I have several large sheets of foamcore and a few pair of little fullrange drivers, like Fountek and Vifa. Might make a fun weekend project.

Cool clips, thanks. That's the mini? Certainly no lack of lower mids, and a good tonal balance.

Might make a fun weekend project.

And we understand you have some take them or lose them days off?

dave

Yes, that is the all foam core mini. Keep in mind that it is flat on the floor, weighs as much as air and some paper, and has a 3.5 inch driver. It sounds even better when properly installed on a wall at proper ear height. I was going to say "hung" on a wall but Cal gave grief the last time I used that choice of word.

Thanks for listening..

Thanks for listening..

I have several large sheets of foamcore and a few pair of little fullrange drivers, like Fountek and Vifa. Might make a fun weekend project.

It is a perfect weekend project, especially now that you have the foam and drivers. Just cut and glue now... Which Vifa driver do you have?

I have a pair of the little Vifa TC9FD18-08. Suitable for the 20" Cornu, perhaps?

That is what I used for the 20 in mini and what you heard in the clips. That is a great little driver.

I wish I bought them by the dozen...

Yes, scale the plan from Planet10. I used 2 and 3/8ths inch but Surface Tension used 2.5 in and it worked too. My 20 incher, I actually hand drew my curves based on plan from Sebastien and I added sharp corners internally.

Cool, thanks. Where did you end up on stuffing?

I have 4 slabs of 38"x7' foamcore gathering dust. Might as well put them to good use.

I have 4 slabs of 38"x7' foamcore gathering dust. Might as well put them to good use.

Stuffed main driver cavity pretty densely, and loosely stuffed about 2 to 3 inches down the throat of each channel. You have to experiment with this. Surface Tension stuffed the mouths inwards with half of a pillow and got good results that way. According to Cal it makes a big difference how much. I got lucky first time.

Update -

To make a long story short, Liquid Nails is probably not the best adhesive for this - the working time is too short. If they make something similar with a longer working time it would probably be fine.

The perfect thing would be a water-based (or at least water clean-up) construction adhesive with a 20 min working time. I have no idea if such a thing exists.

I may wind up making a third one of these -- at every step the second one is much nicer because I figured out how to do it on the first one... Which is the usual story of DIY.

Then again, I won't know until the glue truly sets and the speaker mounted. It might be fantastic, just a bit rough looking. I'm eager to find out. 🙂 🙂 🙂

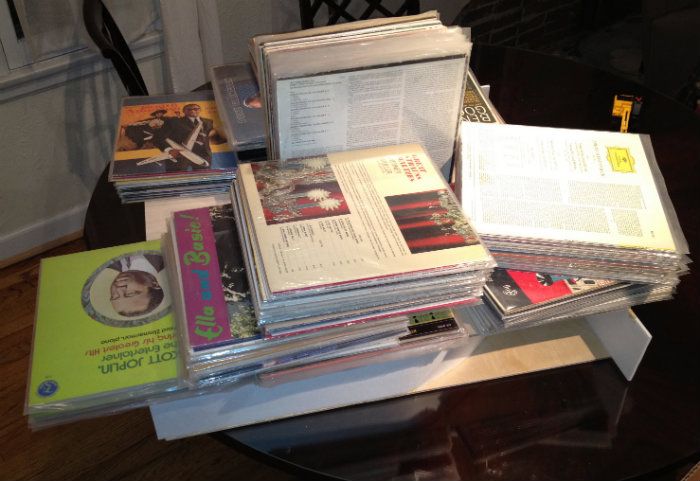

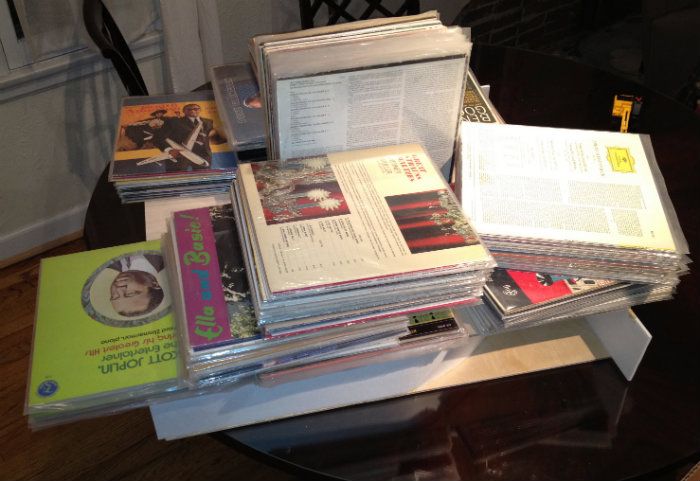

Anyway, here is a humorous photo of my 'clamps' - about 60lb (27kg) of paper and cardboard sleeves containing molded petrochemical. It actually worked well. 😀

To make a long story short, Liquid Nails is probably not the best adhesive for this - the working time is too short. If they make something similar with a longer working time it would probably be fine.

The perfect thing would be a water-based (or at least water clean-up) construction adhesive with a 20 min working time. I have no idea if such a thing exists.

I may wind up making a third one of these -- at every step the second one is much nicer because I figured out how to do it on the first one... Which is the usual story of DIY.

Then again, I won't know until the glue truly sets and the speaker mounted. It might be fantastic, just a bit rough looking. I'm eager to find out. 🙂 🙂 🙂

Anyway, here is a humorous photo of my 'clamps' - about 60lb (27kg) of paper and cardboard sleeves containing molded petrochemical. It actually worked well. 😀

The 20 min water based glue might just be Gorilla glue that Cochleus suggested. I have the same picture of books and dumbbells stacked on for a clamp too. It's amazing how much weight that foam can take in straight down compression. You are almost there....

Both these glues fits my stated requirements -- I think I will try the Gorilla.

Gorilla Glue - Wood Glue

http://www.shoplet.com/Scotch-Quick-Drying-Tacky-Glue/MMM6052B/spdv?ci_src=17588969&ci_sku=MMM6052B

Gorilla Glue - Wood Glue

http://www.shoplet.com/Scotch-Quick-Drying-Tacky-Glue/MMM6052B/spdv?ci_src=17588969&ci_sku=MMM6052B

Let me ask the question another way. I have the TC9FD18-08 but from PE. Are you all suggesting the 20" is closer to optimum for that driver compared to the full 30"?

BTW, Goop has become my go to adhesive for almost all my projects. It grabs and seals almost everything, It comes in a variety of formulas.

BTW, Goop has become my go to adhesive for almost all my projects. It grabs and seals almost everything, It comes in a variety of formulas.

Last edited:

Let me ask the question another way. I have the TC9FD18-08 but from PE. Are you all suggesting the 20" is closer to optimum for that driver compared to the full 30"?

BTW, Goop has become my go to adhesive for almost all my projects. It grabs and seals almost everything, It comes in a variety of formulas.

Bob,

My main reason for making it 20 in was to fit standard foam core sheet sizes, however it is also true that the 30 in size will have a horn tuning freq way too low compared to the vifa's fs of 120 Hz. It may still work but I think the full size is suited for 4 or 5 in drivers.

Thanks, That's much more convent and more efficient with the standard 2 & 4 ft. widths for plywood.

Bob,

If you are going to use plywood in 2x4 ft sheets, a 24 incher will probably work with the Vifa tc9fd, or a 4 incher like a Tang Band.

If you are going to use plywood in 2x4 ft sheets, a 24 incher will probably work with the Vifa tc9fd, or a 4 incher like a Tang Band.

- Home

- Loudspeakers

- Full Range

- Foam Core Board Speaker Enclosures?