Hi X, just wanna say thanks for introducing foam medium, please don't flame me about calculation, I just made this for fun. portable light speaker with a tiny amp. cheers jeff.

http://s29.postimg.org/mlfhwt7bb/IMG_1761_1.jpg

http://s14.postimg.org/otdh3oe8x/IMG_1762_1.jpg

http://s28.postimg.org/v5saaijp9/IMG_1760.jpg

http://s29.postimg.org/mlfhwt7bb/IMG_1761_1.jpg

http://s14.postimg.org/otdh3oe8x/IMG_1762_1.jpg

http://s28.postimg.org/v5saaijp9/IMG_1760.jpg

interestingly they sound quite good, it's driven by PAM8803, battery life is insane, I use a spare mobile phone battery 3.7v li-on 1200mah. last about a week, till recharge. speaker ripped off and old imac, I figure if apple uses these speaker, must be decent enough.

still looking for a nice 1" FRDriver. work to do : add BT module, add bigger volume button. at the moment, i have to poke on the pcb for volume, theres a mini tactile button on the pcb to control up & down volume. but i love the weight it's soo light (thanks to u).

still looking for a nice 1" FRDriver. work to do : add BT module, add bigger volume button. at the moment, i have to poke on the pcb for volume, theres a mini tactile button on the pcb to control up & down volume. but i love the weight it's soo light (thanks to u).

Try the Sure TPA3110D2 amplifier ($10 at PE). Great battery life on that too but requires 6 volts I think. Sounds really good though. If you go with BT, beware of the ground loop noise problem that requires an isolated DC-DC converter. Look in class D forum - several threads there discuss this.

I do own the Sure TPA3110D2. its too to big fit inside the enclosure, would be awesome though.

here's the size comparison, TDA3110D2, YDA148 & PAM8803 (the amp used)

here's the size comparison, TDA3110D2, YDA148 & PAM8803 (the amp used)

An externally hosted image should be here but it was not working when we last tested it.

Last edited:

Jfresh,

Ok, you win the prize for smallest foam speaker - I did not realize it was so small. How do you cut that bead board foam so cleanly? It looks like it was laser/CNC cut?

Great looking build with the plexiglass. Someone really should do that with the Cornu.

Ok, you win the prize for smallest foam speaker - I did not realize it was so small. How do you cut that bead board foam so cleanly? It looks like it was laser/CNC cut?

Great looking build with the plexiglass. Someone really should do that with the Cornu.

X, thanks for the compliment. it was my challenge to make the smallest horn, even so small horn never disappoint. i do own a tiny cnc not laser. the cut is not as clean as you think, it would be perfect with laser.

the board is not actually foam core, just ordinary junk foam from packaging, i made a foam slicer from an old scanner, nothing fancy hot wire & arduino as controller.

yes, it could work with cornu.

the board is not actually foam core, just ordinary junk foam from packaging, i made a foam slicer from an old scanner, nothing fancy hot wire & arduino as controller.

yes, it could work with cornu.

You made your own CNC with Arduino - very impressive! I bet you could make a 3d printer with same technique. I am thinking a hot melt glue gun could be used to melt abs rod stock to lay down layers and print a horn. It could have very complicated 3d channels.

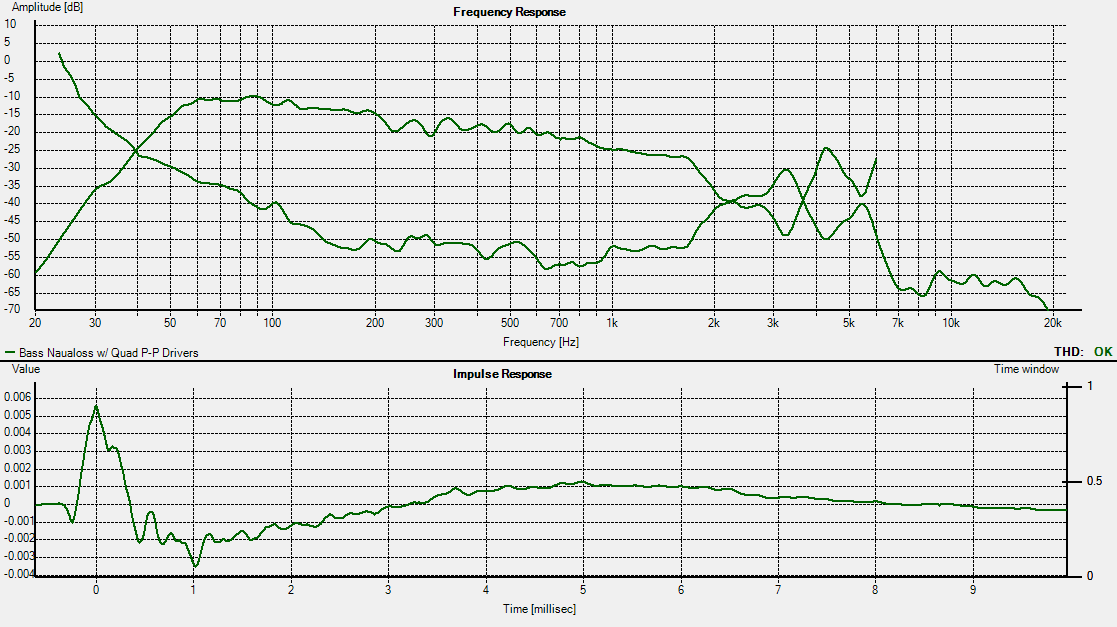

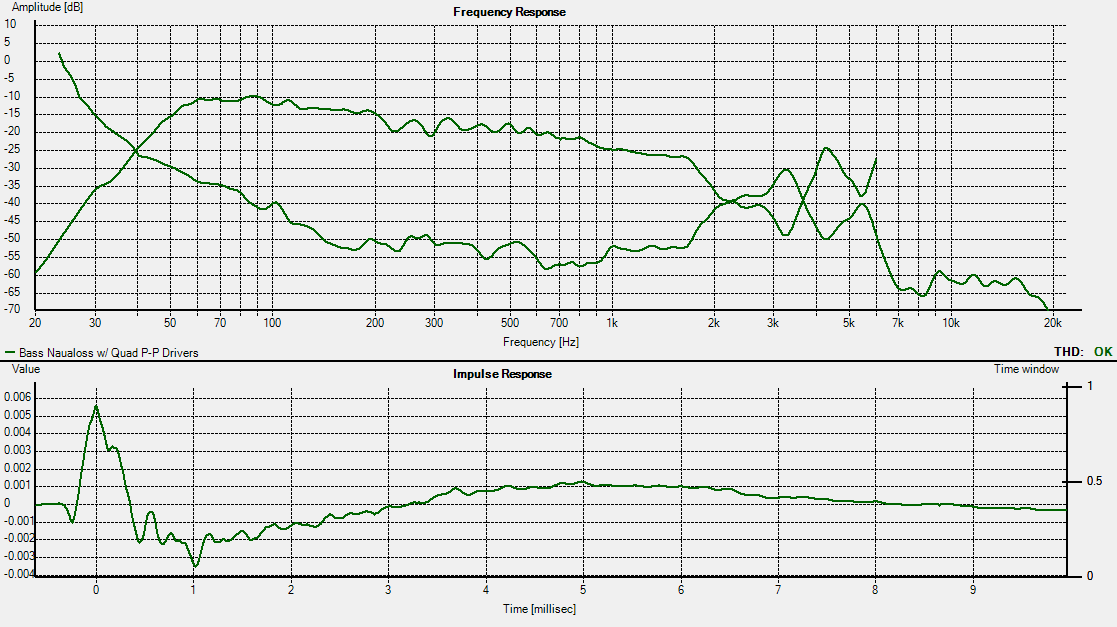

Foam Core Sealed Push-Pull Quad Driver Sub

In case you have not seen this - This is my biggest foam core speaker to date. Each side uses a full sheet and the face where the 4 drivers are mounted uses 3 layers. It sounds really nice with clean tight bass. Extension is only 50 Hz but it reaches clear up to anywhere you want to cross over. Very fun build and measures very well.

http://www.diyaudio.com/forums/full-range/247598-nautaloss-ref-monitor-6.html#post3750186

In case you have not seen this - This is my biggest foam core speaker to date. Each side uses a full sheet and the face where the 4 drivers are mounted uses 3 layers. It sounds really nice with clean tight bass. Extension is only 50 Hz but it reaches clear up to anywhere you want to cross over. Very fun build and measures very well.

http://www.diyaudio.com/forums/full-range/247598-nautaloss-ref-monitor-6.html#post3750186

XPS foam & FC MLTL with PE 6.5 in Polycone driver - Build #1

Starting the next build - my first straight MLTL (aka, monkey coffin) with the wonderful 'Buyout' 6.5 in polycone driver from Parts Express. If you did not get any of these when they were on sale for $4.88, you should have, because they sound great. They are high Qts, but that is perfect for FC projects and they get deeper bass extension in MLTL designs than low Qts drivers. I have measured these in an OB and they are flat from 50 Hz to 2kHz with breakup starting at 3 kHz. They actually sound quite nice on their own but wonderful with a cheap piezo supertweeter - no XO needed.

This design was first optimized for bass extension and flat response first, then modified to fit with available conservation of materials. This is my first project with expanded polystyrene (XPS) foam sheathing insulation from HD. It is 1 in thick - very uniform, strong, and light. Cuts cleanly like butter with a new utility blade. I will use it for the sides and the front, back, tops and bottoms will be dollar store FC. The design ended up at 47 in tall, 8 in wide, 12 in deep with a 2 in x 3.5 in x 3.0 in Long port at 6 in from bottom. The driver is 9 in from the top. This design is predicted to have an average of 90 dB and be able to reach about 30 Hz at -3dB @2.83v at 1m.

For the build, I lined the areas surrounding the driver with open cell foam and added some eggcrate foam at the bottom to prevent reflections. So far I got to the capping operation but ran out of hot melt glue which is needed to tack the sides while the PVA dries. Another trip to the store for hot melt will be needed soon.

Starting the next build - my first straight MLTL (aka, monkey coffin) with the wonderful 'Buyout' 6.5 in polycone driver from Parts Express. If you did not get any of these when they were on sale for $4.88, you should have, because they sound great. They are high Qts, but that is perfect for FC projects and they get deeper bass extension in MLTL designs than low Qts drivers. I have measured these in an OB and they are flat from 50 Hz to 2kHz with breakup starting at 3 kHz. They actually sound quite nice on their own but wonderful with a cheap piezo supertweeter - no XO needed.

This design was first optimized for bass extension and flat response first, then modified to fit with available conservation of materials. This is my first project with expanded polystyrene (XPS) foam sheathing insulation from HD. It is 1 in thick - very uniform, strong, and light. Cuts cleanly like butter with a new utility blade. I will use it for the sides and the front, back, tops and bottoms will be dollar store FC. The design ended up at 47 in tall, 8 in wide, 12 in deep with a 2 in x 3.5 in x 3.0 in Long port at 6 in from bottom. The driver is 9 in from the top. This design is predicted to have an average of 90 dB and be able to reach about 30 Hz at -3dB @2.83v at 1m.

For the build, I lined the areas surrounding the driver with open cell foam and added some eggcrate foam at the bottom to prevent reflections. So far I got to the capping operation but ran out of hot melt glue which is needed to tack the sides while the PVA dries. Another trip to the store for hot melt will be needed soon.

Attachments

I think it's time you quit your day job and opened up a chain of walk-in DIY FC speaker stores.😀 😀 😀

FC Labs

Bob, thanks and happy holidays!

Yes, and I will call it FC Labs... 🙂

The only place you can buy a great sounding full-size speaker that you can pick up with a pinkie finger.

I think it's time you quit your day job and opened up a chain of walk-in DIY FC speaker stores.😀 😀 😀

Bob, thanks and happy holidays!

Yes, and I will call it FC Labs... 🙂

The only place you can buy a great sounding full-size speaker that you can pick up with a pinkie finger.

Attachments

Your wife must be a angel !! Most likely an offspring of Gabriel 😀

Yes, she is, and I am a very lucky man! 🙂

Turk182 pointed out that there were some missing family members in the holiday photo. Still missing 4 sets...

XPS foam & FC MLTL with PE 6.5 in Polycone driver - Build #2

After 6 hrs for the PVA to dry, I installed the driver and a piezo tweeter flush mounted. It is a lot more stable standing upright than I thought it would be given that the majority of the weight is the driver up front. It is a big speaker standing nearly 4 ft tall and 10 wide x 12 in deep. Initial listening impressions are good from bass extension (well into circa mid 30 Hz is my guess from listening to it by ear) but a bit lacking in amplitude of the bass - I think I have too much stuffing. I will reduce stuffing in the morning and listen again. The Realistic piezo tweeter seems to be integrating nicely with the woofer though. If I recall, these units are 3 kHz and above - which is a nice crossover with the woofer. Measurements to come after stuffing adjustment.

After 6 hrs for the PVA to dry, I installed the driver and a piezo tweeter flush mounted. It is a lot more stable standing upright than I thought it would be given that the majority of the weight is the driver up front. It is a big speaker standing nearly 4 ft tall and 10 wide x 12 in deep. Initial listening impressions are good from bass extension (well into circa mid 30 Hz is my guess from listening to it by ear) but a bit lacking in amplitude of the bass - I think I have too much stuffing. I will reduce stuffing in the morning and listen again. The Realistic piezo tweeter seems to be integrating nicely with the woofer though. If I recall, these units are 3 kHz and above - which is a nice crossover with the woofer. Measurements to come after stuffing adjustment.

Attachments

- Home

- Loudspeakers

- Full Range

- Foam Core Board Speaker Enclosures?