique, plus -probably most important- two rings of dimples in the cone. If the somewhat small pictures of the measurements may be believed, this modification should yield one of the very best full ranges, where the drastic removal of cone (and surround interference) break-up has lead to increased bandwidth beyond 20kHz within a few dB, thus a ruler flat SPL.

Most important: these mods were not random hobbyist trials, but every of the three mods was supposed to be the result of cone-dustcap-surround vibration analysis. The article is unfortunately not specfic about the software used, but we may safely assume McK used FEM analysis or/and had access to laser interferometric equipment.

@keantoken : do you have acces to the work with the 10" drivers McK. did?

Most important: these mods were not random hobbyist trials, but every of the three mods was supposed to be the result of cone-dustcap-surround vibration analysis. The article is unfortunately not specfic about the software used, but we may safely assume McK used FEM analysis or/and had access to laser interferometric equipment.

@keantoken : do you have acces to the work with the 10" drivers McK. did?

A good video of FineCone software to design cones, dustcaps and phase plugs, by Peter Larsen.

Slicing is not in the demo. Slices and added glue rims etc. cone edge treatments will add Mms naturally, but reduction of efficiency in usable bandwidth is minimal.

SB Acoustic uses added mass on the backside of the cone edge on some models "ring of glue"

https://www.diyaudio.com/community/threads/sb-acoustics-satori-monitor.220330/page-45#post-4847329

Slicing is not in the demo. Slices and added glue rims etc. cone edge treatments will add Mms naturally, but reduction of efficiency in usable bandwidth is minimal.

SB Acoustic uses added mass on the backside of the cone edge on some models "ring of glue"

https://www.diyaudio.com/community/threads/sb-acoustics-satori-monitor.220330/page-45#post-4847329

Found the McK patent referred to:

https://patentimages.storage.googleapis.com/e6/79/69/7fd36a8aa85545/US20070092101A1.pdf

https://patentimages.storage.googleapis.com/e6/79/69/7fd36a8aa85545/US20070092101A1.pdf

His Tangband thread on this forum also shows a slit cone method, he says both will result in a very good driver.Mark McKenzie together with a certain Spangler wrote an AudioXpress article (around 2002 or so) about drastic improvements of a 3" TangBand polyconed FR driver. The surgery involved replacement of the -ringing- dustcap by a carefully tailored and shaped phase plug/diffuser, stabilization of the inside of the rubber surround by the well known "ring of glue" technique, plus -probably most important- two rings of dimples in the cone.

https://www.diyaudio.com/community/threads/markmcks-tang-band-mods.28355/

Mark specifically asserted that simulation was not good enough to do this work. He mentioned laser measurements and sound pressure measurements so I speculate his method was entirely measurement based maybe with a sprinkle of math.Most important: these mods were not random hobbyist trials, but every of the three mods was supposed to be the result of cone-dustcap-surround vibration analysis. The article is unfortunately not specfic about the software used, but we may safely assume McK used FEM analysis or/and had access to laser interferometric equipment.

No, it has been difficult to find a way to access his material. I made a thread where we can collect stuff:keantoken: do you have acces to the work with the 10" drivers McK. did?

https://www.diyaudio.com/community/...imple-cones-and-madsound.381060/#post-6890582

BTW: Tenson I see you act all innocent but there you are in the old Tangband thread talking it up with McKenzie himself!

Cone break up would not be helped by uneven pressure inside the box which arises in the corners and where space is tight. With small diameter speaker drivers a 19mm depth of MDF puts the basket and cone in a tight spot if the hole in the baffle is a straight cut.

Sculpting material away from the inside edges of the hole or rounding/contouring the edges of the hole to increase air flow and reduce pressure are well known strategies but it is not clear if such have been applied in this case.

I don't know if boxes made from MDF can make the most of Scanspeak slit cone drivers.

Sculpting material away from the inside edges of the hole or rounding/contouring the edges of the hole to increase air flow and reduce pressure are well known strategies but it is not clear if such have been applied in this case.

I don't know if boxes made from MDF can make the most of Scanspeak slit cone drivers.

The box internals have nothing to do with cone break-up at say 3-5 kHz, neither does chamfering.

I thought I saw some measurements where a thick baffle obstructed the rear of the cone near the surround. This probably has the most effect on super efficient light cone drivers.

I've had it in open backed tweeters. Then again it's probably not breakup but just a reflection or resonance in the air gap.

- Home

- Loudspeakers

- Multi-Way

- I sliced my speaker cone!