Looking for a way to cut a 6 inch by 1/8 inch slot through a few mm of aluminum? This will be on the faceplate so it has to look ok (making a chassis for a cd player).

Tools at my disposal: jigsaw, circular saw, sawzall, dremel, palm size router, hand saws (Japanese pull saw too).

Jigsaw or dremel would be the easiest, but I have concerns about how straight I can make the cut.

I don't really want to use a bezel, but will if needed. And I have no clue where I could buy one, its not exactly a common thing.

Tools at my disposal: jigsaw, circular saw, sawzall, dremel, palm size router, hand saws (Japanese pull saw too).

Jigsaw or dremel would be the easiest, but I have concerns about how straight I can make the cut.

I don't really want to use a bezel, but will if needed. And I have no clue where I could buy one, its not exactly a common thing.

You didn't mention drill or drill press in your arsenal of tools. Chain drilling and filing is an option, but it would be a lot of holes to drill over 6 inches. I've gone down the dremel route but it was not pretty (I tried a cutting bit with a template but it got ugly fast 😉 ) but perhaps using a cutting disc for the long cuts would work, and chain drill the short side of the slot and file... Definitely try on some scrap aluminium before you attack the main panel! 🙂

Tony.

Tony.

I have cordless drills but no drill press. Also have step bits, but don't think they'll help. Also have things like speed squares, carpenter squares, etc. I have one thing that let's me drill perpendicular to the piece, but really haven't tried it.

How about some kind of metal bit on the router? All I have is carbide wood bits.

I'll add to this laundry list if I think of anything...

How about some kind of metal bit on the router? All I have is carbide wood bits.

I'll add to this laundry list if I think of anything...

Straight 1/8 metal bit on the router, which *must* move along an rail or against a firmly clamped L shaped aluminum extrusion.

You need a metal bit of the type used in CNC machines (which normally use a router as the cutting element).

https://youtu.be/x5GzCdKhxmQ

You need a metal bit of the type used in CNC machines (which normally use a router as the cutting element).

https://youtu.be/x5GzCdKhxmQ

cut a pair of "almost" adjacent holes with a 1/8" bit. with a jig saw, even with aluminum, you can hold the saw at a 45 degree angle to the surface and gently probe the saw blade down into these two holes. jig saw won't give you a 1/8" kerf, however.

you could come over to my house and we'd use the Grizzly mini-mill.

Edit -- you can always have a high school kid with a 3-d printer make you a dandy bezel to cover your mistakes.

you could come over to my house and we'd use the Grizzly mini-mill.

Edit -- you can always have a high school kid with a 3-d printer make you a dandy bezel to cover your mistakes.

a series of carfully dilled holes as already mentioned, then clamp pieces of some thicker material to help guide a file and protect the surface.

How about a sliding 12 inch mitre saw with a 80 tooth carbide tipped blade.

Clamp both sides of the piece , then push the blade all the way in and start cutting outwards toward yourself. A jacket and full faceshield and hearing protection are a must!!!!

Go slowly so the aluminum doesn't melt onto the blades teeth.

Clamp both sides of the piece , then push the blade all the way in and start cutting outwards toward yourself. A jacket and full faceshield and hearing protection are a must!!!!

Go slowly so the aluminum doesn't melt onto the blades teeth.

Last edited:

Or take your panel to a local metal shop and have them do it.

Before I came over to USA in 2000, my amp building was a work of art (to me) due to availability of local metal shop everywhere. They even let me use their machine once I became friend with them.

But since 2000, although I have built 10+ amps and others, chassis I have are work of shame. Only tool I have is a hand drill.

Learning from your post that there are such local metal shop in USA, how can I find them? What's the keyword in yellow book? How much do they charge? Is there a good metal shop in Maryland?

Use the palm router

That's really nice - looks like you have an adjustable rectangle in the wood!

Can you explain the process - is it 1) make template in wood, 2) clamp metal to top of wood, 3) drill large hole in center for bit to pass through, 4) use the bit with the flush bearing on bottom to trace out the perimeter?

Straight 1/8 metal bit on the router, which *must* move along an rail or against a firmly clamped L shaped aluminum extrusion.

You need a metal bit of the type used in CNC machines (which normally use a router as the cutting element).

https://youtu.be/x5GzCdKhxmQ

I watched the video and upon checking the details all of the router bits specifically state that they should be used with a CNC machine. Do you feel it OK to use with a hand router? I have a 1/4 hand router.

Could you suggest a part# for the bit?

Thanks. nash

rif,

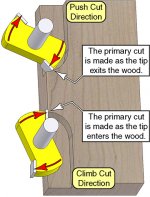

you got it. A hand router is fine. Carbide is harder then aluminum. Same rules as routing wood. I like spiral flute bits but they are not required. Take small bites move not too fast and no climb cutting. The climb cutting thing is tricky at first but becomes second nature. People will say climb cutting gives better results but the chance of the tool getting away from you are too great.

I like these bits but any will work.

Whiteside Machine Company

you got it. A hand router is fine. Carbide is harder then aluminum. Same rules as routing wood. I like spiral flute bits but they are not required. Take small bites move not too fast and no climb cutting. The climb cutting thing is tricky at first but becomes second nature. People will say climb cutting gives better results but the chance of the tool getting away from you are too great.

I like these bits but any will work.

Whiteside Machine Company

Attachments

Looking for a way to cut a 6 inch by 1/8 inch slot through a few mm of aluminum? This will be on the faceplate so it has to look ok (making a chassis for a cd player).

Tools at my disposal: jigsaw, circular saw, sawzall, dremel, palm size router, hand saws (Japanese pull saw too).

Jigsaw or dremel would be the easiest, but I have concerns about how straight I can make the cut.

I don't really want to use a bezel, but will if needed. And I have no clue where I could buy one, its not exactly a common thing.

Other tools that can help:

(1) Nibbling tool - these are available for very reasonable prices and are far faster and leave a better cut line than a row of drilled holes. The classic Adel nibbler is often a better tool than more modern clones of it.

(2) Dremel tool with appropriate circular blade. Choose blade depending on the chassis material. Far easier to cut straightish lines than the router-style cutters.

(3) 3 to 4 1/2 right angle grinder with appropriate cutting or grinding wheel for the chassis material.

Thanks guys, I've got a lot to think about. Keep them coming.

@evanc - just realized that method won't work for a thin slot cut. How about this: I'll use a v-groove bit, routing from the backface, and having the tip protrude from the front. I'd use the built in edge guide or clamp a straight edge.

@evanc - just realized that method won't work for a thin slot cut. How about this: I'll use a v-groove bit, routing from the backface, and having the tip protrude from the front. I'd use the built in edge guide or clamp a straight edge.

Many excellent suggestions above do not apply here because of some very specific parameters to be met by your front panel slot cut:

1) forget V-cutting from behind, you'll never get uniform slot width.

2) forget grinding of any kind, this is soft easily deformable aluminum, edges will have a horrible impossible to hide or correct burr.

If anything, use water jet cutting which sort of self polishes the cut.

3) same applies, to a lesser degree, to any cutting with a mini saw type wheel.

And since it touches panel at an angle, you can't cut vertical walls at the slot ends.

4) straight 1/8" router bit is best.

Of course, neck must be proper diameter to fit your router collar, while cutting edge will be 1/8"

5) since slot width is bit diameter , you won't find one with a tiny tiny ball bearing at the end to guide it ... which to boot requires a previous hole made with a standard drill press, so:

a) this router bit also has a cutting "drill tip" so it can cut its own initial hole:

https://www.burnstools.com/accessories/router-bits/40-001-1-8-hss-router-bit

b) it's HSS steel , not carbide, so it's cheaper 😉

c) more important, it's HSS steel, so slightly flexible, unlike carbide, so I guess is better for hand holding than a carbide one which requires the stability and precision of a CNC machine.

d) since it won't self-guide and human hands are excellent for zigzagging cuts (not your goal I guess) what I do is to *externally* guide the router, by sliding its edge along an L shaped aluminum extrusion or for woodworking, a straight 2" x 6" , firmly clamped to the surface being cut.

In fact I said all this in my earlier post, only I use more words here 😉

1) forget V-cutting from behind, you'll never get uniform slot width.

2) forget grinding of any kind, this is soft easily deformable aluminum, edges will have a horrible impossible to hide or correct burr.

If anything, use water jet cutting which sort of self polishes the cut.

3) same applies, to a lesser degree, to any cutting with a mini saw type wheel.

And since it touches panel at an angle, you can't cut vertical walls at the slot ends.

4) straight 1/8" router bit is best.

Of course, neck must be proper diameter to fit your router collar, while cutting edge will be 1/8"

5) since slot width is bit diameter , you won't find one with a tiny tiny ball bearing at the end to guide it ... which to boot requires a previous hole made with a standard drill press, so:

a) this router bit also has a cutting "drill tip" so it can cut its own initial hole:

https://www.burnstools.com/accessories/router-bits/40-001-1-8-hss-router-bit

b) it's HSS steel , not carbide, so it's cheaper 😉

c) more important, it's HSS steel, so slightly flexible, unlike carbide, so I guess is better for hand holding than a carbide one which requires the stability and precision of a CNC machine.

d) since it won't self-guide and human hands are excellent for zigzagging cuts (not your goal I guess) what I do is to *externally* guide the router, by sliding its edge along an L shaped aluminum extrusion or for woodworking, a straight 2" x 6" , firmly clamped to the surface being cut.

In fact I said all this in my earlier post, only I use more words here 😉

@evanc - just realized that method won't work for a thin slot cut.

Yes it will. Most of the spiral flute bits can plunge. Just set up a straight edge as well as start and stop blocks. You may need to run the router base along the guide and not a bearing on the bit for a cut as small as you want.

Yes it will. Most of the spiral flute bits can plunge. Just set up a straight edge as well as start and stop blocks. You may need to run the router base along the guide and not a bearing on the bit for a cut as small as you want.

Sorry for the confusion, I meant the bearing bit wouldn't work. The router, as you said, should be fine with the right bit and prep work on straight guides, etc.

- Status

- Not open for further replies.

- Home

- Design & Build

- Construction Tips

- Good way to cut a slot in aluminum?