is the foam spiral enough to withstand the weight of the plywood front that has the speaker?

I'd say that the final build is strong enought with just foam and glue, no reinforcements needed with the plywood i used that is 4 mm thick.

Perhaps the key is the glue you use. In my case the spirals and the back piece are foam board and the front is plywood. For glue I used a polyurethane one that is very strong and expands a little, so it fills up al the perimeter.

I agree with Ricren: I used 12mm (0.5in) plywood on my 65 x 7.5cm spirals and the structure is extremely stiff and there is no need for extra bracing.

I agree that the spiral foam bond with the faces is very strong and additional bracing is probably not needed. It is similar to aerospace honeycomb panels with soft honeycomb in the middle. The structure is very stiff and strong and the length of glue bond is quite long. As speakers go, I would bet Cornu's are the strongest or stiffest structures per unit weight.

Today I bought 3 different adhesives. In order to select the best of them I made a simple test: 3 pieces of Foam core glued to a piece of playwood, each one with a differen product. I'll let them dry for 24 hours and tomorrow I'll test how strong is the bond.

I would like to know an ideal glue to use for this project, let us know...

Today I bought 3 different adhesives. In order to select the best of them I made a simple test: 3 pieces of Foam core glued to a piece of playwood, each one with a differen product. I'll let them dry for 24 hours and tomorrow I'll test how strong is the bond.

guess, in US liquid nails seems to be the consensus.

guess, in US liquid nails seems to be the consensus.

My research will not necessary help you because as you may guess, we have different products available.

Anyway I'll detail what i tried:

Adhesive 1: PVA (white carpenter glue): strong, slow, hard when dry. I used it on the spirals against the back foam board.I also used hot glue to fix the spirals while the white glue was drying. After that I caulked the perimeter with silicone sealant. This trick is very important and i got it from this thread. Thanks!

Adhesive 2: I needed something stronger that could also fill the gaps between the base ensamble and the front wood piece, because once glued I was not going to caulk it. So I used a polyurethanic monocomponent glue (ambar colour) that reacts with humidity and inflates a bit when drying, filling the gaps that usually happens on the main horn-front panel interface.

Hope it helps.

Gychang,

I used 1/4" luan plywood for the front and back baffles, typically used for underlayment for carpeting here in the US. I used hot glue to attach the foam board spirals to the front baffle first, then used good quality siliconized latex caulk to attach the front baffle/spirals to the back baffle. Let sit overnight with weights on top to make sure bond was tight, was very liberal with the caulk. I panted the visible portions of the baffles and foam board with black paint, but if I had it to do over I would have used black foam board. The solvent in the pain caused some minor bubbling of the foam board. I would be really careful of using anything like construction adhesive unless you test it on the foam board first, the solvents might eat the foam board.

PJN

I used 1/4" luan plywood for the front and back baffles, typically used for underlayment for carpeting here in the US. I used hot glue to attach the foam board spirals to the front baffle first, then used good quality siliconized latex caulk to attach the front baffle/spirals to the back baffle. Let sit overnight with weights on top to make sure bond was tight, was very liberal with the caulk. I panted the visible portions of the baffles and foam board with black paint, but if I had it to do over I would have used black foam board. The solvent in the pain caused some minor bubbling of the foam board. I would be really careful of using anything like construction adhesive unless you test it on the foam board first, the solvents might eat the foam board.

PJN

I really like Liquid Nails (the VOC compliant one) for final adhesive on foam core projects. Make sure it is not the solvent based one or it will melt your foam core box! One of my tractrix horns gt ruined this way. Once dry it is very strong.

Gychang,

I used 1/4" luan plywood for the front and back baffles, typically used for underlayment for carpeting here in the US. I used hot glue to attach the foam board spirals to the front baffle first, then used good quality siliconized latex caulk to attach the front baffle/spirals to the back baffle. Let sit overnight with weights on top to make sure bond was tight, was very liberal with the caulk. I panted the visible portions of the baffles and foam board with black paint, but if I had it to do over I would have used black foam board. The solvent in the pain caused some minor bubbling of the foam board. I would be really careful of using anything like construction adhesive unless you test it on the foam board first, the solvents might eat the foam board.

PJN

thanks, will check it out at home depot.

I really like Liquid Nails (the VOC compliant one) for final adhesive on foam core projects. Make sure it is not the solvent based one or it will melt your foam core box! One of my tractrix horns gt ruined this way. Once dry it is very strong.

didn't realize more than one Liquid Nails, will read the label carefully...

To my Australian friends contributing to this discussion: Where can foam core be found in Australia? I've tried previously to source some, for other projects, from retail craft stores etc in Sydney but the retailers don't know what it is.

foam core

Hi

Just saw some today in Officeworks! Good timing, I haven't checked out the forum in yonks and was reminded of the Cornu Spiral when I saw the board in officeworks....

Happy building.

PG

Hi

Just saw some today in Officeworks! Good timing, I haven't checked out the forum in yonks and was reminded of the Cornu Spiral when I saw the board in officeworks....

Happy building.

PG

So I picked up a couple of these 2" Tang Band drivers for $4.50 each. Would these be suitable for a micro (14") cornu spiral?

Tang Band 2" Polycone Neodynium Full Range

Tang Band 2" Polycone Neodynium Full Range

Where are they going for $5? That's a great deal for a powerful motor driver. Perfect for a front loaded horn application like a Trynergy.

Yes, they should work fine in a 14in cornu. Even 16 in can work. Make it 2in to 2.5in deep.

Yes, they should work fine in a 14in cornu. Even 16 in can work. Make it 2in to 2.5in deep.

A local source, not an online seller unfortunately. Cornus could be a fun project for the cabin... Will be a while before I can commence, though.

Thanks, I'll check out my local Officeworks store for Foam Board.Hi

Just saw some today in Officeworks! Good timing, I haven't checked out the forum in yonks and was reminded of the Cornu Spiral when I saw the board in officeworks....

Happy building.

PG

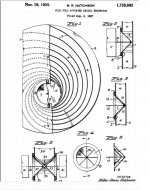

Thanks for finding that George. I am not sure where the actual driver is as I don't see a voice coil or magnet. Just two opposed conics?

The single (or two opposed, both arrangements are shown) "conics" are the driver cones, driven via pushrod from an external unit. In the Cornus in this thread, the arrangement is approximated by having the back of the driver in the throat of the spiral.

- Home

- Loudspeakers

- Full Range

- Ever think of building a Cornu Spiral horn? Now you can!