So I found a Pace MP-1 desoldering station w/ SensaTemp SODR-X-Tractor Handle for $75 shipped to my door. I know that Pace is considered by many to be one of the best desoldering branded tools on the market and rarely do they show on Ebay in any type of working condition. I figured even if I can't get the desoldering station to heat up the tip, I can easily get my money back with just reselling that upgraded handle/iron. That is if the problem isn't in the iron itself (I really hope not), but based on the quote below, I believe the issue is in the desoldering station.

I should have it by the end of the week and I wanted to go ahead and reach out for any info someone could provide if they have worked on this unit before. From what I can gather, this unit has not had any attempts to repair it once it stopped heating up the tip. I assume this because of the quote above, if they know something is moving around inside the case, but don't what it is; that makes me assume it has never been opened/worked on.

Opinions are welcome, even if you have never held this unit in your hands. The theory of operation of a normal soldering station should hold for any desoldering station aside from the vacuum pump. I figure another option is to get an affordable desoldering station off Ebay (station only w/o pen/handle) and use the MP-1's iron. This may obviously require some adapters/modifications.

The seller stated: "Tested to power on. Suction appears to work. The tip did not get hot. The main station makes a rattling noise when turned over."

I should have it by the end of the week and I wanted to go ahead and reach out for any info someone could provide if they have worked on this unit before. From what I can gather, this unit has not had any attempts to repair it once it stopped heating up the tip. I assume this because of the quote above, if they know something is moving around inside the case, but don't what it is; that makes me assume it has never been opened/worked on.

Opinions are welcome, even if you have never held this unit in your hands. The theory of operation of a normal soldering station should hold for any desoldering station aside from the vacuum pump. I figure another option is to get an affordable desoldering station off Ebay (station only w/o pen/handle) and use the MP-1's iron. This may obviously require some adapters/modifications.

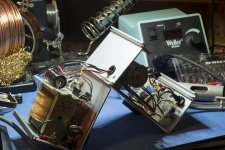

Attachments

The transformer or motor came loose and a heating wire for the tip may be broken. It should be a simple fix.

Duke

Duke

I have a full Pace rework station at my office, they are fantastic!

I would check as Audio1Man says.

If that is unsuccessful then I would be more than happy to test your heating element for you.

I would check as Audio1Man says.

If that is unsuccessful then I would be more than happy to test your heating element for you.

> if they know something is moving around inside the case, but don't what it is

Or they know it is "the part you can not get" and decided not to share that info.

There can't be much to it, and they say the more complex system (suction) works. So open it up, ID the loose part, see where tip-power comes from and look for voltage there. If got voltage, check tip for some low non-zero resistance. Check all wires and connectors, the most popular sources of problems.

> any info someone could provide if they have worked on this

There could be some secret common-knowledge, like "It's always the O2 sensor!" (Hey, this works on two of my cars.) But this sounds like it was dropped, and drop-damage with rattle is usually clear when you open it.

Or they know it is "the part you can not get" and decided not to share that info.

There can't be much to it, and they say the more complex system (suction) works. So open it up, ID the loose part, see where tip-power comes from and look for voltage there. If got voltage, check tip for some low non-zero resistance. Check all wires and connectors, the most popular sources of problems.

> any info someone could provide if they have worked on this

There could be some secret common-knowledge, like "It's always the O2 sensor!" (Hey, this works on two of my cars.) But this sounds like it was dropped, and drop-damage with rattle is usually clear when you open it.

Last edited:

Once you get it working check the filter inside the hand piece. It's probably dirty or filled with bits of solder. And different size tips will be a big help for different desoldering jobs. And every time you suck solder the tip will cool down from the air flow.

Last edited:

And have a piece of piano wire handy to poke out the hollow tip now and then.

Most likely no heat? Bad heating element. The element is a four wire plus ground. Two wires are the heater current, two wires are the temp sensor in the heater. Of course there could be issues in the base unit, also the multipin cable connector on the handle unit.

I like the Pace units I have owned. Been using them for the last 30 years.

Most likely no heat? Bad heating element. The element is a four wire plus ground. Two wires are the heater current, two wires are the temp sensor in the heater. Of course there could be issues in the base unit, also the multipin cable connector on the handle unit.

I like the Pace units I have owned. Been using them for the last 30 years.

Okay so this was pretty hilarious once I got my hands on it and I do need some clarification on a few points.

1. There are two bolts+nuts/washer on the back of the unit that holds the transformer in place. These two parts were gone and the entire transformer was sliding around inside which damaged the main filter capacitor on the PSU board. Where does the green wire (assuming ground) go by default running towards the rear of the unit? I assumed any of the two screws to anchor the green wire/(assumed) ground to the chassis would work.

2: The same green wire was floating around inside the handle. I need to know if this is a general ground where any of the 3 mounting places in the end of the handle, all should be the same unless I am missing something.

Noting else in the entire unit looked damaged except that capacitor from getting hit. The previous owner of this unit didn't even bother to inspect the cause of the "moving parts inside". Those moving parts were replacements tips in a storage area near the center of the unit, about 14 different tips in total in the magnetic storage bay.

I am confident I can repair this unit, especially if I can get pics of the stock wiring at the rear of the desoldering unit along with the end of the handle/iron wire that is again green.

Thanks for all the input so far and whatever else you can provide.

1. There are two bolts+nuts/washer on the back of the unit that holds the transformer in place. These two parts were gone and the entire transformer was sliding around inside which damaged the main filter capacitor on the PSU board. Where does the green wire (assuming ground) go by default running towards the rear of the unit? I assumed any of the two screws to anchor the green wire/(assumed) ground to the chassis would work.

2: The same green wire was floating around inside the handle. I need to know if this is a general ground where any of the 3 mounting places in the end of the handle, all should be the same unless I am missing something.

Noting else in the entire unit looked damaged except that capacitor from getting hit. The previous owner of this unit didn't even bother to inspect the cause of the "moving parts inside". Those moving parts were replacements tips in a storage area near the center of the unit, about 14 different tips in total in the magnetic storage bay.

I am confident I can repair this unit, especially if I can get pics of the stock wiring at the rear of the desoldering unit along with the end of the handle/iron wire that is again green.

Thanks for all the input so far and whatever else you can provide.

Last edited:

I wanted to make it clear that by the "handle", I am talking about the iron + vacuum line unit shown in the OP. This being completely separate pieces of the desoldering/vacuum station.

There is a green wire that was floating around inside the case when I received it at both the transformer (found at the rear) and then at the polar opposite end of the device, another green wire floating around with a lock washer (looks as if you should put it over a bolt or use a screw to secure it for (assuming) a solid common ground between the tip/sleeve and the chassis. These are literally the same wire/s correct? (Just looking at it from both ends/mounting points)

I believe the iron is grounded by the same wire as the chassis, which all makes sense to me, but I want to check if anyone can confirm this for me. You can just peak into the rear section by removing the plate angled and makes up the roof/top of the desoldering station. Leave the majority of the unit together and just see where the green wire is anchored towards the rear wall where the AC cables comes in from the wall outlet.

As mentioned, the stock transformer was no longer secured down (someone removed two bolts from the rear and never put them back) and this resulted in a lot of damage to the only real component sticking off any PCB, the 4700uF 25V "Acrolytic" branded main power filter capacitor. So I grabbed two Panasonic "GE" axial direct stock replacements off Ebay for $5+SH. If you have a larger order, not even just related to this part, Digikey and Mouser can be cheaper than Ebay due to free shipping after passing some dollar mark.

IF swapping the capacitor does not fix this, who would put money on the original transformer which was taken loose who knows how long ago. From that time until I got the unit, the transformer has been sliding forward/backward/upward/downward/left/right and the only thing that could have saved the transformer from destruction, probably the capacitor. I do have an excess of transformers right now, does anyone know the stock specs? I will see if I can find a service manual.

I will be posting high resolution pictures as soon as I get back home again. Left my camera in the wrong spot! I think pictures will make this so much easier to see and understand.

I plan to detail my repair of this unit here (obviously), but I will also be doing a YouTube video or two explaining the fix of an iconic device from the early years of electronics. You can find that and more coming soon to my website (zosoncsu.com), check it out if you want to see my first attempt at an audio review for a well-respected player in the op-amp business, Burson Audio (V5-OPA & V5i series)

There is a green wire that was floating around inside the case when I received it at both the transformer (found at the rear) and then at the polar opposite end of the device, another green wire floating around with a lock washer (looks as if you should put it over a bolt or use a screw to secure it for (assuming) a solid common ground between the tip/sleeve and the chassis. These are literally the same wire/s correct? (Just looking at it from both ends/mounting points)

I believe the iron is grounded by the same wire as the chassis, which all makes sense to me, but I want to check if anyone can confirm this for me. You can just peak into the rear section by removing the plate angled and makes up the roof/top of the desoldering station. Leave the majority of the unit together and just see where the green wire is anchored towards the rear wall where the AC cables comes in from the wall outlet.

As mentioned, the stock transformer was no longer secured down (someone removed two bolts from the rear and never put them back) and this resulted in a lot of damage to the only real component sticking off any PCB, the 4700uF 25V "Acrolytic" branded main power filter capacitor. So I grabbed two Panasonic "GE" axial direct stock replacements off Ebay for $5+SH. If you have a larger order, not even just related to this part, Digikey and Mouser can be cheaper than Ebay due to free shipping after passing some dollar mark.

IF swapping the capacitor does not fix this, who would put money on the original transformer which was taken loose who knows how long ago. From that time until I got the unit, the transformer has been sliding forward/backward/upward/downward/left/right and the only thing that could have saved the transformer from destruction, probably the capacitor. I do have an excess of transformers right now, does anyone know the stock specs? I will see if I can find a service manual.

I will be posting high resolution pictures as soon as I get back home again. Left my camera in the wrong spot! I think pictures will make this so much easier to see and understand.

I plan to detail my repair of this unit here (obviously), but I will also be doing a YouTube video or two explaining the fix of an iconic device from the early years of electronics. You can find that and more coming soon to my website (zosoncsu.com), check it out if you want to see my first attempt at an audio review for a well-respected player in the op-amp business, Burson Audio (V5-OPA & V5i series)

More than likely, any green wire goes to the nearest chassis metal.

I'd put a 2 cent bet that the tranny is 24V, VA rating implied by size/weight, but if I am wrong the 2 cent won't buy you a new heater. Do you even know if the PT is dead? They make good hammers, and the e-cap is a fine cushion. (The 25V caps do suggest it may be 12VAC??)

I'd put a 2 cent bet that the tranny is 24V, VA rating implied by size/weight, but if I am wrong the 2 cent won't buy you a new heater. Do you even know if the PT is dead? They make good hammers, and the e-cap is a fine cushion. (The 25V caps do suggest it may be 12VAC??)

Do you even know if the PT is dead?

I know for sure that it isn't dead, the same transformer powers the diaphragm+motor. This unit gives you the option to run either on 120VAC or 12VDC, I have tried giving it 12V DC and the suction works as with the 120VAC selection, but no heat to the tip.

Power Transformer part numbers (first two are unclear): (T?)(1?) 92-0048 MLI TX-S722 4781

I have been unable to find a transformer that matches those numbers in order to get the datasheet for the tranny. I assume it converts 120VAC -> 12VDC based on the fact the unit runs off either AC+Transformer or 12V DC (input on the front of the unit).

I changed out that primary power cap (4700uF/25V) and now the handle/iron is getting a lot hotter (using AC+Trans), but still not hot enough to desolder. It's probably 100-150F, I have attached a few pictures showing the internals of this unit.

The IC found on the Blue PCB looks to me like it is nearly melted, so I ordered a replacement (TI LM339N Voltage Quad Comparator) just to be safe. It is insanely hard to get a picture of the circuit between the switches/dials.

Does that Blue PCB (pic #3) look like stock parts or something someone tried to repair? I can't find internal shots of this unit to compare anything to. Also, I took out the diaphragm before taking pictures to allow more room.

So the question now is, what could prevent the tip from heating up past 50% of it's normal operating temp? I'd think either you'd get almost no heat or full heat, not sure how I fixed it 50% of the way w/ regard to tip temperature.

If anyone would like more pictures or better pictures of a specific part of the unit let me know.

Attachments

Last edited:

The heat is a controlled circuit, not an on/off switch. There is a thermal sensing circuit in the iron. If that is compromised, it tells the base to stop heating when it is not actually hot enough.

Or it could be trying to heat, but the circuit that controls current to the heating element is compromised so it cannot turn fully on.

I just re-skimmed the thread, did we ever CALL Pace on the phone and ask if they could provide support documentation?

Or it could be trying to heat, but the circuit that controls current to the heating element is compromised so it cannot turn fully on.

I just re-skimmed the thread, did we ever CALL Pace on the phone and ask if they could provide support documentation?

Hello,

Did you ever get your MP-1 to work. Did you get any help from Pace? I have a working unit. I can check resistances, voltages, etc.

Jon

Did you ever get your MP-1 to work. Did you get any help from Pace? I have a working unit. I can check resistances, voltages, etc.

Jon

I was searching the internet for troubleshooting tips for the Pace Micro Portable or MP-1. My MP-1 had started acting up early last year and it’s been on the back troubleshooting burner for a while. Recently on more than 1 occasion I’ve needed it, but no worky. So I was digging and found this thread. My symptoms are basically the same as the original posters unit, except I don’t have loose parts. Vacuum works fine, but tip doesn’t heat up. I saw the date on this thread and was hoping to see it resolved but, it kinda ended. I thought the thread was dead but Jon happens to post up that he has one that’s working and has offered help. Jon where should we start? I was wondering what voltage should be outputting to the heating element?

Have you tried PM'ing the OP? The original thread is only 3 years old. Most people here seem to be helpful.

Hey there Pars! No I hadn't tried PM'ing the OP. I can sure give it a try and see if he had any luck. I hope that maybe Jon will reply as well.

Mark

Mark

Well, I just tried and got this:

"ZoSoNCSU has chosen not to receive private messages or may not be allowed to receive private messages. Therefore you may not send your message to him/her."

So I'll see if any other replies get posted.

"ZoSoNCSU has chosen not to receive private messages or may not be allowed to receive private messages. Therefore you may not send your message to him/her."

So I'll see if any other replies get posted.

Hello,

The hand piece has 4 wires. the green is just grounding the tip, the white is attached to the switch and connects to the black/yellow wire when depressed. those two are ok else your vacuum wouldn't work. the heater is connected between the orange and blk/yel wires. Mine is weak and measures 1.6 ohms at heater. When new it should be around 0.4 ohms to produce 25 watts at 12 volts input. I believe this unit uses a comparator bridge circuit to measure the heater resistance between output pulses. There is no other temperature sensor in the iron. The output pulses seem to last longer when it is colder. I did not scope the output, just observing the indicator LED. I have made up a parts list. Let me know if anyone wants it.

Jon

The hand piece has 4 wires. the green is just grounding the tip, the white is attached to the switch and connects to the black/yellow wire when depressed. those two are ok else your vacuum wouldn't work. the heater is connected between the orange and blk/yel wires. Mine is weak and measures 1.6 ohms at heater. When new it should be around 0.4 ohms to produce 25 watts at 12 volts input. I believe this unit uses a comparator bridge circuit to measure the heater resistance between output pulses. There is no other temperature sensor in the iron. The output pulses seem to last longer when it is colder. I did not scope the output, just observing the indicator LED. I have made up a parts list. Let me know if anyone wants it.

Jon

Thanks Jon. What impedance do you get just across the yellow leads to the heater? I removed it from the handle.

The one yellow lead looked like it may have not been a good connection, so I put it back together and turned it on. It's been a while since I plugged it in. I did notice that the LED no longer illuminates at all no matter where the LO HI settings are. Now I'm wondering if it's a control board issue.

The one yellow lead looked like it may have not been a good connection, so I put it back together and turned it on. It's been a while since I plugged it in. I did notice that the LED no longer illuminates at all no matter where the LO HI settings are. Now I'm wondering if it's a control board issue.

Last edited:

I disconnected the orange heater wire to simulate an open heater circuit. With any temperature setting, I get a continuous faint glow from the LED. You should see it blinking fast in your peripheral vision. The controller thinks that the temperature is too high because the heater resistance leg of the bridge circuit is infinite. As I said, the ideal resistance of the heater is around 0.4 ohm. With reduced heating wattage, mine still works with 1.6 ohms. If you measure voltage across the orange (-) and black/yellow (+) wires, if the heater resistance is good, you will measure from 2 to 14 volts DC (pulsed) when powered from a-c line. If your iron is working correctly, the voltage will start out maximum, and taper off to less than 4 volts when not under thermal load.

- Home

- Design & Build

- Equipment & Tools

- Found a Used PACE MP-1 (Tip doesn't get hot, suction works) Opinions?