Yep, but you weren't before. That's why I called it out.I'm just going by the PS schematic in the F5 Turbo article which shows 7 .47-ohm 3W resistors. '

Yes, but Nelson (assuming he used 15kuF) has 120k. See the schematic.I also have 88kuF of capacitance on each rail.

Edited. Opened the article and zoomed in. He's showing 10kuF (far right side). See... that's what I get for a WAG. So he's got 80k, and you've got 88. Apologies for the smoke without fire.

Last edited:

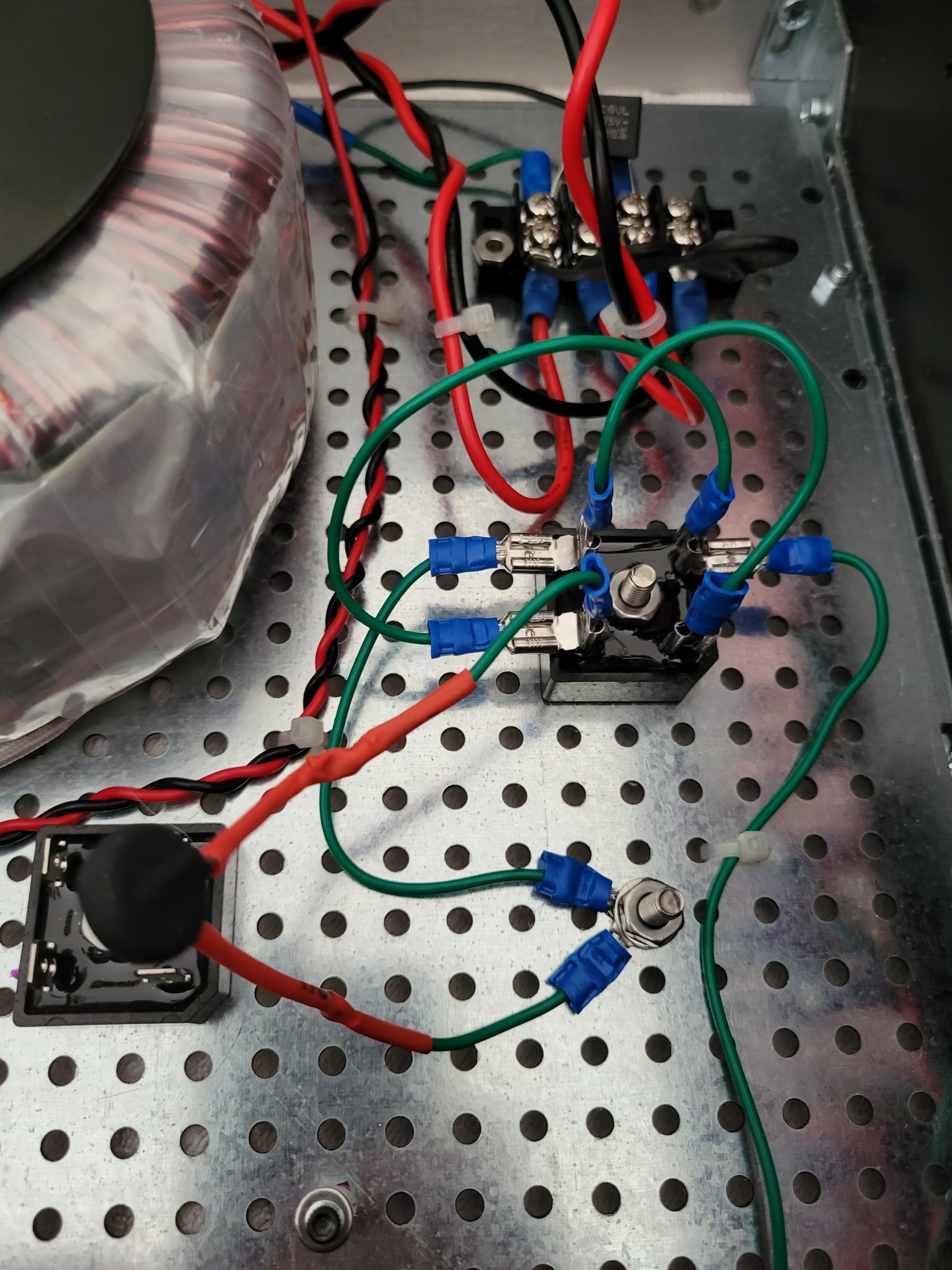

Work continued all morning on this build, and my fingers are sore! Next steps are to:

- Test the power supply on a dim bulb

- Connect the power supply to the boards

- Add the thermistors and solder the mosfets to the boards

- Wire the inputs and outputs

- Start biasing.

Pass DIY Addict

Joined 2000

Paid Member

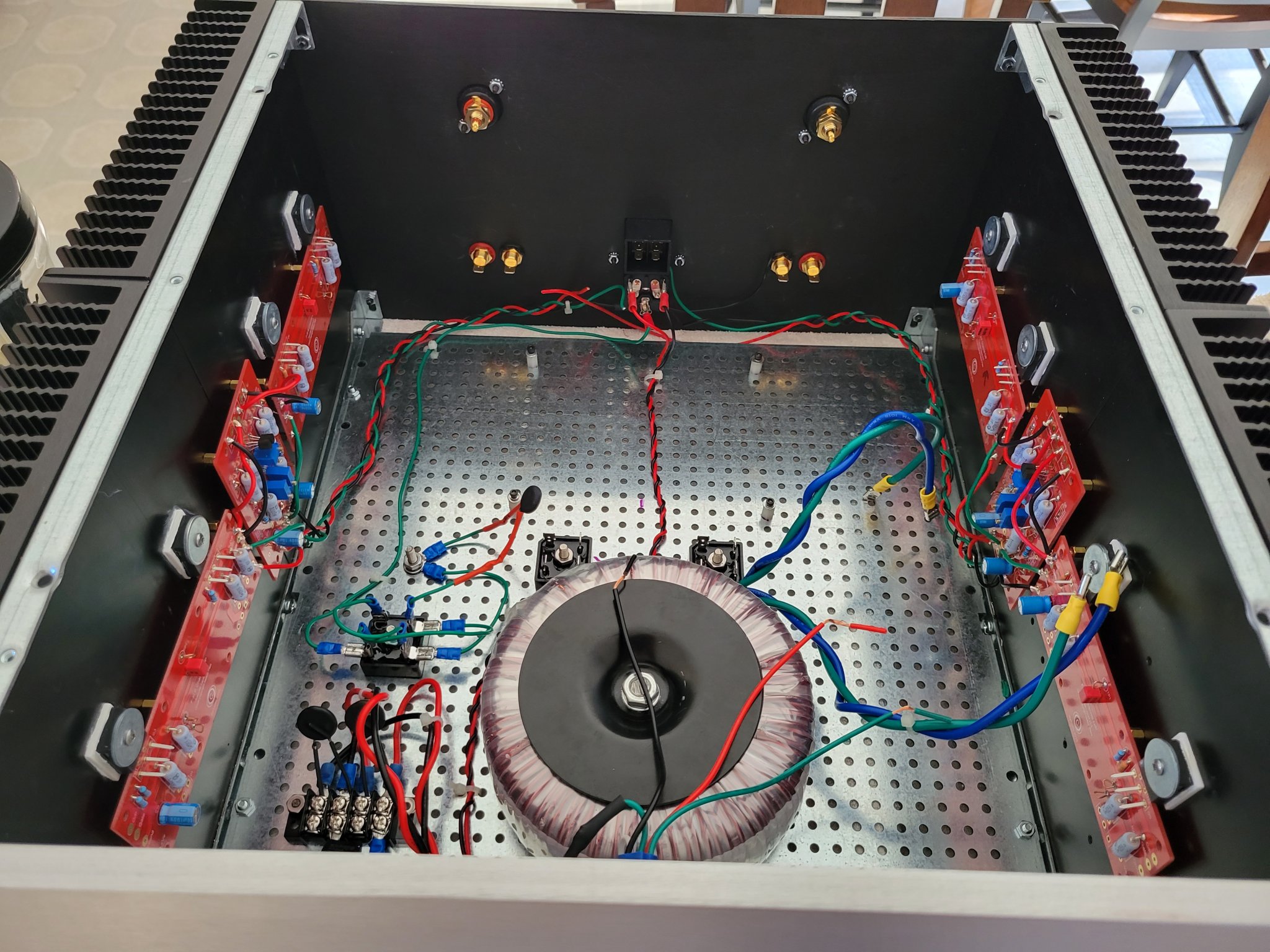

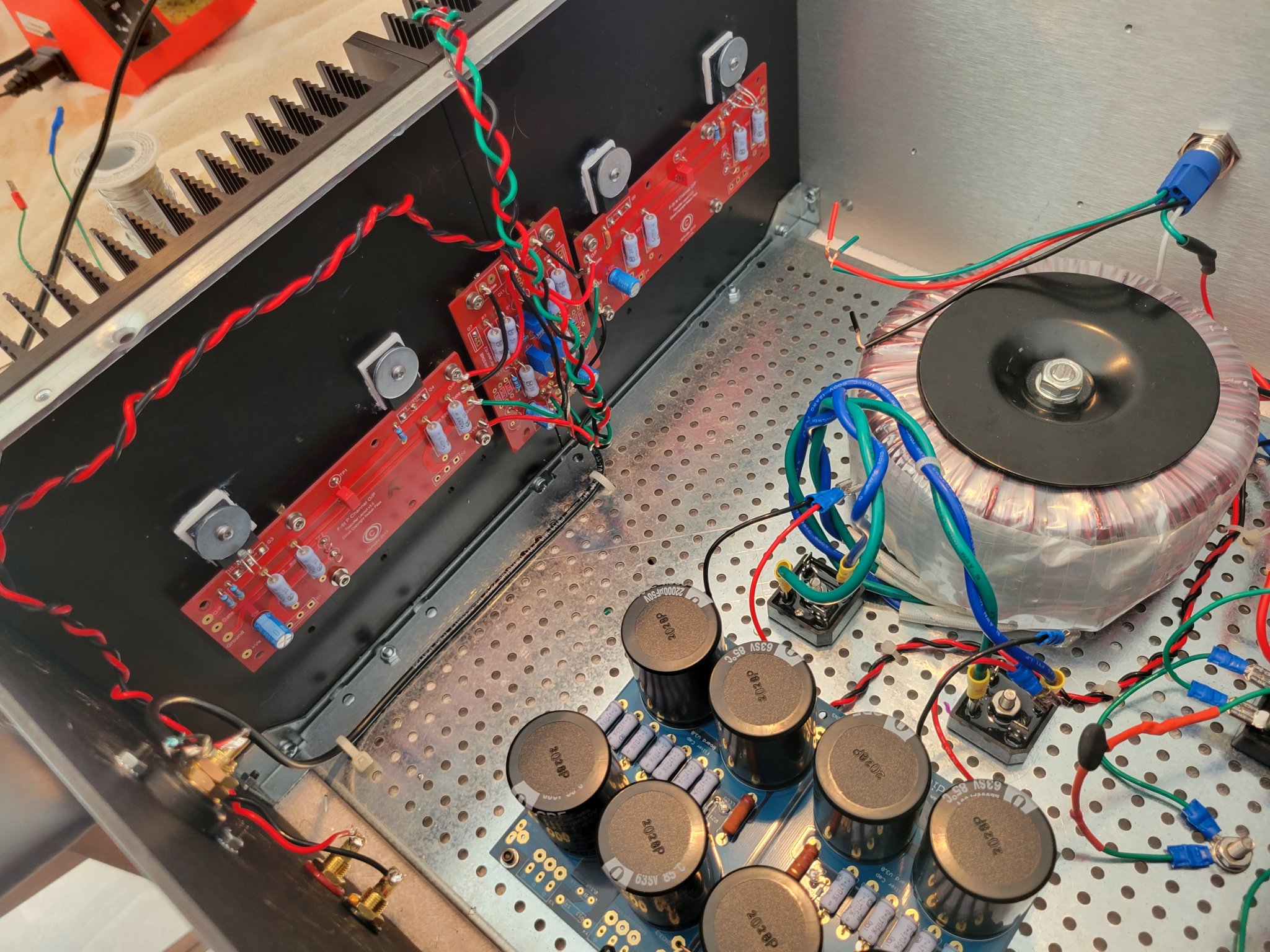

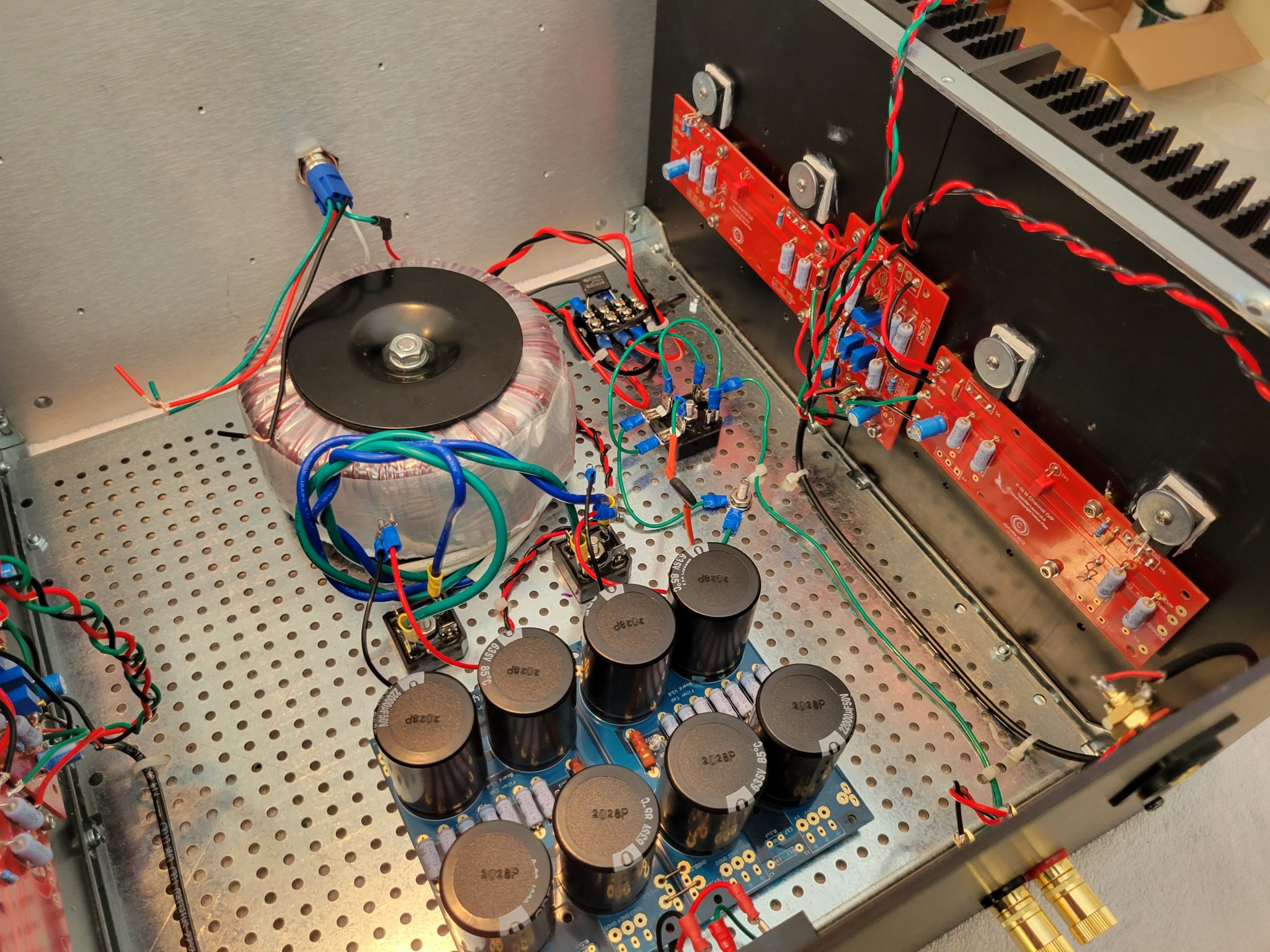

I spent another full morning on it. Power supply fired up fine except the LED on the negative side was backward, fixed that. Inputs and outputs are wired, everything screwed down, MOSFETs soldered. The only thing to do is connect the PS to boards and bias it up.

It's a colorful build.

It's a colorful build.

Just saw your update. I'm glad I'm not off base here, and appreciate you looking out for me!Yep, but you weren't before. That's why I called it out.

Yes, but Nelson (assuming he used 15kuF) has 120k. See the schematic.

Edited. Opened the article and zoomed in. He's showing 10kuF (far right side). See... that's what I get for a WAG. So he's got 80k, and you've got 88. Apologies for the smoke without fire.

Checked the PS with a DBT, then with right channel boards connected, bulb went out right away. Right channel is now cooking at 300mV with the lid on. Heatsink temp is rising into the 90s F.

After a 20 minute cook, bias is stable around 290mV, DC offset is 6.6mV, and heatsinks are at 107F. Taking it to 350mV now and after cooking again I'll do final adjustment and connect the other channel to power.

Powered up the 2nd board on the DBT and the bulb stays lit brightly. I measured the resistance across the output, and it starts shorted then slowly rises. The good side measures a steady 59.5 ohms across the output.

I went over everything visually and verified that the N and P channel transistors are in the right places. Any tips?

I went over everything visually and verified that the N and P channel transistors are in the right places. Any tips?

Pass DIY Addict

Joined 2000

Paid Member

Great to hear that you have one channel up and running. A nice and tidy looking build as well!

For the second channel, the first easy thing to check is to use your DMM and check for electrical isolation between the center pins of your output mosfets and the sink. This should measure open loop. Do this with no power applied. Also, look for any component leads that might be extending through the PCB and hit the sink underneath. Did that trick myself with my last ACA build.

Glad to hear that you powered/tested only one channel at a time - this reduces headaches for sure.

For the second channel, the first easy thing to check is to use your DMM and check for electrical isolation between the center pins of your output mosfets and the sink. This should measure open loop. Do this with no power applied. Also, look for any component leads that might be extending through the PCB and hit the sink underneath. Did that trick myself with my last ACA build.

Glad to hear that you powered/tested only one channel at a time - this reduces headaches for sure.

I found the short, due to the thick insulators I used on the Mosfets, their legs were touching the thermister leads on the back side. I'll trim them as much as possible and add a layer of insulation.. Hopefully, the 100W dim bulb saved that side!

Pass DIY Addict

Joined 2000

Paid Member

final screw tightening goes when everything is aligned

higher level of alignment precision for Modushop cases would more likely induce more problems during assembly , than benefits

and it'll cost more

in fact, from engineering point of view, pretty much every detail on Modu cases is perfect - things which can be made better are ........ irrelevant

higher level of alignment precision for Modushop cases would more likely induce more problems during assembly , than benefits

and it'll cost more

in fact, from engineering point of view, pretty much every detail on Modu cases is perfect - things which can be made better are ........ irrelevant

OK, so loosen everything then line up the holes on the top&bottom. I haven't had to do that with the other Modushop cases.final screw tightening goes when everything is aligned

higher level of alignment precision for Modushop cases would more likely induce more problems during assembly , than benefits

and it'll cost more

in fact, from engineering point of view, pretty much every detail on Modu cases is perfect - things which can be made better are ........ irrelevant

Q6 on the N channel board (right voltmeter) is running hot, 150F vs 120F for the 7 others. Any suggestions? I can't get the voltage up on that board without the offset going way off.

I put in a 4A fuse and it powers on now without blowing it. Unfortunately, the left channel has a problem, and one of the P channel MOSFETs just smoked.

I do have another pair of JFETs, could these cause the voltage imbalance across the N and P channels? I can't find anything else wrong with the boards. The right channel is happy.

I do have another pair of JFETs, could these cause the voltage imbalance across the N and P channels? I can't find anything else wrong with the boards. The right channel is happy.

- Home

- Amplifiers

- Pass Labs

- F5T v2 New Build