Cal,Well, I honestly didn't think it would actually come to this but if you know something about building construction you'd know this is more than just a little exaggeration. I think when Tom used the term "I thought we broke the house once" he kind of gave it away, don't you? 🙂

The low frequency device was not a conventional loudspeaker.

It used a very high velocity three phase blower through a venturi, the output was horn loaded with a huge horn. The venturi could be frequency modulated with a servo motor, but amplitude was dependent on air flow.

There was plenty of air flow.

Think in terms of a frequency modulated siren on steroids, rather than a conventional speaker.

The sonic boom simulator had the displacement equivalent of an 8 foot by 12 foot piston

moving 18" peak to peak.

That is 144 cubic feet of displacement.

Compare that to the displacement of a BC18SW115, a long throw 18, which has 187.6 cubic inches Sd.

I have a pair of those, with one I have rattled chainsaws and various other stuff off the shelves in my shop.

Tools hung on screws fell to the floor, depending on the frequency I tested at.

The sonic boom simulator would be approximately the equivalent to 1326 of those 18” speakers driven with about 2 million watts.

I have seen doors and walls visibly moving with the conventional speakers I use, Tom’s sonic boom simulator (a 3 way system called "speakers from hell" on the "beyond 2000" TV show) was in no way conventional in the low frequency section.

Even though I question some of DSL’s reported sensitivity of some of the current tapped horn speakers, given the nature of the sonic boom simulator beast, I don’t doubt Tom’s wall deflection figures.

Art Welter

The low frequency device was not a conventional loudspeaker.

Hi Art,

This has nothing to do with the woofer. It has to do with building construction. Something I am familiar with.

Entertaining story but that's where it ends.

Cheers.

Hi Art,

This has nothing to do with the woofer. It has to do with building construction. Something I am familiar with.

Entertaining story but that's where it ends.

Cheers.

I have built buildings too, though not as good as the ones my father did 😱.

One had the roof taken completely off by an air pressure differential, and the occupant was unaware, other than some short lived rain leaked through the insulation and sheetrock that were left completely intact.

I'm not sure the building that the Sonic boom experiments were done on were exactly up to any modern building code.

Making walls flop is not so hard if you have something capable of exciting the resonant frequency.

The sonic boom simulator could use it's massive air pressure differential tuned to a wall resonant frequency, where it does not take much energy to make it "flop", similar to opera singers (or Ted Nugent LOL) breaking glass.

Remember the Tacoma Narrows bridge failure?

Resonance had not been figured in to that design, and a fairly benign wind took it down.

The event was filmed, look it up on line and you may reconsider what air pressure differential in a tuned system is capable of.

More Tom Danley quotes:

"I chose the speaker division although it was a hard choice, it turned out to be a wise choice because not that much later the first shuttle blew up setting back any more work for 5 years at least.

It turned out one of the companies strongest suits was taking on the exotic jobs other companies would refer to us.

One of those goofy jobs, was to build a sonic boom simulator for the NASA space plane.

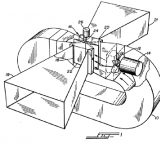

What your looking at is 1/3 of the below 30Hz portion of the system.

These were a push pull valve assembly, in the system in the photo, one has 4, 5HP fans to move the air.

Like this;

http://www.google.com/patents?id=HLo...age&q=&f=false

The system, with it's other speakers, was set up two meters from the outside of an OLD house outside of Atlanta where the research took place.

The system, when we turned it over, could produce a sine wave + - 2 dB from 5KHz down to 3Hz, at a pressure of 132Db at two meters distance."

Attachments

Last edited:

I'm still reading the thread, up to post 140 now, please excuse me for missing or not yet encountering relevant things as I progress, but I started drifting off to dream...of our grand-children's outdoor concert for the entire city from my system on the mountain:

For the extreme highs, a vertical array of conventional compression drivers...but instead of radiating directly thru a horn, each is used in a fluidic amplifier manifold to divert and thus control the more powerful flow of a more powerful stream from a bank of rented 1000 horsepower air compressors available because they don't sand-blast bridges on the weekends.

For the mids, another bank of rented 1000 horsepower air compressors provide the basic energy source which is modulated by a vertical array of balanced opposed needle-valves controlled by conventional voice coil linear motors driven by a few modest class "D" amps for the mids and highs.

For the mid-bass there's a planar array of larger slides, controlled by what looks like many large disk-drive low-mass seek arm actuators, driven by a few modest Nelson Pass class A-AB amps. This modulates a commercial source of a larger volume of lower-pressure compressed air (steam is not used any more because the pitch would vary like an old steam caliope).

For the bass, huge powerful diesel motors burning some "green" ethanol or old cooking oil or something drive large hydraulic pumps. Hundreds of hydraulic motors drive hundreds of fans in a huge planar array, each with hundreds of small blades. Each blade is made of piezoelectic material that changes shape with the modulating control signal. Instead of brushes to a slip ring to transfer the power to the rotating mechanism, each rotating mechansm has a rotating coil that couples magnetically to a stationary field coil that is modulated by the amplifier. Thus the modest amp's modulation of the stationary field coil controls the greater generator output on the rotary mechanism. This makes a mechanical-magnetic amplifier with greater output using energy from the fan's drive motor. Then the piezo blades change shape to convert more of the fan's rotary energy to sound.

Then I heard a multi-million-watt rap beat behind a Bieber boy band and woke up sweating and with a slight taste of vomit in my mouth.

This may sound silly, but there's a dozen potential patent searches in this story.

Consider the mechanical-magnetic rotary low-frequency audio amplifier. Imagine a 3-phase high-speed brushless alternator with many many poles and high shaft speed and AC output above the audio range. Couldn't modulating a comparatively small-signal field coil control a comparatively high-power low-frequency output (after rectification and filtering), drawing significant power from the rotation motor? Might be more bothersome than fan noise, but might be scaled up to create multi-million-watt bass amplifiers controlled with smallish class "D" amps?

(pinch) Am I awake yet?

For the extreme highs, a vertical array of conventional compression drivers...but instead of radiating directly thru a horn, each is used in a fluidic amplifier manifold to divert and thus control the more powerful flow of a more powerful stream from a bank of rented 1000 horsepower air compressors available because they don't sand-blast bridges on the weekends.

For the mids, another bank of rented 1000 horsepower air compressors provide the basic energy source which is modulated by a vertical array of balanced opposed needle-valves controlled by conventional voice coil linear motors driven by a few modest class "D" amps for the mids and highs.

For the mid-bass there's a planar array of larger slides, controlled by what looks like many large disk-drive low-mass seek arm actuators, driven by a few modest Nelson Pass class A-AB amps. This modulates a commercial source of a larger volume of lower-pressure compressed air (steam is not used any more because the pitch would vary like an old steam caliope).

For the bass, huge powerful diesel motors burning some "green" ethanol or old cooking oil or something drive large hydraulic pumps. Hundreds of hydraulic motors drive hundreds of fans in a huge planar array, each with hundreds of small blades. Each blade is made of piezoelectic material that changes shape with the modulating control signal. Instead of brushes to a slip ring to transfer the power to the rotating mechanism, each rotating mechansm has a rotating coil that couples magnetically to a stationary field coil that is modulated by the amplifier. Thus the modest amp's modulation of the stationary field coil controls the greater generator output on the rotary mechanism. This makes a mechanical-magnetic amplifier with greater output using energy from the fan's drive motor. Then the piezo blades change shape to convert more of the fan's rotary energy to sound.

Then I heard a multi-million-watt rap beat behind a Bieber boy band and woke up sweating and with a slight taste of vomit in my mouth.

This may sound silly, but there's a dozen potential patent searches in this story.

Consider the mechanical-magnetic rotary low-frequency audio amplifier. Imagine a 3-phase high-speed brushless alternator with many many poles and high shaft speed and AC output above the audio range. Couldn't modulating a comparatively small-signal field coil control a comparatively high-power low-frequency output (after rectification and filtering), drawing significant power from the rotation motor? Might be more bothersome than fan noise, but might be scaled up to create multi-million-watt bass amplifiers controlled with smallish class "D" amps?

(pinch) Am I awake yet?

Geeze, what was I reading here? What did I have for dinner? Did someone put something in my drink? I dig that system, Weltersys, I saw it in a dream but without the refinement of the recirculation path. Really love this thread so far, as I catch up.

Last edited:

It's such a cool concept/method that I would really love to see someone attempting it.

A guy (Andreas Megner or something pretty close) has done quite a bit in a thread in the DIY speakers forum at AVSForum (sorry, don't remember the title but pretty sure it has "fan" and/or "rotary" in it).

To have a complete wall move 10", you would have to have woofers that can move several feet back and forth... I won't be responding at this subject anymore, I have my limits unlike your woofers. 😉

I wouldn't expect it to be the whole wall, as they in no way approach pistonic behavior

I have built buildings too, though not as good as the ones my father did 😱.

One had the roof taken completely off by an air pressure differential, and the occupant was unaware, other than some short lived rain leaked through the insulation and sheetrock that were left completely intact.

I'm not sure the building that the Sonic boom experiments were done on were exactly up to any modern building code.

Making walls flop is not so hard if you have something capable of exciting the resonant frequency.

The sonic boom simulator could use it's massive air pressure differential tuned to a wall resonant frequency, where it does not take much energy to make it "flop", similar to opera singers (or Ted Nugent LOL) breaking glass.

Remember the Tacoma Narrows bridge failure?

Resonance had not been figured in to that design, and a fairly benign wind took it down.

The event was filmed, look it up on line and you may reconsider what air pressure differential in a tuned system is capable of.

More Tom Danley quotes:

"I chose the speaker division although it was a hard choice, it turned out to be a wise choice because not that much later the first shuttle blew up setting back any more work for 5 years at least.

It turned out one of the companies strongest suits was taking on the exotic jobs other companies would refer to us.

One of those goofy jobs, was to build a sonic boom simulator for the NASA space plane.

What your looking at is 1/3 of the below 30Hz portion of the system.

These were a push pull valve assembly, in the system in the photo, one has 4, 5HP fans to move the air.

Like this;

http://www.google.com/patents?id=HLo...age&q=&f=false

The system, with it's other speakers, was set up two meters from the outside of an OLD house outside of Atlanta where the research took place.

The system, when we turned it over, could produce a sine wave + - 2 dB from 5KHz down to 3Hz, at a pressure of 132Db at two meters distance."

What kind of dimensions are we looking at with that device? Do you think one could prototype something like that with RC car motors and servos or are we talking about washing machine size motors?

Edit: Sorry, didn't read it closely enough. That looks reasonably easy to duplicate, have you tried it?

No, I have no desire or use for a huge machine that uses what sounds like 12 five horsepower fans to achieve 132 dB down to 3 Hz.What kind of dimensions are we looking at with that device? Do you think one could prototype something like that with RC car motors and servos or are we talking about washing machine size motors?

Edit: Sorry, didn't read it closely enough. That looks reasonably easy to duplicate, have you tried it?

Washing machine motors are generally less than one horsepower (756 watts IIRC).

I'd guess the servo to control Tom's blower driven LF machine may be in the the 1 HP range, RC car servos are usually no more than a few watts.

On a similar track, an old professor described to me a horn loaded compressor driven device that was used in WW2 to broadcast propaganda from airplanes.

I have searched for the device on line, but to no avail. It would have been kind of a "Black Ops" device, so the military may have never filed patents.

The sound pressure level from the device was such that the level was very loud on the ground with the airplane safe from enemy ground fire at miles of altitude.

A “comb” in the throat of a reentrant (folded) horn was driven (frequency modulated) from a transducer powered by tube (valve) amplification, a compressor was engine driven, or may have been from engine manifold vacuum or pressure, provided air pressure through the “comb”.

The Auxetaphone may be the precursor to what he described, the pictures of the device match my memory of his description quite closely.

The device the professor described probably had output level less than the Auxetaphone, but far in excess of any standard amp/transducer technology available at the time of WW II, probably in the 150 dB range at a meter.

Art Welter

I wouldn't expect it to be the whole wall, as they in no way approach pistonic behavior

Guys, we are just being silly now. It would be the whole wall or nothing (heavy on the nothing). No wall can flex or move that much without failure. This whole notion can only be considered as a humourous and somehow believed by those who lack construction knowledge. There's no wiggle room here, it's just a fish story.

No, I have no desire or use for a huge machine that uses what sounds like 12 five horsepower fans to achieve 132 dB down to 3 Hz.

Well, what I was thinking about was drawing up something that could achieve the same things a rotary can...only without the $20,000 price tag.

Maybe not 12 5hp motors, but something a little more reasonably sized.

That design looks like it could be implemented a little easier than the fan blade pitching system used in the rotary. I've been very keen on some of these designs where you're basically bringing the whole room up to some amount of positive pressure and then "shaking" it to produce notes.

When I came to JI Case in Hinsdale, IL they told a story about when it used to be International Harvester, and about their computer tape vault room. They downsized the vault, but forgot to downsize the Halon fire suppression system. The next time they tested the Halon, they re-discovered that brick and block walls have strength in compression, but none in shear. The slight increase of interior air pressure when the Halon fire suppression dumped actually caused some structural damage.

Guys, we are just being silly now. It would be the whole wall or nothing (heavy on the nothing). No wall can flex or move that much without failure. This whole notion can only be considered as a humourous and somehow believed by those who lack construction knowledge. There's no wiggle room here, it's just a fish story.

I've seen set walls move that much. ok, so they were hollywood construction muslin flats, and it was a windy day....

you're right, this is just silly...

I've seen set walls move that much. ok, so they were hollywood construction muslin flats, and it was a windy day....

you're right, this is just silly...

It probably depends on how big the wall is, imo. I'm sure you could flex a wall the size of an airplane hangar several inches without collapse, but chances are it would need repair afterwords.

I could however see a poorly constructed wall having drywall separate from studs and flex quite a bit, but again, there would be cracks and screws sticking out.

Cal,Guys, we are just being silly now. It would be the whole wall or nothing (heavy on the nothing). No wall can flex or move that much without failure. This whole notion can only be considered as a humourous and somehow believed by those who lack construction knowledge. There's no wiggle room here, it's just a fish story.

Tom Danley was able to hit the wall’s resonant frequency with very high SPL from the blower driven sub.

Same concept as what caused Tacoma Narrows Bridge collapse.

Tacoma Narrows Bridge Collapse "Gallopin' Gertie" - YouTube

Look at the guy walking off the bridge around 2:03, the wind was not very strong.

I doubt the wall of the old building was built nearly as well as the Tacoma Narrows Bridge 😀.

Using the right resonance frequency, structures can move and be destroyed with relatively little energy input, Tom’s device was capable of a lot of energy input.

Art Welter

Guys, we are just being silly now. It would be the whole wall or nothing (heavy on the nothing). No wall can flex or move that much without failure.

You have a poor understanding of structures, as well as limited experience apparently.

Push on the corner of a cardboard box vs the middle of a side; the displacement of the latter is orders of magnitude larger.

I guess you've never seen how far walls move in an earthquake, or seen movies of buildings in hurricanes etc.

Hi Guys

Art is not pulling your leg and this is not a fish story.

The sonic boom simulator was set up outside of an old house for work studying the effects of the NASA space plane they were going to build. As this was a large craft, it would have a lower frequency sonic boom that fighter planes make.

http://pdf.aiaa.org/preview/1993/PV1993_4430.pdf

This system could produce 132-133dB at two meters on the wall of the house from 4KHz down to 3Hz and in use would produce an “N” shaped wave front which is the trademark of a sonic boom in general.

With such a large signature in time, the sonic boom had a distinct two part KAA BOOM, the pressure first rising rapidly and then a nearly straight line decay through zero to a negative value and then a recovery to zero.

This signal could make things fall off shelves inside and certainly startle people but the wall moving was in testing.

Consider for a moment why a concrete wall doesn’t pass sound well.

It has a huge acoustic impedance mismatch for one but sound can also make concrete or bricks fail. Sound is an alternating pressure but at a low frequency each pressure has time to act on a mass. That pressure causes acceleration which causes motion, which can cause tensile or compression failure. The lower the frequency is, the lower the SPL is required to move something heavy.

In the case of the wall, to be clear the entire wall didn’t move (although it shook the house) only the lowest mode was excited where the edges are clamped. I was deliberately teasing the house with sine waves and found the lowest mode to be around 4.5Hz. So, given the resonant frequency of the diaphragm mode and the size of the wall and that 132dB = + - 2lb per square foot of alternating pressure times the wall area, it really was possible to make the middle region of the wall and window on the old house move a frightening / impossible looking amount. To be sure, this was not good for the house either, I stopped teasing after this.

The best / most fun part though was standing against the house wall with the pickle button and experiencing a sonic boom over and over. After ten or twelve booms, it was breathtaking but also a relief to stop.

Best,

Tom Danley

Danley Sound Labs

this old house

Art is not pulling your leg and this is not a fish story.

The sonic boom simulator was set up outside of an old house for work studying the effects of the NASA space plane they were going to build. As this was a large craft, it would have a lower frequency sonic boom that fighter planes make.

http://pdf.aiaa.org/preview/1993/PV1993_4430.pdf

This system could produce 132-133dB at two meters on the wall of the house from 4KHz down to 3Hz and in use would produce an “N” shaped wave front which is the trademark of a sonic boom in general.

With such a large signature in time, the sonic boom had a distinct two part KAA BOOM, the pressure first rising rapidly and then a nearly straight line decay through zero to a negative value and then a recovery to zero.

This signal could make things fall off shelves inside and certainly startle people but the wall moving was in testing.

Consider for a moment why a concrete wall doesn’t pass sound well.

It has a huge acoustic impedance mismatch for one but sound can also make concrete or bricks fail. Sound is an alternating pressure but at a low frequency each pressure has time to act on a mass. That pressure causes acceleration which causes motion, which can cause tensile or compression failure. The lower the frequency is, the lower the SPL is required to move something heavy.

In the case of the wall, to be clear the entire wall didn’t move (although it shook the house) only the lowest mode was excited where the edges are clamped. I was deliberately teasing the house with sine waves and found the lowest mode to be around 4.5Hz. So, given the resonant frequency of the diaphragm mode and the size of the wall and that 132dB = + - 2lb per square foot of alternating pressure times the wall area, it really was possible to make the middle region of the wall and window on the old house move a frightening / impossible looking amount. To be sure, this was not good for the house either, I stopped teasing after this.

The best / most fun part though was standing against the house wall with the pickle button and experiencing a sonic boom over and over. After ten or twelve booms, it was breathtaking but also a relief to stop.

Best,

Tom Danley

Danley Sound Labs

this old house

Attachments

You're right noah, my experience with buildings is limited to forming, pouring, framing, back framing, block wall, brick laying, roofing, flooring, glazing, steel stud, drywall, finishing, electrical, plumbing and HVAC. Perhaps you can enlighten me as to what else I should know before making such bold statements.You have a poor understanding of structures, as well as limited experience apparently.

Do tell us how this has anything to do with building structure. Last time I checked buildings were not made of cardboard or your words might carry some weight.Push on the corner of a cardboard box vs the middle of a side; the displacement of the latter is orders of magnitude larger.

Again, this is related to wall flexing, without failure, how?I guess you've never seen how far walls move in an earthquake, or seen movies of buildings in hurricanes etc.

As the situation was presented, it is a house with the walls flexing 8-10 inches and the house remained standing.

With all due respect to Tom Danley the walls may have been moving a significant distance but were not moving anywhere near the said amount. First off, the windows would blow out long before the walls flexed very far, yet that has not been mentioned. Second, there are no structural materials used in todays buildings that offer that amount of flex before failure. No sir, not going to happen.

Wait a minute...You know what? I just realized that I am ruining a perfectly good story here. For that I apologize. You guys enjoy and I will stay away.

If you want to take it off line I would be happy to discuss building structures with you but here is obviously not the right place.

Cheers.

Building something per print does not imply or confer understanding.

As evidenced by your failure to grasp the simple analogy that a building is a box whose corners aren't as flexible as the walls in the middle, rendering false your statement that a whole wall moves together.

Quote:

I guess you've never seen how far walls move in an earthquake, or seen movies of buildings in hurricanes etc.

"Again, this is related to wall flexing, without failure, how?"

Observe how much flexure occurs before failure.

As evidenced by your failure to grasp the simple analogy that a building is a box whose corners aren't as flexible as the walls in the middle, rendering false your statement that a whole wall moves together.

Quote:

I guess you've never seen how far walls move in an earthquake, or seen movies of buildings in hurricanes etc.

"Again, this is related to wall flexing, without failure, how?"

Observe how much flexure occurs before failure.

Last edited:

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Subwoofers

- Fan Subwoofer