help, please give me advise for my Garrard 401 Plinth

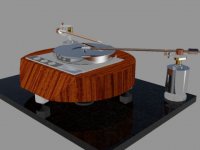

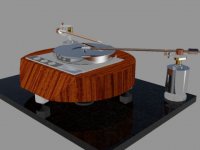

I make my Garrard 401 plinth. and nearing completion.

but I still doubt whether it is right?

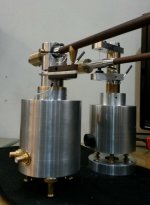

I tried to separate the unit with my DIY tone arm, that I try to make myself.

I made a long tonearm 16.5 ", it is necessary to base large.

all that which I put on a granite base in ply with 4 layers of MDF (4X18MM). (WxD / 80cm x 56cm)

to all friends may be advice for my project.

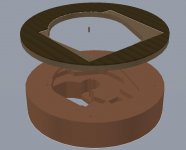

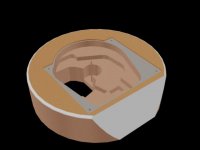

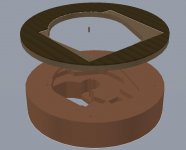

before I make , I tried to draw :

doing work by handmade ( i have not CNC mechine)

I make my Garrard 401 plinth. and nearing completion.

but I still doubt whether it is right?

I tried to separate the unit with my DIY tone arm, that I try to make myself.

I made a long tonearm 16.5 ", it is necessary to base large.

all that which I put on a granite base in ply with 4 layers of MDF (4X18MM). (WxD / 80cm x 56cm)

to all friends may be advice for my project.

before I make , I tried to draw :

doing work by handmade ( i have not CNC mechine)

Last edited:

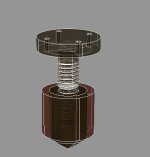

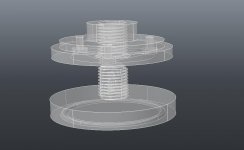

make feet for plinth:

put feet on the plinth and try to put parts according drawing:

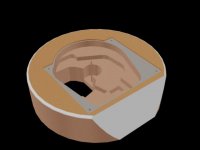

make base table from MDF (18mm) 4 layer:

make feet for base table:

tried replacement granite layer on top base table from MDF and sub base for base arm. :

firsh install on the Rack:

completed replacement part on base table : (but not yet finish)

put feet on the plinth and try to put parts according drawing:

make base table from MDF (18mm) 4 layer:

make feet for base table:

tried replacement granite layer on top base table from MDF and sub base for base arm. :

firsh install on the Rack:

completed replacement part on base table : (but not yet finish)

Last edited:

The aluminum parts? Not handmade??

But very nice work.

My question is how does it sound different than the stock 401?

But very nice work.

My question is how does it sound different than the stock 401?

Nah, don't think I'm going to give you any advice.

I think I'm going to ask your advice.

hello,

this is my first project for build Plinth, i have not experience about that.

i need advise from all friends for my plint

Are this correctly ?

- construction separate the unit and tonearm ( some people said this must be one piece )

- I used granite material and combine with mdf ( my friends said for used slate but i can't get in my town).

- Unusual use of long tonearm more than 12" ( my tone length 16.5 "), but I was inspired devise from Robert Fuchs, and Thomas schick and certainly Schroeder and others.

- And many many question in my mind.

Kind regards

Last edited:

The aluminum parts? Not handmade??

But very nice work.

My question is how does it sound different than the stock 401?

hello ,

thank you for your responded.

metal materials and some wooden I created using a lathe (manual ) with help of a friend.

I was designed with cad drawing.

This is few pictures of feet that i was done:

I never had a standard version of Garrard 401 because I get only units. from ebay UK.

I expect this will be better than the standard.

I've tried to create a simplified version to try My DIY TA.

the results are quite good in my opinion, and when compared with the test results while My new plinth, there are still problem in the high pitch and roll off at low, but I'm looking for a problem where? i think may be in my phono, that have little hum and microphonic.

Best Regards

I don't know if the feet under the main part (the platter) are suspended or not.

If they are, it is not a good idea at all.

Because arm and platter must not have relative movements.

If they are, it is not a good idea at all.

Because arm and platter must not have relative movements.

I don't know if the feet under the main part (the platter) are suspended or not.

If they are, it is not a good idea at all.

Because arm and platter must not have relative movements.

Hi,

i have placement wooden+bronze feet (pic above) on The Main part, not suspended and rigid, but can up and down adjustable ( like bolt) , for flat leveling the main part to the base table (granite).

Wood Plinth and garrard have weight of approximately 17 kg. This is not easy to move and quite heavy.

I think it's easy leveling and isolating vibrations from the motor and platter movement to tonearm.

my friend said to me same with your advise.* what should I attach the main (wood plinth) to the basic table without feet.

This as my first question. I still doubt that what i do.

but your suggestion of my consideration.

and pic below, that feet for the base table , can adjustable and i give O ring rubber for damper.

thank you very much... 🙂 buddy

You may put the platter base rigid on a plane (adjustable of course if you want).

The arm pods rigid too on the same plane.

The motor anywhere out of the plane.

The plane suspended (if possible) on the table, shelf, ...

The arm pods rigid too on the same plane.

The motor anywhere out of the plane.

The plane suspended (if possible) on the table, shelf, ...

You may put the platter base rigid on a plane (adjustable of course if you want).

The arm pods rigid too on the same plane.

The motor anywhere out of the plane.

The plane suspended (if possible) on the table, shelf, ...

Now , i know terminology a part from my plinth, some time i confused to said it.

Now , i know terminology a part from my plinth, some time i confused to said it.yes i have do put the platter base and the arm pods rigid of the same plane ( granite). Are you see my plinth correct?

how about my contruction of the arm pods :

sorry i have much upload pic because give me convince to explain , my English bad😀

![PhotoGrid_1430962223136[1].jpg PhotoGrid_1430962223136[1].jpg](https://www.diyaudio.com/community/data/attachments/443/443207-b3c87b1fcf54e362c251ebdf16840342.jpg?hash=s8h7H89U42)

Very impressive job.

If there is no spring or rubber in the path between the platter and the arms it is all good.

Edit : sorry "pod" is not a good word, my English is not very good too.

If there is no spring or rubber in the path between the platter and the arms it is all good.

Edit : sorry "pod" is not a good word, my English is not very good too.

Last edited:

Very impressive job.

If there is no spring or rubber in the path between the platter and the arms it is all good.

Edit : sorry "pod" is not a good word, my English is not very good too.

thank you for your suggestion to me,🙂

yes, no spring or damper (rubber). all rigid to the plane

.

Your opinion correctly , because i have tried put sponge between layer on the "POD" for damper and i think easy to leveling , resulted my arm become not stability and disorderly.

I make this plinth into separate sections for use tonearm is quite long with both sides.

so I made like this, it is rather the other with the initial design drawing, at the base arm.

The total weight of all, I count the approximate weight of 65 kg.for dampen vibration.

and I hope my table capable of holding the load.🙄

😱

Hi ..... again to you buddy....

You have said in the threads "some diytonearm." .. about tonearm from HD motor?

I have interested. . DIY tonearm with computer's Hard disks.

Are you have experience about that?

I want you will give me advice . And Please don, t ask to me for advice to you. 😱😀

Nah, don't think I'm going to give you any advice.

I think I'm going to ask your advice.

Hi ..... again to you buddy....

You have said in the threads "some diytonearm." .. about tonearm from HD motor?

I have interested. . DIY tonearm with computer's Hard disks.

Are you have experience about that?

I want you will give me advice . And Please don, t ask to me for advice to you. 😱😀

The aluminum parts? Not handmade??

But very nice work.

My question is how does it sound different than the stock 401?

hello Bear,

i have tested my garrard but i not sure this correct, and i have upload the video in youtube . but this not good recording .

may you give feedback to me , what fail about it. 😀😀

https://www.youtube.com/watch?v=xGaBKe59eMU

add video garrard 401 new plinth test 4 on youtube.

i have update tested of my garrard with first power RS241 and 2nd power 300B.

please compare , and give me opinion , what fail of my divice.?

https://www.youtube.com/watch?v=wk7susQlmCI 🙂 RS241

https://www.youtube.com/watch?v=6xnVvwMmJnE 🙂 300B

thank you

Note: recording of the video not good and no Audiophile quality

i have update tested of my garrard with first power RS241 and 2nd power 300B.

please compare , and give me opinion , what fail of my divice.?

https://www.youtube.com/watch?v=wk7susQlmCI 🙂 RS241

https://www.youtube.com/watch?v=6xnVvwMmJnE 🙂 300B

thank you

Note: recording of the video not good and no Audiophile quality

You work at the speed of a rocket !

I have already done .sorry this is flashback what i have done. Just share. 😀

I don't know if the feet under the main part (the platter) are suspended or not.

If they are, it is not a good idea at all.

Because arm and platter must not have relative movements.

" arm and platter must not have relative movements " , you are correct.

problems with my plinth is override micro vibrate from the low sound resonance vibration.

My plinth need some correction.

There are two alternatives of it.

- Combining the plinth (spindle) with Arm. (union)

- Full isolation for both.

for the first choice , i must change the design of the plinth because I had to change the foot of the plinth and the plinth body attached to the plane.

second choice : I need a full isolation of "pods" arm of the plane. of "style freestanding Arm." , I will try to do this.

are you have suggestion to me for my choice ?

regards

ed

- Status

- Not open for further replies.

- Home

- Source & Line

- Analogue Source

- help give me advise for Garrard 401 Plinth