Do the Ovation guitars have the funky, synthetic material, computer modeled body - but still have the Spruce top? Maybe there is something to that particular materials properties as a "membrane-o-phone". Someone's probably making / has made a DML speaker out of that stuff -

Glad to read the

Glad to read the

Was a good experience for you!Chicago School of Guitar Making

Yes, and Sitka Spruce is the pretty much undisputed Grand Daddy of sound boards for guitars, violins, pianos...but not exclusive.

I will be happy to use that, but I still want to test mine which is based more on shape and strength than material. The DML speakers are interesting, I have seen good and not so great reviews, but have never heard one myself.

I will be happy to use that, but I still want to test mine which is based more on shape and strength than material. The DML speakers are interesting, I have seen good and not so great reviews, but have never heard one myself.

The fiberglass body of the Ovation was designed before 1966, probably only meat computers used.Do the Ovation guitars have the funky, synthetic material, computer modeled body - but still have the Spruce top?

The top soundboard is made out of different tonewoods, spruce being one of the more common.

Low frequency horn loaded enclosures with ports (Helmholtz resonators) are nearly as common as with sealed compression chambers.Ian (the owner) reminded me of two guys from this DIY Audio site. First thing he said when he saw a port in my chamber divider was "put a cork in that port".

Horns especially need to have 100% sealed enclosures, I can do that - JJ!

I should have said his horns are are sealed, no ports, maybe personal preference, but he was the same opinion as JJ, mind should be sealed.

Just found some Sitka Spruce pieces made for a Jumbo acoustic that will fit my guitar, will try that after I learn the bracing.

AAA Alaskan Sitka Spruce is not cheap!

Just found some Sitka Spruce pieces made for a Jumbo acoustic that will fit my guitar, will try that after I learn the bracing.

AAA Alaskan Sitka Spruce is not cheap!

This is a solved problem. For some shapes.why not bend the wood and add instead of CNC subtract - Art! I could do that for a small number of guitars, but if this goes to production, that would be very labor intensive

Ever see a chain maker? First hit in YouTube (I have seen better video):

Obviously this machine can bend hard steel all night long, zero labor. Your panels and passages would need different "hands" but pretty much the same servos and cylinders and programming (which can be simple cams, as on this machine at 1:10). Got a 4-door car? That jam between the doors is all folded on molds and hydraulic rams traditionally as fast as a man can insert a blank and remove the finished jam (maybe faster now with union-busting and robots).

When I see something like that, I have to think of the poor guy who's job it is to fix a manufacturing problem like it drops a weld every 7K links or so...and the boss wants to know why. My favorite video moment was of course the tension test! Cool to see the links stretch a little bit, under who knows how much force applied.Obviously this machine can bend hard steel all night long, zero labor.

Welcome back PRR, thanks for the great video and stay in the conversation!

I like having this problem: The most important and most complex shape on this guitar is the body with horns and speakers. It has been proven to work, now we have the luxury to consider what is the best method to make this? We have options!

I like having this problem: The most important and most complex shape on this guitar is the body with horns and speakers. It has been proven to work, now we have the luxury to consider what is the best method to make this? We have options!

Most of Ian's Specimen Audio horns compression chambers are back loaded, not sealed.I should have said his horns are are sealed, no ports, maybe personal preference, but he was the same opinion as JJ, mind should be sealed.

Martin J. King's article gives some good background into that type of horn:

http://www.quarter-wave.com/Horns/BLH_Design_Article.pdf

Yes they are, I was referring to the small cabinet, or chamber, sorry if I am using the wrong terminology, his horns sound great,

in my opinion.!

in my opinion.!

In my shallow xperience with horn drivers, they have a cap on the back;

Me thinks there's more to it, than simply preventing an accident. Given that it's stuffed with the fiberglass pad, someone thought of damping any reflections bouncing around in there. I'm aware of one OB speaker where the horn driver is vented, allowing sound out the back of it. But I believe most are capped and giving the diaphragm something to push against (the small air volume within the cap) allows greater power handling. Thus my thinking regarding Joe's design...

Edit; hopefully more power handling is something that's desirable, versus something like leaking sound back into the soundboard chamber and eventually out the front port. Venting out the back side of the guitar is a different story. Gibson has their "player port" and I'm sure a centered back side driver chamber port would be heard by the player. Plus, he could cover it by pressing the guitar up against his belly, changing the horn's sound character as he plays...

Me thinks there's more to it, than simply preventing an accident. Given that it's stuffed with the fiberglass pad, someone thought of damping any reflections bouncing around in there. I'm aware of one OB speaker where the horn driver is vented, allowing sound out the back of it. But I believe most are capped and giving the diaphragm something to push against (the small air volume within the cap) allows greater power handling. Thus my thinking regarding Joe's design...

Edit; hopefully more power handling is something that's desirable, versus something like leaking sound back into the soundboard chamber and eventually out the front port. Venting out the back side of the guitar is a different story. Gibson has their "player port" and I'm sure a centered back side driver chamber port would be heard by the player. Plus, he could cover it by pressing the guitar up against his belly, changing the horn's sound character as he plays...

Last edited:

So JJ last night I tested my horns covered with 1/2" thick tight fitting Baltic Birch, completely sealed on both sides, no ports. Results:

Distortion was very low by ear, wonderful, could actually turn the amp and preamp up to 10. Sounded closer to the actual acoustic guitar than I ever heard, was thrilled, great lows. This was using a piezo. When I use a piezo straight into an amp, it does not sound bad, it just does not have the warm sound of an acoustic guitar. Then people say use a mic instead, then the mic feeds back. I think the 5 foot long maple horns are warming up the piezo sound, who knows? JJ? Art??

The down side is it does drop volume by about 4-5 dB measured, not bad, but needs improvement. I like getting the great horn tone and low distortion as a basis, THEN improve where needed. Tonight I am ripping apart my new 40 watt acoustic guitar amp (20 per channel), lets see if I can get that extra power and maintain the great tone. JJ/ART this amp has I think a 5" and a 2" speaker (the other amp had two 4" speakers). Is there going to be some crazy crossover due to the different speakers that might wreak havoc with my setup, please advise and thanks!

Still looking to get closer to +/- 5 dB FR in the 100 to 1000 Hz range, trying. The more I rely on acoustics and less on electronics, the better the sound.

Picture attached shows another guitar build kicking it old school. Also shown is my new school guitar neck attached permanently with dovetail, dowel, and two screws. This is tighter than a couple of newlyweds, will not come apart! I was a bit nervous drilling in assembly, but it worked great, lets rock! Joe

Distortion was very low by ear, wonderful, could actually turn the amp and preamp up to 10. Sounded closer to the actual acoustic guitar than I ever heard, was thrilled, great lows. This was using a piezo. When I use a piezo straight into an amp, it does not sound bad, it just does not have the warm sound of an acoustic guitar. Then people say use a mic instead, then the mic feeds back. I think the 5 foot long maple horns are warming up the piezo sound, who knows? JJ? Art??

The down side is it does drop volume by about 4-5 dB measured, not bad, but needs improvement. I like getting the great horn tone and low distortion as a basis, THEN improve where needed. Tonight I am ripping apart my new 40 watt acoustic guitar amp (20 per channel), lets see if I can get that extra power and maintain the great tone. JJ/ART this amp has I think a 5" and a 2" speaker (the other amp had two 4" speakers). Is there going to be some crazy crossover due to the different speakers that might wreak havoc with my setup, please advise and thanks!

Still looking to get closer to +/- 5 dB FR in the 100 to 1000 Hz range, trying. The more I rely on acoustics and less on electronics, the better the sound.

Picture attached shows another guitar build kicking it old school. Also shown is my new school guitar neck attached permanently with dovetail, dowel, and two screws. This is tighter than a couple of newlyweds, will not come apart! I was a bit nervous drilling in assembly, but it worked great, lets rock! Joe

Attachments

I'd put the mic idea along with the port idea. I remember seeing a Dan Hicks video where he had a mic on a gooseneck with the standard threaded base bolted to the front of his acoustic - I cant even find a picture to post a link to, so must've been a gimmick for that particular show.Then people say use a mic instead, then the mic feeds back. I think the 5 foot long maple horns are warming up the piezo sound, who knows?

I'd attribute your sense of warmth from the FR of the horns - versus the amplifier - plus the sound coming from the guitar body in a reasonably familiar way. Whatever the FR of the horns is, it must be overlaying the piezo FR in a good way to you. Another player? Hopefully we can help get any kinks out of this arrangement so that most players will be pleased.

I've been temtped to put 1 or 2 of those Dayton exciters up against the soundboard of my current acoustic. I'd want to mount them on posts, glued to the backside. This would be a precision placement, that would land the exciter's voice coil at mid excursion - i.e. just touching - the back of the soundboard. Honestly, I dont think I have the skill to do it...

The idea would be to use one of those Boss looping pedals to play back a repeating chord sequence (Wooden Ships; Cmaj7 - Em) through the soundboard, where I could solo over the top - not to amplify the guitar. Which would obviously be a feedback laden mess. Maybe get away with amplified vocals from a headset dynamic mic - but I wouldnt count on it.

Yeah those exciters are interesting, have not tried them, they are basically a soundboard. I just tried the mic with piezo, nice Fishman pickup, they are just not the right product for this guitar, the feedback was even worse than expected, squealed like a pig, absolutely horrible. Live and learn!

Warmth from the FR of the horns, I think that might be correct JJ, sounding good!

Warmth from the FR of the horns, I think that might be correct JJ, sounding good!

Joe,When I use a piezo straight into an amp, it does not sound bad, it just does not have the warm sound of an acoustic guitar.

I see you have a Fender amp, have you tried a simple A/B test swapping between it's speaker and your folded horn speaker?

"Warmth" generally means a tilt towards low or low mid frequencies, consistent with what I'd expect from your offset horns.Then people say use a mic instead, then the mic feeds back. I think the 5 foot long maple horns are warming up the piezo sound, who knows? JJ? Art??

Without knowing what model "this amp" is, have no idea of what processing or crossovers it might contain.JJ/ART this amp has I think a 5" and a 2" speaker (the other amp had two 4" speakers). Is there going to be some crazy crossover due to the different speakers that might wreak havoc with my setup, please advise and thanks!

All the amplifiers you seem to be using for testing have tone controls which affect the response of any speaker, a flat response amp is required to test speaker response.

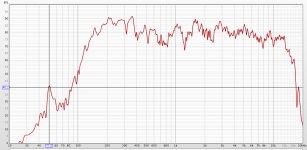

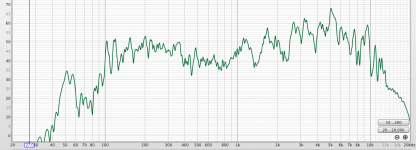

The latest SPL picture you posted does not look anything like what one could reasonably expect as a frequency response of a guitar sized offset horn.

The vertical scale is too large to see what is going on (we don't need to see -250 dB..), and the low frequency response makes no sense- from 6Hz to 60Hz is near the same level as 80Hz to 800Hz.

Art

FR updated to show closer detail Art, yes I need to check on the lack of high low drop off, not sure what happened there. Like the A/B switch idea, easy to do will try. I almost always end up turning all my amp tone controls down, now that the sealed horns are doing the job, yes great horn mids and lows for "warmth", no doubt. Would love to see any recommendations for a battery powered class D amp that might be an improvement. Looking for twenty watts per channel. Need to do the magnetic and piezo pickups together, I think that would be promising, have not combined yet, same great sound from the horns, but a little more clean power.

I am also considering some sliding port covers, would be easy to do with a simple hand adjustment. Start sealed, sounds great, but maybe open the ports to one's liking for certain songs. The goal is to not allow these ports to be open always (not good), but just when needed on more rocking songs, like when playing leads, and want to get some controlled feedback and crunch. I think of it as an acoustic volume/tone control, very unusual, but can do with this design. Thanks much guys, keep it coming!

I am also considering some sliding port covers, would be easy to do with a simple hand adjustment. Start sealed, sounds great, but maybe open the ports to one's liking for certain songs. The goal is to not allow these ports to be open always (not good), but just when needed on more rocking songs, like when playing leads, and want to get some controlled feedback and crunch. I think of it as an acoustic volume/tone control, very unusual, but can do with this design. Thanks much guys, keep it coming!

Attachments

Joe,FR updated to show closer detail Art, yes I need to check on the lack of high low drop off, not sure what happened there. L

Blowing up a portion of a squiggly line is not an "update", the response is still useless, your cabinet does not have a frequency response like pictured.

If you want to show us an actual frequency response, you need to first learn how to measure it.

Can't say what would be an improved amplifier without seeing what the limits of the amp(s) you are using are.

Cheers,

Art

Ouch! 🤣 Not sure why the response does not show low and high drop off, need to spend some more time on that, many options, I will figure it out.

That said the response between 100 Hz and 1000 Hz looks much better. Art, do you think this part is accurate even without the drop off?

I added the detail because I really don't like following the 10 dB lines over all the time, a bit of a visual help for me. Plus the FR is +/- 5 dB mostly, and of course some +/- 10 Db and peak +/- 15 dB with sealed horns. Unsealed horns back in the day where actually +/- 30 dB peak, so much better.

I did set/assemble the Folded Horn guitar neck, sanded the old school guitar top kerfing and glued/clamped the bottom kerfing, so good progress, much to do. Plus now that the horns sound so good, I am playing a lot more! Back to work, probs will not be able to mess with REW until this weekend, stay tuned and thanks! Joe

That said the response between 100 Hz and 1000 Hz looks much better. Art, do you think this part is accurate even without the drop off?

I added the detail because I really don't like following the 10 dB lines over all the time, a bit of a visual help for me. Plus the FR is +/- 5 dB mostly, and of course some +/- 10 Db and peak +/- 15 dB with sealed horns. Unsealed horns back in the day where actually +/- 30 dB peak, so much better.

I did set/assemble the Folded Horn guitar neck, sanded the old school guitar top kerfing and glued/clamped the bottom kerfing, so good progress, much to do. Plus now that the horns sound so good, I am playing a lot more! Back to work, probs will not be able to mess with REW until this weekend, stay tuned and thanks! Joe

No, the signal to noise ratio is too low to trust any part of the measurement.Art, do you think this part is accurate even without the drop off?

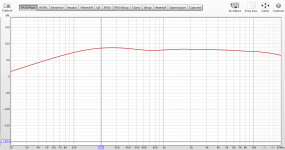

As an example, this is my iMac speaker using the internal mic for testing, 1/48 smoothing:

The spike at 51Hz is from an outdoor air conditioner.

If viewed with 1/1 smoothing on the scale you use, the 51Hz spike or upper peaks and dips can't be seen using the same data:

With the drive level level lowered 30 dB, the response looks like the low and high range has increased due to the reduced signal to noise ratio from the background noise:

Joe, it would be interesting to see what your speaker's response actually is with or without porting, tested under valid conditions.

Art

- Home

- Live Sound

- Instruments and Amps

- Folded Horn Acoustic Guitar Patent # 10,777,172