Hi thanks for a great program. I still have a lot to learn. When I adjust the filling density and recalculate I don’t see a change in the spl graph. Any pointers as to what I am missing? Does the filling and response align with the 0.5 lbs per cubic foot density recommended by MJK to damp tline resonances? Thankyou.

No, I generally keep HR open until a proper computer reboot and put it in sleep mode many times a day with nary an error on waking it up. I had just finished/saved a record, clicked 'add' and got the error.

Hi GM,

Thanks for the additional information. I would very much like to find out why these seemingly intermittent problems are occurring, but in my case the performance is extremely robust and I cannot generate any runtime errors no matter how hard I try 🙂.

Kind regards,

David

Hi woodo,

Absorbent filling material only affects the loudspeaker wizard results. It is not taken into account in results produced by clicking the Input Parameters window Calculate button.

I haven't had the opportunity to compare Hornresp results against those produced by Dr King's software. I am not sure though, that simply specifying a density value would be sufficient information for a theoretically-robust model 🙂. Hornresp shows equivalent weight of Polyfill in kilograms for a given absorbent filling material setting. Either the total amount in the system, or the amount in each segment, can be displayed. The absorbent filling material model used in Hornresp is a very good one. The results should be reasonably accurate.

Kind regards,

David

When I adjust the filling density and recalculate I don’t see a change in the spl graph.

Absorbent filling material only affects the loudspeaker wizard results. It is not taken into account in results produced by clicking the Input Parameters window Calculate button.

Does the filling and response align with the 0.5 lbs per cubic foot density recommended by MJK to damp tline resonances?.

I haven't had the opportunity to compare Hornresp results against those produced by Dr King's software. I am not sure though, that simply specifying a density value would be sufficient information for a theoretically-robust model 🙂. Hornresp shows equivalent weight of Polyfill in kilograms for a given absorbent filling material setting. Either the total amount in the system, or the amount in each segment, can be displayed. The absorbent filling material model used in Hornresp is a very good one. The results should be reasonably accurate.

Kind regards,

David

Attachments

I cannot generate any runtime errors no matter how hard I try

Greets!

Bummer. FWIW I use Google Chrome? and an HP Win 7 pro 450 G3/64 Probook loaded with a bunch of HP programs I don't use, but appear to at least partially interact with what all is running plus it seems like Google is continuously updating/changing in detail recently.

GM

Many thanks David. Got it now. hadn’t tried this option.Hi woodo,

Absorbent filling material only affects the loudspeaker wizard results. It is not taken into account in results produced by clicking the Input Parameters window Calculate button.

I haven't had the opportunity to compare Hornresp results against those produced by Dr King's software. I am not sure though, that simply specifying a density value would be sufficient information for a theoretically-robust model 🙂. Hornresp shows equivalent weight of Polyfill in kilograms for a given absorbent filling material setting. Either the total amount in the system, or the amount in each segment, can be displayed. The absorbent filling material model used in Hornresp is a very good one. The results should be reasonably accurate.

Kind regards,

David

FWIW I use Google Chrome? and an HP Win 7 pro 450 G3/64 Probook

Thanks GM. In theory Hornresp should work just fine in such an environment, but perhaps there is a subtle incompatibility somewhere that is causing the problem. It is proving very difficult indeed to pin down exactly what is generating the error messages you are seeing.

Kind regards,

David

Many thanks David. Got it now. hadn’t tried this option.

Hi David and Woodo,

I can’t speak for Martin King, but I can say that he is quite active online and is frequently available on his qw website/forum

Based in the FB group sections Specific to hobbies, diy speakers, etc. There where he is quick to recommend the horn resp software and even participates in using his own in an effort to assist people while they are building transmissionline and similar speaker cabinets using hornresponse simultaneously and without any particular conflicts of results or the recommendation.

He has often spent a considerable amount of time in some builds and in all of that the only time he’s not been able to aside or advice is if I’m building a cabinet that’s not specific to a fully developed worksheet from his personal mathcad stuff that’s no longer public. Tapped horns might be a good example. Hope that helps Woodo, there’s lots of people using this program there and seems everyone is quite happy with what’s available from two very generous persons quite well known to design and trouble shoot them

Thanks GM. In theory Hornresp should work just fine in such an environment....

You're welcome!

OK thanks! I'm nothing if not contrary by nature. 😉

GM

Thanks Booger. Martin has been very helpful on his site too many as you say including myself and suggests using LATL and HR. George’s Auspurgers (?) software is supposedly available for diy use too. Don’t quote me on that. Kudos to David for the ongoing support on HR.Hi David and Woodo,

I can’t speak for Martin King, but I can say that he is quite active online and is frequently available on his qw website/forum

Based in the FB group sections Specific to hobbies, diy speakers, etc. There where he is quick to recommend the horn resp software..

Need help for modelling Ribben Tweeter

I have been searching over internet for Horn Speaker modelling softwares, and obviously I come to know about HornResp.

I want to create horn casing for Fountek RD 1.0 ribbon tweeter, but I am filling to do so through Hornresp software.

I am also not able to find schematic of desired/required horn shaped casing.

Could someone please help me on this ?

RD1.0

Regards

I have been searching over internet for Horn Speaker modelling softwares, and obviously I come to know about HornResp.

I want to create horn casing for Fountek RD 1.0 ribbon tweeter, but I am filling to do so through Hornresp software.

I am also not able to find schematic of desired/required horn shaped casing.

Could someone please help me on this ?

RD1.0

Regards

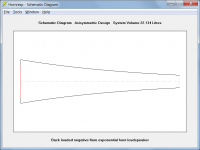

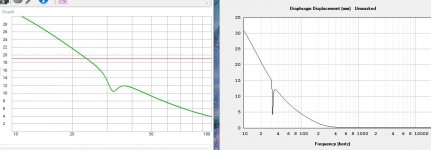

May I simulate a horn used backwards? A driver playing, with its backside, into the mouth of an exponential horn?

What to think about re parameters?

//

What to think about re parameters?

//

Attachments

Last edited:

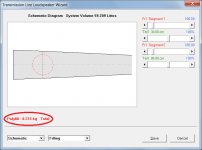

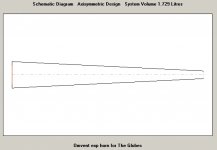

May I simulate a horn used backwards?

Yes, by specifying S1 greater than S2, as shown in the attachments.

Attachments

Need help for modelling Ribben Tweeter

Insufficient information available to simulate in Hornresp.

You could perhaps also try posting your message on the forum linked below:

https://www.diyaudio.com/forums/planars-and-exotics/

Yes, by specifying S1 greater than S2, as shown in the attachments.

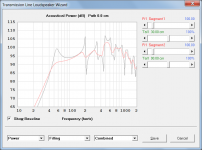

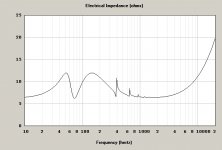

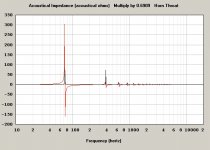

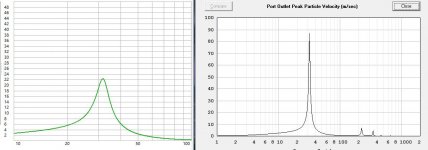

Thanks - then I did it correctly. Just shortly, why would one get these peaks?

It's a horn as per the picture in m post above...

//

Attachments

why would one get these peaks?

The horn has a negative flare, and a relatively small mouth.

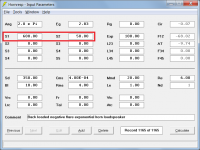

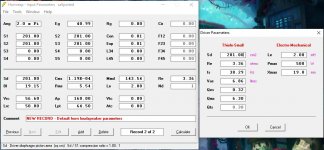

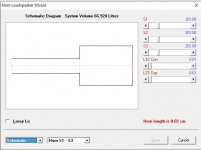

Hi, i'm having this issue where whatever driver/enclosure I model I get an extremely high port velocity/low xmax at tuning compared to other programs like winisd, i'm really not sure what i'm doing wrong, i've attatched hopefully all the information needed

model is sundown sa8v3, 2cuft box with a 20x8cm slot port tuned to 32hz (yes i'm aware a larger box will have a higher peak but this happens with anything I model)

any help is greatly appreciated

model is sundown sa8v3, 2cuft box with a 20x8cm slot port tuned to 32hz (yes i'm aware a larger box will have a higher peak but this happens with anything I model)

any help is greatly appreciated

Attachments

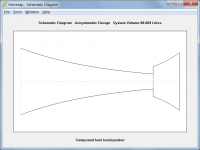

In a front loaded horn, I want to use a closed mouth horn as the rear chamber. Any way to model this in Hornresp?

i'm really not sure what i'm doing wrong

I can't see anything radically wrong with your specified design, assuming that your input values accurately reflect the desired system. Not that it makes any material difference to the results, but I would set S1, S2, S3, L12 and L23 equal to zero, as they serve no real purpose in this case. Hornresp shows the peak velocity. Is WinISD perhaps showing the rms value?

In a front loaded horn, I want to use a closed mouth horn as the rear chamber. Any way to model this in Hornresp?

Only as a compound horn, but with limitations.

Attachments

- Home

- Loudspeakers

- Subwoofers

- Hornresp