Can you cool a Class A amp to the point that sound quality is affected?

Yes you can. A loud fan would affect and fully hide all the possible class A hifi goodness 🙂

But: I have been running cooling fans for years in multiple setups, racks and enclosures. Cool and Silent.

One ring rule to rule them all: Big ring makes almost total silence.

Use the absolute biggest possible fan for the application. That fan will move the largest volyme of air at the lowest rpm.

Really Low rpm is in reality really Low noice.

But, still, you gotta love them fanless designs. No maintenance, full silence.👍

I used once a fan and a 10 times smaller heatsink thatit should be for a class A amp, but I couldn't stand fan's noise.If you're going to use abig fan then where's the size gain?Maybe active cooling gives us a more acceptable chassis size.

This is the professional approach to forced air cooling.

And of course in industrial applications, there is always a thermal switch for safety.

But most effective and compact (locally) is still liquid cooling, of which water is just one example.

Patrick

And of course in industrial applications, there is always a thermal switch for safety.

But most effective and compact (locally) is still liquid cooling, of which water is just one example.

Patrick

Attachments

There is a fan speed regulator project that didn’t get deserved attention with A class amplifier builders:

Fan inside audio chassis

I’ve made PCB for two series connected 12V fans. They are many more types available than for 24V. First try was with four 80 x 80 x 15 mm very silent low speed fans, attached to the amplifier cover. Regulator works very well (as expected).

However, this is not good place for a fan placement. While testing fan operation with cover on the bench, it was absolutely silent. Putting cover in place, reveals that slightest fan vibration is amplified by cover resonance and with amplifier internal volume it produces some droning sound. In dead silent room at cold start, it is barely audible at 1 m distance. After an hour of operation at temperature equilibrium, noise can be heard at more than 2 m distance. Unacceptable.

Temperature inside case drops twice the drop on external heatsinks and overall cooling effect is very good. Next try will be with big fans inside case.

Fan inside audio chassis

I’ve made PCB for two series connected 12V fans. They are many more types available than for 24V. First try was with four 80 x 80 x 15 mm very silent low speed fans, attached to the amplifier cover. Regulator works very well (as expected).

However, this is not good place for a fan placement. While testing fan operation with cover on the bench, it was absolutely silent. Putting cover in place, reveals that slightest fan vibration is amplified by cover resonance and with amplifier internal volume it produces some droning sound. In dead silent room at cold start, it is barely audible at 1 m distance. After an hour of operation at temperature equilibrium, noise can be heard at more than 2 m distance. Unacceptable.

Temperature inside case drops twice the drop on external heatsinks and overall cooling effect is very good. Next try will be with big fans inside case.

Attachments

Hi Tombo,

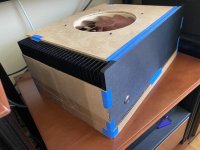

This experiment has worked amazingly well. I played around with fan speed a bit for max cooling without hearing the fan from about 4 feet. My HS temps with conventional fanless cooling were 50 to 52°C. Now they are 37°C, barely above a class AB amplifier! The M2 clone really doesn’t need this fan set up, but for the future with a higher biased class A amplifier in the same size chassis, I believe this will be the solution for me.

This experiment has worked amazingly well. I played around with fan speed a bit for max cooling without hearing the fan from about 4 feet. My HS temps with conventional fanless cooling were 50 to 52°C. Now they are 37°C, barely above a class AB amplifier! The M2 clone really doesn’t need this fan set up, but for the future with a higher biased class A amplifier in the same size chassis, I believe this will be the solution for me.

Attachments

Hi Vunce.

I’ve noticed your previous post with all details (grill cover including). 🙂

I was trying to preserve amplifier looks and have “switch on and forget” all seasons solution. Will play some more with various large fans. Mark’s fan speed regulator works very well.

I’ve noticed your previous post with all details (grill cover including). 🙂

I was trying to preserve amplifier looks and have “switch on and forget” all seasons solution. Will play some more with various large fans. Mark’s fan speed regulator works very well.

Nice DIY! A tunnel makes sure all the air surpasses the heatsink but I don´t understand the position of your fan.This experiment has worked amazingly well.

You are sucking in cold air from the top into the chassis?

Why not blowing in from the bottom?

Both solutions will not work 100% though, as the air is not directed too well and the stream of cold air will create chaotic turbulences within the chassis.

(Remember the old PC big towers where the CPU-fan would simply blow the hot air in all directions?)

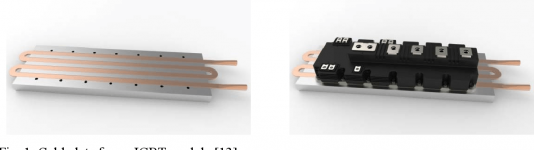

I think something like this

"baby sitter" would work well if fans sit at the edges under the heatsink (and at least partially "overlap").

Simply blowing/accelerating the cold air stream straight up past the fins.

Assuming the bottom and top plate have slits you will also get forced cold air into/through the chassis.

Tunnel solutions from Fischer Elektronik and the likes are nice but also quite expensive.

Fischer

But then, Class-A amps, proper chassis and DIY in general is expensive anyway ;-)

I suppose the "forced" is too harsh of a word...

I use the fans (post #39) just to keep the internal temperature under control during the hottest of days in Australia. I don't really have to do this even if it is very hot outside - I just choose to not let the internal temperature go above 50 deg C... to preserve the capacitors' life, while still making sure the heatsinks are nice and hot at all times. I believe that class A amp should run hot and not be forced to run cold.

I use the fans (post #39) just to keep the internal temperature under control during the hottest of days in Australia. I don't really have to do this even if it is very hot outside - I just choose to not let the internal temperature go above 50 deg C... to preserve the capacitors' life, while still making sure the heatsinks are nice and hot at all times. I believe that class A amp should run hot and not be forced to run cold.

I believe any amp will benefit from just a simple fan. My choice is a twin fan unit, quiet works well. Heat build up over time will shorten the life of components.Can you cool a Class A amp to the point that sound quality is affected?

Continuous Power per channel both channels driven 20 Hz to 20 kHz 2 ohms: 800 WattsThis is the professional approach to forced air cooling....

_________________________________________________________________________

Peavy:

"A classic problem when using forced air to cool a multiplicity of devices arrayed along a heat tunnel is to equalize the device temperatures along the length of the heat tunnel. In high-power amplifiers you routinely use several power devices in parallel. If one receives less cooling than the others, it will run hotter. Like the weak link in a chain, it will reach its maximum temperature and fail first.

Even if all of the power devices have the exact same access to the cooling air- flow, the air picks up heat as it passes over preceding devices. This hotter air can't absorb heat as readily as the cool air. The classic solution for equalizing the thermal gradient in a heat tunnel is to tune the length of the heat sink fingers. Just look inside the industry standard CS800X, The heat sink at the hot, exit end of the heat tunnel has much more aluminium and longer fingers than the cool inlet end.

Multi-stage, graduated-heat tunnels are complex and difficult to manufacture. Our new heat sink approach is deceptively simple. By angling two heat sink extrusions toward each other, forming a truncated "V", the heat transfer is significantly increased at the narrow end.

The cool ambient air enters at the wide end, top of the "V." As the cool air moves through the heat tunnel gaining heat, the walls move closer together increasing air flow and velocity across the fins and helping the hotter air extract the same amount of heat the cooler air did in the previous section. By the time the hottest air gets to the end of the tunnel, the heat transfer is at it's maximum. The net result of tuning the heat sink for air temperature, the devices all operate at close to the same temperature and the amplifier will be able to do more work before the hottest power device gets too hot."

I guess its just a different way of looking at things but for me there is only passive convection and forced convection.The best cooling is still water / fluid.

The actual part that cools and spreads the heat is the metal with its great thermal conductivity.

The air just makes this heatspreader much more effective and the water transports (big heat capacity) the heat away and gets cooled itself somewhere else.

Both air and water are very lousy heat conductors.

Both are nice methods but unfortunately relatively loud (esp. the water pump), prone to failure and use some energy themselves to operate obviously.

The very best cooling is simply passive convection/radiation. Anything mechanically moving/turning will cause noise and moving of dirt/dust. Secondly wearout of fans is an issue. Maybe the amplifiers could be smaller in power and in dissipation to avoid all this?! Fins of the heatsinks could be at the outside of the device too. In my professional life I deal with forced cooled high power devices on a daily basis and the few devices that are passively cooled really have the least of maintenance needed. They are also a joy to maintain since they are practically silent. Fan noise is a terrible annoyance and fans are a simply a silly thing in a living room, I can not imagine anyone to like that let alone the idea to use water cooling in living room electronics?! Since I personally don't need more than a few Watts output power my solution was a 2 x 4W amplifier. Recently I was visiting a person that "needed" 2 x 400W so maybe my situation is not normal 😀 Still it is a good idea to adapt output power to real life necessities with a small margin. It seems more effective than needing to cool devices with many tricks and whistles without a real need for the output power and dissipation.

What I see at many places is a V12 that can reach 250 km/h but never goes faster than 30 km/h with still a lot of noise and lousy fuel economy. As with many things audio maybe the goal of the device should be re-evaluated. Is it to playback music without any obstruction or is its main goal to simply exist and make noise itself?

What I see at many places is a V12 that can reach 250 km/h but never goes faster than 30 km/h with still a lot of noise and lousy fuel economy. As with many things audio maybe the goal of the device should be re-evaluated. Is it to playback music without any obstruction or is its main goal to simply exist and make noise itself?

Last edited:

For A-class lovers struggling with hot days, the water cooling option offers a way to move the heat right out of the room.

The classic DIY option is to run a low flow hose from a garden tap, in via a window and out to top up the pool. No noise. No dust. Incredible heat transfer.

Of course sooner or later there will be a leak in the amp. Unless the water jacket is designed for harmless leaks eg mounted under the amp there will be more water leaking via tears

The sensible thing is to fun a more efficient system in the heat and fire up the Class-A convection air room heater when its chilly. But if we were sensible we would just but some good headphones and relax.

The classic DIY option is to run a low flow hose from a garden tap, in via a window and out to top up the pool. No noise. No dust. Incredible heat transfer.

Of course sooner or later there will be a leak in the amp. Unless the water jacket is designed for harmless leaks eg mounted under the amp there will be more water leaking via tears

The sensible thing is to fun a more efficient system in the heat and fire up the Class-A convection air room heater when its chilly. But if we were sensible we would just but some good headphones and relax.

I have electric baseboard heating in my home, so I pay for electricity to heat my room.

I also have a few Class A single ended solid state amplifiers of various power output and power dissipation. So during the heating season the amplifiers do double duty providing heat and music, thereby reducing the amount of heat that I need from the electric baseboards. During the coldest months I use my amp with the highest power dissipation, and I switch to lower power dissipation amps as the seasons change and the heating requirements are less. My speakers are very sensitive so low power amps are enough in the summer, and in the winter high power amps just idle along most of the time.

Since I need to use electricity to heat my room, the heat dissipated by the amplifier is not wasted during the heating season. I get free music with my heat.

I also have a few Class A single ended solid state amplifiers of various power output and power dissipation. So during the heating season the amplifiers do double duty providing heat and music, thereby reducing the amount of heat that I need from the electric baseboards. During the coldest months I use my amp with the highest power dissipation, and I switch to lower power dissipation amps as the seasons change and the heating requirements are less. My speakers are very sensitive so low power amps are enough in the summer, and in the winter high power amps just idle along most of the time.

Since I need to use electricity to heat my room, the heat dissipated by the amplifier is not wasted during the heating season. I get free music with my heat.

Aha that is a clear explanation 😀 The necessary fans also provide for a nice air flow/ventilation while sitting in a hot living room in the middle of summer I presume?

The heatsink spreads the heat from the power device by conduction, fully correct.

The heatsink metal does not take away the continuous thermal energy.

If there were no air or water being circulated (e.g. cover it with a thick blanket), the temperature of the heatsink would keep rising.

Whether it is air or water, the fluid medium takes the thermal energy away by an increase in the temperature of that medium.

A necessity is that there is a continuous flow, which then has to be dissipated into the atmosphere eventually.

Many CNC hobbists using 500W water-cooled high-speed spindles for milling.

They just use a large rainwater tank lifted at 1.5m or so, and use gravity to feed.

No pump required. Will last for hours.

And in any case the pump, if a must, can be outside the house which I presume is well insulated acoustically.

Yes, 1kW of Class A dissipation will keep your house warm in winter.

But there are those who live in Malysia or Singapore, or Texas, .... who have 25~35°C all year round.

I am sure a few of them want to, and are entitled to, enjoy Class A as well.

Cheers,

Patrick

The heatsink metal does not take away the continuous thermal energy.

If there were no air or water being circulated (e.g. cover it with a thick blanket), the temperature of the heatsink would keep rising.

Whether it is air or water, the fluid medium takes the thermal energy away by an increase in the temperature of that medium.

A necessity is that there is a continuous flow, which then has to be dissipated into the atmosphere eventually.

Many CNC hobbists using 500W water-cooled high-speed spindles for milling.

They just use a large rainwater tank lifted at 1.5m or so, and use gravity to feed.

No pump required. Will last for hours.

And in any case the pump, if a must, can be outside the house which I presume is well insulated acoustically.

Yes, 1kW of Class A dissipation will keep your house warm in winter.

But there are those who live in Malysia or Singapore, or Texas, .... who have 25~35°C all year round.

I am sure a few of them want to, and are entitled to, enjoy Class A as well.

Cheers,

Patrick

Yes all known simple stuff but .... 1 kW?!? So a kiloWatt... for what? 🙂 To generate heat and to keep fans spinning? As precise as some designs are designed... there seems to be some inconsistency in the requirements. Maybe a simpler approach is to adjust to environmental temperatures + loudspeaker requirements for reasonable volume and use smaller passively cooled class A amplifiers? What is not dissipated does not need to be cooled (my design parameter). All the class A defense aside, if one lives in 25~35°C all year round one is not better off with 1 kW extra heat (keeps the airco busy as well) for a few Watts to speakers...Just saying....

Last edited:

Still 100W short of 1kW. Pass Labs XS300So a kiloWatt... for what? 🙂

If one would show on my doorsteps, I wouldn’t ask "for what". 😀

- Home

- Amplifiers

- Pass Labs

- Forced cooling a class A amp