Having recently acquired a QA403 audio analyzer I looked at the linearity of some film caps I have, all ostensibly PP 100nF. I found 3 kinds of distortion profile among them, making me wonder if these are routinely being faked with cheaper dielectrics. The test setup was a divider, 100nF cap on top, 6k8 metal film resistor on bottom. This has a high pass response with -3dB point around 250Hz.

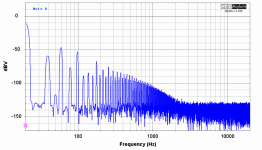

The responses I see from the three types of cap are:

Clearly cap1 is a high-k ceramic cap with high amounts of distortion evident. caps 2 and 3 are clearly different dielectrics, or very different film thicknesses (unlikely as these are all 100V rated). Only cap3 type seems to actually be PP with its very low distortion.

Here are the 3 tested samples, cap1 at top (its poor printing registration is further evidence for this being a counterfeit part):

Since these are all from my 100nF bin I don't have records of where each came from, alas, but its quite possible some are eBay, which would account for the rogues - so now I'm faced with the task of testing all my film caps...

The responses I see from the three types of cap are:

Clearly cap1 is a high-k ceramic cap with high amounts of distortion evident. caps 2 and 3 are clearly different dielectrics, or very different film thicknesses (unlikely as these are all 100V rated). Only cap3 type seems to actually be PP with its very low distortion.

Here are the 3 tested samples, cap1 at top (its poor printing registration is further evidence for this being a counterfeit part):

Since these are all from my 100nF bin I don't have records of where each came from, alas, but its quite possible some are eBay, which would account for the rogues - so now I'm faced with the task of testing all my film caps...

QA403 audio analyzer! Congratulation!

Assuming 5mm lead spacing and based on their size I doubt those are PP caps.

Can you test a trusted one and compare the results? Thanks

Assuming 5mm lead spacing and based on their size I doubt those are PP caps.

Can you test a trusted one and compare the results? Thanks

Crack them open and see what's inside, at least real PP should feel waxy/fatty/oily similar to PTFE when rubbing between the fingers.

I know cap1: it is a chinese imitation of miniature PET caps made by Thomson (those are boxed, rather than resin-cast). Inside, you find a high k MLCC cap, just as you guessed.

The white one is an actual PET cap, exactly lke the Thomson ones except the box is white instead of yellow.

I have no idea about the last one, but your measurement shows it is probably a metallized PP cap.

Apart from THD, a good way to determine the material is the dielectric loss factor: 0.4% is PET, 0.1% polycarbonate, and below it is PP, PS or group I ceramic

The white one is an actual PET cap, exactly lke the Thomson ones except the box is white instead of yellow.

I have no idea about the last one, but your measurement shows it is probably a metallized PP cap.

Apart from THD, a good way to determine the material is the dielectric loss factor: 0.4% is PET, 0.1% polycarbonate, and below it is PP, PS or group I ceramic

Another way is to either heat the cap with a hair drier, or freeze it by leaving them outside in the winter, while measuring the capacitance. If the capacitance goes down as the temperature goes up (negative tempco), it's polypropylene. Everything else should go to the bin.

The critical ones are in the 0.1-1uF range with a spacing of 5-10mm: most of them are polyester, no matter what the datasheet says. On the contrary, most of the X2 caps are polypropylene, and don't have the piezo effect.

The critical ones are in the 0.1-1uF range with a spacing of 5-10mm: most of them are polyester, no matter what the datasheet says. On the contrary, most of the X2 caps are polypropylene, and don't have the piezo effect.

Those generic caps can really vary, no doubt.

Thanks for sharing the measurements, nice new toy. I would be busy for hours if I had something like that!

Thanks for sharing the measurements, nice new toy. I would be busy for hours if I had something like that!

Question I have is how do you know that dielectric materials are causing the observed behavior, and not some difference in the physical structure of the different capacitors?

For film caps, the main structural difference is metallized vs. plain foil. Metallization slightly degrades the performances, but doesn't change the character of the dielectric.Question I have is how do you know that dielectric materials are causing the observed behavior, and not some difference in the physical structure of the different capacitors?

You can always find pathological examples in all categories, but they are caused by a manufacturing defect, water ingress etc.

10dbV I think - that legend at the top is the signal level I thinkHow much driving voltage did you apply during that test?

Its a good question, I guess you have to make the assumption that the conductors are metal and any ferromagnetism is too low at signal current levels to show up - there could be some such effect though - checking with a magnet shows 1 and 3 are steel leaded, cap 2 is non magnetic...Question I have is how do you know that dielectric materials are causing the observed behavior, and not some difference in the physical structure of the different capacitors?

Acoustic vibration and resonance could be important in some situations, but these spectral plots don't show definite peaks. placing a microphone on each cap might be worth doing.

Interestingly I looked at the residual for cap1, and its very similar to cross-over distortion, which accounts for the large numbers of harmonics generated.

Compare for instance to some of the plots in https://sound-au.com/articles/crossover-distortion.htm - clearly most of the distortion is to do with the point at which the electric field reverses, not some sort of smooth but non-linear response curve, though that's no doubt also present. This is more dramatic that some of the articles about ceramic cap hysteresis tend to suggest

Here's the harmonics for a 250Hz tone for instance:

Compare for instance to some of the plots in https://sound-au.com/articles/crossover-distortion.htm - clearly most of the distortion is to do with the point at which the electric field reverses, not some sort of smooth but non-linear response curve, though that's no doubt also present. This is more dramatic that some of the articles about ceramic cap hysteresis tend to suggest

Here's the harmonics for a 250Hz tone for instance:

That is very strange, because the high dielectric constant MLCCs show high levels of 3rd harmonic as the capacitance plunges at higher voltages. At low voltages, they are reasonably linear and there is no obvious crossover mechanism. Is your waveform shifted 90 degrees by the current and voltage on a capacitor?Interestingly I looked at the residual for cap1, and its very similar to cross-over distortion, which accounts for the large numbers of harmonics generated.

View attachment 1251128

Compare for instance to some of the plots in https://sound-au.com/articles/crossover-distortion.htm - clearly most of the distortion is to do with the point at which the electric field reverses, not some sort of smooth but non-linear response curve, though that's no doubt also present. This is more dramatic that some of the articles about ceramic cap hysteresis tend to suggest

Here's the harmonics for a 250Hz tone for instance:

View attachment 1251130

I would expect the dC/dV Variation being max at low voltage. Explaining most non-linearity around zero crossing.

Note that there was no DC offset on the tested capacitors which for an ceramic MLCC capacitor (Y5V, X7R etc) is worst case as bucks bunny points out.

Mark, thank you for starting this thread. The test method is so simple and obvious, and yet until I saw it I had never even thought of it. 😀

Mark, thank you for starting this thread. The test method is so simple and obvious, and yet until I saw it I had never even thought of it. 😀

Ah, that would make sense - I suspect there's a complex mix of different grain sizes in the dielectric leading to similarly complex behaviour.I would expect the dC/dV Variation being max at low voltage. Explaining most non-linearity around zero crossing.

I used low frequency stimulus to ensure the relative phasing of input and output was close - not entirely sure of the latency of the QA403, but with a 20Hz signal and 192kSPS I'm confident the phase error is pretty small between waveform and residual.

The previous measurements were with the divider being RC, however using an CR divider the residual is more complex, presumably as the signal across the capacitor is smaller and within the worst performing region:

and the harmonics more notable (as the circuit isn't low-pass filtering them):

Attachments

The other reason to avoid MLCC in sensitive audio paths is microphony. Yesterday I tested a wireless setup with my electric guitar. S/N somewhere in the range of 100dB looks pretty good - but when using hi-gain distortion, acoustical feedback takes in due to microphonic behaviour of the receiver. Looking inside I could not discover any film caps - so MLCCs are the obvious culprit. An absolute no-go, I returned to cable connection. Sometimes even me can hear bad capacitors!

Shockingly high distortion. I got worried.

Here is what I get with 100 nF Wima MKP4 + 6K8. Introduced distortion is only H3 and rest is signal generator + ADC residual distortion. Increasing AC voltage results with rising H3.

To me, all that harmonics in your measurement look like 50 Hz harmonics (despite low pass), not like a capacitor introduced distortion.

Here is what I get with 100 nF Wima MKP4 + 6K8. Introduced distortion is only H3 and rest is signal generator + ADC residual distortion. Increasing AC voltage results with rising H3.

To me, all that harmonics in your measurement look like 50 Hz harmonics (despite low pass), not like a capacitor introduced distortion.

- Home

- Design & Build

- Parts

- Fake PP film caps?