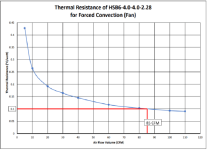

To answer the question in the title, here is a nice graph.

Just to show the curve of airflow vs temperature.

https://www.researchgate.net/figure...s-fan-air-flow-volume-graph-33_fig1_373703026

YMMV

Just to show the curve of airflow vs temperature.

https://www.researchgate.net/figure...s-fan-air-flow-volume-graph-33_fig1_373703026

YMMV

Attachments

Last edited:

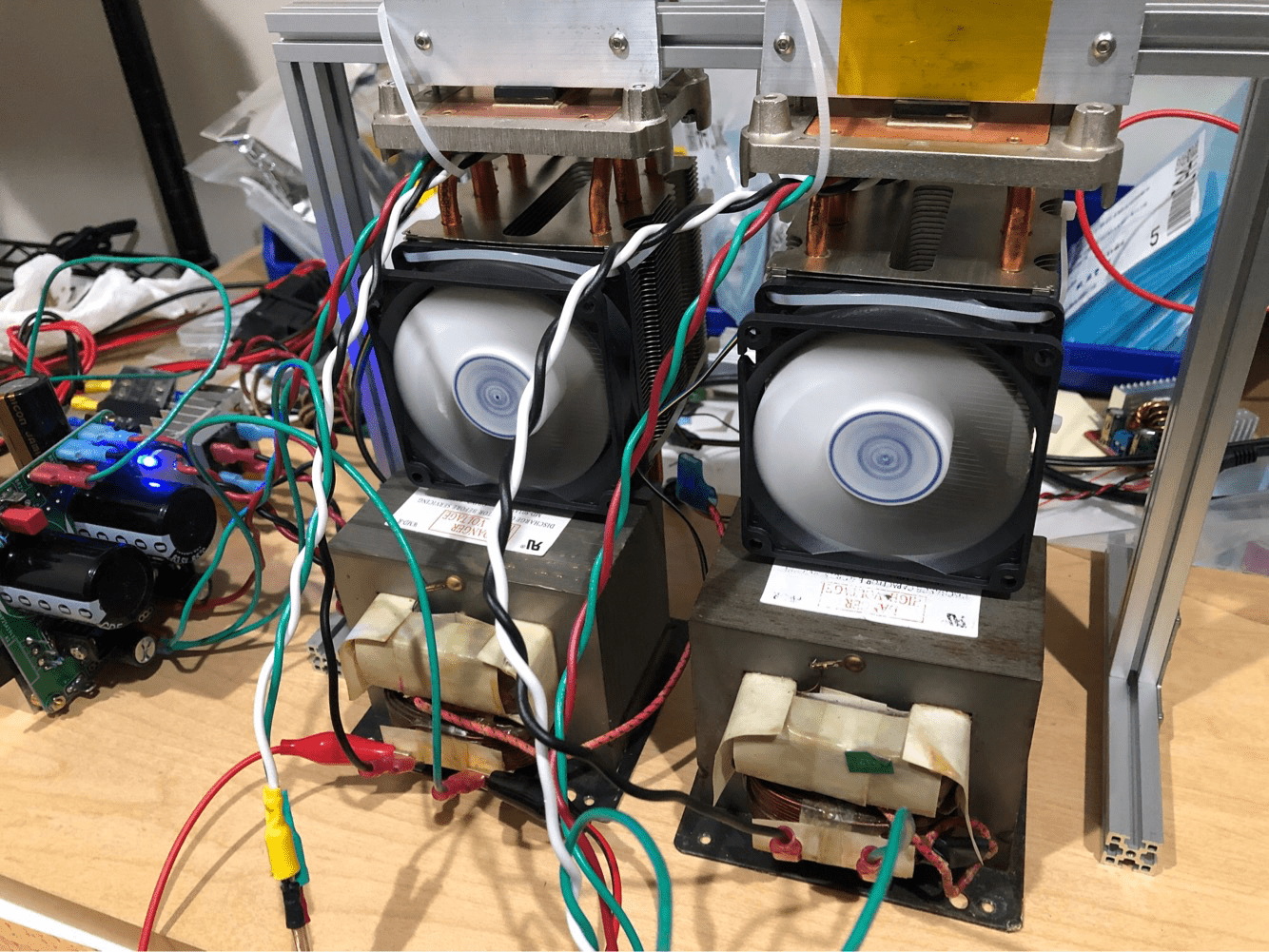

Looks like there is a lot of surface dust on everything. It might surprise you how much cooler it will run after the heat sinks are cleaned. I suspect that grime is also responsible for the difficulty in gluing down the thermocouple.

You might try reversing the fan so it is blowing instead of sucking or vice-versa. Fans are generally more efficient at blowing than sucking. I think the Noctua fans have an arrow to indicate the best air flow direction.

Looks like there is a lot of surface dust on everything. It might surprise you how much cooler it will run after the heat sinks are cleaned. I suspect that grime is also responsible for the difficulty in gluing down the thermocouple.

That is truly just due to all the construction going on in my house. I’m using these two amps and a pair of ADS L1590s to play music for all of the workers. I don’t feel any noticeable difference in heat between being freshly restored and now.

You have got 10 amplifiers.

I'm sure there's one with a working channel.

Measure the bias.

None of the amplifiers are in a state that I would power them on. I’m certain that nearly all of them would either make the dim bulb tester, go ultra bright, or do absolutely nothing at all. I will say that with both of these amplifiers after replacing the electrolytics and whatever few bad components there were all four channels between the two amplifiers were biased right around 500 mA. With all the trimmers in the factory position, each channel was between 490 and 510mA. They did run warm, but I was able to run them for a couple days without any issue. I did not like how hot they were running though, even though I’ve had a Hafler mosfet amp with passive cooling that you could cook and egg on, so I asked around. There was another member here who had trouble finding biasing instructions for this exact amp and contacted Hafler and was told to copy the procedure from another amp, which is a procedure I explained. 100 mA per device device plus 50 for the front end. So if you want an idea of where they were at before I got them, it was about 150 mA higher than they are now.

Dan

You might try reversing the fan so it is blowing instead of sucking or vice-versa. Fans are generally more efficient at blowing than sucking. I think the Noctua fans have an arrow to indicate the best air flow direction.

That is something to consider, if I flipped the fan around would this be enough clearance on the backside for it to get good airflow? is better to have more airspace behind the fan than in front. Is that right?

Dan

I think that sucking air from the top would be less of a problem than blowing air against the top panel. The intake area at the top is spread around the perimeter compared to the exit which is the diameter of the fan. I think it is likely the intake airspeed is less than the exit airspeed, so if that is the case, blowing is definitely better.

It would be easy to test. Just flip the fan upside down and try it out.

It would be easy to test. Just flip the fan upside down and try it out.

Actually, contrary to common beleaves, extracting hot air from a hot surface is more efficient, unless you have more airflow restriction on the outlet. Offcourse the fan itself will then be burdened with additonal to the heat produced by its own operatio, also with the extracted heat .

So, you thinck, with a given amount of energy you can move more of cold air, denser, heavier air? I do not thinck so...

Anyway, you want to extract as much hot air as possible from the hot surface, not mix it with allready fan preheated air.

What is most important is the restriction on the ouflow side, it has the largest impact to the amount of actual airflow.

Also, if the heatsource is below, i would work with, not against the natural heatflow

Anyway, you want to extract as much hot air as possible from the hot surface, not mix it with allready fan preheated air.

What is most important is the restriction on the ouflow side, it has the largest impact to the amount of actual airflow.

Also, if the heatsource is below, i would work with, not against the natural heatflow

Last edited:

You do not need a lot of air to make a huge difference. The general rule of thumb is that forced convection is 10x better than natural convection. So you can use even a fan at 1/5th nominal flow and it will make a big difference.

Run Noctua at low speed to point where you can’t hear it. Use an IR thermometer on the surface of interest. Inside wall of heatsink is good. Use piece of Kapton or black vinyl tape to transmit heat without low emissivity of metal that can cause errors. Even paper tape like blue tape works. The tape takes on temp of surface if touches but has almost perfect emissivity.

I can run a 150w Class A dissipation in a single mosfet with a heat pipe cup cooler and a small Noctua fan at minimum speed. It works like a champ. 150w would require a massive tank of a heatsink fin slab.

This one is running about 125W dissipation per fan.

Use the $5 PWM speed controllers and PWM fans. You can control speed and put temp sensor in air flow to kick up speed in case it gets too hot.

Run Noctua at low speed to point where you can’t hear it. Use an IR thermometer on the surface of interest. Inside wall of heatsink is good. Use piece of Kapton or black vinyl tape to transmit heat without low emissivity of metal that can cause errors. Even paper tape like blue tape works. The tape takes on temp of surface if touches but has almost perfect emissivity.

I can run a 150w Class A dissipation in a single mosfet with a heat pipe cup cooler and a small Noctua fan at minimum speed. It works like a champ. 150w would require a massive tank of a heatsink fin slab.

This one is running about 125W dissipation per fan.

Use the $5 PWM speed controllers and PWM fans. You can control speed and put temp sensor in air flow to kick up speed in case it gets too hot.

I love the Noctua fans as well. They're a bit expensive, but they are very quiet.In my experience, it doesn't take much airflow to transfer heat from the heatsinks. I would try one fan first. I have used Noctua fans and they are quiet and efficient.

One can get an idea of how little airflow is needed to make a big difference in heat sink thermal resistance from the temperature compensation data published by Aavid:

Heat sinks are commonly specified at 75 ºC temperature rise (so 25 ºC ambient -> 100 ºC heat sink temp) as they are more efficient at higher temperatures, thereby, look better on the sell sheet. The reason for the higher efficiency at higher temperature is the chimney effect. The heat itself causes a greater amount of air flow.

Note that going from 75 ºC temperature rise to 30 ºC temperature rise makes the heat sink almost 26 % less efficient. It's not like going from 30 ºC to 75 ºC is causing a gale here. The airflow is basically going from near still to slightly less still. Imagine what even a gentle breeze from a fan would do.

I think it was the designer of the Wolverine amp who showed off his build at Burning Amp 2022. He'd used a 4U x 400 mm ModuShop chassis. The heat sinks by themselves are not big enough for this high-powered amp, but with some strategically placed holes in the heat sinks and a Noctua fan blowing air out the bottom he was able to get enough air moving to keep the amp cool. I thought that was an ingenious solution.

Tom

- Home

- Amplifiers

- Solid State

- How much does cooling fan air volume affect overall heatsink temps?