I’ve been doing a lot of reading and I’m getting somewhat nowhere lol. I’ve read that you shouldn’t go too much higher than what the manufacturer used and I’ve read that you can use whatever will physically fit as long as the capacitance is the same.

Most of what I’ve read is replacing a 6.3v -16v rated cap with something like 50v rated. Pretty much everyone says that’s okay.

I’m replacing a 22uF 160v rated cap and I have several Nichicon 22uF 450v rated caps. The old and the new are pretty close to the same physical size. I’m thinking it’ll be just fine, but thought I’d ask.

Thanks,

Dan

Most of what I’ve read is replacing a 6.3v -16v rated cap with something like 50v rated. Pretty much everyone says that’s okay.

I’m replacing a 22uF 160v rated cap and I have several Nichicon 22uF 450v rated caps. The old and the new are pretty close to the same physical size. I’m thinking it’ll be just fine, but thought I’d ask.

Thanks,

Dan

I’m replacing a 22uF 160v rated cap and I have several Nichicon 22uF 450v rated caps.

That will work, but using an electrolytic at a small fraction of its working voltage will cause it to gradually degrade.

Not sure if that also increases outright failure rate. Use only recent fresh caps for replacement, regardless.

That will work, but using an electrolytic at a small fraction of its working voltage will cause it to gradually degrade.

Not sure if that also increases outright failure rate. Use only recent fresh caps for replacement, regardless.

Thank you, yes these are new. They were purchased from mouser about 5-6 months ago or so for a tube amp I was rebuilding. Of course it’s a much better deal when you buy 10 or more so I have 9 left over from that lol.

Do you know of any evidence of this degradation? I’m curious at what percentage of the rated voltage you have to meet in order to prevent this and if it’s really an issue. Also would like to know how long a capacitor will last in circuit like this.

Thank you much!

Dan

When you apply no voltage at all for decades, the leakage current becomes excessive. It slowly turns back to normal when you then charge them slowly. (When you try to charge them quickly, they heat up too much and may explode, which is one of the reasons why you should never switch on a tube radio that hasn't been used for decades without special measures, such as a light bulb connected in series with the radio that limits the charging current.)

I'm no electrolytic capacitor expert, but as far as I know, when you only apply voltages well below the specified working voltage, the leakage at higher voltages very slowly increases. That is usually no problem, because the capacitor is not used at those voltages.

I'm no electrolytic capacitor expert, but as far as I know, when you only apply voltages well below the specified working voltage, the leakage at higher voltages very slowly increases. That is usually no problem, because the capacitor is not used at those voltages.

I use caps that have superior rubber seals (3000-10000 hour service life rating) 11 years old sometimes. If they are over 6 months old I charge them to 12 v through a 47 k resistor, however long it takes. None has exploded or failed early, & I've installed over 300 (organs + amps). Newark stars * and discounts e-caps at end of shelf life. I buy those & charge before use; I'm not going to use everything I buy in 6 months. Before last year I was charging caps to 2 v with the DVM ohms scale, and those don't fail either.Use only recent fresh caps for replacement, regardless.

I won't buy a 500 hour or 1000 hour service life cap anymore. Rubber deteriorates in service or sitting on the shelf. I've had to replace TV parts store front shelf e-caps 4 times in the ST70 amp: life is too short to repeat that job that much. Now the internet & debit cards allow me to buy parts with superior specifications.

Last edited:

I charged up some 10,000µF 400V caps through several k ohms using an adjustable HV supply, letting them sit for a few minutes between voltage increments. Fairly nerve-wracking given the stored energy involved and the voltages. The caps had only been stored for a few years too, but I didn't want to take any chances. The bleeder resistor array dissipated several 10's of watts and still took a while to make them safe!

Does anyone have an authoritative report on operating electrolytics far below the rated voltage?

I doubt you'll find much if anything, that just isn't normally done.

Physical size is roughly proportional to the CV product. Also cost.

Last edited:

I can't agree to that, as low-valued electrolytics are often only available with high working voltages.

Perhaps in leaded parts in recent years, but certainly not in smt packages.

Last edited:

Does anyone have an authoritative report on operating electrolytics far below the rated voltage? I find lots of hearsay and guessing out there, but nothing from a manufacturer

What you will find suggests that they will become lossy after storage/no voltage, so one can assume that when the voltage applied becomes too low, a similar affect can happen.

...you shouldn’t go too much higher...

I have known cases where 450V caps used at 20V all died in a year. (This was a 4-section cap where for simplicity all sections were specced the same.)

And I have seen 35V caps worked at zero hold their value for decades.

I think a fully stabilized e-cap will hold breakdown voltage and capacitance for a very long time even at low/no volts. And there are poorly stabilzed caps on the market.

If it fails, will somebody die? If not, then just go with what you can get. If it fails, repair with another brand/batch.

It's done a lot to simplify BOMs. If I have a design with a 24 V power supply and a 3V3, I might have many 35V parts and a single capacitor of the same value on the 3V3. It is tempting to use the 35v part again if space is not an issue and the cost saving is lowI doubt you'll find much if anything, that just isn't normally done.

Physical size is roughly proportional to the CV product. Also cost.

I might have many 35V parts and a single capacitor of the same value on the 3V3.

It is tempting to use the 35v part again if space is not an issue and the cost saving is low

Not when there is such a discrepancy in voltages. Poor practice, and would never be done in industry.

Manufacturing is done off reels in assembly plants. Diy can do anything, of course.

Last edited:

Avoiding extra reels is always a challenge as a change of reels due to the capacity limits of the pick and place machine raises costs a lot.Not when there is such a discrepancy in voltages. Poor practice, and would never be done in industry.

Manufacturing is done off reels in assembly plants. Diy can do anything, of course.

I’m replacing a 22uF 160v rated cap and I have several Nichicon 22uF 450v rated caps. The old and the new are pretty close to the same physical size. I’m thinking it’ll be just fine, but thought I’d ask.

Thanks,

Dan

i have done this and never regretted, but it is only me, ymmv...

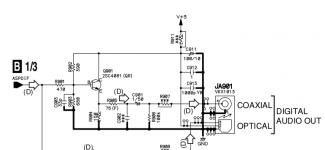

Small part of the schematic of the Panasonic DV-575A DVD-A, DVD-V, CD and SACD player, showing a 100 uF, 10 V electrolytic capacitor biased at 3.3 V (V+3 is 3.3 V nominal) and a 1 uF, 50 V electrolytic capacitor biased at even less voltage.

Actually it's a Pioneer rather than a Panasonic.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Design & Build

- Parts

- Higher capacitor voltage rating and forming.