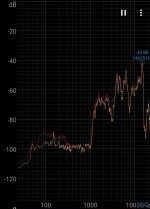

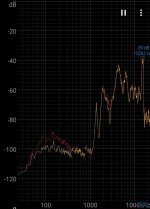

measured both piezos again.

The one with the broader plateau in the lows is the MPT-142.

But in the end not much difference.

Maybe something could be gained smoothing out the horn throat step with silicone and smoothing the edge of the piezo driver by removing some plastic.

For more power in the mids a true dynamic horn driver is the only way.

The one with the broader plateau in the lows is the MPT-142.

But in the end not much difference.

Maybe something could be gained smoothing out the horn throat step with silicone and smoothing the edge of the piezo driver by removing some plastic.

For more power in the mids a true dynamic horn driver is the only way.

Attachments

now found an older thread with someone showing original motorola piezo design ksn1142.

Looks like a sophisticated design:

Supported piezo disc helps it to push itself against the paper cone

uneven spread holes in the disc helps it bend itself easier

uneven glued on substrate giving differently distributed dispersion of resonance frequencies

paper giving isolation making the construction airtight

there is something to be learned here!

Looks like a sophisticated design:

Supported piezo disc helps it to push itself against the paper cone

uneven spread holes in the disc helps it bend itself easier

uneven glued on substrate giving differently distributed dispersion of resonance frequencies

paper giving isolation making the construction airtight

there is something to be learned here!

PIEZO ARE GREAT SOUND MACHINES :MOTOROLA is the best >>experienced !

The quality of a piezo speaker is directly proportional to the size and quality of the piezo element used :ORIGINAL Motorola (now PIEZOSOURCE >>> Piezo Source, Inc. ),Goldwood (https://www.goldwood.com/goldwood/mids-and-tweeters/piezo-tweeters/ )

and MONACOR (MONACOR: Search Results "piezo" ) with the same GOOD QUALITY 22mm. diameter piezo element inside for ALL the models:They are the best brands on the market.

Having tried them personally (and checked the internal quality), what I write is...

The quality of a piezo speaker is directly proportional to the size and quality of the piezo element used :ORIGINAL Motorola (now PIEZOSOURCE >>> Piezo Source, Inc. ),Goldwood (https://www.goldwood.com/goldwood/mids-and-tweeters/piezo-tweeters/ )

and MONACOR (MONACOR: Search Results "piezo" ) with the same GOOD QUALITY 22mm. diameter piezo element inside for ALL the models:They are the best brands on the market.

Having tried them personally (and checked the internal quality), what I write is...

Attachments

If I understand well Motorola did not step up their piezos because in pro use there is more a danger of damage due to excessive amplifier power.

Bill Fitz Maurice (seller of speaker plans for diy pa speakers) puts piezos in arrays and in groups in series for getting higher voltage resilience omitting motorolas ptc elements and light bulbs.

Funny idea to use ksn1016 piezo tweeters in "melded" arrays as "V" formed acoustic dispersion elements for the pa loudspeaker behind them. And the cut and reglued tweeters themselves for a better horizontal dispersion.

Bill Fitz Maurice (seller of speaker plans for diy pa speakers) puts piezos in arrays and in groups in series for getting higher voltage resilience omitting motorolas ptc elements and light bulbs.

Funny idea to use ksn1016 piezo tweeters in "melded" arrays as "V" formed acoustic dispersion elements for the pa loudspeaker behind them. And the cut and reglued tweeters themselves for a better horizontal dispersion.

the smaller white round disc on the 1142 could just be some damping of resonances.

Its not part of the piezo disc as it is not electrically connected.

Electrical connection and the mechanical support of the piezo disc is in one integrated element.

Its not part of the piezo disc as it is not electrically connected.

Electrical connection and the mechanical support of the piezo disc is in one integrated element.

Funny idea to use ksn1016 piezo tweeters in "melded" arrays as "V" formed acoustic dispersion elements for the pa loudspeaker behind them. And the cut and reglued tweeters themselves for a better horizontal dispersion.

just to understand to what I refer

https://billfitzmaurice.info/W10.html