Hi friends

Those numbers are confusing (still)...

A good thermal pad has a low thermal resistance and a high thermal conductivity, is that correct?

And a lower resistance is somewhat more important then high(ish) conductivity? (I understand it as: Since a pad barely has mass, a lower resistance helps to accelerate the transfer into the heatsink...)

Electric non-conductivity: how high should I aim for electric insulation (correct term?) of those germanium-biguns and some such beasts

(Or, to shoot down all that questioning, should just put some keratherm under all those buggers? 😀 )

Those numbers are confusing (still)...

A good thermal pad has a low thermal resistance and a high thermal conductivity, is that correct?

And a lower resistance is somewhat more important then high(ish) conductivity? (I understand it as: Since a pad barely has mass, a lower resistance helps to accelerate the transfer into the heatsink...)

Electric non-conductivity: how high should I aim for electric insulation (correct term?) of those germanium-biguns and some such beasts

(Or, to shoot down all that questioning, should just put some keratherm under all those buggers? 😀 )

Reread what they mean until they click 🙂Those numbers are confusing (still)...

Both mean the exact same thing.A good thermal pad has a low thermal resistance and a high thermal conductivity, is that correct?

Read above answer.And a lower resistance is somewhat more important then high(ish) conductivity?

Any transistor insulator I know of has at least some hundred Volt insulation so not a problem here.Electric non-conductivity: how high should I aim for electric insulation

Germaniums in general work with not-that-high voltages, so no poblem.(correct term?) of those germanium-biguns and some such beasts

Keratherm is an excellent quality product, so ... why not?(Or, to shoot down all that questioning, should just put some keratherm under all those buggers? )

I use solely HARD MICA buying them in a thickness of 0.1mm and then using a art knife to slice them do 0.05mm (or even thinner) applying Unick silicone Heat sink compound and I never have to worry for the next 5 years, about heating up..

do no use silicone soft for Class A, it's too slow to get the heat of..

do no use silicone soft for Class A, it's too slow to get the heat of..

Ok then.

Thank you JM for clarifying resistance/conductivity. (Writing it up like this makes it clear…)

I‘m quite inclined to give (hard) mica a try. Until now, I more or less exclusively used keratherm. Curiosity shall prevail 🙂

But halving a 0.1 mm pad, woah!

Thank you JM for clarifying resistance/conductivity. (Writing it up like this makes it clear…)

I‘m quite inclined to give (hard) mica a try. Until now, I more or less exclusively used keratherm. Curiosity shall prevail 🙂

But halving a 0.1 mm pad, woah!

I've just purchased some of this material to use with my SissySIT build - it seems to have a high specification and is rated by the computer tweaking community.

One enjoy Thermalright Thermal Pad 12.8 W/mK, 85x45x1mm, Non Conductive Heat Resistance High Temperature Resistance, Silicone Thermal Pads for Laptop Heatsink/GPU/CPU/LED Cooler (1mm) - Amazon.co.uk

One of the reasons I bought it is because the bottom faces of the Tokin SITS aren't perfectly flat and this stuff seems to perfrom well while being capable of gap filling - we're not talking big gaps, just a fraction of a millimetre of rocker.

One enjoy Thermalright Thermal Pad 12.8 W/mK, 85x45x1mm, Non Conductive Heat Resistance High Temperature Resistance, Silicone Thermal Pads for Laptop Heatsink/GPU/CPU/LED Cooler (1mm) - Amazon.co.uk

One of the reasons I bought it is because the bottom faces of the Tokin SITS aren't perfectly flat and this stuff seems to perfrom well while being capable of gap filling - we're not talking big gaps, just a fraction of a millimetre of rocker.

You (I mean, we) should take HIS opinion into consideration—keratherm is sensitive)

(And be careful what you say, he see everything 😀 )

(And be careful what you say, he see everything 😀 )

Keratherm seems okay-ish. Other brands claim much better performance, like the Thermalright nautibuoy linked. Some claim 16 W/mK.

Arctic MX-5 is often recommended as paste but again, other brands claim much better performance. Having used MX-5, and plenty other brands, for years I was thoroughly impressed by Thermal Grizzly Kryonaut. This stuff is amazing.

In reality, the difference between a 6 W/mK and 12 W/mK product is much less than the numbers indicate.

Mica and paste here too.

Arctic MX-5 is often recommended as paste but again, other brands claim much better performance. Having used MX-5, and plenty other brands, for years I was thoroughly impressed by Thermal Grizzly Kryonaut. This stuff is amazing.

In reality, the difference between a 6 W/mK and 12 W/mK product is much less than the numbers indicate.

Mica and paste here too.

Both mean the exact same thing.

JM, pardon me, but...

I just looked at 2 thermal pads' specs:

Bergquist 2165479 5 W/mK and 0.32 K/W

Bergquist 2165470 3 W/mK and 0.12 K/W

Their respective thermal conductivity and ^resistance aren't correlating, and I wonder what's behind. Could it be a mass-thing of sorts?

(Or otherwise asked, which one is better?)

🙄physics!🙄

Their respective thermal conductivity and ^resistance aren't correlating, and I wonder what's behind.

for the first product you refer to:

the thermal conductivity (5) is given in W/mK (Watt per meter*Kelvin, not milli-Kelvin!) which is the material's specific dimensionless value (no thickness and surface considered).

the thermal resistance of 0,32 is given in K/W on the vendor's page apparently for a specific thickness and dimension of a pad, but if you look into the data sheet you see that it is not correct, as this value is defined as thermal imedance in "°C-in2/W", the thermal resistance depends on far more factors, see data sheet:

TO220 with 20 mil pad and 10 psi pressure: 1,18 °C/W (=K/W)

TO220 with 20 mil pad and 200 psi pressure: 0,72 °C/W

it should be possible to take the thermal conductivity value and calculate the heat flow for a specific tickness and surface and get the corresponding thermal resistance... i can try this later!

(edit) ... and regarding which one is better: 0.12 K/W should be keeping the heat source cooler but check the datasheet for reliable values!

Last edited:

Their respective thermal conductivity and ^resistance aren't correlating, and I wonder what's behind. Could it be a mass-thing of sorts?

(Or otherwise asked, which one is better?

Thermal resistance (or impedance) is the better one to use as it takes into consideration the thickness of that particular pad amongst other characteristics

grüezi myleftear,

theoretical thermal resistance can be calculated as follows (anyone correct me if i am wrong!):

variables:

Q: rate of heat flow in [W]

A: surface in [mm2]

delta T: temperature difference in [K or °C]

l: thickness in [mm]

k: thermal conductivity in [W/mK] or, for easier calculation in [W/mmK]

values:

Q = 1 W (to get the thermal resistance in K/W)

A = 150 mm2 (10 mm * 15 mm, roughly for TO220)

delta T = to be calculated

l = 0,508 mm (20 mil)

k = 5 W/mK = 0,005 W/mmK

formula:

delta T = (Q *l) / (A * k)

with values inserted:

delta T = (1W * 0,508 mm) / (150 mm2 * 0,005W/mmK) = 0,677 K

this means that a S35 pad with 20 mil used for TO220 will have an ideal thermal resistance of 0,677 K/W.

actual thermal resistance squeezing the pad with 200 psi is rated 0,72 K/W (slightly worse, maybe my surface assumption was too optimistic).

so coming back to your question:

Gap Pad ® 5000S35 has the better specific non-dimensional thermal conductivity (5 watts per meter*kelvin instead of 3).

however, Gap Pad® 3000S30 is available with half the thickness and in this case has lower thermal resistance even with it's smaller thermal conductivity.

theoretical thermal resistance can be calculated as follows (anyone correct me if i am wrong!):

variables:

Q: rate of heat flow in [W]

A: surface in [mm2]

delta T: temperature difference in [K or °C]

l: thickness in [mm]

k: thermal conductivity in [W/mK] or, for easier calculation in [W/mmK]

values:

Q = 1 W (to get the thermal resistance in K/W)

A = 150 mm2 (10 mm * 15 mm, roughly for TO220)

delta T = to be calculated

l = 0,508 mm (20 mil)

k = 5 W/mK = 0,005 W/mmK

formula:

delta T = (Q *l) / (A * k)

with values inserted:

delta T = (1W * 0,508 mm) / (150 mm2 * 0,005W/mmK) = 0,677 K

this means that a S35 pad with 20 mil used for TO220 will have an ideal thermal resistance of 0,677 K/W.

actual thermal resistance squeezing the pad with 200 psi is rated 0,72 K/W (slightly worse, maybe my surface assumption was too optimistic).

so coming back to your question:

Gap Pad ® 5000S35 has the better specific non-dimensional thermal conductivity (5 watts per meter*kelvin instead of 3).

however, Gap Pad® 3000S30 is available with half the thickness and in this case has lower thermal resistance even with it's smaller thermal conductivity.

Last edited:

Hello stv

Wow thank you!

Will have to bend myself over it after having bent myself towards you!

[emoji144]

Wow thank you!

Will have to bend myself over it after having bent myself towards you!

[emoji144]

measurements

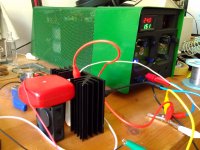

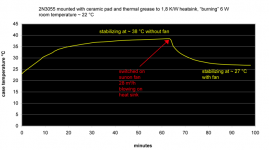

i did some tests and measurements some time ago, that may be useful.

pictures should be self-explanatory.

some findings, that may be obvious 😀:

i did some tests and measurements some time ago, that may be useful.

pictures should be self-explanatory.

some findings, that may be obvious 😀:

- any imperferction between the surfaces will hugely degrade heat transfer. this was probably the case with my ceramic pad without thermal grease. resulting total thermal resistance was 4,9 K/W of which only 1,8 K/W is heat sink to air - pure waste of heat sinks!

- surface imperfections will be filled out using either thermal grease or soft thermal foil. in my case not using kerafol and direct mounting was worse than using kerafol thermal foil.

- best method for isolated mounting in my test was using thermal grease, big heat spreading aluminium and corresponding kerafol film on the heat sink (total Rth=2,4 K/W). improvement was not huge, but could probably be maximized by adding more (isolated) screws and using thicker aluminium

- a fan obviously improves the thermal flow between heat sink and air. i did not expect it to be so much (total Rth was lowered to about 25%)

Attachments

Last edited:

I use solely HARD MICA buying them in a thickness of 0.1mm and then using a art knife to slice them do 0.05mm (or even thinner) applying Unick silicone Heat sink compound and I never have to worry for the next 5 years, about heating up..

do no use silicone soft for Class A, it's too slow to get the heat of..

I do not like those rubbery pads at all..... period.

To me, they're junk.

MICA is all I ever use, with thermal paste.

I'm Old School, and stay Old School.

i did some tests and measurements some time ago, that may be useful.

pictures should be self-explanatory.

some findings, that may be obvious 😀:

- any imperferction between the surfaces will hugely degrade heat transfer. this was probably the case with my ceramic pad without thermal grease. resulting total thermal resistance was 4,9 K/W of which only 1,8 K/W is heat sink to air - pure waste of heat sinks!

- surface imperfections will be filled out using either thermal grease or soft thermal foil. in my case not using kerafol and direct mounting was worse than using kerafol thermal foil.

- best method for isolated mounting in my test was using thermal grease, big heat spreading aluminium and corresponding kerafol film on the heat sink (total Rth=2,4 K/W). improvement was not huge, but could probably be maximized by adding more (isolated) screws and using thicker aluminium

- a fan obviously improves the thermal flow between heat sink and air. i did not expect it to be so much (total Rth was lowered to about 25%)

The mounting variants are especially telling!

The yollow, blue, and green trace!

(I shall reconsider the method I‘ll use for the connection between heatsink and spreader of my ongoing project, mighty ZM‘s old soul…)

Last edited:

I do not like those rubbery pads at all..... period.

To me, they're junk.

MICA is all I ever use, with thermal paste.

I'm Old School, and stay Old School.

Me being a newcomer, I haven’t established a bias. I have to find out out what method is best for a given situation…

- Home

- Design & Build

- Construction Tips

- How to select thermal pads: Thermal resistance, thermal / electric conductivity