Nice rig. I have just added fresh peroxide to my solutions when they get sketchy to prolong their useful life. That should help some if you have left a solution to sit for a while, but 30 boards seems like a good lifetime of your solution to me.

hmm yes, you are right...I just treated an analytical grade copper solution with NaOH and got something blue. 🙂

But I remember dark sludges from etching solutions...😕

But I remember dark sludges from etching solutions...😕

juergenk said:hmm yes, you are right...I just treated an analytical grade copper solution with NaOH and got something blue. 🙂

But I remember dark sludges from etching solutions...😕

Did you mix the developer solution into the etch solution? You may have gotten some polymeric crud in there.

The process that i use is this:

http://myweb.cableone.net/wheedal/pcb.htm

In step 5 i use boiled tap water, i leave the board there for about 30 min to cook the paper (make the fiber of the paper more soft), after that i just peel off the paper very very easy.

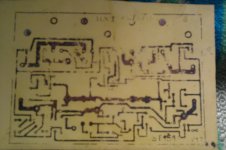

Here are some samples:

I've done many boards all with 100% success with that process.

http://myweb.cableone.net/wheedal/pcb.htm

In step 5 i use boiled tap water, i leave the board there for about 30 min to cook the paper (make the fiber of the paper more soft), after that i just peel off the paper very very easy.

Here are some samples:

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

I've done many boards all with 100% success with that process.

Quite ok. Just that some are over etch.

Make sure when you expose the board over the UV, the overlay should be

sticking close to the board. This is to prevent the UV from entering those trace you want to preserve. If you use laser toner method, make sure you have good transfer. When etching, try to stir the agent against the board. This is to ensure the etching process is even throughout the board.

This may be a reference to you,

DIY Home PCB Fabrication

Make sure when you expose the board over the UV, the overlay should be

sticking close to the board. This is to prevent the UV from entering those trace you want to preserve. If you use laser toner method, make sure you have good transfer. When etching, try to stir the agent against the board. This is to ensure the etching process is even throughout the board.

This may be a reference to you,

DIY Home PCB Fabrication

dear all reader,

i have etch some pcb which are not etch properly can any one help me.with regards masood alvi

- Status

- Not open for further replies.