Hey guys,

I'm not exactly new to audio stuff in general, but this is the first time I've had a go at designing/building crossovers from scratch and finishing off some smaller full range enclosures to an acceptable level.

Basics are:

*Tweeter - Seas 27TFF

*Mids - Seas P17RE/P

*Crossovers: first order, l-pad attenuated tweeter, custom wound inductor, zobel-correct mids - all designed using this guide. I actually struggled with some of the numbers I was getting from measurements on the spreadsheet so I worked everything out by hand - chances are I was just doing something wrong but a 400uf capacitor for the zobel seemed a bit crazy 😱

*Enclosure: 17mm structural ply with ample bracing, 7.5L, airtight sealed with silicone internally, truck bed liner painted (what I'm most disappointed with - the finish didn't 'set' in 8hrs so I installed everything while it was a bit tacky. Probably did a great job for sealing around the tweeter, but not so much for random dust that got stuck in the paint).

Overall, pretty damn happy with how they turned out and a massive improvement over what I replaced (AIWA 2 ways that I've used daily for almost 12 years - they don't sound amazing but I haven't had a single issue with this or the attached amplifier). Anything below 60Hz is a bit lacking, so with the next few sets I'm building I will go bigger to either twin sealed mids, or porting a single.

I have one last question about crossover design - when calculating values for parallel/series mids, do you just treat the measured impedance and stated voice coil inductance as being twice/double, or would you double up on zobel/lpf components (ie. separate resistors/caps and inductors for both)?

I'm not exactly new to audio stuff in general, but this is the first time I've had a go at designing/building crossovers from scratch and finishing off some smaller full range enclosures to an acceptable level.

Basics are:

*Tweeter - Seas 27TFF

*Mids - Seas P17RE/P

*Crossovers: first order, l-pad attenuated tweeter, custom wound inductor, zobel-correct mids - all designed using this guide. I actually struggled with some of the numbers I was getting from measurements on the spreadsheet so I worked everything out by hand - chances are I was just doing something wrong but a 400uf capacitor for the zobel seemed a bit crazy 😱

*Enclosure: 17mm structural ply with ample bracing, 7.5L, airtight sealed with silicone internally, truck bed liner painted (what I'm most disappointed with - the finish didn't 'set' in 8hrs so I installed everything while it was a bit tacky. Probably did a great job for sealing around the tweeter, but not so much for random dust that got stuck in the paint).

Overall, pretty damn happy with how they turned out and a massive improvement over what I replaced (AIWA 2 ways that I've used daily for almost 12 years - they don't sound amazing but I haven't had a single issue with this or the attached amplifier). Anything below 60Hz is a bit lacking, so with the next few sets I'm building I will go bigger to either twin sealed mids, or porting a single.

I have one last question about crossover design - when calculating values for parallel/series mids, do you just treat the measured impedance and stated voice coil inductance as being twice/double, or would you double up on zobel/lpf components (ie. separate resistors/caps and inductors for both)?

Last edited:

Hi,

FWIW the ESP article is a terrible guide to doing x/o's properly,

but a tour de force in describing some of the theory you do need.

The theory is fine, but not enough, for most practical examples.

The approach is too electrical, and not enough acoustics by far.

The theory you do need, look at designs at : Zaphaudio.com

rgds, sreten.

FWIW the ESP article is a terrible guide to doing x/o's properly,

but a tour de force in describing some of the theory you do need.

The theory is fine, but not enough, for most practical examples.

The approach is too electrical, and not enough acoustics by far.

The theory you do need, look at designs at : Zaphaudio.com

rgds, sreten.

That's a very nice combo of drivers and a pretty decent build, even with the problems.

Personally I would have gone a little bigger on the cabinet (14L box with a 1.5" x 5" long port, tuned to 40 Hz) and you would have a competent full-range speaker, that's gets down into the mid-30's and wouldn't need a sub for music.

I would also agree with Sreten, that although the site you linked is good for the electrical XO theory, you might have left some performance on the table by not using a completely optimized XO design. Beauty of DIY...learn more every time you build.

Personally I would have gone a little bigger on the cabinet (14L box with a 1.5" x 5" long port, tuned to 40 Hz) and you would have a competent full-range speaker, that's gets down into the mid-30's and wouldn't need a sub for music.

I would also agree with Sreten, that although the site you linked is good for the electrical XO theory, you might have left some performance on the table by not using a completely optimized XO design. Beauty of DIY...learn more every time you build.

Hi,

FWIW the ESP article is a terrible guide to doing x/o's properly,

but a tour de force in describing some of the theory you do need.

The theory is fine, but not enough, for most practical examples.

The approach is too electrical, and not enough acoustics by far.

The theory you do need, look at designs at : Zaphaudio.com

rgds, sreten.

Will do, thanks man.

Simple fix for next time is to flush mount the drivers. Particularly the tweeter. Zaph|Audio

I thought about that, but my portable router just broke and the table-mounted one is too unwieldy. Thankfully I found a hole saw the perfect size which made everything easy - for the next build I'll definitely be flush mounting everything to make it look a bit better.

That's a very nice combo of drivers and a pretty decent build, even with the problems.

Personally I would have gone a little bigger on the cabinet (14L box with a 1.5" x 5" long port, tuned to 40 Hz) and you would have a competent full-range speaker, that's gets down into the mid-30's and wouldn't need a sub for music.

I would also agree with Sreten, that although the site you linked is good for the electrical XO theory, you might have left some performance on the table by not using a completely optimized XO design. Beauty of DIY...learn more every time you build.

I have another heap of these to build so definitely will be going ported with better crossovers - luckily I have a good bandpass sub that helps fill the gaps. The first one is a weird, 3D cross with a slanted face to be hung up inside a gym - we have one with 12 drivers already in my workshop and it sounds pretty good despite being sealed so I'm hoping that the bass response will be better with 3/4 the drivers.

Have you tried XSim? It's a great crossover simulator, and really helps learn about concepts. It makes a great experimental lab for crossovers and drivers.

Best,

Erik

Unfortunately I found this after I made all the boards and finished the inductors. I'll definitely be using this to design the next lot though!

Will do, thanks man.

I thought about that, but my portable router just broke and the table-mounted one is too unwieldy. Thankfully I found a hole saw the perfect size which made everything easy - for the next build I'll definitely be flush mounting everything to make it look a bit better.

Sometimes adding is easier than taking away.

If you get some 5mm MDF (or similarly easy to cut material) material, you can cut it to the correct shape with hand tools, then laminate it onto your existing baffle to get the drivers flush.

A layer of felt or similar would probably be better again, if you'd be happy with that appearance. I'm curious to try this myself, for some oval drivers that are difficult to flush mount neatly. I have some of this stuff to experiment with:

800 x 600 x 9mm Acoustic Pinboard | Bunnings Warehouse

Sometimes adding is easier than taking away.

If you get some 5mm MDF (or similarly easy to cut material) material, you can cut it to the correct shape with hand tools, then laminate it onto your existing baffle to get the drivers flush.

A layer of felt or similar would probably be better again, if you'd be happy with that appearance. I'm curious to try this myself, for some oval drivers that are difficult to flush mount neatly. I have some of this stuff to experiment with:

800 x 600 x 9mm Acoustic Pinboard | Bunnings Warehouse

I've actually got a heap of 5mm MDF so that might be the way to go. I've had a quick look but can't find an 'easy' way route them in - I could have sworn I've seen some router bits with a bearing on top and a flat cutter (like a dado/spoil board bit) that would have worked but I can't see them anywhere in any of the online stores I normally look at.

Side note: anybody know something easier to paint them with? I'm guessing because the ply wasn't undercoated the paint just sank in and didn't keep any texture. I've seen a few different types of plasticized/rubberised paints for automotive purposes but wasn't sure which would work best.

Anything that's easy to finish will be ideal as I HATE painting haha

Router bits - maybe look at the CARB-I-TOOL catalogue.

I wouldn't bother, though: 5mm MDF is easy enough to cut with a Stanley knife or even a retractable knife from a $2 shop. Take it slowly, do each curve in multiple passes, cut ~1 mm deeper each time. It takes a few minutes, but less hassle easier than setting up a router, putting on a mask etc, then cleaning up afterwards.

Regarding paint - look at the Cannonsound website: DuraTex. That's meant to be easier to work with.

I wouldn't bother, though: 5mm MDF is easy enough to cut with a Stanley knife or even a retractable knife from a $2 shop. Take it slowly, do each curve in multiple passes, cut ~1 mm deeper each time. It takes a few minutes, but less hassle easier than setting up a router, putting on a mask etc, then cleaning up afterwards.

Regarding paint - look at the Cannonsound website: DuraTex. That's meant to be easier to work with.

One of the sets I have to make will have a hardwood front, so having some way to recess it into a solid piece would be nice (Christmas present for dad, who currently is using a shitty little Logitech 2.1 speaker system with a subwoofer that doesn't work. Building a Gainclone with some extra bits like a preamp/etc, so that should be a big improvement for him). Thanks for the suggestions though.

I've had a little play with Xsim, however the issue I'm having is I can't seem to figure out how to make the FRD/ZMA even close to what I want. Is there an easy way to do this if I have complete sets of information for each driver?

I've had a little play with Xsim, however the issue I'm having is I can't seem to figure out how to make the FRD/ZMA even close to what I want. Is there an easy way to do this if I have complete sets of information for each driver?

Hi Dread!

It's a place to start with those files. You still have to figure out the actual acoustic distance between the drivers. What it won't do is create the crossovers for you. 🙂 That takes some work.

Others here can help you adjust the FRD based on your box design.

Best,

Erik

It's a place to start with those files. You still have to figure out the actual acoustic distance between the drivers. What it won't do is create the crossovers for you. 🙂 That takes some work.

Others here can help you adjust the FRD based on your box design.

Best,

Erik

I can't help with Xsim questions.

Do you have the timber picked out already?

Dad has slabs and slabs of seasoned camphor laurel in his shed that have already been thicknessed from 20-50mm. I've already asked for a few for some other projects, so I suspect he will be surprised if I send one of them back...in sorts 😛 Thinking that I might use structural ply sides that are painted, and just an oiled wood front - I don't think I have the finesse to do the entire thing out of camphor laurel to a level I'd be happy with.

Hi Dread!

It's a place to start with those files. You still have to figure out the actual acoustic distance between the drivers. What it won't do is create the crossovers for you. 🙂 That takes some work.

Others here can help you adjust the FRD based on your box design.

Best,

Erik

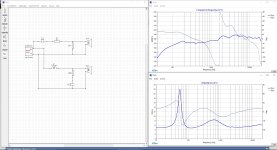

Thankyou very much! I modeled the crossovers I used and it looked -ok-, however I'm not sure if the tweeter attentuation worked as I planned as it still seems to be fairly 'bright' - but that could just be I have no idea what I'm doing. One thing I noticed with this setup is one of the holes disappears if I swap the phase of the tweeter. Attached is what my crossover looks like in modeling.

Boxes I'm intending on using are:

* 2 drivers in parallel (and tweeters in series for ~10 ohms - not ideal but about as good as I can do)

*Vol=34L

*Vb=34L

*Fb=45Hz

*F3=43Hz

*Port @ 45Hz=2x60mm x195mm. Predicted velocity of 24m/s - too high?

I have access to basically any passive crossover components I want (polypropylene caps from 100nf>15uf, bipolar electro's, 5w/10w resistors, inductors I can wind/rewind to any value and can etch or cut PCB's on a CNC cutter). Pretty well equipped electronics lab and measurement tools (signal generator, quality power amp, oscilloscope, lab DMM's, etc).

Dread,

The crossover looks to be good, but too simple to be real. 🙂 This warns me you haven't assessed the acoustic centers of the drivers (i.e. distance) or input them into XSim yet. Also, use ground symbols to connect the (-) amp if convenient. It reduces wiring and makes it a little easier to read for some. Instead of individual resistors, use an L pad which you'll find under "CircuitBlocks" in XSim. It will make it a lot easier for you to adjust the tweeter level and maintain a constant impedance.

Add about 1.3" to 1.5" to the woofer distance and see how things change. Just as a learning experience. What you should see is that everything goes to heck. 🙂 That's the real challenge of crossover design.

Here are a couple of guides. First, here's a thread about measuring a 2 way to enable accurate crossover design:

http://www.diyaudio.com/forums/multi-way/288141-omnimic-far-field-xsim-dats-v2-success.html

Next, my blog posting on measuring acoustic distance. This will help you find the real driver distances.

If money is an issue, use Room EQ Wizard with the iMM-6 Dayton Microphone ($12), but I usually recommend OmniMic + DATS as the goto, all in one package.

Best,

Erik

The crossover looks to be good, but too simple to be real. 🙂 This warns me you haven't assessed the acoustic centers of the drivers (i.e. distance) or input them into XSim yet. Also, use ground symbols to connect the (-) amp if convenient. It reduces wiring and makes it a little easier to read for some. Instead of individual resistors, use an L pad which you'll find under "CircuitBlocks" in XSim. It will make it a lot easier for you to adjust the tweeter level and maintain a constant impedance.

Add about 1.3" to 1.5" to the woofer distance and see how things change. Just as a learning experience. What you should see is that everything goes to heck. 🙂 That's the real challenge of crossover design.

Here are a couple of guides. First, here's a thread about measuring a 2 way to enable accurate crossover design:

http://www.diyaudio.com/forums/multi-way/288141-omnimic-far-field-xsim-dats-v2-success.html

Next, my blog posting on measuring acoustic distance. This will help you find the real driver distances.

If money is an issue, use Room EQ Wizard with the iMM-6 Dayton Microphone ($12), but I usually recommend OmniMic + DATS as the goto, all in one package.

Best,

Erik

Ok, probably a question that will get me destroyed - is it possible to make ACCEPTABLE crossovers without knowing more than box and driver specifications, or from data you can measure directly from the speaker without spending too much time messing around with FRD and ZMA files?

These will be used on a verandah and shed respectively, so there's absolutely NO need to the highest SQL possible. As I mentioned, the existing sound system is so poor that anything will be an upgrade.

These will be used on a verandah and shed respectively, so there's absolutely NO need to the highest SQL possible. As I mentioned, the existing sound system is so poor that anything will be an upgrade.

Last edited:

It is possible to make 'acceptable' speakers without doing any measurements. Either way though it will take time.

For the crossover you might think along the lines of a handful of clip leads, various sand cast resistors, caps and coils. if you can get your hands on some variable L-pads (tweeter level controls) it will make the job easier.

For the crossover you might think along the lines of a handful of clip leads, various sand cast resistors, caps and coils. if you can get your hands on some variable L-pads (tweeter level controls) it will make the job easier.

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Multi-Way

- First Speakers + Crossover Build