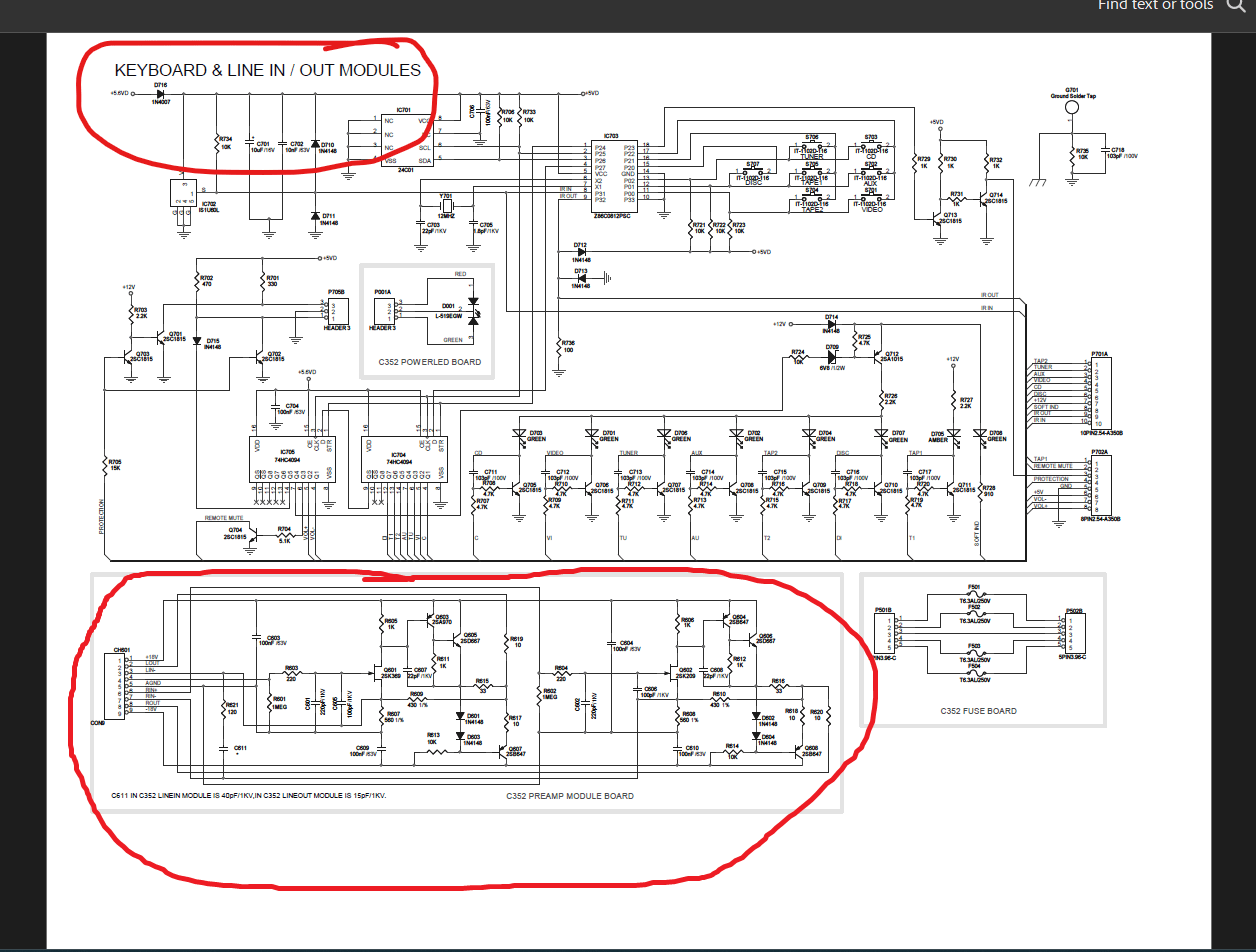

I looked at the preamp schematic signal chain again -So I think they are in series . Previously I thought they were in parallel, one module with vol pot giving output at preout 2 RCA and the other with no vol control to preout I RCA

preamp module M301 output is fed to Vol. Bal. and tone control circuit and from there it goes to preamp module M302

Learning a lot from kind and helpful members, hopefully the amp should be up and running by this weekend

C611 is 33pF / 1KV in both modules

I'm not surprised tbh. Keeping it the same keeps costs down and they probably figured a compromise in value worked well enough.

I checked temperatures of various components, with no input signal , things go beyond 62 degree Celsius pretty quickly(<30s). Really bad thermal design

Sounds like a typical NAD 😉

I looked at the preamp schematic signal chain again -

You have to be logical fault finding. The crackling will show on a scope and you have to work 'forwards' toward the input sockets and see where the crackle appears, or of course work the other way from an input toward the power amp and see where the noise begins to show.

To sum up all my findings-

1. One module's L ch is faulty

2. Swapping them causes noise to go from full blast to "dependent" on vol knob position due to their placement in audio chain (Obviously!)

3. Note to self - Never buy NAD again, just D.I.Y. or diy tryin'

1. One module's L ch is faulty

2. Swapping them causes noise to go from full blast to "dependent" on vol knob position due to their placement in audio chain (Obviously!)

3. Note to self - Never buy NAD again, just D.I.Y. or diy tryin'

To sum up all my findings-

That is much easier to understand 🙂

Replacing the transistors as a first step would be my advice... and that includes the FET.

From a practical point if the 2SD and 2SB output transistors run hot then they could be suspect. That type of device has a poor track record in my experience. If any of the small caps are the 'compressed disc' ceramic type then they are always suspects.

Are they static sensitive? handling precautions?that includes the FET.

Even with open cabinet and AC set at 25 C, almost all transistors were running "U Can't Touch This" level hot . Everyone is a suspect here, thanks to B(N)AD thermal design.2SD and 2SB output transistors run hot then they could be suspect.

Digging thru audiokarma NAD C352 repair threads, I came to know of PCB tracks peeling off, components / heatsinks managing to get de-soldered themselves under intense heat + the usual suspects, JH caps leaking out-

They are static sensitive up to a point but I can't ever recall damaging one and they are nothing like CMOS chips in being susceptible to damage. Not really a problem in practice.

I have used jumper wires to connect the faulty module. The noise pickup is really horrible as these wires are from a ribbon cable, no shielding .

BTW somehow the crackling noise is not coming but just the humming sound, It varries with the placement of module. music playing properly from both of the channels .

I will resolder it back in its place and give an update

BTW somehow the crackling noise is not coming but just the humming sound, It varries with the placement of module. music playing properly from both of the channels .

I will resolder it back in its place and give an update

Attachments

My 2 cts .

Can you get isopropyl alcohol to clean your pcb?

It is very oxidized in several places and it is difficult to distinguish the visual state of the components (which could give a clue)

Also pay attention to the screws where there are ground

Can you get isopropyl alcohol to clean your pcb?

It is very oxidized in several places and it is difficult to distinguish the visual state of the components (which could give a clue)

Also pay attention to the screws where there are ground

They use NC thinner to clean PCBs In this workshop , but the supervisor warned me it will also remove any capacitor markings. Used thinner to clean track sides of those modules and mainboard only, while leaving out the component side. I live near salt pan - creek side area, things get corroded pretty quickly over here . Once this repair work is over , I will clean it with IP at home, as you have recommended.

Last edited:

SUCCESS!

Reason for noise was the preamp module pins were slightly corroded, in my previous attempts, I didn't cleaned it but had reflowed all other components. Before proceeding with any next attempts, I gently polished the pins and soldered it. Voila , that worked out!

Right now listening and enjoying music thru my NAD C352

Some pending work still remaining -

Reflowing the dry solder joints of power resistors , transistors, etc as these feel a bit loose when pushed and tone control pots seems to have gone bad

Thanks dear all and special thanks to @Mooly . BTW how did you get the preamp module schematic? If possible can you share full schematic please?

Reason for noise was the preamp module pins were slightly corroded, in my previous attempts, I didn't cleaned it but had reflowed all other components. Before proceeding with any next attempts, I gently polished the pins and soldered it. Voila , that worked out!

Right now listening and enjoying music thru my NAD C352

Some pending work still remaining -

Reflowing the dry solder joints of power resistors , transistors, etc as these feel a bit loose when pushed and tone control pots seems to have gone bad

Thanks dear all and special thanks to @Mooly . BTW how did you get the preamp module schematic? If possible can you share full schematic please?

Well done 👍 pleased to hear you have fixed it.

The preamp is in the manual on page #7

The preamp is in the manual on page #7

- Home

- Amplifiers

- Solid State

- Help! NAD C352 making loud crackling noise in L ch