I've had BFA types bend or snap off if not careful with the plugs. I like them better than nine-tine/four-tine types for contact area.

For a more bullet-proof banana...

AECO makes these spiral-cut cylindrical bananas for 4mm jacks. Some like Cardas are a little bigger and the AECO won't fit tightly. Yes- they are a bit costly, but well made.

AECO:

https://www.amazon.com/s?k=aeco+banana+plugs&ref=nb_sb_noss

Then there are the Furez and Viborg types:

Viborg:

https://www.amazon.com/Viborg-4XPur...0-spons&keywords=banana+jacks+and+plugs&psc=1

Furez (solderable):

Furez Products – Douglas Connection

Later,

Wolf

For a more bullet-proof banana...

AECO makes these spiral-cut cylindrical bananas for 4mm jacks. Some like Cardas are a little bigger and the AECO won't fit tightly. Yes- they are a bit costly, but well made.

AECO:

https://www.amazon.com/s?k=aeco+banana+plugs&ref=nb_sb_noss

Then there are the Furez and Viborg types:

Viborg:

https://www.amazon.com/Viborg-4XPur...0-spons&keywords=banana+jacks+and+plugs&psc=1

Furez (solderable):

Furez Products – Douglas Connection

Later,

Wolf

Personally, I use these for most of my stuff... Set screw but there are two of them, and it'll take #8 wire. I know it says 12AWG, but it works...

https://www.amazon.ca/Banana-FosPow...=1&keywords=banana+plug&qid=1603981795&sr=8-5

https://www.amazon.ca/Banana-FosPow...=1&keywords=banana+plug&qid=1603981795&sr=8-5

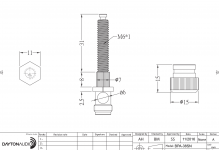

My cabinets will have these Dayton Audio binding posts which accept banana plugs or large fork terminals.

How do you know for sure what the diameter of the post is, as spades are typically either 1/4" or 5/16", when even the drawing omits it? I suppose assume 5/16" diameter as it would be pretty hard to drill a 6mm hole in a 1/4 inch post?

Attachments

I use these fork terminals for 1/4" stud & #10 wire that crimp on. McMaster-Carr

You spread the forks a little. Use a klein or Ideal crimp tool and pull test after application.

If you don't have any current and are using 14 or 16 wire, these are for 1/4 stud: McMaster-Carr

You spread the forks a little. Use a klein or Ideal crimp tool and pull test after application.

If you don't have any current and are using 14 or 16 wire, these are for 1/4 stud: McMaster-Carr

Would there be a problem using these cheap spades for speakers and amps? I plan to get the 8mm (M8 I believe).

https://www.aliexpress.com/item/3256803271282932.html?spm=a2g0o.cart.0.0.634938dajyFwTl&mp=1

https://www.aliexpress.com/item/3256803271282932.html?spm=a2g0o.cart.0.0.634938dajyFwTl&mp=1

I've soldered a short piece of 12/14 gauge solid copper wire to each end of a stranded cable and put a piece of shrink-wrap over the solder joint. The solid wire gets well connected to the push-open clamp connectors often seen on amps and speakers, and fits through the holes on combination screw-on banana connectors. This may not last long for daily connections/disconnections, but is fine for weekly or monthly changes.I'm entering the final stages of my floorstanding 3-way tower build and I'm starting to thinking about making a nicer set of speaker wires to hook them up with. By "nicer" I simply mean terminating the bare wire ends to that I'm not clamping down on bare stranded wires which will eventually break off.

The next (perhaps only) step up is Speak-On, that I've read bout for at least 20 years. They're purpose-designed for high-power PA speakers, and should be all one needs for hifi speaker connections.

IMO, Speak-On and mini-XLR are in the waiting to take over for all "speaker-level" and line-level audio connections.

Depends on the amplifier. I have had cheap ****ese terminals melt the wire at 30 amps. The ones from Mcmaster are 3M brand wihich is good for that much.Would there be a problem using these cheap spades for speakers and amps? I plan to get the 8mm (M8 I believe).

The 3mOhm connection of the Speakon is hard to beat. I've changed years ago on my own projects. It is just a sturdy well proven concept thats easy to work with. The bigger cable connectors w. metal housing also offer solderability.The next (perhaps only) step up is Speak-On, that I've read bout for at least 20 years. They're purpose-designed for high-power PA speakers, and should be all one needs for hifi speaker connections.

IMO, Speak-On and mini-XLR are in the waiting to take over for all "speaker-level" and line-level audio connections.

For active speakers it is also a nice convenience with 4 and 8 connections.

I use these:

The terminal block are available in 12-type as well. You can drill out the copper and split the block at that point. Rating of 30 A should be sufficient.

The terminal block are available in 12-type as well. You can drill out the copper and split the block at that point. Rating of 30 A should be sufficient.

How can you measure/tell if these wouldn’t handle an amplifier that is capable of 30A output?Would there be a problem using these cheap spades for speakers and amps? I plan to get the 8mm (M8 I believe).

https://www.aliexpress.com/item/3256803271282932.html?spm=a2g0o.cart.0.0.634938dajyFwTl&mp=1

If your speaker dips to 1 ohm at a specific frequency and you out 30 amps to it, that's 900 watts - a little excessive IMO. 30 amp ratings are not particularly meaningful by themselves. A thick steel rod can handle 30A, but that doesn't make it a good connector. You want low resistance and multiple insertion capability, which are more important for high current connections (all kinds).

The spades you are asking about are perfectly fine. I use similar ones to connect a subwoofer array and they held up for a decade of use with no degradation.

The spades you are asking about are perfectly fine. I use similar ones to connect a subwoofer array and they held up for a decade of use with no degradation.

The contact resistance of the best connectors is still 0.05 ~ 0.1 ohms. I am not talking about audio but about industrial connections where this is really an issue. So it won't get any better and any reasonable connector will perform satisfactorily.

My experience with these Chinese connectors is that sometimes they are made so darn cheap that they are too thin to hold the crimped wire. The wire simply slips out after time because the material is not thick and strong enough to stay closed.

You don't know beforehand. The picture on the page you refer to show connectors which seem all right, but you never know what you get from the Chinese. It is not always what is in the picture. It doesn't help to order them from Amazon or so because Amazon is not in control of the quality.

My preference is to crimp and solder the wires. Even if the spade is way too thin the distance is so short it won't have any effect. Like I said, there is always a connection resistance. And that resistance is much larger than resistance of the tiny piece of material of the spade.

My experience with these Chinese connectors is that sometimes they are made so darn cheap that they are too thin to hold the crimped wire. The wire simply slips out after time because the material is not thick and strong enough to stay closed.

You don't know beforehand. The picture on the page you refer to show connectors which seem all right, but you never know what you get from the Chinese. It is not always what is in the picture. It doesn't help to order them from Amazon or so because Amazon is not in control of the quality.

My preference is to crimp and solder the wires. Even if the spade is way too thin the distance is so short it won't have any effect. Like I said, there is always a connection resistance. And that resistance is much larger than resistance of the tiny piece of material of the spade.

I also saw these ring connectors. IMO, these seem to a better solution than spades but I guess not all binding posts can be removed completely (you know what I mean) and maybe possible touching each other (positive to negative)? But in theory these should work the best. It will never come off no matter what.

https://www.aliexpress.com/item/3256806097321114.html?spm=a2g0o.cart.0.0.66ad38daHF2EFy&mp=1

https://www.aliexpress.com/item/3256806097321114.html?spm=a2g0o.cart.0.0.66ad38daHF2EFy&mp=1

Bigger higher current connectors have more surface area and less resistance. For example Anderson powerpole 75A connectors, resistance is quoted as 0.0002 ohms.... That's still over 1W of heat generated in the contact area alone at 75A. If it had 0.05 ohms it would melt, dissipating nearly 300W at 75A.The contact resistance of the best connectors is still 0.05 ~ 0.1 ohms. I am not talking about audio but about industrial connections where this is really an issue.

I estimate a chunky brass terminal post at 0.0001 ohms, i.e. the cabling and thickness of the spade would be the limiting factors.

- Home

- Design & Build

- Parts

- Fork terminals for speaker wires