how are the drivers getting destroyed during the build. If I ruin an HPM900 driver during crossover work and refoaming, I am screwed.

the other aspects of the work look good.

the other aspects of the work look good.

how are the drivers getting destroyed during the build.....

If i remember correct the damaged transducers belong to another story/build from the past, in below link and picture see that Halair made some nice 20x TC9 arrays back in year 2014 that down the road had some transducers damaged by a cat or dog or whatever it was.

https://www.diyaudio.com/forums/ful...ne-array-build-20-fr-drivers.html#post3864883

Attachments

how are the drivers getting destroyed during the build.

When my youngest boy was 2 and equipped with a ballon stick (the one you get at McDonalds) he decided to poke holes in those he could reach

Those have since been replaced and the bad drivers are now used as test dummies 😀

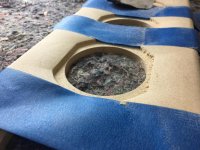

Some progress:

Last night I sanded the first baffle and tonite I gave it its first coat of primer (epoxy). Also managed to do the sanding on half of the 2nd baffle, which will be completed tomorrow + its 1st coat of primer.

Masked each adjacent driver when sanding, trying to preserve as much as possible of the sharp "edge" the profile have.

Weather is awefull at the moment, no sidepanel cutting possible today or tomorrow...🙁

Last night I sanded the first baffle and tonite I gave it its first coat of primer (epoxy). Also managed to do the sanding on half of the 2nd baffle, which will be completed tomorrow + its 1st coat of primer.

Masked each adjacent driver when sanding, trying to preserve as much as possible of the sharp "edge" the profile have.

Weather is awefull at the moment, no sidepanel cutting possible today or tomorrow...🙁

Attachments

Progress = good... even if it moves a bit more slowly than you'd want.

The baffles are going to look great!

The baffles are going to look great!

@wesayso:

Yeah, every little bit helps - you should know 😀

I have today managed to prep and 2nd coat both baffles which right now is curing downstairs 🙂

@Johnnycamp5:

These will get 24 drivers per side, grouped in two sections of 12 so I can use two amp channels per side.

My current line arrays run 20/side and one channel per side.

I am adressing 4 means of improvements this time around, with one single purpose as end-game - a bigger grin when using them :

:

Why not use 25?

Lack ceiling clearance 😱

😱

Yeah, every little bit helps - you should know 😀

I have today managed to prep and 2nd coat both baffles which right now is curing downstairs 🙂

@Johnnycamp5:

These will get 24 drivers per side, grouped in two sections of 12 so I can use two amp channels per side.

My current line arrays run 20/side and one channel per side.

I am adressing 4 means of improvements this time around, with one single purpose as end-game - a bigger grin when using them

:

:- Better looking

- More driver area (20 -> 24)

- More power to drive them (2x140W -> 4x140W)

- Improved cabinet in terms of more mass / more inert

Why not use 25?

Lack ceiling clearance

😱

😱Two coats of epoxy, unsanded 🙂

Will wait with primer/sanding/primer/sanding untill the cabinet is cast, in case I get some nicks and bruises on them 🙂

This weekend: Cutting the sideboards as a new saw have been purchased 😀

Will wait with primer/sanding/primer/sanding untill the cabinet is cast, in case I get some nicks and bruises on them 🙂

This weekend: Cutting the sideboards as a new saw have been purchased 😀

Attachments

Count me in the group that likes a texture to the finish, compared to completely smooth.

Looking amazing thus far!

Too bad it would be near impossible for me to send you some stone side panels.

I think that would look great!

Looking amazing thus far!

Too bad it would be near impossible for me to send you some stone side panels.

I think that would look great!

Thanks for the feedback - I like them smooth 😛

I know that smooth = more prep work

When the front baffles lie on the floor they look decievingly small/short... 😱

Stone side walls would be totally cool, perhaps for mk3 😉

I have played with the idea of creating a 3D pattern, machined to MDF side panels - see attached image for example

Planned progress for the weekend:

I know that smooth = more prep work

When the front baffles lie on the floor they look decievingly small/short... 😱

Stone side walls would be totally cool, perhaps for mk3 😉

I have played with the idea of creating a 3D pattern, machined to MDF side panels - see attached image for example

Planned progress for the weekend:

- Get the side panels cut to size

- Create the top cover and machine a pair

- Design the speaker base and inserts for the vertical cabinet, these will be cast inside the EG matrix. The inserts will be machined out of 15mm alu and tapped for M10 fasteners.

Attachments

Last edited:

@wesayso - I agree! I would love something like that for the sides as a shape/visual accent to the array 😀

BTW - Seeing is believing, tall and slender she is 🙂

210cm tall, 17cm wide and 35cm deep.

BTW - Seeing is believing, tall and slender she is 🙂

210cm tall, 17cm wide and 35cm deep.

Attachments

Last edited:

Some hard data:

Per array, the weight of the wood (measured) alone = 24kg

Epoxy/Sand matrix (calculated) to 45kg

Mass of drivers = 7,2kg

Moving mass = 58g

Speaker base plate = unknown

This give me a moving mass/inert mass ratio exceeding 1:1300

Surface area exceed a std 15" (but not displacement obviously)

This means soon I wont be able to handle these alone... 😱

Per array, the weight of the wood (measured) alone = 24kg

Epoxy/Sand matrix (calculated) to 45kg

Mass of drivers = 7,2kg

Moving mass = 58g

Speaker base plate = unknown

This give me a moving mass/inert mass ratio exceeding 1:1300

Surface area exceed a std 15" (but not displacement obviously)

This means soon I wont be able to handle these alone... 😱

That second back-wall panel would look awesome as a diffraction device!

LA mk3 (Anno 2025) ?? 😀

Attachments

Halair,

Looks you already have a "road map" of line array speakers in place? 😀

Always projects and ideas floating around upstairs

Just messing around in Fusion360 to get better at it

Just messing around in Fusion360 to get better at it

First cabinet glued up, waiting for the glue to harden (24hr epoxy)

Attachments

- Home

- Loudspeakers

- Full Range

- HalAir Aeralis - Fullrange Line Array (Vifa TC9-18-08)