Maybe it's worth mentioning that only mundorf has a foil cap 220uF limited to 250V. Other than that only ClarityCap they go up to 600V iirc

The other ones from brands like Kemet are meant for industrial and automotive use. Maybe they work great for audio aswell but they didn't get manufactured with that application in mind.

The other ones from brands like Kemet are meant for industrial and automotive use. Maybe they work great for audio aswell but they didn't get manufactured with that application in mind.

For me, I just don't know for sure if there would be audible differences that I could hear.

I very much liked the sound of a diy tube amplifier with 2 x EL5 ul pp in which I used a solid state bridge rectifier, a 25 uF motor run capacitor as the first capacitor, followed by a 10 H choke, and a 100 uF electrolytic in the power supplies (the power stage of each channel had its own power supply).

I also very much like the sound of my diy headphones amplifier (Aikido with ECC40 and E182CC per channel, and a regulated power supply using 5 tubes) in which I only used one 1000 uF electrolytic per channel for by-passing the cathode resistor of the output stage, and only some electrolytics for the dc-filament supply for the tubes and for elevating some of the filament supplies. But I just don't know how this amplifier would sound when I would have used (more) electrolytics in the power supply.

So to be honest, for me it is more a matter of 'better safe than sorry' and 'it won't hurt either' that I now tend to use oil or other capacitors instead of electrolytics in power supplies. Some years ago somebody gave me a crate full of all kinds of oil and MKP capacitors so I have a good reason to use those anyway.

By the way: I do always use electrolytics in the power supplies of my diy guitar amps. Using foil or oil capacitors in the power supplies of guitar amps seems over the top to me.

I very much liked the sound of a diy tube amplifier with 2 x EL5 ul pp in which I used a solid state bridge rectifier, a 25 uF motor run capacitor as the first capacitor, followed by a 10 H choke, and a 100 uF electrolytic in the power supplies (the power stage of each channel had its own power supply).

I also very much like the sound of my diy headphones amplifier (Aikido with ECC40 and E182CC per channel, and a regulated power supply using 5 tubes) in which I only used one 1000 uF electrolytic per channel for by-passing the cathode resistor of the output stage, and only some electrolytics for the dc-filament supply for the tubes and for elevating some of the filament supplies. But I just don't know how this amplifier would sound when I would have used (more) electrolytics in the power supply.

So to be honest, for me it is more a matter of 'better safe than sorry' and 'it won't hurt either' that I now tend to use oil or other capacitors instead of electrolytics in power supplies. Some years ago somebody gave me a crate full of all kinds of oil and MKP capacitors so I have a good reason to use those anyway.

By the way: I do always use electrolytics in the power supplies of my diy guitar amps. Using foil or oil capacitors in the power supplies of guitar amps seems over the top to me.

I found this article hereIf they are magical, as many seem to thing, why didn't Quad, Leak and many more renown HiFi designer incorporate them in their designs I wonder.

A good quality electrolytic or two and decent mains borne interference reduction, is all that is required.

http://aeaaudio.com/audiophile-quality-capacitors-going-beyond-the-simple-re-cap/

"Electrolytics used for cathode bypass must be replaced or bypassed with good quality polyethylene types for the best sound—even though they can be rather expensive. Very few amp restorations, or even newly designed tube amps for that matter, take this critical step to improve performance."

"We also add one or more high quality, high capacitance polypropylene types in parallel, allowing higher frequencies in the return signal path to bypass the electrolytics, thus avoiding the problem."

This is interesting because the guy that built my amplifier also recommended me to add some foils to the power supply caps in parallel .

Still interesting. My WAD6550 push pull was designed by Andy Grove. It uses two U54 rectifiers and feeds into 50uf/2.5L/50uF filter. I wonder if using 2x5U4 allows a input bigger cap?Nothing, that was just an example. EZ81, 5Y3 etc etc are similar but the GZ34 can stand a higher capacitance on the cathode than say a 5Y3 or GZ37 or U54 as the latter can only use a 4uF tank capacitor. Have a look at the valve data sheets.

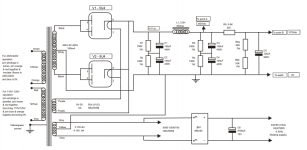

Attachments

Your schematic shows 5U4. The maximum capacitance is 32 uF for one. So the 50 uF for 2 x 5U4 in this amplifier seems in line with this maximum (2 x 32 uF = 64 uF).

This datasheet for the U54 doesn't state a maximum value for capacitance. It only states 4 uF as "typical operation".

U54 Marconi

This datasheet for the U54 doesn't state a maximum value for capacitance. It only states 4 uF as "typical operation".

U54 Marconi

Last edited:

None of those are SE, and polys cost a lot more than elco. Cost plays a big role in moderately priced gear like you mention.If they are magical, as many seem to thing, why didn't Quad, Leak and many more renown HiFi designer incorporate them in their designs I wonder.

dave

Lots of BS there with no proof. Typical audiophool site pretending to be scientific.I found this article here

http://aeaaudio.com/audiophile-quality-capacitors-going-beyond-the-simple-re-cap/

"Electrolytics used for cathode bypass must be replaced or bypassed with good quality polyethylene types for the best sound—even though they can be rather expensive. Very few amp restorations, or even newly designed tube amps for that matter, take this critical step to improve performance."

"We also add one or more high quality, high capacitance polypropylene types in parallel, allowing higher frequencies in the return signal path to bypass the electrolytics, thus avoiding the problem."

This is interesting because the guy that built my amplifier also recommended me to add some foils to the power supply caps in parallel .

What? Did you read their credentials?Lots of BS there with no proof. Typical audiophool site pretending to be scientific.

No I read the Bs.

"Turning your living room into a listening room… one especially designed for tube amplifiers."

" your living room needs to absorb as much sound as possible. It needs to be acoustically dead."

"Ours is the only measurement system in existence that actually reveals how an amplifier performs in the real world–"

"It’s not surprising that an enormous improvement occurs, since the effects of changing even a single capacitor from one type to another can be heard"

"As for performance, even the highest sampling rate digital recordings still fall a little short of the best vinyl for the ultimate in sound quality"

"Add up their generally superior sound quality, low relative cost, constantly increasing value, plus unique retro décor appeal— and you have arguably the best value in today’s high-end audio market"

There are a lot of good points in the article but there are also the usuall audiophool nonsense.

"Turning your living room into a listening room… one especially designed for tube amplifiers."

" your living room needs to absorb as much sound as possible. It needs to be acoustically dead."

"Ours is the only measurement system in existence that actually reveals how an amplifier performs in the real world–"

"It’s not surprising that an enormous improvement occurs, since the effects of changing even a single capacitor from one type to another can be heard"

"As for performance, even the highest sampling rate digital recordings still fall a little short of the best vinyl for the ultimate in sound quality"

"Add up their generally superior sound quality, low relative cost, constantly increasing value, plus unique retro décor appeal— and you have arguably the best value in today’s high-end audio market"

There are a lot of good points in the article but there are also the usuall audiophool nonsense.

Okay you have a point there, also they wrote an article about tubes where they said that tubes don't have a sound signature, that's bs.No I read the Bs.

"Turning your living room into a listening room… one especially designed for tube amplifiers."

" your living room needs to absorb as much sound as possible. It needs to be acoustically dead."

"Ours is the only measurement system in existence that actually reveals how an amplifier performs in the real world–"

"It’s not surprising that an enormous improvement occurs, since the effects of changing even a single capacitor from one type to another can be heard"

"As for performance, even the highest sampling rate digital recordings still fall a little short of the best vinyl for the ultimate in sound quality"

"Add up their generally superior sound quality, low relative cost, constantly increasing value, plus unique retro décor appeal— and you have arguably the best value in today’s high-end audio market"

There are a lot of good points in the article but there are also the usuall audiophool nonsense.

But on the other hand what irritates me that audiophile always want "scientific proof" and measurements which they can't even interpret correctly. If I buy a bottle of wine and I think it was so much better than the other bottle I bought last week from a different wine maker at a different price, nobody is gonna tell me "you have no proof" or asking me for measurements if I tell friends about it.

For some people everything is audiophoolery except their $100 chi-fi amp and dac and their $6000 Susvara headphones

For the OPs 220uf cap requirement, there would imho be no benefit related to ripple current or hum/esr. In reality an e-cap may have tangibly better total equipment hum performance due to smaller charging circuit loop layout.

Tubes dont have a sound signature they have a transfer function and the circuit there in is more important. If a device is supposed to improve something by breaking Ohms law would you believe it, or are you a science denier? And why do you think "they" cant interpret the measurements. And different wines do taste different while different cables (and caps in most cases) don't sound different. Dumb comparison.Okay you have a point there, also they wrote an article about tubes where they said that tubes don't have a sound signature, that's bs.

But on the other hand what irritates me that audiophile always want "scientific proof" and measurements which they can't even interpret correctly. If I buy a bottle of wine and I think it was so much better than the other bottle I bought last week from a different wine maker at a different price, nobody is gonna tell me "you have no proof" or asking me for measurements if I tell friends about it.

Last edited:

The point of power supply caps is to maintain a low power supply output impedance across the range of frequencies in which the amplifier is used. This is the same as for the power supply of any amplifier.

The solution which is commonly seen is to parallel several different caps. Electrolytics are almost a necessity for maintaining a low output impedance at low frequencies, since you need quite a lot of stored energy in this frequency range.

Electrolytics do tend to be less ideal at higher frequencies, and some are better than others. This can be compensated for by paralleling a smaller-value film cap. That smaller value film cap should ideally be located quite close to the output devices.

For those who will inevitably ask, regulation doesn't really solve the problem, because most regulator circuits don't have a flat output impedance across a very wide range of frequencies. Take a $5,000 Keysight power supply and hit it with a fast, pulsed load and you'll see what I'm talking about. The regulator takes some time to compensate for the change in load (that time varies based on the type of power supply and how it's compensated).

For tube amps that I build, I typically use some pretty chunky electrolytics for the bulk filtering. I usually oversize these a bit, since it allows one to get away with a somewhat squishier plate transformer without any real impact on sonics. I then usually put a few smaller value film caps (say 10 uF) right by the output tubes.

The effectiveness of this is easy enough to test by hitting the power supply with a pulsed current and watching how it affects the rail voltage with a scope.

The solution which is commonly seen is to parallel several different caps. Electrolytics are almost a necessity for maintaining a low output impedance at low frequencies, since you need quite a lot of stored energy in this frequency range.

Electrolytics do tend to be less ideal at higher frequencies, and some are better than others. This can be compensated for by paralleling a smaller-value film cap. That smaller value film cap should ideally be located quite close to the output devices.

For those who will inevitably ask, regulation doesn't really solve the problem, because most regulator circuits don't have a flat output impedance across a very wide range of frequencies. Take a $5,000 Keysight power supply and hit it with a fast, pulsed load and you'll see what I'm talking about. The regulator takes some time to compensate for the change in load (that time varies based on the type of power supply and how it's compensated).

For tube amps that I build, I typically use some pretty chunky electrolytics for the bulk filtering. I usually oversize these a bit, since it allows one to get away with a somewhat squishier plate transformer without any real impact on sonics. I then usually put a few smaller value film caps (say 10 uF) right by the output tubes.

The effectiveness of this is easy enough to test by hitting the power supply with a pulsed current and watching how it affects the rail voltage with a scope.

That's just ********, sorry. Try to run a Russian Svetlana Rectifier in your amp and then change to a Mullard Blackburn, the difference will be day and night. Just like there will be a day and night difference if you use a Reflektor E88CC as input tube and then change to a Siemens E88CCa.Tubes dont have a sound signature they have a transfer function and the circuit there in is more important.

Sometimes audiophiles should stop theoricrafting or believe in wannabe science and just try out things for themselves.

Just try out 2 different tubes and then come back, and don't tell me you did, because in case you did you should go visit an audiologist.

I tell you what is science, differences in the dielectric material in a capacitor affect the sound. What also is science, is that you want as low ESR as possible.

Last edited:

The point of power supply caps is to maintain a low power supply output impedance across the range of frequencies in which the amplifier is used. This is the same as for the power supply of any amplifier.

The solution which is commonly seen is to parallel several different caps. Electrolytics are almost a necessity for maintaining a low output impedance at low frequencies, since you need quite a lot of stored energy in this frequency range.

Electrolytics do tend to be less ideal at higher frequencies, and some are better than others. This can be compensated for by paralleling a smaller-value film cap. That smaller value film cap should ideally be located quite close to the output devices.

For those who will inevitably ask, regulation doesn't really solve the problem, because most regulator circuits don't have a flat output impedance across a very wide range of frequencies. Take a $5,000 Keysight power supply and hit it with a fast, pulsed load and you'll see what I'm talking about. The regulator takes some time to compensate for the change in load (that time varies based on the type of power supply and how it's compensated).

For tube amps that I build, I typically use some pretty chunky electrolytics for the bulk filtering. I usually oversize these a bit, since it allows one to get away with a somewhat squishier plate transformer without any real impact on sonics. I then usually put a few smaller value film caps (say 10 uF) right by the output tubes.

The effectiveness of this is easy enough to test by hitting the power supply with a pulsed current and watching how it affects the rail voltage with a scope.

Well not really, you don't need electrolytics to store quite a lot of energy. I mean, it depends on the design on the amplifier, how much capacitance your capacitors need. But nowadays, you can find foil capacitors up to 220uF maybe even higher, problem is they cost 10x as much and take up much more space. That's why only few people use it let alone tried it, for most people it's just not worth to spend so much for the expected performance gain.

There are two perfectly plausible reasons those tubes sound different.That's just ********, sorry. Try to run a Russian Svetlana Rectifier in your amp and then change to a Mullard Blackburn, the difference will be day and night. Just like there will be a day and night difference if you use a Reflektor E88CC as input tube and then change to a Siemens E88CCa.

Sometimes audiophiles should stop theoricrafting or believe in wannabe science and just try out things for themselves.

Just try out 2 different tubes and then come back, and don't tell me you did, because in case you did you should go visit an audiologist.

I tell you what is science, differences in the dielectric material in a capacitor affect the sound.

1) Just because they both say ECC88 doesn't mean they have the same electrical characteristics. This is easy enough to measure, and many have taken the time to do so. Tube characteristics vary quite disturbingly from manufacturer to manufacturer.

2) You've tricked yourself into believing that you hear something even when it isn't there. This is easy to do. I've tricked myself into thinking that my push-pull 6L6 amp is my MC650 by mixing up cables during testing.

I said they're almost a necessity. You can store a lot of energy with film caps, but it's expensive and takes up a lot of space. For the space and cost of a 220 uF film cap, you can achieve better results by paralleling electrolytics and film caps.Well not really, you don't need electrolytics to store quite a lot of energy. I mean, it depends on the design on the amplifier, how much capacitance your capacitors need. But nowadays, you can find foil capacitors up to 220uF maybe even higher, problem is they cost 10x as much and take up much more space. That's why only few people use it let alone tried it, for most people it's just not worth to spend so much for the expected performance gain.

Where film caps, oil-filled caps, etc. are really great is in durability. Electrolytics don't like huge pulse currents, they don't like having their voltage rating pushed, and they don't like heat.

Not really.Is there no problem when // caps such those technologies having huge esr difference ?

- Home

- Amplifiers

- Power Supplies

- Foil vs electrolytic capacitors for tube amplifier power supplies