Pass DIY Addict

Joined 2000

Paid Member

oreo: See e) above in Methods section. Screw head both measured highest and provided best consistency.

kasey: you are quite welcome!

rookakoma: black kept the mosfet the coolest, resulting in slightly higher sink temp. This makes sense: heat from the mosfet is dissipating through the sink the best. If I had a DMM that reported temps with decimals (rather than integers), there might be more interesting things to see here.

Mark: Wow- I didn't know such a device existed! This looks like it would provide better data. Next time I place an order, I'll have to grab a few.

kasey: you are quite welcome!

rookakoma: black kept the mosfet the coolest, resulting in slightly higher sink temp. This makes sense: heat from the mosfet is dissipating through the sink the best. If I had a DMM that reported temps with decimals (rather than integers), there might be more interesting things to see here.

Mark: Wow- I didn't know such a device existed! This looks like it would provide better data. Next time I place an order, I'll have to grab a few.

Urban Legends about Thermal Interface Materials by INFINEON

As Infineon put it: there is no correlation at all between the chip temperature achieved in the test and the datasheet value given for thermal conductivity p.24 middle row

https://www.infineon.com/dgdl/Infin...n.pdf?fileId=db3a304343e0037c0143f875b52e3343

As Infineon put it: there is no correlation at all between the chip temperature achieved in the test and the datasheet value given for thermal conductivity p.24 middle row

https://www.infineon.com/dgdl/Infin...n.pdf?fileId=db3a304343e0037c0143f875b52e3343

Eric, Thank you very much for testing and sharing the results. Good to know that Aluminum Oxide Ceramic works well compared to the expensive Keratherm.

I use the 900S in my F5. SP900S-0.009-00-104 Bergquist | Fans, Thermal Management | DigiKey

Last I checked the body of the MOSFET was a couple degrees higher than the heatsink (black aluminum from the store).

Last I checked the body of the MOSFET was a couple degrees higher than the heatsink (black aluminum from the store).

rookakoma: black kept the mosfet the coolest, resulting in slightly higher sink temp. This makes sense: heat from the mosfet is dissipating through the sink the best. If I had a DMM that reported temps with decimals (rather than integers), there might be more interesting things to see here.

Eric, Wrong conclusion!

Better heatsink emission means better dissipation and / or better radiation.

At your experiment the dissipation factor is constant (because you used the same heatsink), so better radiation makes cooler heatsink.

1°C is not too much at heatsink... It makes 1°C cooler device (when the thermal resistance between the device and sink is constant).

The reason of the different device temperatures at your experiment is th. res. between the device and heatsink.

This conclusion based on the lows of thermodynamic.

Tighten a transistor onto a heatsink, and watch that goop squirts-out... slowly -> a very very satisfying feeling indeed.

I would have expected a good mica insulator to be better than the others, but with serious fussiness with getting a very thin paste layer. Your mica must be thick or something was not flat.

If you use so much paste that is squeezes out, you have too much and may have big trouble later as it dries out.

If you use so much paste that is squeezes out, you have too much and may have big trouble later as it dries out.

Pass DIY Addict

Joined 2000

Paid Member

rookakoma: fair enough - thank you for the additional details.

davidsrsb: it is possible that something was not flat. The mounting hole was drilled on my drillpress, so I'd expect it to be reasonably perpendicular to the surface of the sink, though it is possible that something is off. The same hole was used for all measurements, though some of the thermal interfaces were more rigid than others. If the hole is not perpendicular and this disadvantaged the mica & grease, then the AlOx performs even better than measured as it is also rigid.

One of my motivations was to actually see what happens since we all have certain expectations. I like data.

davidsrsb: it is possible that something was not flat. The mounting hole was drilled on my drillpress, so I'd expect it to be reasonably perpendicular to the surface of the sink, though it is possible that something is off. The same hole was used for all measurements, though some of the thermal interfaces were more rigid than others. If the hole is not perpendicular and this disadvantaged the mica & grease, then the AlOx performs even better than measured as it is also rigid.

One of my motivations was to actually see what happens since we all have certain expectations. I like data.

The silver paste (conductive metal particles) doesn’t belong in an amplifier, unless by chance electric isolation is not a factor.

Pass DIY Addict

Joined 2000

Paid Member

How would only thermal grease (the white stuff) compare?

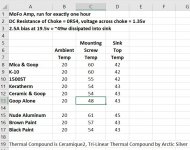

Some of the comments that were posted made me wonder about about how perpendicular my hole was in the surface of my sink. I double checked my drill press - the table is as perpendicular as I can make it (I ended up not actually adjusting it). I drilled a new hole and was as careful as I could be to make sure the hole was true. I then re-ran my experiment as described in my first post. The results were the same (ambient temp may have drifted a bit, but I compensated in my table to provide the same starting point).

I added a new measurement: only thermal grease was used between the mosfet and the sink. This only works for a single channel of the MoFo amp, DON'T DO THIS WITH ANY OTHER AMP HERE - you'll create an electrical short.

I expected thermal paste alone to perform the best, but the magnitude of the difference was a bit of a surprise to me. I have attached an updated chart with the new test condition.

Finally, the thermal compound that was used for all tests is Ceramique2, Tri-Linear Thermal Compound by Arctic Silver.

Attachments

Last edited:

Can you measure your mica thickness. I have seen it being split into thinner sheets.

I have also read that the mica available these days is coarse stuff compared with in the 70s

I have also read that the mica available these days is coarse stuff compared with in the 70s

I expected thermal paste alone to perform the best, but the magnitude of the difference was a bit of a surprise to me. I have attached an updated chart with the new test condition.

With thermal paste only the temp of the screw is significant lower than the other options. What can be concluded from this observation? …...that the temp of the chip/junction is lower also using thermal paste only?

Pass DIY Addict

Joined 2000

Paid Member

david: I will measure the mica thickness tonight and let you know what I find. I used the mica that was supplied in the VFET2 kit just because it was available.

MEPER: My interpretation is that lower temps of the mounting screw indicate lower transistor temps because there is better heat flow from the transistor into the sink. As the performance of the thermal interfaces improved, the mosfet temps were successively cooler. Thus, the best thermal interface is the minimal one: just goop. If I'm wrong, someone please correct me...

MEPER: My interpretation is that lower temps of the mounting screw indicate lower transistor temps because there is better heat flow from the transistor into the sink. As the performance of the thermal interfaces improved, the mosfet temps were successively cooler. Thus, the best thermal interface is the minimal one: just goop. If I'm wrong, someone please correct me...

isn't better to measure temperature of the mid pin of the mosfet?

it is directly in contact with the die

it is directly in contact with the die

isn't better to measure temperature of the mid pin of the mosfet?

it is directly in contact with the die

Wouldn't that short the temp probe? I've seen it happen.

Pass DIY Addict

Joined 2000

Paid Member

Mica wafer is 0.07mm thick and the center pin of the mosfet is equal in temperature to the screw head.

I did manage to short the temp probe on an old meter - it was because I was simultaneously using the voltage probes. Oops...

I did manage to short the temp probe on an old meter - it was because I was simultaneously using the voltage probes. Oops...

0.07mm is the usual 0.003" mica, which is 0.009W/in/sqin/C

3W/sqin/C.

This is only an average thermal conductor

3W/sqin/C.

This is only an average thermal conductor

Goop only...

Hi Eric,

When trying to get the very best thermal contact between a CPU and heatsink I have lapped the CPU and heatsink with fine “wet & dry” to ensure they are as flat as possible (thus maximising the contact area). Could you do the same and report relative results from your test rig please? I’m asking because I will be directly mounting my FETs to the heatsink with goop...

Hi Eric,

When trying to get the very best thermal contact between a CPU and heatsink I have lapped the CPU and heatsink with fine “wet & dry” to ensure they are as flat as possible (thus maximising the contact area). Could you do the same and report relative results from your test rig please? I’m asking because I will be directly mounting my FETs to the heatsink with goop...

For your reference (free download courtesy of an Didden) :

https://linearaudio.net/sites/linearaudio.net/files/v3 euvl.pdf

https://www.diyaudio.com/forums/pass-labs/37262-mica-goop-6.html#post1032023

Patrick

https://linearaudio.net/sites/linearaudio.net/files/v3 euvl.pdf

https://www.diyaudio.com/forums/pass-labs/37262-mica-goop-6.html#post1032023

Patrick

I'd be interested in how a ''directly'' mounted FET would keep up, that is without any insulator and no goop at all.

- Status

- Not open for further replies.

- Home

- Amplifiers

- Pass Labs

- Experiment: Which mosfet thermal interface material is best?