It takes about 1.25" of MDF to be as stiff as 18mm quality ply.

So that's 31.75mm of mdf vs 18mm ply 😱

With 2 similar masses the less stiff one is the more easily energised.

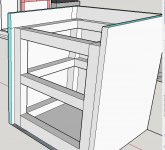

This is my final design, it's simple but effective I think... 2x2 lumber on every corner, without forgetting the middle part. Although they are not hardwood, this sticks (2x2 lumber) are pretty damn hard, which combined with 3/4 mdf, I think I will get more than enouugh Stiffness. What do you think about this? It's for a 12" and 2sf sealed enclosure box. I am going to use #10 4" screws and titebond 2 glue. The nice part about using 2x2 sticks, is that I wont screw any MDF edge, but only on their faces, close to the edge. I am also going to put double baffle and bottom. This will be a solid war tank he he.

Attachments

Last edited:

That's not going to do what you want- the most important parts are the cross-connection of panels in the middle of the enclosure- ribs are much less effective. Couple the ribs to each other through the middle of the enclosure and you'll have a much better bracing design.

That's not going to do what you want- the most important parts are the cross-connection of panels in the middle of the enclosure- ribs are much less effective. Couple the ribs to each other through the middle of the enclosure and you'll have a much better bracing design.

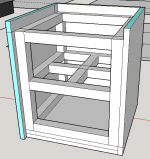

😱 Oh yeah, I think you are right, I actually going to put a cross connection in the middle part. 😀

Attachments

Last edited:

Better. Do the the top and bottom too, best if you can join all the bracing together. Also, slightly off-center for all the ribs/bracing is preferred. I don't see where the driver's going to mount- make sure that panel is really solid.

There's a message in that photo. It's in the upper left corner.a big holey brace is just the ticket !

Nice shorts by the way. 🙂

There's a message in that photo. It's in the upper left corner.

He did heed the message Cal....

Better. Do the the top and bottom too, best if you can join all the bracing together. Also, slightly off-center for all the ribs/bracing is preferred. I don't see where the driver's going to mount- make sure that panel is really solid.

Yeah, that's what I was thinking about, only problem may be the top, where is where the speaker seats, so I am only bracing everything, except top.

Yeah, too much bracing everywhere, but I am counting the space that the bracing is taking, so even with lots of bracing, I will have about 2 sf of free space.

Can I expect a high quality sound from this? because I am pointing this thing to be a high performance sealed enclosure, that's the reason i don't care if there's too much bracing or end with a heavy weight. I think all this I am doing, is perfect for sealed enclosures, don't you think?

Attachments

Vertical brace would be better to connect the top to the bottom in one continuous piece, neither should be mounted dead centre, and you can intersect them with a half-lap joint if you like.

I couldn't be more in agreement with all folks counselling use of high quality plywood for speaker cabinets, sub boxes included - several years ago I built a custom box for B&W 15" with two layers of 18mm BB and lots of bracing, including cradle to support woofer magnet- but if you're determined to use 1" MDF, you could eliminate all those 12 pieces around the perimeter by using dimple dadoes, and just to make Cal happy, I'll suggest you could also use smaller battens, either in support of dadoes, or by themselves.

Glue / lock miter or box joints on all 6 panels of a box with that material would be an absolute pain in the tukus, particularly if trying to fit any type of wooden bracing during assembly.

I would also recommend screws designed specifically for MDF - we use Robertson brand Lo-Roots- no larger than #8s required here- just be sure to properly pilot drill. Note than commercial trade wood screws often have nibs to aid in countersinking, it'll almost always add to your labour to rely on those alone. Always pilot with countersink into face of MDF to avoid bulging of surface- once the heat tempered face of the MDF is broken, the underlying fibrous core will expand and defragment - it's much easiest to fill a small "bullet" hole in this material than a defragmented/exploded crater.

I couldn't be more in agreement with all folks counselling use of high quality plywood for speaker cabinets, sub boxes included - several years ago I built a custom box for B&W 15" with two layers of 18mm BB and lots of bracing, including cradle to support woofer magnet- but if you're determined to use 1" MDF, you could eliminate all those 12 pieces around the perimeter by using dimple dadoes, and just to make Cal happy, I'll suggest you could also use smaller battens, either in support of dadoes, or by themselves.

Glue / lock miter or box joints on all 6 panels of a box with that material would be an absolute pain in the tukus, particularly if trying to fit any type of wooden bracing during assembly.

I would also recommend screws designed specifically for MDF - we use Robertson brand Lo-Roots- no larger than #8s required here- just be sure to properly pilot drill. Note than commercial trade wood screws often have nibs to aid in countersinking, it'll almost always add to your labour to rely on those alone. Always pilot with countersink into face of MDF to avoid bulging of surface- once the heat tempered face of the MDF is broken, the underlying fibrous core will expand and defragment - it's much easiest to fill a small "bullet" hole in this material than a defragmented/exploded crater.

Vertical brace would be better to connect the top to the bottom in one continuous piece, neithe...

Because of those battens, theres no need to worry about screwing the mdf, I can use any screw and the MDF won't split (any MDF will be connected together indirectly by the 2x2 wood.). The good thing of locating the mounting hole at the top, is that it creates enough space for very big speaker magnets, so that's an advantage. I think that I am finish with that last design I showed, any other thing may be a minimal factor. All the battens are going to be connected by 4" screws, and glued with titebond II. which is a pretty damn good glue. I won't get any trouble installing the bracing, I am planning first glueing, then drilling and screwing. I have the tools to make extremely accurate cuts, so I expect everything fitting right once i am mounting everything. 😱 I really appreciated the comments, next time will see to use plywood and compared. Thanks.

Last edited:

Pre-drill all screws into mdf and you should be good. I did that on my box with 2 inch deck screws and it worked well. My big box store had 3/4 inch square dowels I used those for battens and they worked very well. I recommend biscuits or dowels to ensure alignment. If not corner clamps are a must.

If the drawing is to scale, which I assume it is, the battens and bracing are going to consume a lot of volume. I like battens as they make keeping the enclosure square easier during the build, but the volume will inevitably increase to overall size of the enclosure.

If the drawing is to scale, which I assume it is, the battens and bracing are going to consume a lot of volume. I like battens as they make keeping the enclosure square easier during the build, but the volume will inevitably increase to overall size of the enclosure.

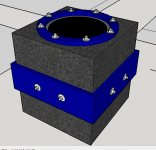

I didn't care too much about saving space or keeping light or compact, primordial factor was to build something suitable for high performance in sealed box. I am done cutting the MDF and all battens, now I am gluing the god crosses 😀 and preparing next steps. if everything keep going as good as so far, it should look like this. I forgot to mention that actually this design evolve some space saving, because of its verticallyti. In the middle I put a belt made of 3/4 wood, which adds even more strength in that part.

Attachments

Last edited:

The loss of interior volume will compromise your bottom end more than any benefits (esp from the many useless braces) can help the sound. Just use cross bracing dowels and toss the rest.

Been to the dry-goods store (or Parts Express) to buy stuffing?

Ben

Been to the dry-goods store (or Parts Express) to buy stuffing?

Ben

The loss of interior volume will compromise your bottom end more than any benefits (esp from the many useless braces) can help the sound. Just use cross bracing dowels and toss the rest.

Been to the dry-goods store (or Parts Express) to buy stuffing?

Ben

All the braces are useful, some of them are intended to act as a link between the MDF faces, so theres no need to screw the mdf edges, even if it was plywood, I would use those battens, they give extra support to corners. Interior volume without counting braces, is 2.3 sf, bracing is taking about 0.3 sf. At the bottom I have a MDF square, then it's reinforced with the battens, at the center I have another cross, linked with bottom cross, then it links with an external belt, which is not exactly light, that thing is massive, and at the top we have double baffle, the battens, and that circle that also should add more resistance. I don't understand if you say that my configuration is not ok, everything is necessary. The 3/8 bolts are for holding and adding aesthetics, I think look good. I was not sure if adding double bottom, considering that there seats a cross, maybe it was not necessary, and then we have the external belt, which is close to bottom and up side.

Last edited:

Does anyone know if wood glue actually works carpeting the enclosure?

Or a staple gun works nicely and is more forgiving of errors.

If carpet is interior, you don't want to stick it to the walls but to be spaced above.

Ben

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Subwoofers

- Five hole bracing for sealed enclosure.