Hi,

I have my first DIY speakers ready to be assembled and glued.They are small size monitors.However my woodwork class teacher told me that mdf doesn't glue very well and I should nail, screw or put dowels. This means either that there will be a cosmetic problem or a lot of extra work (dowels).I see lot of DIYers just glueing and clamping their speakers .

So is just glueing and clamping enough or not?

I have my first DIY speakers ready to be assembled and glued.They are small size monitors.However my woodwork class teacher told me that mdf doesn't glue very well and I should nail, screw or put dowels. This means either that there will be a cosmetic problem or a lot of extra work (dowels).I see lot of DIYers just glueing and clamping their speakers .

So is just glueing and clamping enough or not?

Assuming you are using PVA or similar water based glue that will be fine for a set of monitor speakers, you can add small cleats on the inside corners for extra strength.

most of the cheap chinese speaker cabinets I've seen are some kind of MDF held together soley with glue, they seem to hold together ok.

most of the cheap chinese speaker cabinets I've seen are some kind of MDF held together soley with glue, they seem to hold together ok.

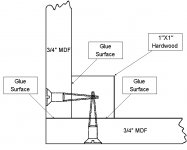

I always use this method when assembling MDF.Volenti said:...you can add small cleats on the inside corners for extra strength.

Attachments

biscuit joinery is a lot easier than dowels, and an excuse to buy another tool. 😉

I once helped a buddy build cabinets using his brad nailer, with cleats like Roddyama suggests. Boy, was that quick, and more accurate than I've been able to set screws into the cleats. Unfortunately I cannot bring myself to buy a compressor just to use a brad nailer. 🙁

I once helped a buddy build cabinets using his brad nailer, with cleats like Roddyama suggests. Boy, was that quick, and more accurate than I've been able to set screws into the cleats. Unfortunately I cannot bring myself to buy a compressor just to use a brad nailer. 🙁

BobEllis said:biscuit joinery is a lot easier than dowels, and an excuse to buy another tool. 😉

you'll want a good quality biscuit cutter... the one I used was a Dewalt.... set you back like $AU300... lol

see my website for my boxes.. 🙂 website.. website.. hmm.. lol

With small cabs, glues work just fine.

A biscuit (or plate) joiner is very handy. It adds some strength but mainly makes it easier to allign panels during assembly.

You can make a servicable plate joiner out of a router and a slot cutting bit, and make your own biscuits, (from the same stock if working with hardwoods) it's the accuracy of cutting the slot that's essential.

You could also use this slot cutter for spline joints, partial, or full length. (This can also be done on a table saw)

BobEllis- You've used the tool. I suggest looking at the package deals at the hardware warehouse. You can often get a brad or finish nailer and a small compressor for a reasonable price. Then you become an easy person to buy gifts for, as there are many reasonably priced pneumatic tools worth having on hand.

The speed factor of pneumatics is even dwarfed by it's handiness, when you consider both one-handed assembly, and the willingness to assemble those jigs that would make the job go much easier.

A biscuit (or plate) joiner is very handy. It adds some strength but mainly makes it easier to allign panels during assembly.

You can make a servicable plate joiner out of a router and a slot cutting bit, and make your own biscuits, (from the same stock if working with hardwoods) it's the accuracy of cutting the slot that's essential.

You could also use this slot cutter for spline joints, partial, or full length. (This can also be done on a table saw)

BobEllis- You've used the tool. I suggest looking at the package deals at the hardware warehouse. You can often get a brad or finish nailer and a small compressor for a reasonable price. Then you become an easy person to buy gifts for, as there are many reasonably priced pneumatic tools worth having on hand.

The speed factor of pneumatics is even dwarfed by it's handiness, when you consider both one-handed assembly, and the willingness to assemble those jigs that would make the job go much easier.

BobEllis said:biscuit joinery is a lot easier than dowels, and an excuse to buy another tool. 😉

I once helped a buddy build cabinets using his brad nailer, with cleats like Roddyama suggests. Boy, was that quick, and more accurate than I've been able to set screws into the cleats. Unfortunately I cannot bring myself to buy a compressor just to use a brad nailer. 🙁

I have used a friend's biscuit cutter (Fried) and it is excellent for cabinetry where there will not be a lot of stress -- it makes assembling cabinet doors a breeze. If the cabinet has to carry a load, however, the biscuits don't provide any strength -- use battens. Fine Woodworking did an article which reached the same conclusion -- about 2 years ago.

I would use screws and battens (I rip 1X4 into 1X1's) for speakers, just make sure to adjust your volume calculations for the added materials.

A great place for air tools is Harbor Freight. You can get them for really cheap. I'm not sure on the quality, but what do you expect for a $14 brad nailer!

Like the guys said.... Glue works just fine. I use a speciel glue that "expands" when getting dry, so all small "cracks" are being filled and the box gets air tight.

Unfourtunately i don't know what the glue is called on English but on Danish it's called POLYUHRETAN glue! Does anybody else use this kind of glue? I don't know if PVC glue expands, cause i newer really use it?!?

Therac

Unfourtunately i don't know what the glue is called on English but on Danish it's called POLYUHRETAN glue! Does anybody else use this kind of glue? I don't know if PVC glue expands, cause i newer really use it?!?

Therac

Glue joints holds just fine on MDF. The problem is that the glue joint is much stronger then the MDF. When you glue a butt jointit provides a lot of leverage against the joint and if you're not careful the MDF will split.

I have used a friend's biscuit cutter (Fried) and it is excellent for cabinetry where there will not be a lot of stressMaybe if you're doing edge-banded cabients, for framework cabients it's far more then strong enough. We regularly set granite on our shop's cabients with no problems.

As for MDF, I'd just use yellow wood glue for small stuff, larger stuff I'd either biscuit or use a rabbit joint. Both for strengh and very much so for alignment, as it'll make your life much easier. Brads are also great for helping alignment, but don't really provide any strength, always use a good amount of clamps in any case. I wouldn't screw into MDF either, pre-drill through larger then the entire with of your screw into your cleat. It should stop any sort of split from happening and give you a little movement for getting things aligned. When the glue is semi-hard take a (paint) scraper and remove the glue that squirted out.

As for that brad nailer, have fun with it. I've found cheap brad guns(along with un-oiled bradguns) have a tendancy to fire more then once each time you the trigger far too often, which can leave you with a brad going through something you don't want it to, or if you're like me it'll fire twice, hitting the first brad, causing the gun to jump hitting your finger again and shooting another brad, into your thumb, fun 🙂.

Yellow glue on MDF is more than enough. I have been woodworking for alot of years and can tell you with great confidence that this is so. Brad nailing is not necessary and will add next to nothing to your cabinet in terms of strength. I use a brad nailer often when assembling cabinets (speakers or not) but I use the brads to simply hold the boards together until the glue dries. The brads are no substitute for clamps however. I simply tack the joint with the brad nailer so I don't have to fumble around when clamping. I have a woodworking website with forums if you have any questions about woodworking. Alot of experienced woodworkers spend some time on the forum. There is also a live chat every night from 9PM to 11PM EST if you care to have your questions answered live. The URL is www.woodworkersweb.com. If you click on Michele and Guy's Woodshop you can have a peek at my shop. HTH

kilowattski said:Yellow glue on MDF is more than enough. I have been woodworking for alot of years and can tell you with great confidence that this is so. Brad nailing is not necessary and will add next to nothing to your cabinet in terms of strength. I use a brad nailer often when assembling cabinets (speakers or not) but I use the brads to simply hold the boards together until the glue dries. The brads are no substitute for clamps however. I simply tack the joint with the brad nailer so I don't have to fumble around when clamping. I have a woodworking website with forums if you have any questions about woodworking. Alot of experienced woodworkers spend some time on the forum. There is also a live chat every night from 9PM to 11PM EST if you care to have your questions answered live. The URL is www.woodworkersweb.com. If you click on Michele and Guy's Woodshop you can have a peek at my shop. HTH

If my garage looked like that, I would be in trouble because I would build speakers 24/7

aayyyye proto....tell your teacher he is a thatcher not a carpenter....he`ll get a kick out of that........glue is just fine in smaller cabinets

DIRT®

DIRT®

Wood Screws and Glue

protos

The best joint is using both wood screw and Glue. Glue by it self will hold MDF add the screw every 125mm or 5 “will make the joint extremely tight. The tight joint couples the sidewalls and can reduce cabinet resonances.

I like to use square drive screws the bit will last a long time. Also counter, sink all screws and fill them with wood putty. If you are planning to disassemble the cable, for example in the back to adjust the crossover just us wood screws there.

I guess the last thing I would do to a cabinet is nail it

😉

protos

The best joint is using both wood screw and Glue. Glue by it self will hold MDF add the screw every 125mm or 5 “will make the joint extremely tight. The tight joint couples the sidewalls and can reduce cabinet resonances.

I like to use square drive screws the bit will last a long time. Also counter, sink all screws and fill them with wood putty. If you are planning to disassemble the cable, for example in the back to adjust the crossover just us wood screws there.

I guess the last thing I would do to a cabinet is nail it

😉

Wood Screws and Glue

Screws are really not necessary because a properly glued joint will be stronger than the surrounding material. But, if one feels the need for screws, care should be given not to screw into the endgrain of the MDF. A simple cleat can be used so that the MDF can be screwed in from it's face side.

Screws are really not necessary because a properly glued joint will be stronger than the surrounding material. But, if one feels the need for screws, care should be given not to screw into the endgrain of the MDF. A simple cleat can be used so that the MDF can be screwed in from it's face side.

biscuit joinery is a lot easier than dowels, and an excuse to buy another tool. 😉

I once helped a buddy build cabinets using his brad nailer, with cleats like Roddyama suggests. Boy, was that quick, and more accurate than I've been able to set screws into the cleats. Unfortunately I cannot bring myself to buy a compressor just to use a brad nailer. 🙁

I use an electric brad nailer. They work fine.

I have recently discovered the joys of a 45 Degree lock Mitre joint.

🙂

Anthony

I've been using a lock miter joint for years, pain to set up but once you get it correct nothing is stronger

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Multi-Way

- Glueing MDF enough?