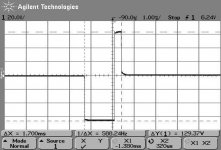

This is the output waveform (time triggered) of an AMC 5 channel amplifier model (I think it is a copy of a NAD?)

One channel exhibits this large spike (as per attatch) thru the speaker about once every half hour or so. Totally makes you jump out of your skin!!!

Does anyone have any ideas on what would cause this fault?

It occurs regardless of a speaker load connected or not.

I know it is not the power supply as the other 4 channels don't have this fault at all.

One channel exhibits this large spike (as per attatch) thru the speaker about once every half hour or so. Totally makes you jump out of your skin!!!

Does anyone have any ideas on what would cause this fault?

It occurs regardless of a speaker load connected or not.

I know it is not the power supply as the other 4 channels don't have this fault at all.

Attachments

Or clean and wiggle all the connectors. Also tap on the protection relay if there're some.

good luck.

good luck.

I vote for an intermittend leaking electrolytic cap. Or, less probable but possible, a semiconductor (diode or transistor). I don't think it is a solder joint. Forget the output relay. As the man said, do you have a schematic?

Jan Didden

Jan Didden

Oh nice! I used to service these things. Resoldering the board will be lots of fun! They normally blast the outputs right to heaven (or hell depending on your outlook).

This may be a bad solder joint or an intermittent transistor junction. Either way the amp is unsafe at the moment.

There was, at one point, another board added to the heatsink that makes getting to the screws for the outputs difficult. Draw or take pictures and do take your time.

I will also say I've never seen one of these with this fault. They were normally blown by the time I saw them. A variac may be handy here.

-Chris

This may be a bad solder joint or an intermittent transistor junction. Either way the amp is unsafe at the moment.

There was, at one point, another board added to the heatsink that makes getting to the screws for the outputs difficult. Draw or take pictures and do take your time.

I will also say I've never seen one of these with this fault. They were normally blown by the time I saw them. A variac may be handy here.

-Chris

looks like semiconductor problem to me most likely of vas origin, you cant pin down a fault without doing some tests first and you dont mention any tests

youve done so my suggestion is highly generalised,good luck

cheers

youve done so my suggestion is highly generalised,good luck

cheers

Thanks for the pointers guys.

Yes, it is the AMC model 2N 100 (5 channel amplifier)

It employs dual rails +/- 40 volt and +/- 70 volt rails.

(were AMC making stuff for NAD or not??...maybe there is a

parallel to the Nad circuits?. I know some early CD players were.

I have the schem in paper form and will try to beg, steal or borrow a scanner to get it online before the thread runs out...

pcb pick.

Regards

Yes, it is the AMC model 2N 100 (5 channel amplifier)

It employs dual rails +/- 40 volt and +/- 70 volt rails.

(were AMC making stuff for NAD or not??...maybe there is a

parallel to the Nad circuits?. I know some early CD players were.

I have the schem in paper form and will try to beg, steal or borrow a scanner to get it online before the thread runs out...

pcb pick.

Regards

Attachments

And some tests that have been done.

Tests so far were:

test 1 loaded 8 ohms with 1K sinewave test (0.5 hours)

test 2 loaded with a speaker load (a very old cheap speaker)and music playing (12 hours)

test 3 with the OPS loaded / and unloaded,amplifier idling and no driving signal applied to the input.The trigger sensing shows waveform (as per first pic). The Spikes show up regardless of loading the OPS.

I will redo test1 and see if the spike shows up when it is drawing some load current.

The pops occur about every half hour or thereabouts so maybe it is a capacitive timing thing. This is a good one!

Tests so far were:

test 1 loaded 8 ohms with 1K sinewave test (0.5 hours)

test 2 loaded with a speaker load (a very old cheap speaker)and music playing (12 hours)

test 3 with the OPS loaded / and unloaded,amplifier idling and no driving signal applied to the input.The trigger sensing shows waveform (as per first pic). The Spikes show up regardless of loading the OPS.

I will redo test1 and see if the spike shows up when it is drawing some load current.

The pops occur about every half hour or thereabouts so maybe it is a capacitive timing thing. This is a good one!

Hi andjur78,

Their quality has gone up. That is good. The same factory can make several brands, but only the build quality will be similar. The schematics and layout are done elsewhere.

Thanks for the schematic. Now to look at it.

-Chris

Their quality has gone up. That is good. The same factory can make several brands, but only the build quality will be similar. The schematics and layout are done elsewhere.

Thanks for the schematic. Now to look at it.

-Chris

sorry about the low res schems.

I'm Trying to find a scanner to get a clearer loaded pic online...

...unless anyone out there has a clear pic ready to upload?

I'm Trying to find a scanner to get a clearer loaded pic online...

...unless anyone out there has a clear pic ready to upload?

I am far from an expert but I'd personally expect something temperature/connection related. Perhaps a bad connection breaks after some warmup time. If the breaks happen more often with output loading look towards ouput stage, if not, focus on driver stages.

The positive pulse might just be the feedback system reacting to the initial negative pulse, so I'd focus on things that might cause a swing to the negative rail.

I know it sounds odd, but I'd wiggle and bend (just a bit) the transistor leads to change the pressure that they put on the connections. You could also power up the amp and tap transistors/resistors/caps with a plastic pen to see if you can evoke the response. If you can then you know which connections to reheat.

If you make your living fixing amps then you certainly know more about amp reapir that I do. So these suggestions might be a bit too obvious....

Is the pulse really loud and sudden? I am sure someone thought the amp was possesed!

Keep us updated, I'd like to know what the problem turns out to be.

Hope this helps,

Doug

The positive pulse might just be the feedback system reacting to the initial negative pulse, so I'd focus on things that might cause a swing to the negative rail.

I know it sounds odd, but I'd wiggle and bend (just a bit) the transistor leads to change the pressure that they put on the connections. You could also power up the amp and tap transistors/resistors/caps with a plastic pen to see if you can evoke the response. If you can then you know which connections to reheat.

If you make your living fixing amps then you certainly know more about amp reapir that I do. So these suggestions might be a bit too obvious....

Is the pulse really loud and sudden? I am sure someone thought the amp was possesed!

Keep us updated, I'd like to know what the problem turns out to be.

Hope this helps,

Doug

Hi Doug and thanks for your reply.

I have done pro audio amp repairs for the past 10 years.

I'll never say "I know it all" as this one has me stumped!

Still persistance...

Update so far- I have removed every electrolytic from the pcb and are awaiting on a new 100R bias pot.(This pot had had a small crack on it's plastic slotted part)

One stand out thing is that the brown glue they use to mount the electrolytics seems to "eat away" other components around where it has been placed. One small diode had a very corroded lead.

I will re assemble the unit with new electro caps this week and soak test again.

Will keep you all posted. Cheers Andjur78.

I have done pro audio amp repairs for the past 10 years.

I'll never say "I know it all" as this one has me stumped!

Still persistance...

Update so far- I have removed every electrolytic from the pcb and are awaiting on a new 100R bias pot.(This pot had had a small crack on it's plastic slotted part)

One stand out thing is that the brown glue they use to mount the electrolytics seems to "eat away" other components around where it has been placed. One small diode had a very corroded lead.

I will re assemble the unit with new electro caps this week and soak test again.

Will keep you all posted. Cheers Andjur78.

Have you tried to use circuit coolent spray to locate the faulty component (if this is the problem)? I found it quite effective to locate weaken components.

I've seen the brown adhesive become conductive. Touching the scope lead to it while the amplifier is in operation will tell you if it's happening in your case.

The corrosion sounds more like leaking electrolyte. If that's the case, you need to thoroughly clean the board with a solvent (acetone) before replacing the caps. Since it's a double-sided board, you need to make sure that any feed-throughs under the cap are still intact.

Many defective semiconductors are sensitive to temperature change. The cooling spray is a good idea. Placing your soldering iron very close to (or touching) small driver transistors will heat them up. Most of the semiconductor manufacturers use a plastic with a melting point above what your soldering iron can produce but a few (philips) sometimes use a plastic with a low melting point so be careful if you actually touch the plastic case of the drivers with your iron.

The corrosion sounds more like leaking electrolyte. If that's the case, you need to thoroughly clean the board with a solvent (acetone) before replacing the caps. Since it's a double-sided board, you need to make sure that any feed-throughs under the cap are still intact.

Many defective semiconductors are sensitive to temperature change. The cooling spray is a good idea. Placing your soldering iron very close to (or touching) small driver transistors will heat them up. Most of the semiconductor manufacturers use a plastic with a melting point above what your soldering iron can produce but a few (philips) sometimes use a plastic with a low melting point so be careful if you actually touch the plastic case of the drivers with your iron.

Perry Babin said:I've seen the brown adhesive become conductive. Touching the scope lead to it while the amplifier is in operation will tell you if it's happening in your case.

The corrosion sounds more like leaking electrolyte. If that's the case, you need to thoroughly clean the board with a solvent (acetone) before replacing the caps. Since it's a double-sided board, you need to make sure that any feed-throughs under the cap are still intact.

Many defective semiconductors are sensitive to temperature change. The cooling spray is a good idea. Placing your soldering iron very close to (or touching) small driver transistors will heat them up. Most of the semiconductor manufacturers use a plastic with a melting point above what your soldering iron can produce but a few (philips) sometimes use a plastic with a low melting point so be careful if you actually touch the plastic case of the drivers with your iron.

I have seen that brown stuff also, can get down to k-ohm range when it gets old enough, usually its in megaohms.

(just stuck your multimeter leads to it and see)

I remember at least one piece of VCR where corrosion was for sure because of that glue, not electrolytics.(none of them anywhere near corrosion spots)

For leaking caps boards I use hot tap water+dishwashing soap+toothbrush. followed with compressed air, flushing with IPA and compressed air again. Works like charm, just dont *****ing smoke at the same time when blowing IPA off with air 😀 Acetone is not so good as most of acids and salts have good much better solubility on water and in tricky case IPA or Acetone wash alone can leave some salty residues on board that are still causing leaking. (alltough some 100meg leakage resistance is not so big problem in audio circuits as some others)

Corrosion caused by cap electrolyte or that glue can be a real pain in a *** to repair, as it eats thin traces intermited without visual change. Only way is to measure them to be sure. (having repaired more than 100 piece particular model of smps power supplies) (and dont ask me what I think about Panashitronic el-caps after replacing more than 900 pieces of p*ssing HFZ series)

How about disconnecting the PSU, and monitoring it for glitches.

At the same time you could power-up the amp via an external PSU and monitor that too. Next stage, I suppose, would be to disconnect each stage in turn (I'd start with the driver stage), and see where the pulses are introduced.

At the same time you could power-up the amp via an external PSU and monitor that too. Next stage, I suppose, would be to disconnect each stage in turn (I'd start with the driver stage), and see where the pulses are introduced.

- Status

- Not open for further replies.

- Home

- Amplifiers

- Solid State

- Here's a good power amp fault