been looking around for mylar in the UK.

I can get the 0.00025 (thats about 6 micron right?), or i can get 3 micron from one thing audio who re-build quad ESL's.

Will 3 micron be ok for headphones?

It works out more economical too as i'd have load left for futer speaker projects 🙂

Hi,

3 microns Mylar should be fine. 🙂

Wachara C.

Straightening copper wire for stators

Hi All,

Very interesting thread this one 🙂 Thanks for sharing your thoughts and knowledge on this subject.

I haven't read the full thread but noticed phil47's posts earlier in the thread where there was a photo of copper wire stators.

In case some of you have considered building phones like these and would like to use e.g. copper wires, and have a challenge straightening the wires, I used to straight out the wires by stretchening them. I.e I firmly tied one of the ends to a fixed point (like a radiator) and then pulled the wire - with force - until I noticed that it got longer. In the same round the wire straightened out (completely). Doing this while the wire is lying on a table should give a straight wire that may be cut for stators.

Maybe useful?

Greetings & Happy New Year 😉

Jesper

Hi All,

Very interesting thread this one 🙂 Thanks for sharing your thoughts and knowledge on this subject.

I haven't read the full thread but noticed phil47's posts earlier in the thread where there was a photo of copper wire stators.

In case some of you have considered building phones like these and would like to use e.g. copper wires, and have a challenge straightening the wires, I used to straight out the wires by stretchening them. I.e I firmly tied one of the ends to a fixed point (like a radiator) and then pulled the wire - with force - until I noticed that it got longer. In the same round the wire straightened out (completely). Doing this while the wire is lying on a table should give a straight wire that may be cut for stators.

Maybe useful?

Greetings & Happy New Year 😉

Jesper

Thanks for sharing your wire straightening approach, Jesper. Have you noticed any trouble with the insulation after the wire is stretched---or perhaps you're using uninsulated wire?

Few

Few

I only used uninsulated wire but my guess would be that if it is a lacquer insulation then it may crack. I would guess that other types of insulation (plastics) would stretch and more or less stay in place.

The elongation of the wire (1,5 mm thickness and 2 meter length) is ~ 0,8 cm so maybe this gives you an idea of what will happen with the insulation.

Best,

Jesper

The elongation of the wire (1,5 mm thickness and 2 meter length) is ~ 0,8 cm so maybe this gives you an idea of what will happen with the insulation.

Best,

Jesper

Straightening wire can be done with an electric screwdriver, just stick one end of the wire in a hole of wire diameter in your workbench, bend it 90 degrees, stick the other end in your screwdriver, pull gently as you operate the screwdriver clockwise for a few seconds.

Hi JonasKarud,

Thanks for sharing your technique on making wire stators. I'm sure it will benefit a lot of people here. Since I have a CNC machine, I feel that it's much easier to make stators using PCBs. I will try to drill PCBs to imitate wire stators and see if I will find any difference in sounding.

Wachara C.

Thanks for sharing your technique on making wire stators. I'm sure it will benefit a lot of people here. Since I have a CNC machine, I feel that it's much easier to make stators using PCBs. I will try to drill PCBs to imitate wire stators and see if I will find any difference in sounding.

Wachara C.

The kind of glue makes the difference. Tests with UHU glue which looks smells and tastes the same failed completely.

Have you tried the Tesa glue without ink? Maybe the Tesa glue is conductive enough by itself.

Hi guys,

I'm working with the pva glue / water / ink coating on 1.4 micron mylar, but am having a hard time distributing an even layer. I find that as it dries, it puddles unevenly on the film and picks up dust. Perhaps hitting it with a hairdryer would help?

I'm considering reverting back to powdered graphite, since it's easier to touch up if uneven, resistant to moisture, and as light as can be.

I'm working with the pva glue / water / ink coating on 1.4 micron mylar, but am having a hard time distributing an even layer. I find that as it dries, it puddles unevenly on the film and picks up dust. Perhaps hitting it with a hairdryer would help?

I'm considering reverting back to powdered graphite, since it's easier to touch up if uneven, resistant to moisture, and as light as can be.

Hi Pelikan,

Graphite powder works fine as long as you can rub it into the diaphragm hard enough. As for me, I prefer using the PVA, water and ink. I experienced what you mention before. If you clean your diaphragm using alcohol before applying the glue, it should help. Good luck.

Can you show us your headphones?

Wachara C.

Graphite powder works fine as long as you can rub it into the diaphragm hard enough. As for me, I prefer using the PVA, water and ink. I experienced what you mention before. If you clean your diaphragm using alcohol before applying the glue, it should help. Good luck.

Can you show us your headphones?

Wachara C.

I have a theoretical question regarding phase response and square wave reproduction of electrostatic headphones.

What's bugging me is the capacitative nature of their impedance and corresponding phase-out of voltage and current. Does this affect the phase of the sound as well, particularly in the closed pressure chamber of the headphone? Or I don't have any reason to worry and when voltage at the amp input rises, the pressure at the ear rises the same way, and square waves are reproduced correctly?

Has anyone seen any measurements of any ESL headphone's square wave response? I've noticed there are some people on the forum with DIY ESL headphones and some measurement equipment, maybe they have done such measurements?

Thanks.

What's bugging me is the capacitative nature of their impedance and corresponding phase-out of voltage and current. Does this affect the phase of the sound as well, particularly in the closed pressure chamber of the headphone? Or I don't have any reason to worry and when voltage at the amp input rises, the pressure at the ear rises the same way, and square waves are reproduced correctly?

Has anyone seen any measurements of any ESL headphone's square wave response? I've noticed there are some people on the forum with DIY ESL headphones and some measurement equipment, maybe they have done such measurements?

Thanks.

I don't think headphones are particularly good at square waves due to the fact that they are constructed to suit the ear channels acoustic properties.

This is done, among other things, by giving the headphone an inherent nonlinear frequency response, thus destroying square waves.

Read:

HeadWize - Article: A Quick Guide To Headphones (A HeadWize Headphone Guide)

This is done, among other things, by giving the headphone an inherent nonlinear frequency response, thus destroying square waves.

Read:

HeadWize - Article: A Quick Guide To Headphones (A HeadWize Headphone Guide)

Hi JonasKarud,

Thanks for the link. It's an interesting article to read. I agree with the article that we should not trust on the test figures so much. The best is to actually listen to the headphones. That way we will know if we really like them.

Wachara C.

Thanks for the link. It's an interesting article to read. I agree with the article that we should not trust on the test figures so much. The best is to actually listen to the headphones. That way we will know if we really like them.

Wachara C.

Hi Nevod,

I do not have any equipment for testing frequencies response of my headphones. I have not seen any testing figures from our friends here on electrostatic headphones either. If you find any link to it, please let me know.

Wachara C.

I do not have any equipment for testing frequencies response of my headphones. I have not seen any testing figures from our friends here on electrostatic headphones either. If you find any link to it, please let me know.

Wachara C.

chinsettawong

I have certainly seen some guy here on the diyaudio posting some measurements of his headphones', based on your emitter, and also experimenting with various surface resistance values of membrane coating. But I don't remember his nick nor thread title..

JonasKarud

I have seen some measurements of newer high-end headphones trying to approach, and even, in case of Audeze LCD-2, having real square wave response. Though the measurements may have been done on dummy head, I don't know exactly. Actually, it's the LCD-2 that made me worry - they are described by most people as even better than Stax ones, but they are orthodynamic, and orthos aren't very diy-able. So I want to have a hope that ESLs are still better. 🙂

I have certainly seen some guy here on the diyaudio posting some measurements of his headphones', based on your emitter, and also experimenting with various surface resistance values of membrane coating. But I don't remember his nick nor thread title..

JonasKarud

I have seen some measurements of newer high-end headphones trying to approach, and even, in case of Audeze LCD-2, having real square wave response. Though the measurements may have been done on dummy head, I don't know exactly. Actually, it's the LCD-2 that made me worry - they are described by most people as even better than Stax ones, but they are orthodynamic, and orthos aren't very diy-able. So I want to have a hope that ESLs are still better. 🙂

Hi Nevod,

You must be referring to the tests done by Arend-Jan. Yes, he did use the stators and spacers he got from me to make some tests. However, those tests were done without the cups and couldn't simulate the actual "wear on the head" hearing.

Wachara C.

You must be referring to the tests done by Arend-Jan. Yes, he did use the stators and spacers he got from me to make some tests. However, those tests were done without the cups and couldn't simulate the actual "wear on the head" hearing.

Wachara C.

Maybe, in a dummy head, the square wave looks better.

I enclose a near field (5 mm) measurement of my Stax electrostatic EarSpeaker SR-80, not a pretty sight!

Read:

Learning Center - Build a Headphone Graph | HeadRoom Audio

I enclose a near field (5 mm) measurement of my Stax electrostatic EarSpeaker SR-80, not a pretty sight!

Read:

Learning Center - Build a Headphone Graph | HeadRoom Audio

Attachments

I have a theoretical question regarding phase response and square wave reproduction of electrostatic headphones....Has anyone seen any measurements of any ESL headphone's square wave response?

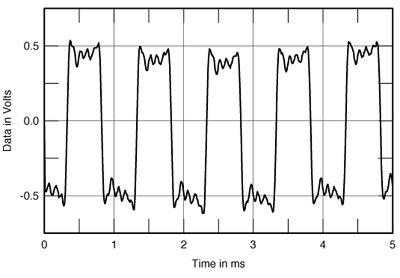

This is from a Stereophile test of the Quad ESL-63. The ESL-63 is a full size loudspeaker rather than a set of headphones, of course, so these results don't address the question of how the ear canal etc. affects the response, but it does show that there's nothing inherent in the ESL that prevents good reproduction of square waves.

Fig.6 Quad ESL-63, 1kHz squarewave response on listening axis at 1m (5ms time window).

Few

Thanks! Looks good, but still, with headphone, there is that "pressure chamber" point. But I'm already assured.

chinsettawong

Yes, thanks, seem to be arend-jan. But I still can't find his posts on surface resistance and distortion.. Should contact him directly.

JonasKarud

Here is Audeze LCD-2 measurement, done in that lab. Dummy head is seen, but we don't still know wether it has ears or not. The graphs look really near perfect.

Thanks! Looks good, but still, with headphone, there is that "pressure chamber" point. But I'm already assured.

chinsettawong

Yes, thanks, seem to be arend-jan. But I still can't find his posts on surface resistance and distortion.. Should contact him directly.

JonasKarud

Here is Audeze LCD-2 measurement, done in that lab. Dummy head is seen, but we don't still know wether it has ears or not. The graphs look really near perfect.

Wachara, I don't know if You have grasped the difference between low and high resistance coatings, distortion wise, but I'm willing to stick my chin out and show some besserwisser behavior.

Think of the low resistance membrane in its stationary position. You have an electric field between one stator and coating of, lets say, 1500 volt/mm.

Then you move the membrane toward one stator, the distance decreases between one stator and coating. But because the voltage on the coating is constant, due to its low resistance, the electric field strength increases and the moving forces on the membrane becomes higher the closer the membrane comes to the stator. Constant voltage means distortion. The opposite is true for the other side of the membrane.

But, when you have a high resistance coating, and you move the membrane out of its stationary position, the voltage on the membrane area closest the the stator decreases, which it can do due to its high resistance, and the field strength is constant. Constant charge means less distortion. You can also think like this: A high resistance coating is electrically "transparent" as it moves in a constant electric field between stators, but a low resistance coating disturbs the electric field between the stators in a non linear way.

People may have their opinion, but I personally think that low resistance membranes adds a glowing spark to the music.

Think of the low resistance membrane in its stationary position. You have an electric field between one stator and coating of, lets say, 1500 volt/mm.

Then you move the membrane toward one stator, the distance decreases between one stator and coating. But because the voltage on the coating is constant, due to its low resistance, the electric field strength increases and the moving forces on the membrane becomes higher the closer the membrane comes to the stator. Constant voltage means distortion. The opposite is true for the other side of the membrane.

But, when you have a high resistance coating, and you move the membrane out of its stationary position, the voltage on the membrane area closest the the stator decreases, which it can do due to its high resistance, and the field strength is constant. Constant charge means less distortion. You can also think like this: A high resistance coating is electrically "transparent" as it moves in a constant electric field between stators, but a low resistance coating disturbs the electric field between the stators in a non linear way.

People may have their opinion, but I personally think that low resistance membranes adds a glowing spark to the music.

- Home

- Amplifiers

- Headphone Systems

- Has anybody made an ELS headphone?