For the GK-71 users out there-what do you guys use for anode cap?

I never saw the original and it looks like it's,well,umm...unobtainium.

The anode caps for 829/GU29/832/GU32 are of no use since the pins are 1,5mm .The GK-71 anode pin has a diameter of 3mm.

For safety reasons I would like a ceramic cap for this,not bakelite if possible.

Any hint welcomed,DIY included. 🙂

THX!

I never saw the original and it looks like it's,well,umm...unobtainium.

The anode caps for 829/GU29/832/GU32 are of no use since the pins are 1,5mm .The GK-71 anode pin has a diameter of 3mm.

For safety reasons I would like a ceramic cap for this,not bakelite if possible.

Any hint welcomed,DIY included. 🙂

THX!

The only thing I have been able to come up with is a single piece of a European-style terminal strip that I cut off with a knife.

https://www.jaycar.com.au/6-amp-12-...8c8ff6d610d03106267608a99d2f44&sort=relevance

It's obviously not ideal and needs to be replaced periodically as the plastic part discolors from the heat. For partial safety, you could put a plastic washer around your wire where it could rest against the top of the terminal held down by gravity.

ray

https://www.jaycar.com.au/6-amp-12-...8c8ff6d610d03106267608a99d2f44&sort=relevance

It's obviously not ideal and needs to be replaced periodically as the plastic part discolors from the heat. For partial safety, you could put a plastic washer around your wire where it could rest against the top of the terminal held down by gravity.

ray

@ratbagp thanks for replying.

Your solution is one (kinda) temporary, "tech's shortcut" wich I'm aware of but it's not what I'm looking for as permanent.

As for the wire isolation against the heated glass top as well as for "through-chassis" ,I use ceramic elements as seen in the pic attached (OK,it's a choke I couldn't cram under but the same policy applies for all the anode cap tubes I work with).

Any other ideas?

THX

Your solution is one (kinda) temporary, "tech's shortcut" wich I'm aware of but it's not what I'm looking for as permanent.

As for the wire isolation against the heated glass top as well as for "through-chassis" ,I use ceramic elements as seen in the pic attached (OK,it's a choke I couldn't cram under but the same policy applies for all the anode cap tubes I work with).

Any other ideas?

THX

Attachments

Hello?

Still no products marketed ?

the only ones I have seen are made for radio and are not isolated.

Still no products marketed ?

the only ones I have seen are made for radio and are not isolated.

I ran into this yesterday on a smaller scale with a 954 acorn tube. Grid and plate are both off-socket pins. The solution was cannibalizing the motherboard fan connectors from an old HP. Perfect fit

3 mm sleeves are available but you're into fabricating a cap.

http://www.britishwiring.com/Lucas-159SA-Switch-Plug-p/c836.htm

3 mm sleeves are available but you're into fabricating a cap.

http://www.britishwiring.com/Lucas-159SA-Switch-Plug-p/c836.htm

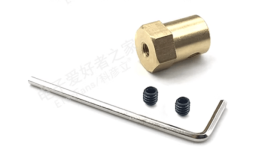

How about making an adapter from aluminium rod/tube to fit to one the standard size anode caps. 14mm rod or 14mm external 2mm internal alu hollow tube can be found on that auction site. The latter could be bored/drilled out to 3mm, and use an eimac style screw for clamping or perhaps 2.5mm hole with a slot cut so it naturally clamps on. The big 14mm (for 813 tubes etc) ceramic anode clamps would then fit on top. Shouldn't be to hard to make with a few tools drill/drill press, hack saw, vice/clamp.

It could be the case that there was never an insulated anode cap for the GK-71. As an example, the original anode caps for a GU-72 are also non-insulated.

You could take a close look at Wavebourn's build of his GK-71 amplifer . Videos are posted on his YouTube channel. It looks like he might have used some kind of sleeve to go over the pin and then connected wire to that and possibly covered with insulation/heat-shrink.See #4

I don't know a lot about the Russian tubes and their way of doing things but western makes such as Eimac used pins like that where the tube was expected to dissipate a lot of power and the cooling cap needed to keep the metal to glass seal temperature down. If looking to run the GK71 hot, I'd think it not stupid to take that extra step. You could always do what Magz did with his "The Midlife Crisis" amp (posted on this forum) , putting a glass chimney around the tube which together with the right size opening below channels a flow of air around the tube, and made enough taller than the tube with screen above prevents inadvertent contact with the plate cap.

The fellow who used to make the ones pictured here is not doing them anymore but CNC machining is easily accessible these days , and metal printing seems not far behind.

Attachments

- Home

- Amplifiers

- Tubes / Valves

- GK-71 anode cap - suggestion?