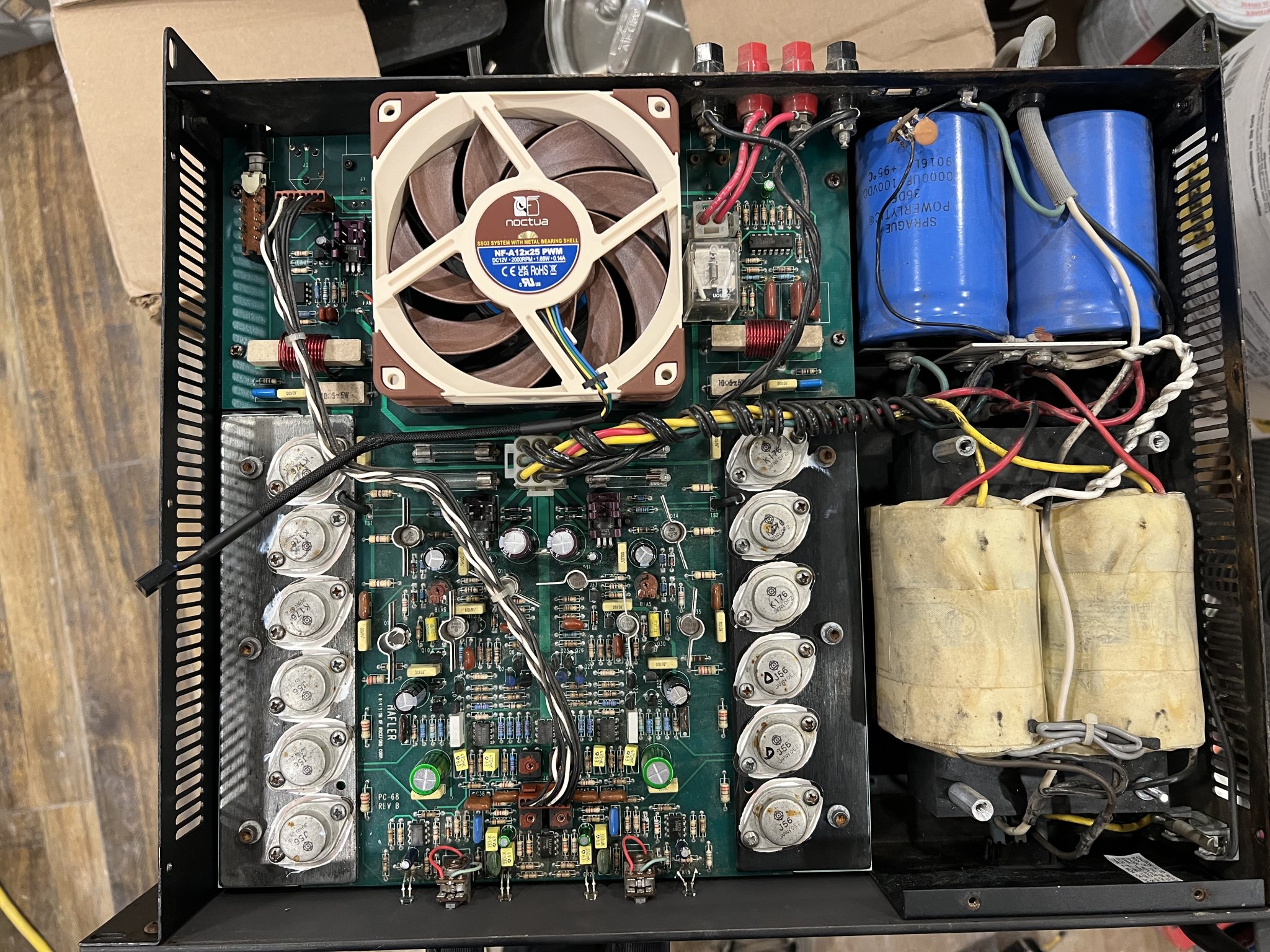

I wasn’t entirely sure of where to post this thread. I have a stack of Hafler pro amps, and I need to replace a couple of the fans in them. Amps use lateral MOSFETs that are hard to find and very expensive when you do. So I want to make sure that I have enough cooling for them. The fans are not overly loud, but it would be nice to make them a bit lower. I have a bunch of the Yamaha PC-9501n amplifiers, and they are dead quiet.

This is the current fan that is in them, as you can see the one in my hand is broken.

It is a 5 blade fan that draws 350 mA, I found that is spins at about 2550 rpm. I cannot find a spec for air volume on it. I did find another fan from the same company that has eight blades and has a speed of 2800 rpm. It draws 550 mA and moves a volume of 115 cfm. Clearly the fan in my amps will move less volume, but I don’t know how much less.

I purchased this van last night, it is referred to as one of the best performing fans if you want ultra quiet.

It’s spins at a speed of 2000 RPM and draws only 140mA. I found it moves a volume of 60 CFM. Do any of you think that this fan will be up to the task of keeping these MOSFETs cool?

You can see there is some space above the original fan. I was reading that there is another fan that may be even better, but it is 30 mm thick and not all scenarios can support that. I ordered a three pack of them, Phantek T-30.

https://www.phanteks.store/products/phanteks-t30-120-fans?variant=39439636856887

It spins at a higher speed of 3000 RPM, draws like 360 mA which is closer to the original and it moves over 100 CFM. I could run it at the lower speed of 2000 RPM and it will move 67 CFM, of course faster spin, speed and air movement equals more noise. So I was hoping to get your input on this, do you think that the Noctua up to the task? If it is, I will buy nine more and all of the Haflers with it. I’m just not sure how many degrees of difference on the heat sink there will be if you cut the air volume movement down. With the original fans, the amp do run warm. The amplifiers are biased to about 100 mA per output device.

Thank you.

Dan

This is the current fan that is in them, as you can see the one in my hand is broken.

It is a 5 blade fan that draws 350 mA, I found that is spins at about 2550 rpm. I cannot find a spec for air volume on it. I did find another fan from the same company that has eight blades and has a speed of 2800 rpm. It draws 550 mA and moves a volume of 115 cfm. Clearly the fan in my amps will move less volume, but I don’t know how much less.

I purchased this van last night, it is referred to as one of the best performing fans if you want ultra quiet.

It’s spins at a speed of 2000 RPM and draws only 140mA. I found it moves a volume of 60 CFM. Do any of you think that this fan will be up to the task of keeping these MOSFETs cool?

You can see there is some space above the original fan. I was reading that there is another fan that may be even better, but it is 30 mm thick and not all scenarios can support that. I ordered a three pack of them, Phantek T-30.

https://www.phanteks.store/products/phanteks-t30-120-fans?variant=39439636856887

It spins at a higher speed of 3000 RPM, draws like 360 mA which is closer to the original and it moves over 100 CFM. I could run it at the lower speed of 2000 RPM and it will move 67 CFM, of course faster spin, speed and air movement equals more noise. So I was hoping to get your input on this, do you think that the Noctua up to the task? If it is, I will buy nine more and all of the Haflers with it. I’m just not sure how many degrees of difference on the heat sink there will be if you cut the air volume movement down. With the original fans, the amp do run warm. The amplifiers are biased to about 100 mA per output device.

Thank you.

Dan

Use a thermocouple to check the device case temperature after warmup.

Then you can calculate the junction temperature and see.

Or reduce the bias for cooler running, if necessary.

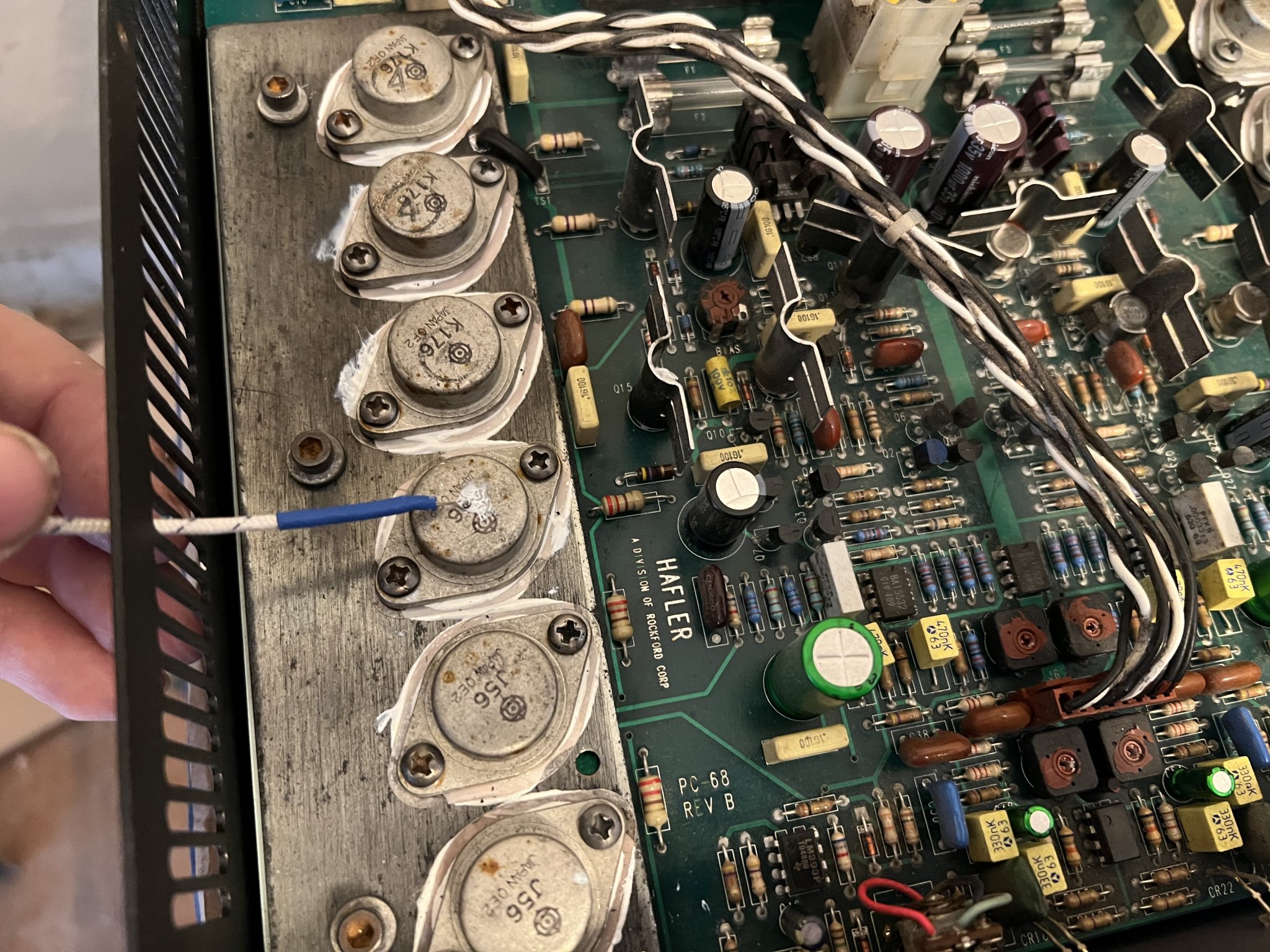

That is very good thinking. Where would you place the thermocouple exactly? Should I put it directly on top of the heat sink next to one of the MOSFETs? Would put it on the side of the case really give me much info?

I hadn’t thought of using the thermocouple to measure the temp, excellent suggestion.

Dan

Use the device case instead of the heat sink, if possible, since this bypasses the thermal interface loss.

Make sure the chassis is buttoned up as normal, to get an accurate reading.

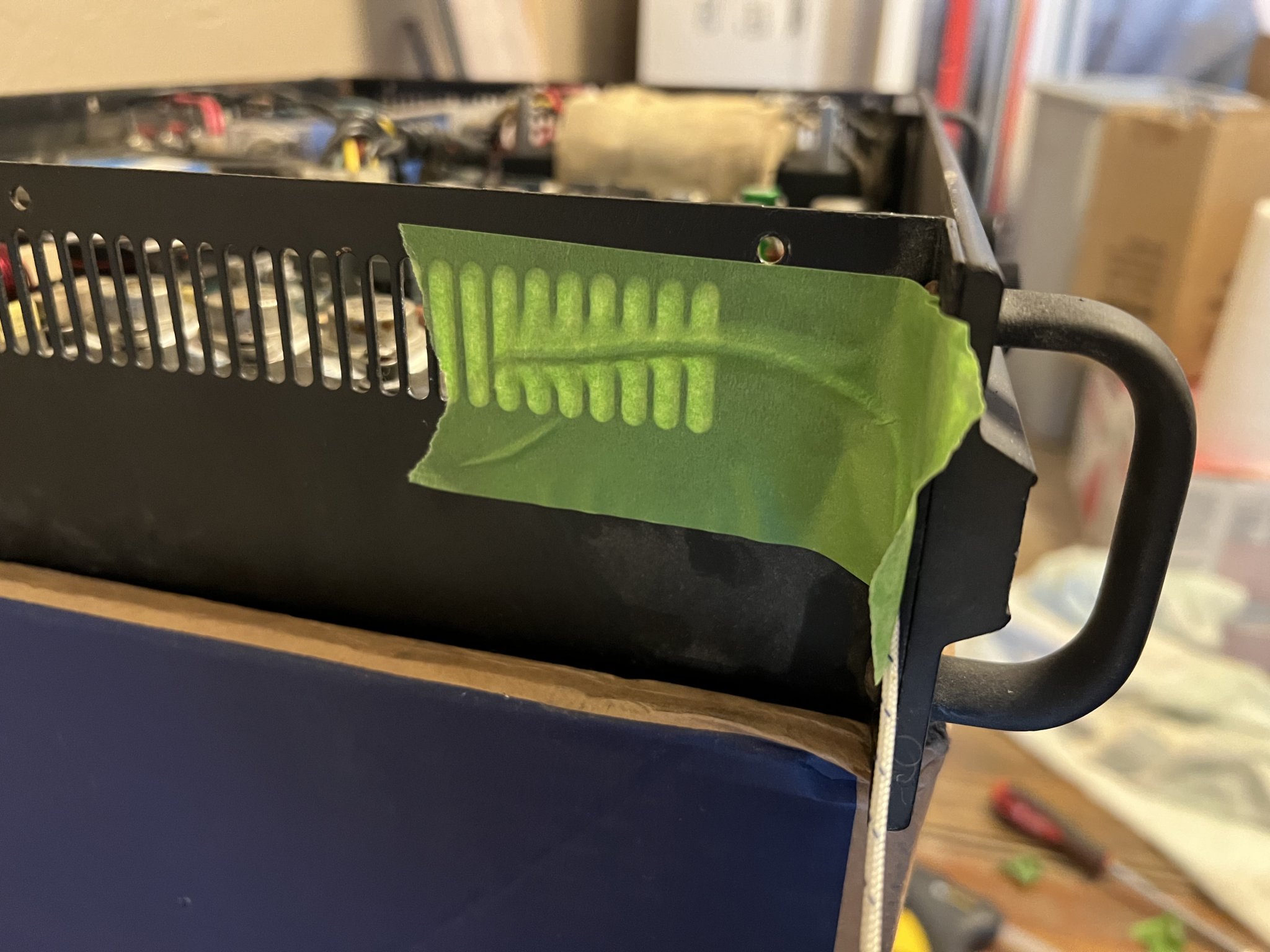

I don’t mean to make this more complicated than it is or make it seem like I need my hand held. So should I just use something like kapton tape to tape it to the side here

It being close to the heatsink. Or go for the top of the case.

It gets warmish, but definitely not the warmest part of the case. I guess any part will give me data as long as I tape it to the same spot.

Dan

Sorry, I meant to say the metal case of the lateral mosfets.

We've used thermal epoxy to fasten the thermocouple to the transistor case,

but Kapton tape can also work ok.

You could also check the temperature of the electrolytic capacitors while you are at it.

The cooler, the better, for those.

We've used thermal epoxy to fasten the thermocouple to the transistor case,

but Kapton tape can also work ok.

You could also check the temperature of the electrolytic capacitors while you are at it.

The cooler, the better, for those.

lol, duh. Of course that’s what you meant and now that I read it again that’s exactly what it says.Sorry, I meant to say the metal case of the lateral mosfets.

We've used thermal epoxy to fasten the thermocouple to the transistor case,

but Kapton tape can also work ok.

You could also check the temperature of the electrolytic capacitors while you are at it.

The cooler, the better, for those.

I didn’t even thing if using epoxy. Never have before, doesn’t it take time to setup and then a bit of a pain to remove it from the devices?

Should I use just kapton or should I use a bit of thermal compound as well?

Dan

I would not stack two fans to try to improve airflow. There needs to be clearance space between the top of the fan and the underside of the case cover.

It looks like the fan blows air down to the underside of the circuit board where the air flows through heatsinks and exits out the front of the case. If there is not enough room above the fans to suck air in, then your airflow will be severely restricted and overheating will result.

In my experience, it doesn't take much airflow to transfer heat from the heatsinks. I would try one fan first. I have used Noctua fans and they are quiet and efficient.

Edit: Looking at your picture, I see you probably did not intend to stack the fans. It just looks like there is no clearance above the Noctua. However, clearance above the fan is important.

It looks like the fan blows air down to the underside of the circuit board where the air flows through heatsinks and exits out the front of the case. If there is not enough room above the fans to suck air in, then your airflow will be severely restricted and overheating will result.

In my experience, it doesn't take much airflow to transfer heat from the heatsinks. I would try one fan first. I have used Noctua fans and they are quiet and efficient.

Edit: Looking at your picture, I see you probably did not intend to stack the fans. It just looks like there is no clearance above the Noctua. However, clearance above the fan is important.

Last edited:

Amps use lateral MOSFETs that are hard to find and very expensive when you do. So I want to make sure that I have enough cooling for them.

In simple terms, reliability doubles for every 10*C reduction in junction temperature. Now, since junction temperature is simply the heatsink temperature plus a power-dependent term, the sink temperature at (say) half power would be what I'd be looking at, in order to get an assessment of the heat removal.Where would you place the thermocouple exactly? Should I put it directly on top of the heat sink next to one of the MOSFETs?

If the fan is not a controlled type, then matching the RPMs would match the flow rate and so on. However, if the fan is a speed-controlled one, then you'd have to match the number of poles inside both motors to get the same voltage vs. speed (and therefore cooling) characteristics.I have a stack of Hafler pro amps, and I need to replace a couple of the fans in them.

I would not stack two fans to try to improve airflow. There needs to be clearance space between the top of the fan and the underside of the case cover.

It looks like the fan blows air down to the underside of the circuit board where the air flows through heatsinks and exits out the front of the case. If there is not enough room above the fans to suck air in, then your airflow will be severely restricted and overheating will result.

In my experience, it doesn't take much airflow to transfer heat from the heatsinks. I would try one fan first. I have used Noctua fans and they are quiet and efficient.

Edit: Looking at your picture, I see you probably did not intend to stack the fans. It just looks like there is no clearance above the Noctua. However, clearance above the fan is important.

Thank you for the response. I would definitely not stack the fans, I just had the Noctua in there to see what it would look like. Actually, the fans suck Erin through the front, through the heat sinks, and then up. I recently had some pipes burst and it flooded my kitchen, so I’m having drywall work done right now and you can see drywall dust collecting on one of the amps that I have fixed.

I was given 10 of these amps, all broken. I picked up the first two, went through them, and found that the outputs were good. So I fixed them. I figure that as long as the outputs are good in all of these amps then no problem. So far I’ve had to replace a couple BJTs and the caps. It also has some 2SK170s and 2SJ74, but I have plenty of those. My only worry are the outputs..

These will likely be used for hi-fi/home theater. So they will have a fairly easy life compared to what they were built for. Having so many of them, I was thinking of using them for my fronts and going active crossovers.

Dan

Hifi and home theater. They’ll have a fairly easy life.

Dan

The fans being used are two wire type, so only one fan speed. I will start comparing them and post my results here.In simple terms, reliability doubles for every 10*C reduction in junction temperature. Now, since junction temperature is simply the heatsink temperature plus a power-dependent term, the sink temperature at (say) half power would be what I'd be looking at, in order to get an assessment of the heat removal.

If the fan is not a controlled type, then matching the RPMs would match the flow rate and so on. However, if the fan is a speed-controlled one, then you'd have to match the number of poles inside both motors to get the same voltage vs. speed (and therefore cooling) characteristics.

Dan

I learned very quickly that nothing really sticks to these transistors. I tried three different kinds of tapes, and then finally used a pretty decent size glob of hot glue. Even the hot glue lifted off with zero effort, there was no adhesion.

So I fed the thermocouple through event and taped it to the side. There was a spring force that was holding it up against the side of the case.

Good enough.

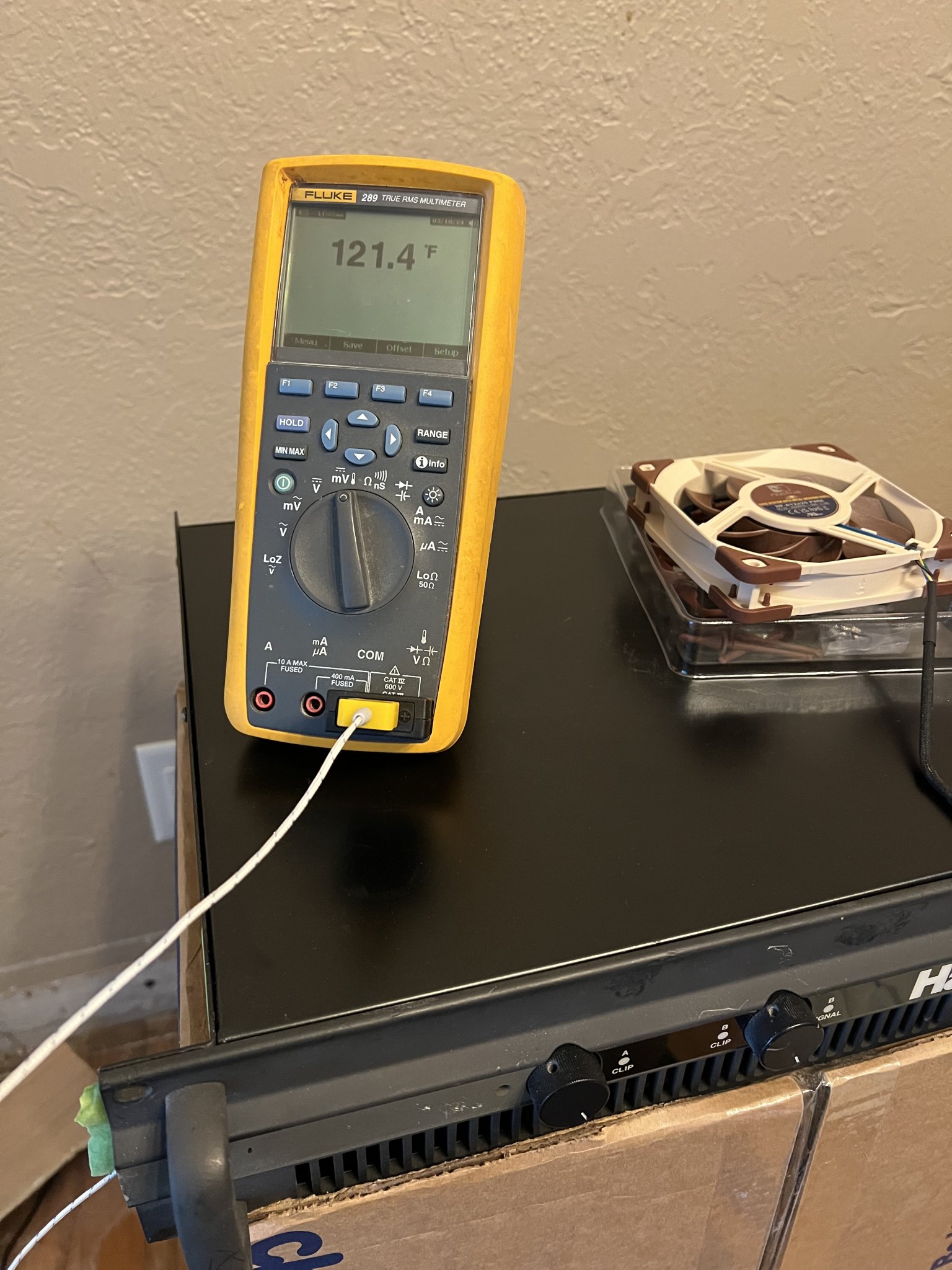

With the factory fan in place I let it run for a little over an hour and for the last 15 minutes or so it was fluctuating right around 121-121.5

I then placed in the Noctua, it was in the exact correct place, but it was not bolted down. In order to bolt the fans to the CB I would have to completely remove it from the amp and I wasn’t going to do that.

This fan is dead silent. You could see it spinning, but hear no noise after I put the top on top of the amplifier and screwed it down you could barely hear the vibration of the fan. This is an excellent option if you want a silent fan.

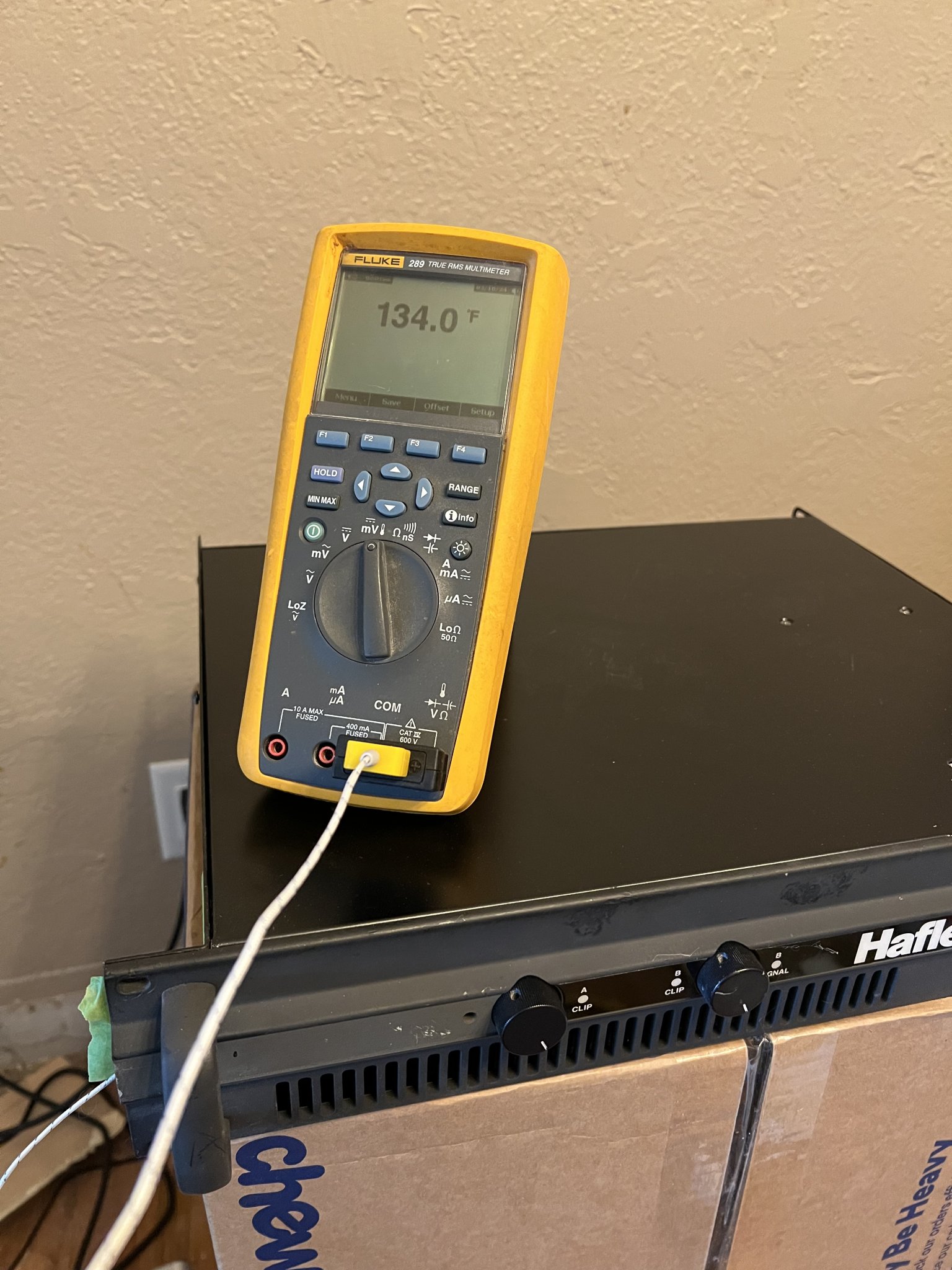

It settled out at 133.5-134. So about 12°F higher than the original fan. But does not surprise me. Is this something to be worried about?

To go in was the Phantek. It was hard to find wiring instructions on this, but I believe I got it, correct, as it was definitely spinning faster than the previous one it is louder than the Noctua but definitely quieter than the factory fan. This one did much better.

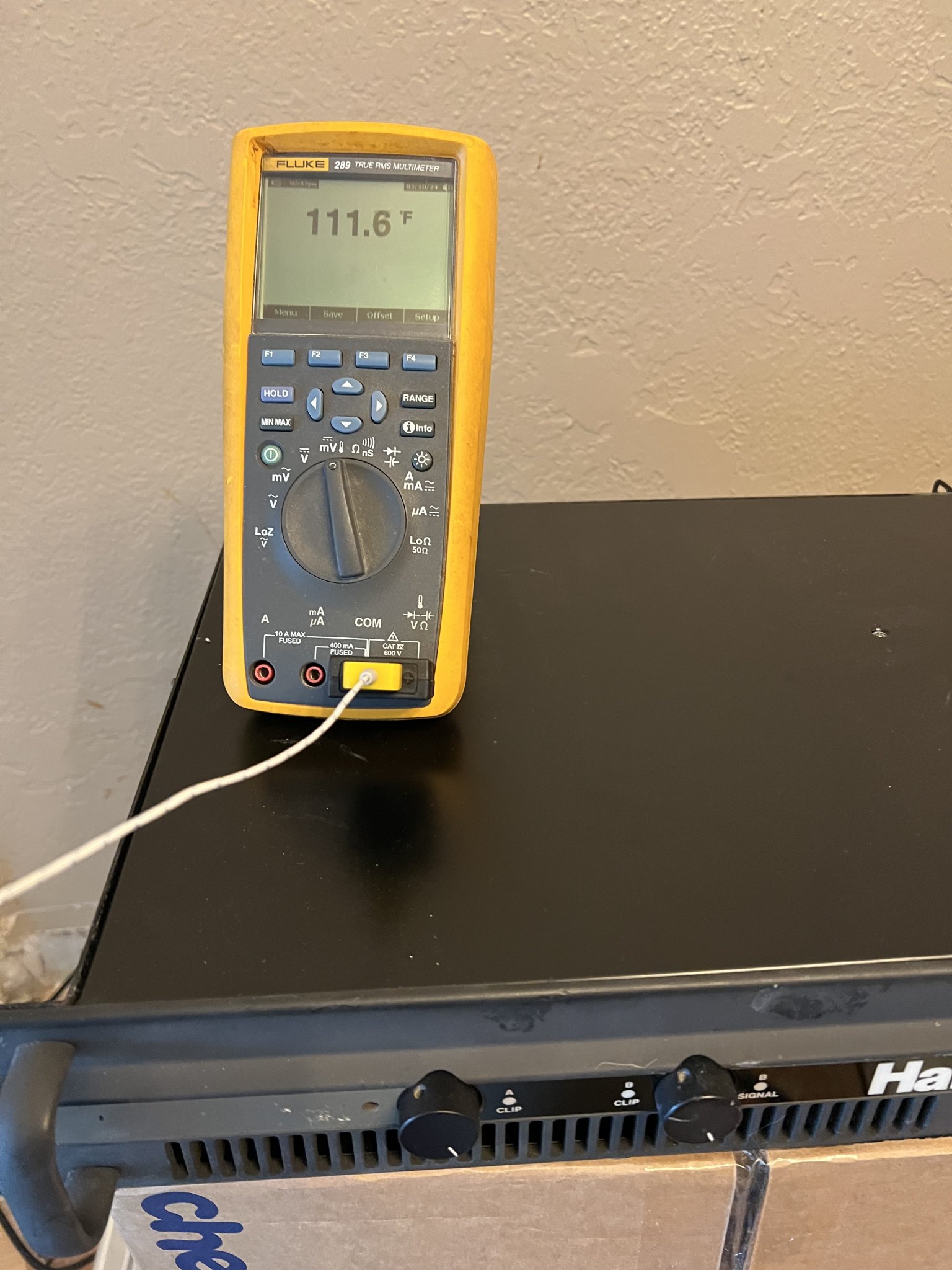

No matter how long I left it I could not get it to hit 112°. So this fan keeps the mosfets about 10° cooler than the original. One concern I have is the current draw, the fans I received have different different spec than the ones advertised.

Here you can see at the highest speed the advertisement is 360 mA

Yet on the fans I received it shows the highest speed having a current draw of 410 mA

I’m guessing that for the 12 V regulator this won’t be an issue. I’m pretty sure it’s a one amp device.

If I can figure out how to wire it to get the 2000 RPM speed then I’m want to try that. I’m guessing it will be quieter than it is, and will do superior than the Noctua?

What would you all use? It seems like the Phantek is best of both worlds. at top speed, you can’t hear the fan at all as soon as you back away a couple of feet whereas with the original, you can hear it if you’re in the same room with it. Plus, it keeps the MOSFETs than the original.

I have to do some more testing with the phanteks it seems like when you power the amp on it wants to initially spin the fan in reverse but then as it goes the correct way, it has to ramp up to the 3000 RPM. With the other fans, the power switch and the fans go up to full speed very quickly, about 10 seconds for the Phantek.

Dan

So I fed the thermocouple through event and taped it to the side. There was a spring force that was holding it up against the side of the case.

Good enough.

With the factory fan in place I let it run for a little over an hour and for the last 15 minutes or so it was fluctuating right around 121-121.5

I then placed in the Noctua, it was in the exact correct place, but it was not bolted down. In order to bolt the fans to the CB I would have to completely remove it from the amp and I wasn’t going to do that.

This fan is dead silent. You could see it spinning, but hear no noise after I put the top on top of the amplifier and screwed it down you could barely hear the vibration of the fan. This is an excellent option if you want a silent fan.

It settled out at 133.5-134. So about 12°F higher than the original fan. But does not surprise me. Is this something to be worried about?

To go in was the Phantek. It was hard to find wiring instructions on this, but I believe I got it, correct, as it was definitely spinning faster than the previous one it is louder than the Noctua but definitely quieter than the factory fan. This one did much better.

No matter how long I left it I could not get it to hit 112°. So this fan keeps the mosfets about 10° cooler than the original. One concern I have is the current draw, the fans I received have different different spec than the ones advertised.

Here you can see at the highest speed the advertisement is 360 mA

Yet on the fans I received it shows the highest speed having a current draw of 410 mA

I’m guessing that for the 12 V regulator this won’t be an issue. I’m pretty sure it’s a one amp device.

If I can figure out how to wire it to get the 2000 RPM speed then I’m want to try that. I’m guessing it will be quieter than it is, and will do superior than the Noctua?

What would you all use? It seems like the Phantek is best of both worlds. at top speed, you can’t hear the fan at all as soon as you back away a couple of feet whereas with the original, you can hear it if you’re in the same room with it. Plus, it keeps the MOSFETs than the original.

I have to do some more testing with the phanteks it seems like when you power the amp on it wants to initially spin the fan in reverse but then as it goes the correct way, it has to ramp up to the 3000 RPM. With the other fans, the power switch and the fans go up to full speed very quickly, about 10 seconds for the Phantek.

Dan

121F (49C) with a stock fan seems rather high at idle.

You may want to check on the quiescent current of the power mosfets.

I mentioned that it ran warm. I said the bias as most other Hafler amps are run using these MOSFETs. I was instructed on here to bias at roughly 100 mA per device (3 positive and 3 negative per channel and since each channel have their own rail fuses I would go for 300 mA) plus an extra 50 or so for the front end. I will let it warm up for a bit, but so far I am looking like I’m pretty much dead on to what I set it at.

Dan

- Home

- Amplifiers

- Solid State

- How much does cooling fan air volume affect overall heatsink temps?