Goal

I needed some small desktop speakers to listen to while I work.

Simple Solution

Take the pair of EL70s I already had and build some quick boxes for them, turn on music, enjoy. To easy...

Complicated Solution

Decide that the EL70s were going to require too big of boxes, do a bunch of late night reading on diyaudio, decide that I can never have enough drivers around and order a pair of FF85WKs, wait... make that two pairs since a friend wants some desktop speakers as well.

There are multiple build threads for the uFonkens already so I'm not going to go into a lot of details on the process. This thread will be more focused on pictures and my impression of the speakers.

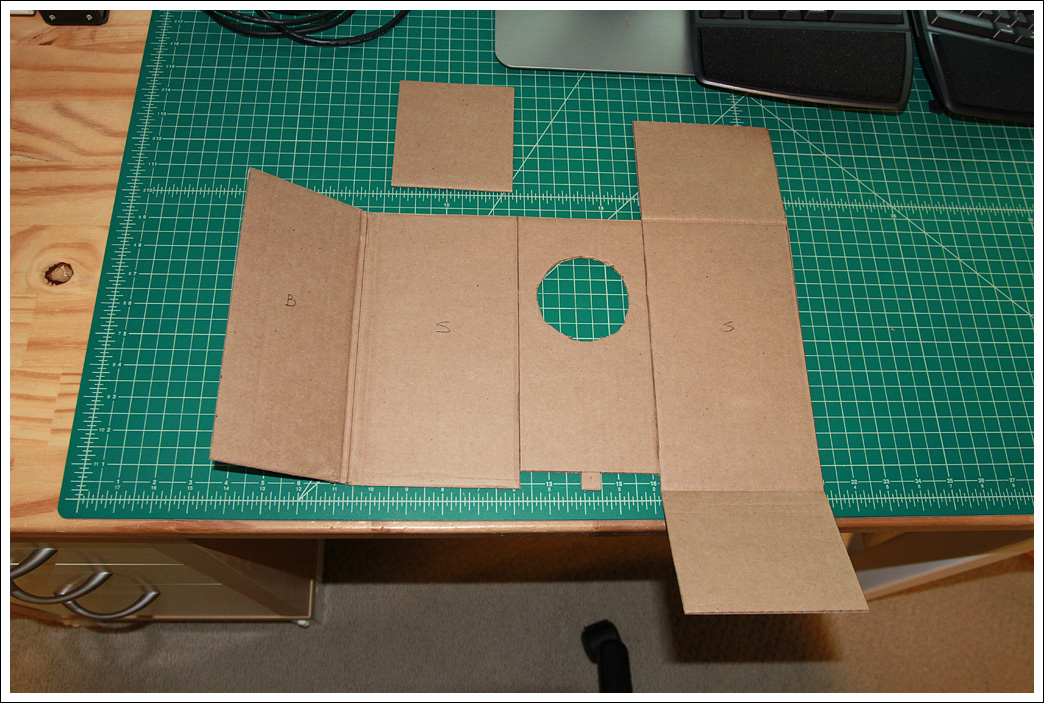

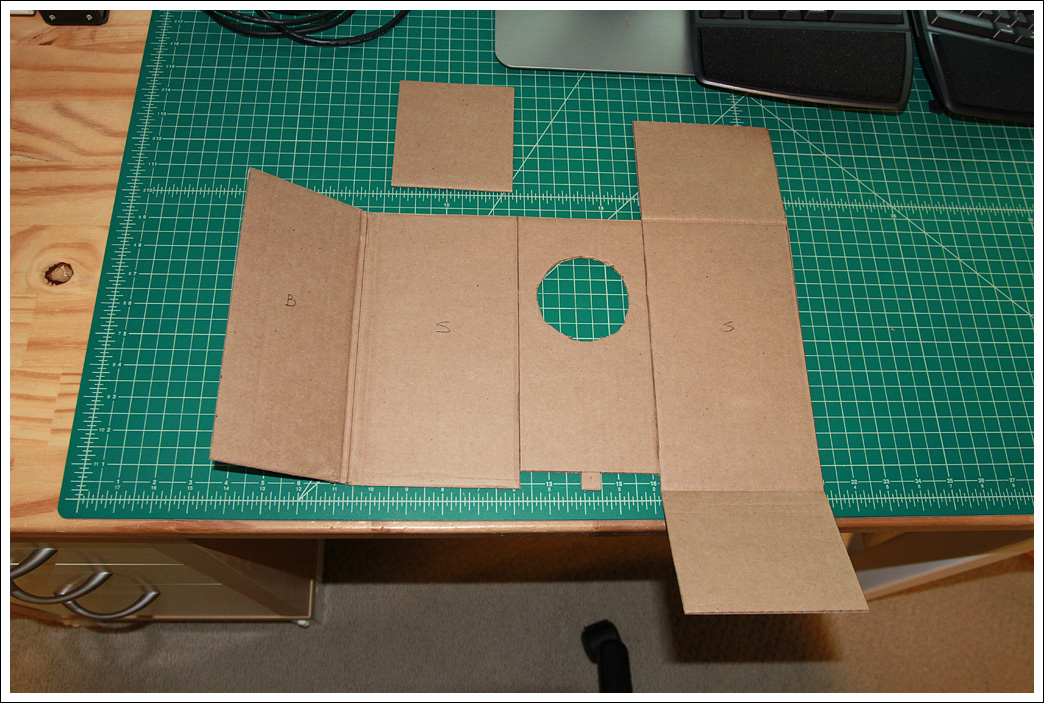

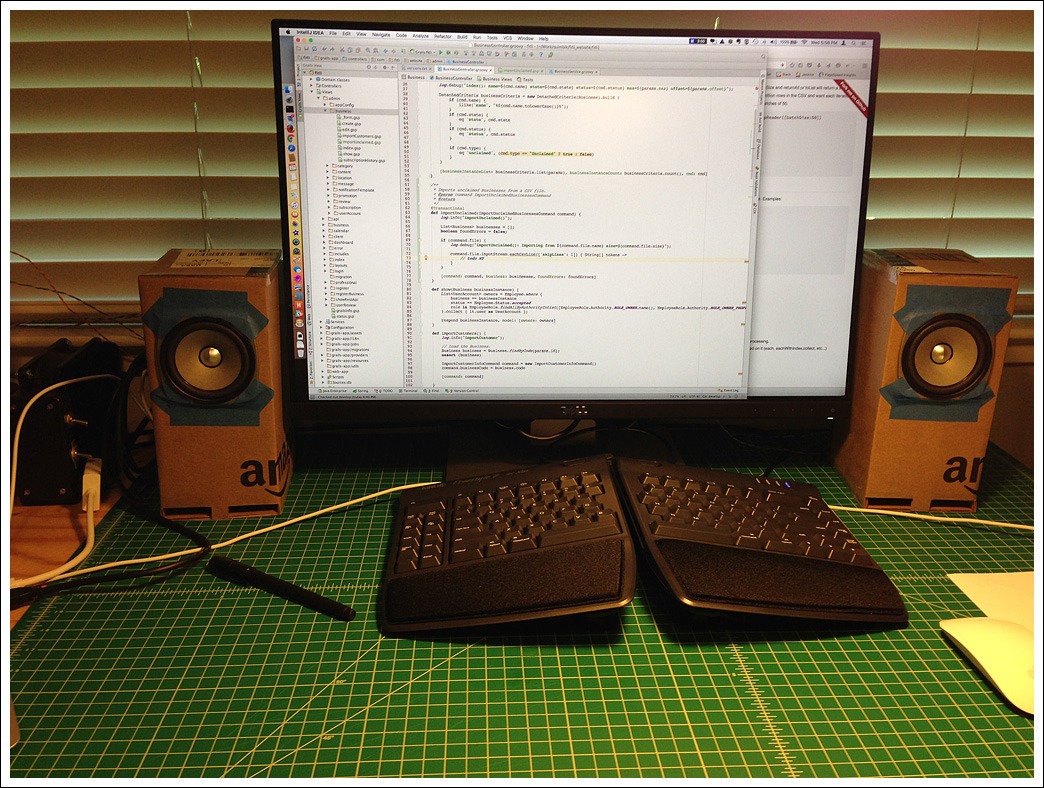

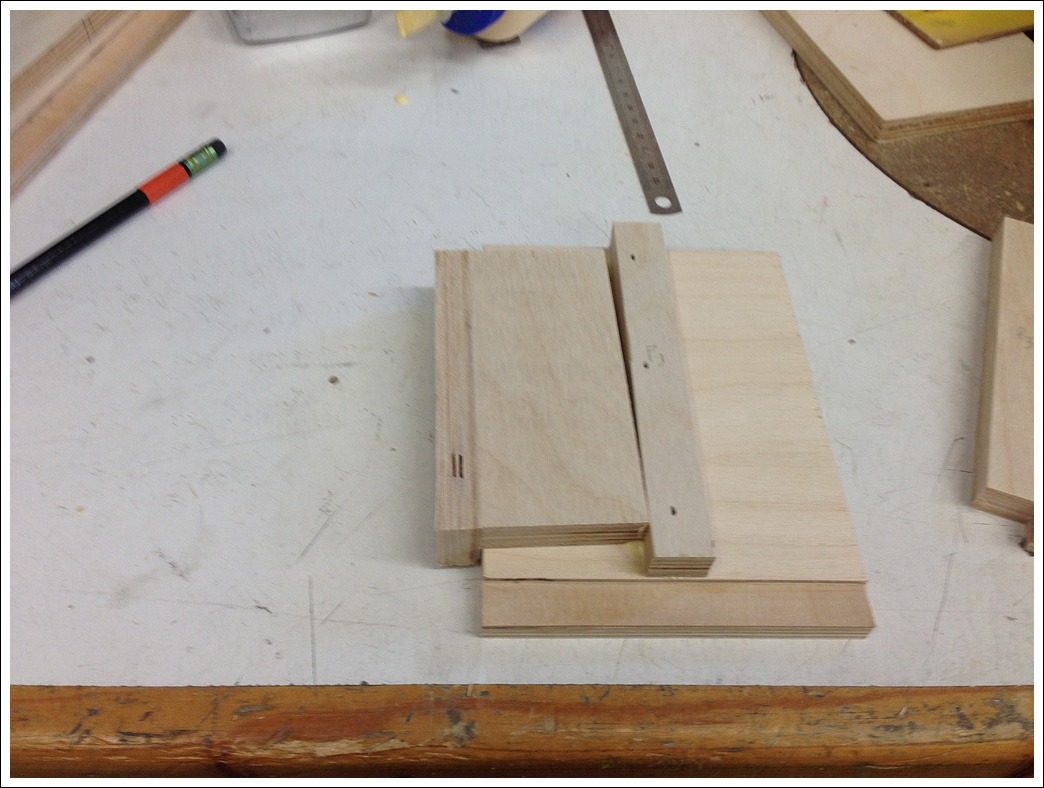

Step 1: The drivers arrive and you want to hear them right away. Amazon corrugated enclosures to the rescue.

Note the shelf for the vent.

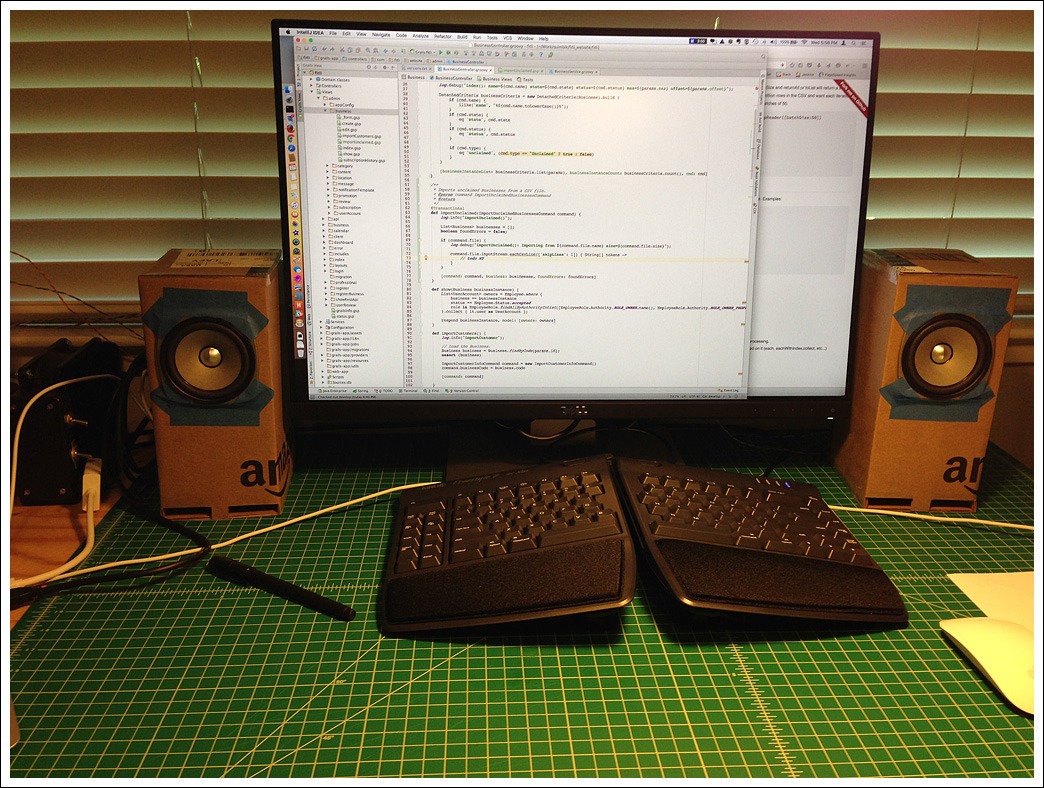

These already sound surprisingly good, especially considering that the drivers are taped in place and the boxes resonate like crazy. No bass, but that is to be expected. I powered them with an LM3886 chipamp (Blank Photos :: LM3886 Chipamp).

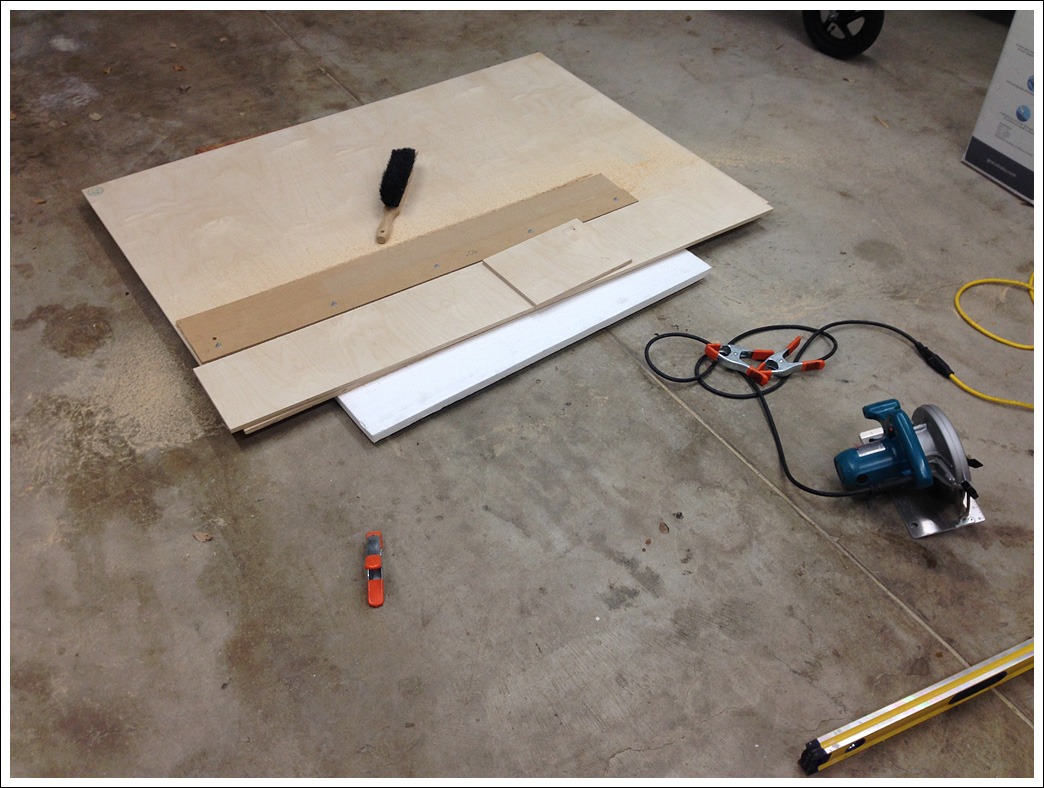

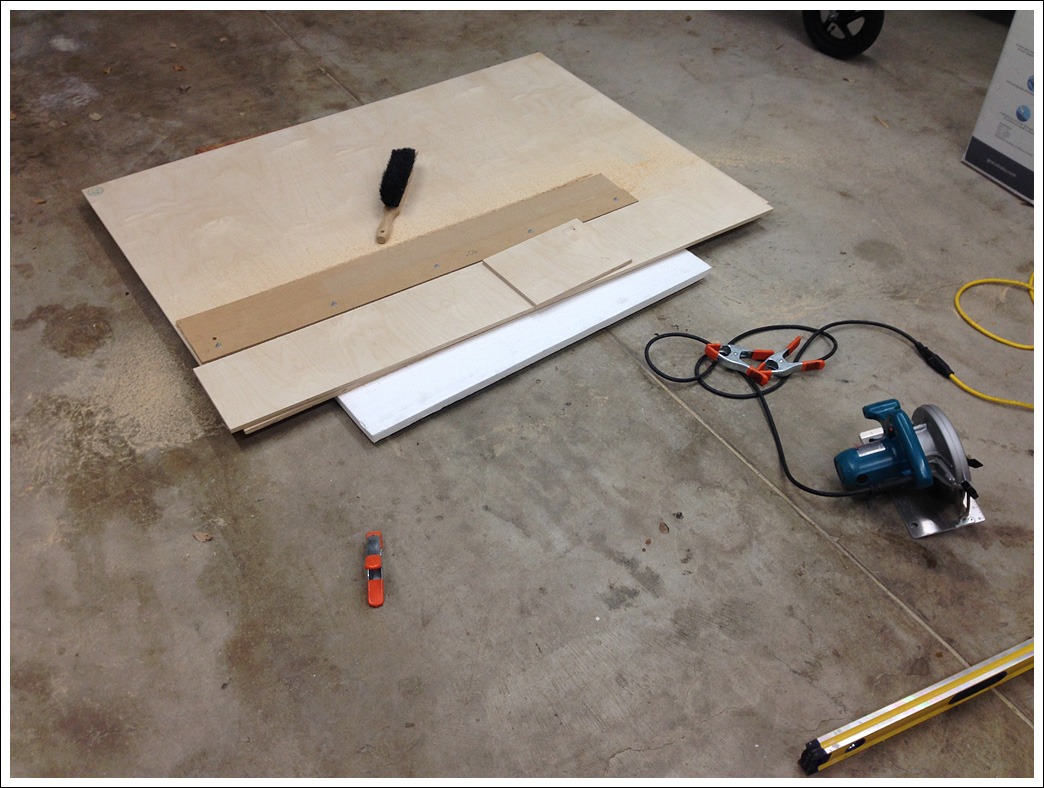

Ok, let's get serious. Since I ordered a set of drivers for a friend as well I figured I'd just build 4 enclosures so he didn't have to do any work. This took just a fraction of a 5x5 sheet of 12mm baltic birch plywood.

More pictures tomorrow...

I needed some small desktop speakers to listen to while I work.

Simple Solution

Take the pair of EL70s I already had and build some quick boxes for them, turn on music, enjoy. To easy...

Complicated Solution

Decide that the EL70s were going to require too big of boxes, do a bunch of late night reading on diyaudio, decide that I can never have enough drivers around and order a pair of FF85WKs, wait... make that two pairs since a friend wants some desktop speakers as well.

There are multiple build threads for the uFonkens already so I'm not going to go into a lot of details on the process. This thread will be more focused on pictures and my impression of the speakers.

Step 1: The drivers arrive and you want to hear them right away. Amazon corrugated enclosures to the rescue.

Note the shelf for the vent.

These already sound surprisingly good, especially considering that the drivers are taped in place and the boxes resonate like crazy. No bass, but that is to be expected. I powered them with an LM3886 chipamp (Blank Photos :: LM3886 Chipamp).

Ok, let's get serious. Since I ordered a set of drivers for a friend as well I figured I'd just build 4 enclosures so he didn't have to do any work. This took just a fraction of a 5x5 sheet of 12mm baltic birch plywood.

More pictures tomorrow...

Nice cardboard box. 🙂

Thanks, I made sure to use audiophile approved tape on the seams. 🙂

Here are some more pictures.

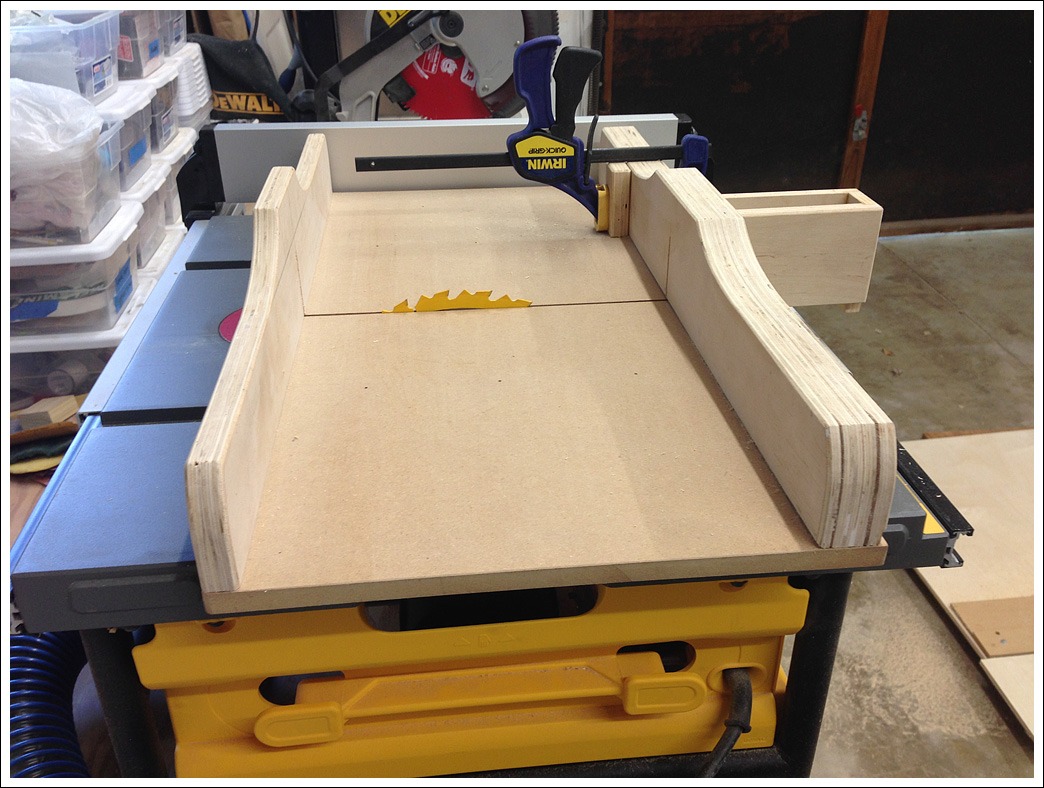

Using a stop block on the table saw sled to cut the sides to length.

This blade is a bit dull so I got a bit of tearout and some saw kerf marks, but I'm going to be veneering the speakers so it doesn't matter.

Jig used to position the rib in the center of the vents

Making a mess.

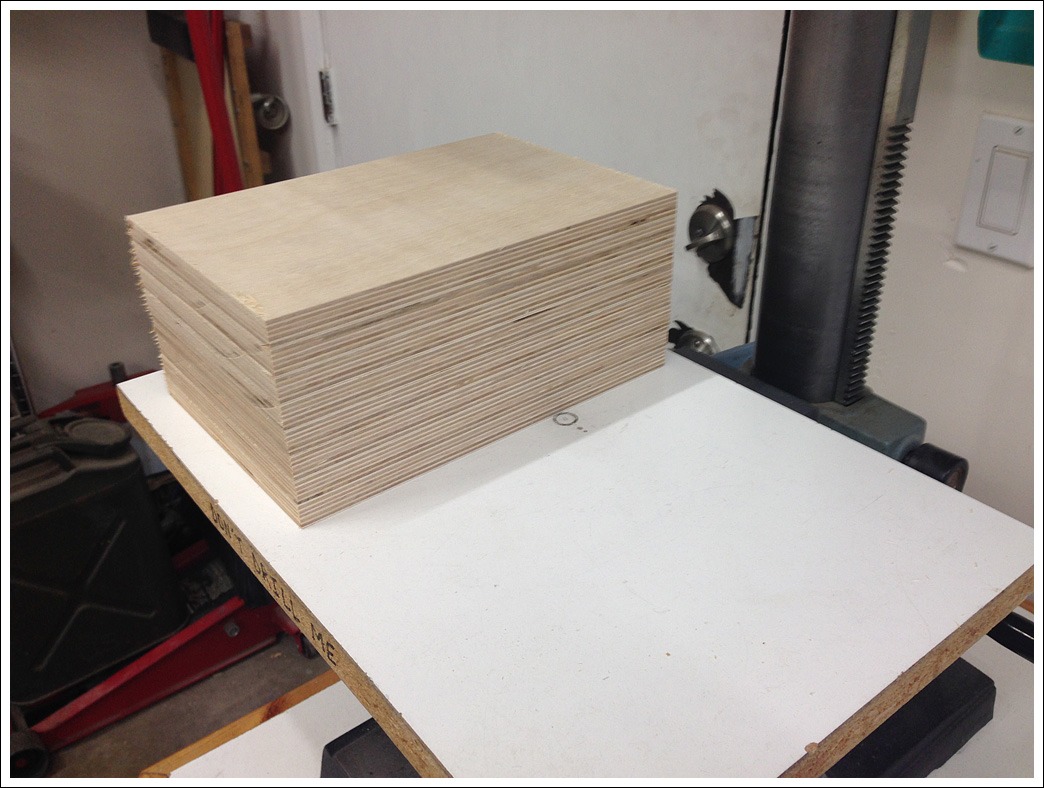

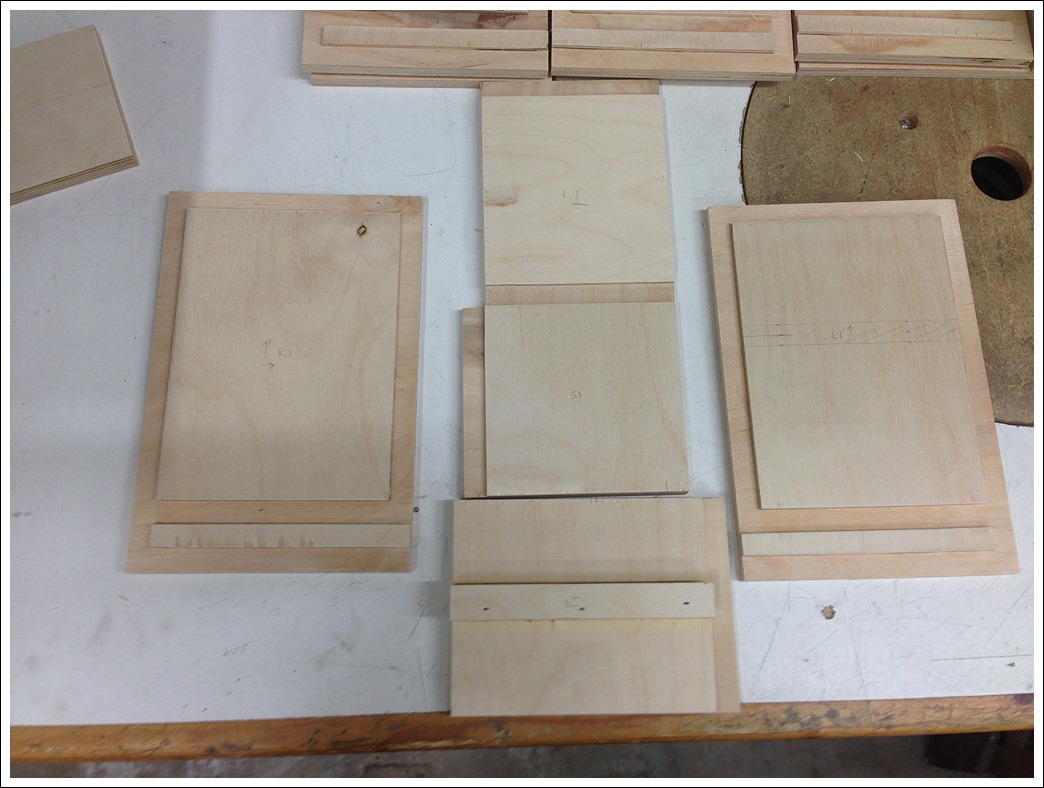

Building 4 enclosures results in a lot of small parts.

I cut of dados and rabbits on the side panels to ease assembly and to make sure things are airtight. The arbor on my table saw is too short to support a 1/2" dado stack, so these were all cut on the router table.

Starting the glue up. I ran the dados for the vent shelf all the way through the piece so that I could use the same setup for all 8 panels. This leaves a small (1/2x1/2x1/8) void on each side which I guess could theoretically effect the vent size on a speaker this small. I might fill them in at some point.

On pair glued together. I used some 18g brads to hold things together while the glue dried, and the front panels are in place to help hold things square.

Scallops on the backside of the driver holes.

I went back and forth about the order in which to do the glue up, and ultimately decided to leave the front and back panels for last.

On pair glued together. I used some 18g brads to hold things together while the glue dried, and the front panels are in place to help hold things square.

Scallops on the backside of the driver holes.

I went back and forth about the order in which to do the glue up, and ultimately decided to leave the front and back panels for last.

… This leaves a small (1/2x1/2x1/8) void on each side which I guess could theoretically effect the vent size on a speaker this small. I might fill them in at some point.

I wouldn't worry about it.

dave

I wouldn't worry about it.

dave

I don't know, you guys took the time to specify the dimensions to the 32nd of an inch, so accuracy must count. 🙂

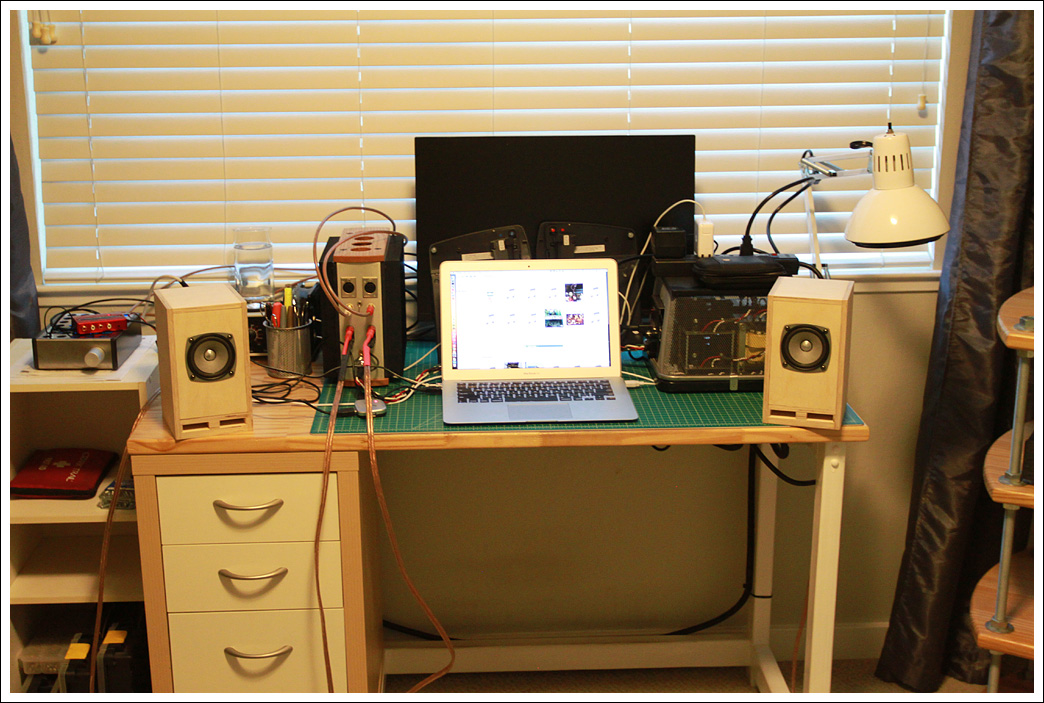

Here is the last set of pictures for now. I'm at the point where the drivers are installed in the enclosures and the back panels are friction fit in place so that I can do some initial listening.

I haven't yet decided what kind of sound dampening to use on the inside. It doesn't really make sense to pay shipping rates from CSS for a small amount of 1/2" Ultra-touch insulation, and unfortunately nobody else seems to carry that same product.

Home Depot has a similar (not the same) product that is 3/8" thick. I might order some of this to try out on the uFonkens and another project.

UltraTouch 48 in. x 6 ft. Radiant Barrier-30000-11406 - The Home Depot

Once everything is buttoned up I will be veneering the cabinets. And then possibly building some kind of subwoofer to add in a bit more bass.

On with the pictures...

Gluing on the fronts.

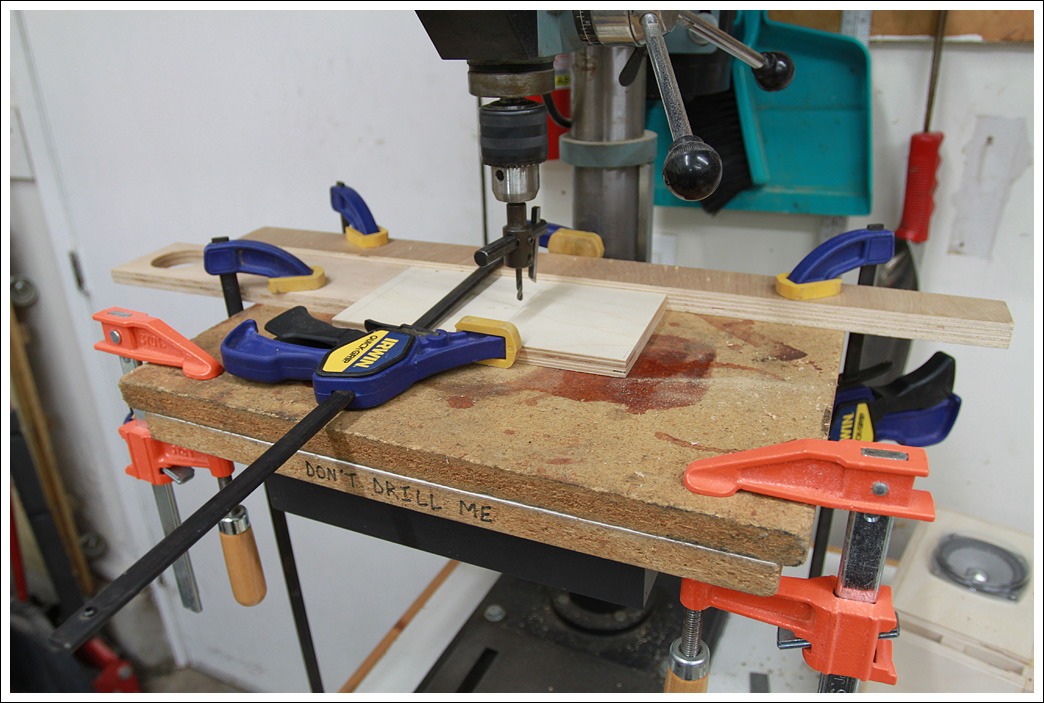

I had used a 73mm hole saw to cut out the driver openings. Fostex's paperwork says a 73mm hole, the uFonken plans say 71mm. I went with 73mm because I could get a hole saw in that size. This turns out to be a little loose, so 71mm would probably be a more exact fit.

I didn't have a hole saw the right size for the speaker terminals I purchased, so I had to use a fly cutter. I have injured myself with this seemingly innocuous tool several times, so as you can see in the picture I don't joke around with clamping down the work piece. The problem with the fly cutter is that you can't see the outside arm when it is spinning, and it is really easy to have it hit your finger, or for it to seize the work piece and whack you with it. Use with caution.

Here is the "kit" that I made for a friend. He now gets to have fun trimming the front and back panels to length and gluing everything together.

And the temporarily assembled speakers hooked up so I could see what they sound like. The clutter on the desk consists of a Mac playing lossless audio files over USB into a Behringer UA222, which outputs over optical into a MiniDIGI/MiniDSP combination (silver box on the far left). This then feeds into a Pass Mini-Aleph that puts out a massive ~10w of class A power. The MiniDSP is only being used for D/A conversion for now, in the future I'll use it to try out some BSC options.

Here is a closeup of a uFonken. They are a great size for desktop speakers, and I'm really glad I went with these over something larger using my EL70s. I haven't yet decided if I want to bevel the edges or not. The bevel would only be about 5/8" wide so I'm not sure how much it would help with edge diffraction, and it would make veneering more difficult. If anybody has an opinion on this let me know. In the background you can see part of the power supply for the Mini-A.

That's it for now. These were a lot of fun to build, even with the extra effort required to cut all the dados. I'd like to give a big thanks to the gentlemen at Planet 10 for making the uFonken plans available.

Oh, and how do they sound?

Caveats:

- boxes are not 100% sealed yet (back panels are just pressed in place)

- no interior sound deadening is present

- driver brace is not installed yet

- front edges are not beveled

So far I'm really liking these little speakers. As expected they image exceedingly well since they are small diameter point sources. Vocals are very clean with little or no noticeable sibilance. They really resolve a lot of detail, I've already heard things on recordings that I had never noticed before.

As expected they don't get very loud, and there is minimal bass response. When used as nearfield monitors neither of these is really a big deal, but I'll probably hook up a subwoofer at some point.

My only disappointment is with the treble, and this is an issue I have with all full range drivers. There just isn't that "shimmer" that you get from a dedicated tweeter, and it is especially noticeable on cymbals. It could be that I wasn't perfectly on axis, but to my ear something is missing on the very top end. This is one of the tradeoffs of fullrange speakers, and if you can't hear over ~12-15k it's not really a problem.

- Matt

Caveats:

- boxes are not 100% sealed yet (back panels are just pressed in place)

- no interior sound deadening is present

- driver brace is not installed yet

- front edges are not beveled

So far I'm really liking these little speakers. As expected they image exceedingly well since they are small diameter point sources. Vocals are very clean with little or no noticeable sibilance. They really resolve a lot of detail, I've already heard things on recordings that I had never noticed before.

As expected they don't get very loud, and there is minimal bass response. When used as nearfield monitors neither of these is really a big deal, but I'll probably hook up a subwoofer at some point.

My only disappointment is with the treble, and this is an issue I have with all full range drivers. There just isn't that "shimmer" that you get from a dedicated tweeter, and it is especially noticeable on cymbals. It could be that I wasn't perfectly on axis, but to my ear something is missing on the very top end. This is one of the tradeoffs of fullrange speakers, and if you can't hear over ~12-15k it's not really a problem.

- Matt

I don't know, you guys took the time to specify the dimensions to the 32nd of an inch, so accuracy must count. 🙂

Actually to the millimetre. The CAD software adds the closest imperial measure.

dave

Matt - how close is your listening position?

As for the missing "shimmer / air" - I'd be guessing that your hearing is not yet as deficient above 10kHz as with many of us old farts. I personally don't find the FF85WK particularly lacking, but then after listening to them for several years, have probably become acclimated enough to their tonal balance.

If there are any similar projects in your future, another excellent little driver that works very well in a small box for this type of application would be the Alpair6 metal - no lack of shimmer there

As for post veneering of the enclosure, if using flexible paper backed product, with only a little practice you should be able to fold over a bevel on the long front edges - it'll be trimming out around the vent slots that I think you'll find to be more "fun"

As for the missing "shimmer / air" - I'd be guessing that your hearing is not yet as deficient above 10kHz as with many of us old farts. I personally don't find the FF85WK particularly lacking, but then after listening to them for several years, have probably become acclimated enough to their tonal balance.

If there are any similar projects in your future, another excellent little driver that works very well in a small box for this type of application would be the Alpair6 metal - no lack of shimmer there

As for post veneering of the enclosure, if using flexible paper backed product, with only a little practice you should be able to fold over a bevel on the long front edges - it'll be trimming out around the vent slots that I think you'll find to be more "fun"

Last edited:

Oh, and how do they sound?

Caveats:

- boxes are not 100% sealed yet (back panels are just pressed in place)

- no interior sound deadening is present

- driver brace is not installed yet

- front edges are not beveled

So far I'm really liking these little speakers. As expected they image exceedingly well since they are small diameter point sources. Vocals are very clean with little or no noticeable sibilance. They really resolve a lot of detail, I've already heard things on recordings that I had never noticed before.

As expected they don't get very loud, and there is minimal bass response. When used as nearfield monitors neither of these is really a big deal, but I'll probably hook up a subwoofer at some point.

My only disappointment is with the treble, and this is an issue I have with all full range drivers. There just isn't that "shimmer" that you get from a dedicated tweeter, and it is especially noticeable on cymbals. It could be that I wasn't perfectly on axis, but to my ear something is missing on the very top end. This is one of the tradeoffs of fullrange speakers, and if you can't hear over ~12-15k it's not really a problem.

- Matt

Nice work on the boxes.

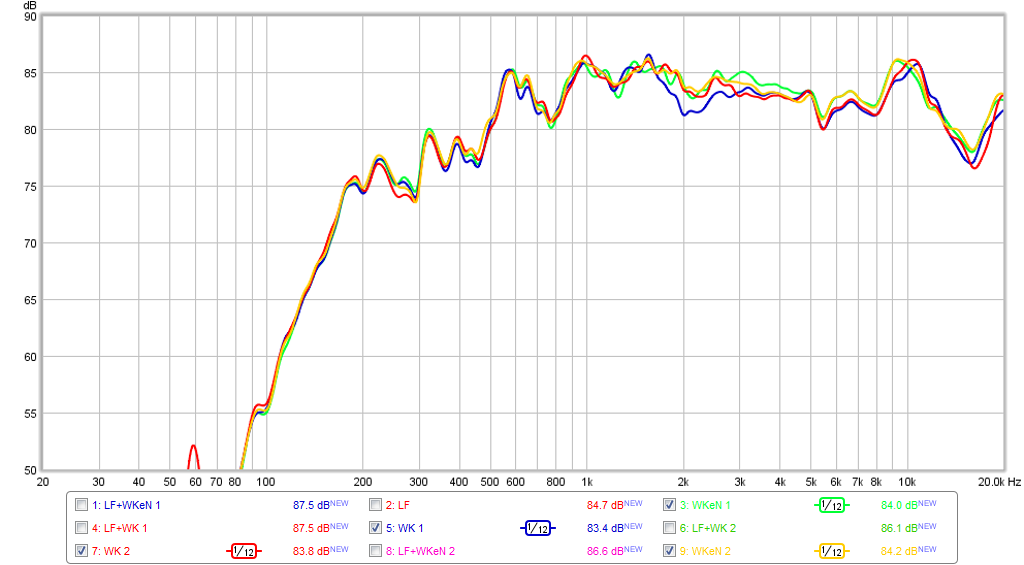

Regarding lack of treble: I also find them a bit soft on the high registers and my measurements in the Subjective Blind ABX test of eNabled FF85WK's confirms it. There is about an 8dB dip in the treble response from 10k to 16k and then it rises 5dB to 20k. This is on axis, off axis the falloff is steeper. Here are 4 drivers measured with a third party calibrated mic. Two are stock and two are EnABLed by Planet10.

The measurement is consistent with shape in factory measurement:

An externally hosted image should be here but it was not working when we last tested it.

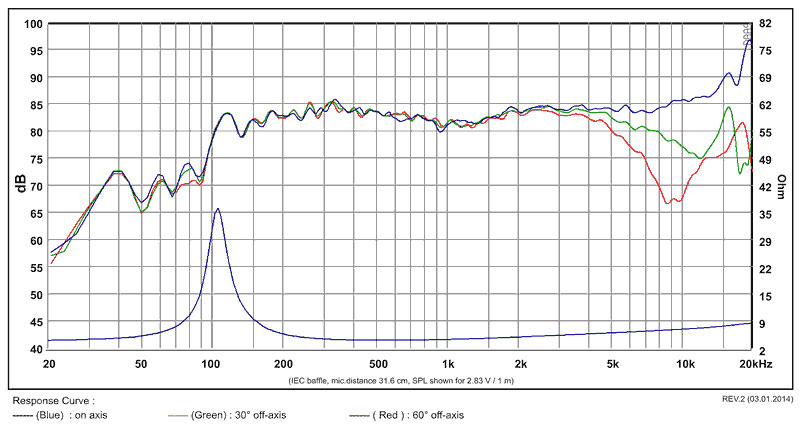

One of the few full range drivers I have heard and measured that has almost the same air as a dome tweeter is the SB65WB25AC-4. It's got a solid treble response but is only a 2.5in driver and has much lower sensitivity:

Having said that, the FF85WK is a very capable driver of nice sound that is quite good. Listen to the sound clips here and compare to the reference source tracks. It's remarkable how close it is.

http://www.diyaudio.com/forums/full...-blind-abx-test-enabled-ff85wk-round-6-a.html

Note the middle graph (Fostex's factory graph?) in above post extends to 50kHz, so those of us who make only a cursory glance at the general shape of an FR graph might fit it a bit misleading

X- that's an interesting measurement for the SB driver - particularly what appears to be a major discrepancy between an and off axis response in the approx octave between 6 and 12k, followed by the pronounced rise on axis of over 10dB .

And I forgot to mention above the Alpair5.2 - not too much chatter about that little guy yet - I don't know how it would measure in same conditions as those published above, but it doesn't lack for shimmer & detail.

X- that's an interesting measurement for the SB driver - particularly what appears to be a major discrepancy between an and off axis response in the approx octave between 6 and 12k, followed by the pronounced rise on axis of over 10dB .

And I forgot to mention above the Alpair5.2 - not too much chatter about that little guy yet - I don't know how it would measure in same conditions as those published above, but it doesn't lack for shimmer & detail.

Note the middle graph (Fostex's factory graph?) in above post extends to 50kHz, so those of us who make only a cursory glance at the general shape of an FR graph might fit it a bit misleading

X- that's an interesting measurement for the SB driver - particularly what appears to be a major discrepancy between an and off axis response in the approx octave between 6 and 12k, followed by the pronounced rise on axis of over 10dB .

And I forgot to mention above the Alpair5.2 - not too much chatter about that little guy yet - I don't know how it would measure in same conditions as those published above, but it doesn't lack for shimmer & detail.

Yes, Fostex graph does go to 50k. But I refer to 10k to 20k region that has same behavior as what I measure. Fostex is 10dB/Div whereas mine is 5dB.

The SB65 curve is factory SB Acoustics pulled from Madisound site.

Send me an A5.2 and I will be glad to measure and post.

Matt - how close is your listening position?

As for the missing "shimmer / air" - I'd be guessing that your hearing is not yet as deficient above 10kHz as with many of us old farts. I personally don't find the FF85WK particularly lacking, but then after listening to them for several years, have probably become acclimated enough to their tonal balance.

If there are any similar projects in your future, another excellent little driver that works very well in a small box for this type of application would be the Alpair6 metal - no lack of shimmer there

As for post veneering of the enclosure, if using flexible paper backed product, with only a little practice you should be able to fold over a bevel on the long front edges - it'll be trimming out around the vent slots that I think you'll find to be more "fun"

Hi Chris,

In final usage I'll be sitting about 0.5m from the speakers, while testing them out I've been anywhere from that distance to about 3m away.

I just did a quick test and I can still definitely hear 15kHz, so the drop between 10-16kHz measured by xrk971 might be why I feel these miss some "shimmer". It's not a deal breaker by any means.

On the veneer front I might just be a glutton for punishment. Many years ago I decided to veneer some round speakers in book matched raw wood cherry veneer. After dealing with some fairly significant splitting I swore I would never use raw wood veneer again.

For my next speakers I used paper back veneer and had no issues.

But, earlier this year I acquired some nice raw wood veneers that would be perfect for the uFonkens, so I might tempt fate again.

Thanks for the warning about trimming around the vent slots. On the MTMs above I applied the veneer after routing the driver holes, and it was a lot of work to cleanly trim the veneer to match. I suspect the uFonken vents will be similar. I now have a 1/4" carbide veneer trimming bit for the router, so I should be able to use that for the straight edges and then just clean up the corners with a knife.

xrk971,

Thanks for the response plots. I'm still trying to find time to take part in the driver comparison experiment.

- Matt

Good job! I appreciate the detailed build updates with pics, surely helps a lot for a newbie in woodworking like me.

Matt,

Congrats - neat build, clean cuts all around, well documented with good quality pics, and quick completion of the project. 🙂

Congrats - neat build, clean cuts all around, well documented with good quality pics, and quick completion of the project. 🙂

Good job! I appreciate the detailed build updates with pics, surely helps a lot for a newbie in woodworking like me.

Matt,

Congrats - neat build, clean cuts all around, well documented with good quality pics, and quick completion of the project. 🙂

Thanks, I'm glad people are finding the pictures useful.

Today I "ear balled" a baffle step correction filter on the MiniDSP, and now these speakers are sounding really nice. With the ~5" front baffle the f3 of the step should be around 900hz. After doing a couple quick tests I settled on a 2db step with a Q of 0.8 at 500hz. This is just a temporary solution, but I'm liking the sound of it.

- Matt

It's been 5 months and I'm still really enjoying the speakers. They are still in raw plywood with no damping on the inside.

One thing I am missing is the bass, specifically when listening at non-nearfield distances, so I'm thinking of going with some kind of FAST setup. I don't really want to buy more drivers, so I'm thinking of using something that is sitting around.

Here are the options:

1. Pioneer B20fu

2. ApexJr Super 8 Super 8

3. Unmarked 8" test drivers from Velodyne. The ones I used here http://www.diyaudio.com/forums/full-range/227082-css-el70-lx521-fast-something-like.html.

The Super 8s are subwoofers and probably wouldn't sound good crossed over this high.

The Velodyne drivers are ok, but I'm wondering if the B20fus would work well in this situation. They are full range drivers with a pretty clean response up to 700 hz, and they put out some decent bass.

http://brinesacoustics.com/Pages/Articles/BOFU/B20FU_FR.gif

What do you all think? One option would be to build a set of "half chang" enclosures for the B20s and then set the uFonkens on top of those and use a 1st order xover somewhere around 300-500hz between the two. Crazy?

- Matt

One thing I am missing is the bass, specifically when listening at non-nearfield distances, so I'm thinking of going with some kind of FAST setup. I don't really want to buy more drivers, so I'm thinking of using something that is sitting around.

Here are the options:

1. Pioneer B20fu

2. ApexJr Super 8 Super 8

3. Unmarked 8" test drivers from Velodyne. The ones I used here http://www.diyaudio.com/forums/full-range/227082-css-el70-lx521-fast-something-like.html.

The Super 8s are subwoofers and probably wouldn't sound good crossed over this high.

The Velodyne drivers are ok, but I'm wondering if the B20fus would work well in this situation. They are full range drivers with a pretty clean response up to 700 hz, and they put out some decent bass.

http://brinesacoustics.com/Pages/Articles/BOFU/B20FU_FR.gif

What do you all think? One option would be to build a set of "half chang" enclosures for the B20s and then set the uFonkens on top of those and use a 1st order xover somewhere around 300-500hz between the two. Crazy?

- Matt

- Home

- Loudspeakers

- Full Range

- FF85WK uFonken project