I think the first choice is better.

thankyou for advice to me.

and my mind i hope you sugest my choice ...😀😀😀😀😀😀

i will trying for micro vibration.

i still try out.....😀

congrats for this nice build.

I did several plinth for the 401 but never did it this way ... awesome

Nah, don't think I'm going to give you any advice.

I think I'm going to ask your advice.

Yes, Ed is to modest

I'm enjoying his creativity..

congrats for this nice build.

I did several plinth for the 401 but never did it this way ... awesome

Hi Rolf.

thank's Rolf.

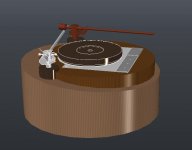

i'm a newbie, not experience make plinth, this my first project.

Micro vibration, i do not know this is wrong : D

Because when i play the vinyl (more Bass / low) and i turn the volume to high, rise like hum ... (low) and i think the cantilever like tremor ....

and i think this may be resonance from the lower sound.

when i turn to low volume (NORMAL) or i lift the arm the hum disappear.

my diagnosis from symptoms ...: D: D: D

DD (differential diagnosis):

lower resonance vibration from sound

humble from the motor.

and i do not know what happen? confused: D

and opinion from "Stanton" my plinth need to repair.

regards

ed

Dear ed,

you should go for rubber rings between Garrard´s motor deck and your plinth as it is mentioned in the Garrad manual also. This limits any mechanical resonances to be transported from the motor deck to the plinth.

If you recognize any resonances after you inserted these rubber rings then you need to work on the motor.

you should go for rubber rings between Garrard´s motor deck and your plinth as it is mentioned in the Garrad manual also. This limits any mechanical resonances to be transported from the motor deck to the plinth.

If you recognize any resonances after you inserted these rubber rings then you need to work on the motor.

hi Rolf.

thank you for you suggetion.

i will looking for my problem like you said.

i hope this is not motor...

but I can still enjoy my new plinth provided it's not a loudness.

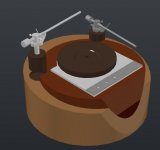

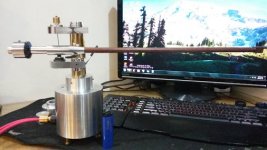

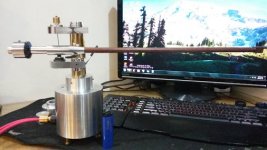

I just finished wiring, tonearm magnet version Schroerder and finished trying.

regards

ed

this is my upload video of DIY TA magnet cloning schroeder.

My DIY tonearm version schroerder.... magnet, put in pivot to hole of arm base.... go down very slowly.... vacuum..... pneumatic

https://plus.google.com/u/0/photos/...859&sqsi=6b9ec799-5a4c-4755-a139-47755ce790dc

thank you for you suggetion.

i will looking for my problem like you said.

i hope this is not motor...

but I can still enjoy my new plinth provided it's not a loudness.

I just finished wiring, tonearm magnet version Schroerder and finished trying.

regards

ed

this is my upload video of DIY TA magnet cloning schroeder.

My DIY tonearm version schroerder.... magnet, put in pivot to hole of arm base.... go down very slowly.... vacuum..... pneumatic

https://plus.google.com/u/0/photos/...859&sqsi=6b9ec799-5a4c-4755-a139-47755ce790dc

Last edited:

Hi "Stanton"

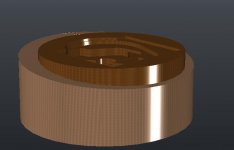

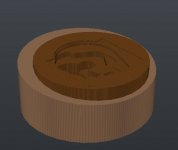

Last day i have tried to full attach wooden base arm to plane granite.. and i give 3 ball bearing Between the basearm and pod basearm. Become space and not body contact.

This is give up a sound become detail. And for attachment of plinth to plane i still planning how i do.

Full contact or with center spacer contact .

Last day i have tried to full attach wooden base arm to plane granite.. and i give 3 ball bearing Between the basearm and pod basearm. Become space and not body contact.

This is give up a sound become detail. And for attachment of plinth to plane i still planning how i do.

Full contact or with center spacer contact .

Attachments

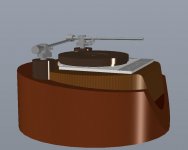

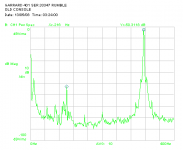

Garrard 401 Plinth measurements

To get a better insight about what the plinth does to motor vibration from a Garrard 401 drive I did two vibration measurements with a testrecord .

ref.signal 315Hz at 5.42cm/sec. and motorvibration on 100Hz .

A better build console gives an improvement of 15 db !

First one with a four layer 15 mm plywood .

Second one with four layer 18mm birch plywood and one toplayer 18mm mdf.

To get a better insight about what the plinth does to motor vibration from a Garrard 401 drive I did two vibration measurements with a testrecord .

ref.signal 315Hz at 5.42cm/sec. and motorvibration on 100Hz .

A better build console gives an improvement of 15 db !

First one with a four layer 15 mm plywood .

Second one with four layer 18mm birch plywood and one toplayer 18mm mdf.

To get a better insight about what the plinth does to motor vibration from a Garrard 401 drive I did two vibration measurements with a testrecord .

ref.signal 315Hz at 5.42cm/sec. and motorvibration on 100Hz .

A better build console gives an improvement of 15 db !

]

Hi.

Good information abaout my problem...

Your have RTA for frekuensi measurement . It is to easily to know.

What are the vinyl to frekuensi measurement ? Like pink noise on cd (digital).

I have see your chart , and your plinth can reduced with your mixed the layer design. Good idea..

And i have see your plinth , open on below the plinth. What are this can reduced rumble if our compare with closed at solid plinth?

:Maybe " my rumble problem from motor because i heard lower sound.

I will tryout. ..

Thankyou for share ...

Regards

Ed

Hi.

Good information abaout my problem...

Your have RTA for frekuensi measurement . It is to easily to know.

What are the vinyl to frekuensi measurement ? Like pink noise on cd (digital).

I have see your chart , and your plinth can reduced with your mixed the layer design. Good idea..

And i have see your plinth , open on below the plinth. What are this can reduced rumble if our compare with closed at solid plinth?

:Maybe " my rumble problem from motor because i heard lower sound.

I will tryout. ..

Thankyou for share ...

Regards

Ed

More layers birchplywood with different dimensions and the use of another ayer ,mdf, greathly reduce the vibrations .More research is needed to see which will save the best results.

But as always with old idler tables starting with motor revision etc.

You can use good testrecords with ref.level on it for measurement .

Volken

More layers birchplywood with different dimensions and the use of another ayer ,mdf, greathly reduce the vibrations .More research is needed to see which will save the best results.

But as always with old idler tables starting with motor revision etc.

You can use good testrecords with ref.level on it for measurement .

Volken

how about which i apply granite and mdf ?

in my mind garnite give rigid.. and leveling. but that have large resonance effect , for that i give at below 4 layer MDF for damping and reduce resonance from granit.

for temporary attachment granite to MDF with bolt.

if i sure. i will give glue (full attach) . i have done to my "pods" armbase , that become detail.

i have not good measurement.

and i have cek and setting a motor and pulley to idler , and tight bolt magnet to chassis and not contact to a part of motor or chassis.

how about which i apply granite and mdf ?

in my mind garnite give rigid.. and leveling. but that have large resonance effect , for that i give at below 4 layer MDF for damping and reduce resonance from granit.

for temporary attachment granite to MDF with bolt.

if i sure. i will give glue (full attach) . i have done to my "pods" armbase , that become detail.

i have not good measurement.

and i have cek and setting a motor and pulley to idler , and tight bolt magnet to chassis and not contact to a part of motor or chassis.

Maybe I'm not sure never tried it save bet on several layers birch ply !

- Status

- Not open for further replies.

- Home

- Source & Line

- Analogue Source

- help give me advise for Garrard 401 Plinth