Take a look at the power transformer, the shield plus the clamping screw, if not properly insulated, is a short circuit turn.

Well, I have measured B+ voltage on top of the input triodes anode and there is ~170 mV AC in both channels. DO you think that those 170 mV AC can cause audible hum?

Regarding power transformer - this was my first idea that there a coubling between power transformer and output transformers. Therefore I put shield around it but there was no change - still the same level of hum.

Regarding power transformer - this was my first idea that there a coubling between power transformer and output transformers. Therefore I put shield around it but there was no change - still the same level of hum.

That seems quite a lot. Where precisely did you measure this? At the anode of the upper valve? Could be a decoupling capacitor (or wiring) open circuit.

just want to share my 2 cents

I have experienced building the DIY from HK

I am suspecting all the parts is not ORIGINAL

My suggestion drastically change Resistor and Capacitor

I did that with my JP200 and now sound very very good and no hum at all

Also I noticed that the PS play important part on all tube

Even I change all the parts on Pre-amp some time I still hear the static noise on it.

So I decided to change all the component from PS .... and sound like heaven now...

If you want to get more information pls inbox me

tks

I have experienced building the DIY from HK

I am suspecting all the parts is not ORIGINAL

My suggestion drastically change Resistor and Capacitor

I did that with my JP200 and now sound very very good and no hum at all

Also I noticed that the PS play important part on all tube

Even I change all the parts on Pre-amp some time I still hear the static noise on it.

So I decided to change all the component from PS .... and sound like heaven now...

If you want to get more information pls inbox me

tks

Well, I have measured B+ voltage on top of the input triodes anode and there is ~170 mV AC in both channels. DO you think that those 170 mV AC can cause audible hum?

Regarding power transformer - this was my first idea that there a coubling between power transformer and output transformers. Therefore I put shield around it but there was no change - still the same level of hum.

He means that if the shield and the bolt that goes through the toroidal power transformer are electrically connected, then they form a short circuit for the magnetic field around the transformer. This would overload it and cause other problems. Make sure the bolt that goes through the shield on the power transformer is not electrically connected to the shield itself.

Have you tried different tubes?

Well, I have measured B+ voltage on top of the input triodes anode and there is ~170 mV AC in both channels. DO you think that those 170 mV AC can cause audible hum?

Regarding power transformer - this was my first idea that there a coubling between power transformer and output transformers. Therefore I put shield around it but there was no change - still the same level of hum.

Good data point. 170mV sounds like a lot of ripple.

You have components that should filter conducted ripple on the B+ fine. The power supply sees a static load (i.e. - no music, only quiescent bias) for this testing, so at the moment I doubt it is a component issue in the power supply filtering.

There seem to me to be two possiblities.

One is heater-induced hum from the 6.3VAC heater supply. Several posters have suggested testing your amp using a 6V lantern battery for the filament supply - this sounds like a relatively simple test and should help determine whether the heater is a source of trouble.

If you replace the AC filament supply with a battery and still have hum, then at least you can put the heater supply question aside for the moment. If the hum goes away, or drops dramatically, then you can explore heater supply options or biasing.

The second is coupling between the power and output transformers. Remember, this coupling will be magnetic so an electrostatic shield won't help - the shield needs to be iron-based (ferrous), and even then I can't say whether it would be effective. Aluminum or copper shielding won't do a thing about the magnetic fields, they will pass right through and tickle the output transformers.

The best test I can think of to resolve transformer coupling is to set up a test to move the output trannies away from the power transformer.

For this experiment, you may need to lengthen the wires connecting the output transformers so you can move them a foot or two away. If you can move the output and power transformers closer together and further apart and can hear (or see on a scope) the hum increase or decrease in amplitude then you have found a coupling path.

I would try the battery-filament power first, simply because it's less invasive to your setup. If that doesn't work (you still have hum with DC filament supply) then try separating the output transformers from the power supply by a foot or two to see if that reduces the hum.

Best luck - and don't give up, there are a lot of folks here interested in the puzzle, I just hope we aren't overwhelming you with well-intentioned advice. If nothing else, it's a good learning experience for all of us!

~ RF Dude

Move the toroidial power transformer out of the enclosure (and preferably a foot away). I'll bet most of the hum disappears. A power transformer should be MUCH farther away from the tubes, the printed circuit, input wiring, output transformers, etc. Mount the toroid with plastic zip-ties, inside its own metal box. Try turning it in differnt directions to minimize hum.

Put small ceramic disc or mica chip capacitors across the main power supply rectifier diodes, to absorb any switching noise.

Put a small ceramic disc and a MOV across the power transformer primary.

A single-ended amp does not cancel noise on the B+, so you need MUCH better filtering than for a push/pull. Use power supply simulation software; it's easy & fun & free. If you make the caps a lot bigger, add a current-inrush limiter on the transformer primary, and you may need to upgrade the rectifiers to handle the start-up current reliably. Then a C-L-C filter network. I would especially make the second Capacitor much larger or consider using a capacitance-multiplier, which is a wonderful way to smooth ripple economically in a small space. Then another R-C is optional.

Twist the heater wires, and consider putting a braid shield over them and running them in a seperate cable if you remote the power supply.

Instead of referencing the heater center-tap to ground, reference the heaters to a voltage divider (beteen 2 resistors in series) so it is referenced to about 1/10 of B+ instead of to ground.

You can also consider DC heaters for the first stage.

Use metal-film resistors for the first stages.

Use shielded wire from the input jack and to/from all pots.

I see you went to great lengths to package this thing compactly, but that's really not a great idea. Put the power transformer and first filters in their own box.

Put small ceramic disc or mica chip capacitors across the main power supply rectifier diodes, to absorb any switching noise.

Put a small ceramic disc and a MOV across the power transformer primary.

A single-ended amp does not cancel noise on the B+, so you need MUCH better filtering than for a push/pull. Use power supply simulation software; it's easy & fun & free. If you make the caps a lot bigger, add a current-inrush limiter on the transformer primary, and you may need to upgrade the rectifiers to handle the start-up current reliably. Then a C-L-C filter network. I would especially make the second Capacitor much larger or consider using a capacitance-multiplier, which is a wonderful way to smooth ripple economically in a small space. Then another R-C is optional.

Twist the heater wires, and consider putting a braid shield over them and running them in a seperate cable if you remote the power supply.

Instead of referencing the heater center-tap to ground, reference the heaters to a voltage divider (beteen 2 resistors in series) so it is referenced to about 1/10 of B+ instead of to ground.

You can also consider DC heaters for the first stage.

Use metal-film resistors for the first stages.

Use shielded wire from the input jack and to/from all pots.

I see you went to great lengths to package this thing compactly, but that's really not a great idea. Put the power transformer and first filters in their own box.

Last edited:

One thinkg I tried as well was that I doscinnected AC heater volateg from one channel while keeping B+ voltage connected and this channel was without hum. Does this mean that there is something wrong with heaters?

Once the valves have warmed enough, and have full power, carefully disconnect the heaters in one channel, if the hum disappears immediately you must go to DC heater supply.

Well, I have measured B+ voltage on top of the input triodes anode and there is ~170 mV AC in both channels. DO you think that those 170 mV AC can cause audible hum?

Much, but not how to measure ripple in a huming amp. IMHO.

Measure the current consumption, then disconnect the whole amp (or just remove all valves) and put a dummy load on PSU, and then measure AC ripple.

Last edited:

Something to try,

Just disconnect the Gnd from the heater supply and put a 0.1uf polypropylene cap rated at 600v one end on the connection Ground and the other to the heater. See what happens.

Do the same to the other channel. You can remove any dividers for the HT/B+ lifting and just float the heaters with the cap...

Regards

M. Gregg

Just disconnect the Gnd from the heater supply and put a 0.1uf polypropylene cap rated at 600v one end on the connection Ground and the other to the heater. See what happens.

Do the same to the other channel. You can remove any dividers for the HT/B+ lifting and just float the heaters with the cap...

Regards

M. Gregg

Last edited:

Well, I have measured B+ voltage on top of the input triodes anode and there is ~170 mV AC in both channels. DO you think that those 170 mV AC can cause audible hum?

Well there is your hum. Your DMM is measuring the RMS value of that AC signal and that 170mV equates to about 500mV P/P. That noise is either being created in the power supply module, or being induced into the B+ from the "AC Ground". Since you added a choke of 10H earlier and saw no improvement, then I would guess that the B- is tied to the incoming line AC ground and is picking up the noise from there.

I'll bet the worst problem is the power transformer so close to the circuit and the tubes.

Yes, it could very well be, and/or the connections from and to the transformer, or maybe even the ones between the rectifiers/reservoir caps.

Also, there are likely MANY current loops with "enclosed loop area", which could be getting AC currents induced in them, by those AC fields. The input signal and ground conductors are usually the worst, for that. But it could be also be significantly affecting others. It depends on the layout.

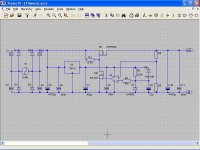

gootee: I don't resist 🙂 I'm just not sure what to improve. I believe that I don't have any ground loops. As for the input - there are inpit jacks on the back panel (isolated) with shielded coaxial cable feeding both GND and signal wire to input terminal. Here the GNDs for L and R channel are connected together and to PCB. Please check attached photo. Is there anything wrong with it?

As for the star GND it is shown on the photo as well and it is close to filter capacitors. All the wires from output transformers and outpu terminals goes to this point (not the input GND that is connected on the other side of the PCB to input terminal). Star GND is connected to chassis with a single wire as well PE from mains and trnasformer shielding is connected to this single point on chassis.

If I shorten the input RCA jack, input terminal or grid of input triode to GND it is always the same. I mean the audible hum level is not changed.

OK. I see now that it is done significantly better than I thought.

Except: HOW, exactly, do the ground ends of R6 and R7 get to the ground of the last PSU cap (C5)? Is there a ground plane on the other side of the board?

If not, then it appears that maybe the heater circuit is sharing part of a ground trace with the input resistors (If that's R15, above the left 12AX7, in the photo in post 60). A photo of the other side of the board would help.

Is this board made to be used only with constant DC heater currents?

I would definitely try that, at this point. Fixing the ground layout (if that is a problem) might not be easy.

filament should be insulated from cathode by aluminum oxide coating, maybe is there shortcircuitSo what can be wrong with just the input tube?

I will try to increase filtering for input tube as you recommended.

Anything else to try?

(white dust fallen down inside tube ?)

it may not be measurable when cold, but if hot - filament goes larger and can touch the cathode (if aluminum oxide broken)

i use AC center tap, non elevated heaters, no hum if ECC803 or 802 -srpp

twisted wires, even touching tubes

halfwave silicon HV type rectifiers , everything dirty connected

Thanks for all your comments and ideas. It seems I made some progress 🙂

Well, first I removed the PCB, transformers etc. out of the chassis and tried to elaborate with power transformer's position with respect to PCB and output transformer's position. No change. Then I covered the power trnasformer with magnetic iron shiled. Again no improvement.

The next thing I tried was to:

- disconnect CT resistor network in AC heater voltage from the ground

- replace AC heater voltage by DC - bridge rectifier + 4700u elko + 7805 with 2 diodes + 2x decoupling 100n at the input and output --> 6.3 V DC

- connect minus pin of this DC regulated power supply to amp GND (star GND on the PCB) - without grounding it there was a lot of noise in speakers - oscillations

and WOW - there is no hum in one channel now!

And now the question - what should I do with it?

Well, I can build 2 DC power supplies (left + right channel) for heater using original AC voltage + above described regulator but... more components (space) + a lot of heat from the 7805 regulator and bridge rectifier.

Any other suggestions? If we analyze the root cause - AC heater voltage - and found that making it DC helps are there any other things to try while keeping the heater voltage AC? e.g. CT resisots network connected to +B to GND resistor divider discussed before?

Well, first I removed the PCB, transformers etc. out of the chassis and tried to elaborate with power transformer's position with respect to PCB and output transformer's position. No change. Then I covered the power trnasformer with magnetic iron shiled. Again no improvement.

The next thing I tried was to:

- disconnect CT resistor network in AC heater voltage from the ground

- replace AC heater voltage by DC - bridge rectifier + 4700u elko + 7805 with 2 diodes + 2x decoupling 100n at the input and output --> 6.3 V DC

- connect minus pin of this DC regulated power supply to amp GND (star GND on the PCB) - without grounding it there was a lot of noise in speakers - oscillations

and WOW - there is no hum in one channel now!

And now the question - what should I do with it?

Well, I can build 2 DC power supplies (left + right channel) for heater using original AC voltage + above described regulator but... more components (space) + a lot of heat from the 7805 regulator and bridge rectifier.

Any other suggestions? If we analyze the root cause - AC heater voltage - and found that making it DC helps are there any other things to try while keeping the heater voltage AC? e.g. CT resisots network connected to +B to GND resistor divider discussed before?

Last edited:

You may be able to use AC by disconnecting the heater traces on the PCB and using tightly twisted wire instead. If you are very careful in cutting the traces you might even be able to repair them again if you decide to go to DC heaters. The idea is to isolate each heater connection from the PCB trace, yet leaving just enough copper to solder a wire to. The newly unused heater tracks should then be grounded.

Regarding DC heaters, you may find that the existing secondaries cannot supply DC as that will require about 3 times as much VA rating.

Regarding DC heaters, you may find that the existing secondaries cannot supply DC as that will require about 3 times as much VA rating.

Thanks for all your comments and ideas. It seems I made some progress 🙂

Well, first I removed the PCB, transformers etc. out of the chassis and tried to elaborate with power transformer's position with respect to PCB and output transformer's position. No change. Then I covered the power trnasformer with magnetic iron shiled. Again no improvement.

The next thing I tried was to:

- disconnect CT resistor network in AC heater voltage from the ground

- replace AC heater voltage by DC - bridge rectifier + 4700u elko + 7805 with 2 diodes + 2x decoupling 100n at the input and output --> 6.3 V DC

- connect minus pin of this DC regulated power supply to amp GND (star GND on the PCB) - without grounding it there was a lot of noise in speakers - oscillations

and WOW - there is no hum in one channel now!

And now the question - what should I do with it?

Well, I can build 2 DC power supplies (left + right channel) for heater using original AC voltage + above described regulator but... more components (space) + a lot of heat from the 7805 regulator and bridge rectifier.

Any other suggestions? If we analyze the root cause - AC heater voltage - and found that making it DC helps are there any other things to try while keeping the heater voltage AC? e.g. CT resisots network connected to +B to GND resistor divider discussed before?

AC heaters are a PITA, try this, is a DC PSU with low voltage drop, and put an end to about 70 V with respect to ground.

BTW. On both sides of the power transformer, you have enough space.

Ufil = [(R4+R5)/R5)] Ureff

Ureff = 1.2V (LM385 1.2)

Ureff = 2.5V (LM385 2.5)

Hint: If a 7805 seems too much, you can use a 5 V zener.

Any low noise, single supply, op amp can work. 😉

Attachments

Last edited:

With respect to isolating the AC heater traces on the pcb - this would need to be done where the traces connect to each valve base, and the AC voltage not taken to the board - so that no traces have the voltage on them.

But to help yourself understand, and others, it would be good to have photos of both sides of pcb and an assessment of how close these traces get to sensitive signal traces.

Before you do any cutting, do you have an alternative transformer that can supply an AC heater voltage. The idea is to power the heaters from a separate transformer - this may indicate if the noise is just 50Hz, or includes hash noise from the HT rectifier coupling in through the heater winding.

But to help yourself understand, and others, it would be good to have photos of both sides of pcb and an assessment of how close these traces get to sensitive signal traces.

Before you do any cutting, do you have an alternative transformer that can supply an AC heater voltage. The idea is to power the heaters from a separate transformer - this may indicate if the noise is just 50Hz, or includes hash noise from the HT rectifier coupling in through the heater winding.

this may indicate if the noise is just 50Hz

Here's a 60Hz hum. Does it sound close to this or higher in frequency?

https://www.youtube.com/watch?v=SVZ2P0KsLic

- Home

- Amplifiers

- Tubes / Valves

- Hum in tube amp