What is the best way to securely hold large electrolytic power supply caps in place when you don't have any of those silver rings that bolt them to the bottom of the amp?

buy the silver rings

or make some

or use the buss bars to hold them, using insulating hardware (not reccommended)

or hot-melt glue (kidding)

or make some

or use the buss bars to hold them, using insulating hardware (not reccommended)

or hot-melt glue (kidding)

Parts Express sell 1 3/8" mounting brackets, and you can find other sizes at Digikey and other online stores. I highly recommend you use them, as a large capacitor coming adrift can cost way more than you save by hot-gluing the thing. I was a repair tech before getting becoming an engineer - you should see the damage a loose cap can cause. It's not worth the trouble to futz around if you can get the real thing by return post.

http://www.surplussales.com/Capacitors/capclmp.html

Francois.

http://www.surplussales.com/Capacitors/capclmp.html

Francois.

capacitor mounting

I think about mounting large (4"height, 2"diam) caps to a pcb using its screw terminals. I don't know whether the screw terminals are strong enough. What do you think?

I think about mounting large (4"height, 2"diam) caps to a pcb using its screw terminals. I don't know whether the screw terminals are strong enough. What do you think?

Plastic plumbing pipe clips that screw to the wall.

They come in a wide range of sizes from 1/2" upwards...

Owen

They come in a wide range of sizes from 1/2" upwards...

Owen

I was thinking about some of these:

http://www.altronics.com.au/index.asp?area=item&id=H4120

(they're nylon cable tie mounts with adhesive/screw points)

and some decent HD Cable ties to suit...

The standard mounting hardware is not always convenient.

Michael

http://www.altronics.com.au/index.asp?area=item&id=H4120

(they're nylon cable tie mounts with adhesive/screw points)

and some decent HD Cable ties to suit...

The standard mounting hardware is not always convenient.

Michael

Hot glue never holds, I've even tried cleaning the spots with acetone. 😱 😉

If you don't have the metal clamp rings, make some! If I need to strap caps flat to a chassis I just cut a strip, bend it around the cap and bend a tab on the end (after cutting to proper length), drill for the screw and tighten it down.

With some fancier tin-snip work you can cut wings on it to mount the cap vertically through a hole, recreating commercial items.

Tim

If you don't have the metal clamp rings, make some! If I need to strap caps flat to a chassis I just cut a strip, bend it around the cap and bend a tab on the end (after cutting to proper length), drill for the screw and tighten it down.

With some fancier tin-snip work you can cut wings on it to mount the cap vertically through a hole, recreating commercial items.

Tim

Aluminum flashing. I just happen to have some, and I think that might be just the material for creating the rings myself. It may prove too soft, although maybe I could double up the thickness. Worth a shot anyway...

Don't laugh, I've had excellent luck with Liquid Nails or similar construction adhesives. It looks unbelievably awful, but it holds tight for years and even provides a modicum of damping.

Peter Daniel has shown pictures of his chipamps and he uses some white plastic to hold them. Not sure what type it is (possibly high molecular weight plastic?). I like that solution for when you have a bank of large capacitors.

Yeah, I would guess HDPE, UHMWPE, nylon in particular, um what else, PETE (if it were used for anything besides soda bottles!), etc. Teflon (and related, e.g. delrin, IIRC) is no good because it creeps over time.

SY: Liquid nails eh? Does that end up something like the goo around large caps on PCBs (like computer PSUs etc.)?

Tim

SY: Liquid nails eh? Does that end up something like the goo around large caps on PCBs (like computer PSUs etc.)?

Tim

Sch3mat1c said:Liquid nails eh? Does that end up something like the goo around large caps on PCBs (like computer PSUs etc.)?

Yup. It's particularly suitable for caps laid down at chassis folds so that you can get two beads holding it. If you look at the bottom of my Eico HF87, you'll see a bunch of photoflash caps tucked in just this way. And it seems to be rugged- I just disassembled a preamp I build in grad school (25 years ago) and had to chisel the caps out.

Something as cheap and boring as bathroom silicone does the job.....and it comes in different colours 😉

Magura 🙂

Magura 🙂

Maybe, but it is also a type of sealant used on metal roofs and gutters between sheets of metal. It remains waterproof forever because it doesn't harden and flexes with thermal expansion.

I used a tube to glue 12 caps together as a kid. Mabe a hella mess. I thought it would hold great after it dried because it was so sticky....but it never dried. I used a gallon of laquer thinner to reclaim my caps.

I later learned what its intended use was.

I used a tube to glue 12 caps together as a kid. Mabe a hella mess. I thought it would hold great after it dried because it was so sticky....but it never dried. I used a gallon of laquer thinner to reclaim my caps.

I later learned what its intended use was.

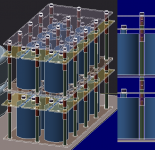

I have to mount a lot of medium sized caps as compact as possible and like to discuss the idea I had to do this.

The construction is made of hexagonal bolts size M4, some made of steel for stability and others made of polyamide for insulation. For electrical connection and mounting of the caps I use metal sheets 2mm strong, most likely stainless steel. The caps are pressed against a sheet of foam to dampen vibration. All insulating hex bolts are female types and have the metal threaded bolts screwed into.

What do you think about the idea?

I'm not good at mechanical design but from my point of view it's a cheap, easy to do and clean solution. It might not survive being dropped hard. For the case someone drops the amp I'm in serious trouble anyway.

The construction is made of hexagonal bolts size M4, some made of steel for stability and others made of polyamide for insulation. For electrical connection and mounting of the caps I use metal sheets 2mm strong, most likely stainless steel. The caps are pressed against a sheet of foam to dampen vibration. All insulating hex bolts are female types and have the metal threaded bolts screwed into.

What do you think about the idea?

I'm not good at mechanical design but from my point of view it's a cheap, easy to do and clean solution. It might not survive being dropped hard. For the case someone drops the amp I'm in serious trouble anyway.

Attachments

Plastic plumbing pipe clips that screw to the wall.

They come in a wide range of sizes from 1/2" upwards...

Owen

I used metal ones, but indeed, they are very convenient, and much cheaper and easier to find (hardware store) than those cap clamps 🙄

- Status

- Not open for further replies.

- Home

- Design & Build

- Parts

- How to hold large capacitors in place