Hi Guys.

I want to have a crack at building some 2 way speakers for home.

Ive been reading lots of tutorials and youtubing to get a design going.

I've always wanted something with twelves in it and was looking at using p.audio HP-12W as the main driver.

I would prefer a sealed enclosure but being my first attempt, I may try ported as well and see what i like better.

Trying a few different programs for simulating the cabinet size, most recommend 185 litres.

This will be a fairly large cabinet to get that volume.

What effect will reducing this size have (in a sealed box) or should I look for a different driver?

Or should I just suck it up and go big.

(I have no issue with a big cabinet, just worried about the spouse approval).

I want to have a crack at building some 2 way speakers for home.

Ive been reading lots of tutorials and youtubing to get a design going.

I've always wanted something with twelves in it and was looking at using p.audio HP-12W as the main driver.

I would prefer a sealed enclosure but being my first attempt, I may try ported as well and see what i like better.

Trying a few different programs for simulating the cabinet size, most recommend 185 litres.

This will be a fairly large cabinet to get that volume.

What effect will reducing this size have (in a sealed box) or should I look for a different driver?

Or should I just suck it up and go big.

(I have no issue with a big cabinet, just worried about the spouse approval).

Hello. It changes the Q of the system, which involves compromises, it's up to you what your priorities are. Bare in mind the largest factor on the low frequency response will be the listening room and positioning of both you and the speakers.

Or should I just suck it up and go big.

(I have no issue with a big cabinet, just worried about the spouse approval).

You can build that into a 25-35L box and use a series capacitor - approx 800uF for that kind of a woofer. That will get you a rolloff between sealed and ported, with some advantages of both. The box and driver together needs to have Q of at least 4 for this to work, and there is a formula to get to the right values of the capacitor.

Basically the cap interacts with the voice coil inductance to flatten out the bump.

Here's some reading:

Capacitor loading a woofer in a small box

That woofer have too high Qts for vented box in general, and too low xmax for a low (0.5-0.7) Qtc sealed box, although a smaller sealed box would be better than a vented even with a Qtc around 1 or more. Some are prefer a higher sealed box Q than the normal 0.707, and that higher Qtc may help to compensate the low xmax and with good positioning the room acoustics will fill the low end response.

Just my 2 cents.

Just my 2 cents.

You can build that into a 25-35L box and use a series capacitor - approx 800uF for that kind of a woofer.

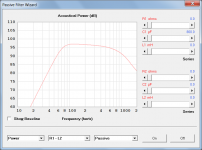

The attachment shows the power response for a HP-12W driver in a 35 litre enclosure, with a series 800uF capacitor.

Attachments

Thanks for the reply's.

David McBean, what is that program you are using to simulate the capacitors effects?

I have been using WinIsd and VituixCad for modeling.

I'd like to play around simulating different cabinet sizes and capacitors to find a good compromise on what will look good as well as sound good.

Although, when I do build something, I will probably play around with lots of different crossover components until I get it to sound right.

David McBean, what is that program you are using to simulate the capacitors effects?

I have been using WinIsd and VituixCad for modeling.

I'd like to play around simulating different cabinet sizes and capacitors to find a good compromise on what will look good as well as sound good.

Although, when I do build something, I will probably play around with lots of different crossover components until I get it to sound right.

David McBean, what is that program you are using to simulate the capacitors effects?

Hornresp - it can be downloaded from the site linked below.

I get it to sound right.

If you want it to sound right, try to aim for a 2dB bump in tuning before the rolloff.

If you try to max out extension by keeping a flattish response, things do not work out well in practice. It looks better on the sim, but is tough as nails to integrate in a room due to LF boost near boundaries.

I may even just get some cheap MDF and knock up a few quick cabinets of different sizes and externally mount the crossover to trial a few options in my room.

I'll use alligator clip leads to make changing crossover components easily.

I was planing on using Marine Ply for the final cabinet.

On another note, I am enjoying the planing and designing phase (as steep a learning curve it is).

I'll use alligator clip leads to make changing crossover components easily.

I was planing on using Marine Ply for the final cabinet.

On another note, I am enjoying the planing and designing phase (as steep a learning curve it is).

Sealed boxes are very forgiving and it is actually quite hard to make them too big within reason.

What are you intending to use for the top octaves and where are you thinking of crossing over to the top?

Locally chipboard may be cheaper than MDF

What are you intending to use for the top octaves and where are you thinking of crossing over to the top?

Locally chipboard may be cheaper than MDF

I wanted to try a horn p.audio PHT-404 was what I had in mind.

I've never owned horn speakers and was curious to how they sounded to me long term.

If I don't like the sound, I can always rebuild them.

I was going to cross them around 1400-1500.

Going by the manufactures graphs, I could be pushing it without a midrange but that's the whole fun of this project.

My simulations don't look too bad to me but sims and real life are two different things aren't they.

As for timber, I'll probably just do what I always do for building things. Go to Bunnings and find what ever is cheapest that I can fit in the van. Or use scrounged scrap. No big deal for prototypes. I'll take more care in the final product.

I've never owned horn speakers and was curious to how they sounded to me long term.

If I don't like the sound, I can always rebuild them.

I was going to cross them around 1400-1500.

Going by the manufactures graphs, I could be pushing it without a midrange but that's the whole fun of this project.

My simulations don't look too bad to me but sims and real life are two different things aren't they.

As for timber, I'll probably just do what I always do for building things. Go to Bunnings and find what ever is cheapest that I can fit in the van. Or use scrounged scrap. No big deal for prototypes. I'll take more care in the final product.

Have you seen and read this?

Mystery 1 PA - July 2013 - Loudspeakermagazine 2013 | Loudspeakerbuilding

Seems like a good fun & cheap party project

I think I might have a pair of the 10" somewhere in the shed, something similar anyway

Mystery 1 PA - July 2013 - Loudspeakermagazine 2013 | Loudspeakerbuilding

Seems like a good fun & cheap party project

I think I might have a pair of the 10" somewhere in the shed, something similar anyway

185lt internal enclosure is pretty big. At this size, the box will need plenty of internal bracing so as not to produce secondary emissions that are detrimental to sound quality.

If you are going sealed, it's better to start with half that size and as suggested, compensate for part of the bump before the roll off with a suitable capacitor.

A large sealed enclosure lowers the Q of the system. A low Q is supposedly better for transient response but listening tests supposedly showed that a low Q system sounds dead and dry in the low frequency.

The legendary BBC LS3/5a were designed for a Q of about 1.1-1.2, generating a bass bump to compensate for their lack of bass (due to size) in small spaces and nearfield listening. So these two additional parameters (size of room and location of speakers) influence the design goals.

For a ported speaker, the effect of the box size to tuning (in unison with the port) is a bit more delicate and needs care to make it right. And the port itself introduces considerations on placement, diameter (the smaller diameters generate higher velocities, puffing sounds and influence the correction factor for calculating the port length and tuning frequency). And the ported enclosure, having no load to the woofer below the tuning frequency, really needs a roll off to be introduced (a capacitor again) to protect the woofer from large excursions in very low frequencies. Especially if you are listening to vinyl.

If you are going sealed, it's better to start with half that size and as suggested, compensate for part of the bump before the roll off with a suitable capacitor.

A large sealed enclosure lowers the Q of the system. A low Q is supposedly better for transient response but listening tests supposedly showed that a low Q system sounds dead and dry in the low frequency.

The legendary BBC LS3/5a were designed for a Q of about 1.1-1.2, generating a bass bump to compensate for their lack of bass (due to size) in small spaces and nearfield listening. So these two additional parameters (size of room and location of speakers) influence the design goals.

For a ported speaker, the effect of the box size to tuning (in unison with the port) is a bit more delicate and needs care to make it right. And the port itself introduces considerations on placement, diameter (the smaller diameters generate higher velocities, puffing sounds and influence the correction factor for calculating the port length and tuning frequency). And the ported enclosure, having no load to the woofer below the tuning frequency, really needs a roll off to be introduced (a capacitor again) to protect the woofer from large excursions in very low frequencies. Especially if you are listening to vinyl.

- Home

- Loudspeakers

- Multi-Way

- How important is box size