Personally, I use a 2mm chisel bit for ALL my SMD work and have had no problems. If you use too fine a tip, it's very difficult to keep the tip tinned which means it's harder to get a thermal contact with the part.

So I would go for a B005360 bit - And don't forget the solder wick!

So I would go for a B005360 bit - And don't forget the solder wick!

Just need to make sure the tip is clean and well tinned - I use a damp sponge and that course wire wool stuff.

Life just isn't complete without solder wick - I use 2 widths for SMD - 1.5mm and 2.5mm. When soldering something like the WM8804, I find the best method is to flood solder the pins, then wick off the excess, which should also get rid of any bridges. Be VERY careful not to let the wick "freeze" to the chip pins or pads - Just keep the solder molten and the wick moving.

You will almost certainly want some additional flux - I use a gel flux and apply it with a syringe - Use plenty because the flux in cored solder burns off quickly.

Good luck - Ken

Life just isn't complete without solder wick - I use 2 widths for SMD - 1.5mm and 2.5mm. When soldering something like the WM8804, I find the best method is to flood solder the pins, then wick off the excess, which should also get rid of any bridges. Be VERY careful not to let the wick "freeze" to the chip pins or pads - Just keep the solder molten and the wick moving.

You will almost certainly want some additional flux - I use a gel flux and apply it with a syringe - Use plenty because the flux in cored solder burns off quickly.

Good luck - Ken

Thank you.

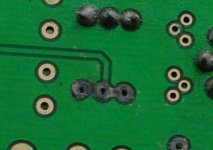

Off topic: been de soldering trimming pot , and somehow ring on pcb around wiper is not visible any more.

I have checked continuity between wiper and adjacent pole and it is there (as on the rest of pots) and not sure is pcb damaged or continuity is there for a reason 🙂

Any ideas ?

P.S. Hate desoldering ...

Off topic: been de soldering trimming pot , and somehow ring on pcb around wiper is not visible any more.

I have checked continuity between wiper and adjacent pole and it is there (as on the rest of pots) and not sure is pcb damaged or continuity is there for a reason 🙂

Any ideas ?

P.S. Hate desoldering ...

Hi Ivan, Bit of a problem there - Is the PCB double sided? And which pad has lifted - Solder side or component side? If it's the component side pad thats lifted, you should be OK assuming the through plating is good. If it's the solder side, you will need to scrape and tin the trace and piece out with a short bit of wire.

Hope that makes sense.

Ken

Hope that makes sense.

Ken

It is Uriah's Lighter note. It is the solder side. No pads were lifted its just the black ring surrounding wiper got missing.

I ll try to scrap , otherwise order replacement pcb. Only few components been soldered so damage is not that big... the learning curve !

I ll try to scrap , otherwise order replacement pcb. Only few components been soldered so damage is not that big... the learning curve !

It is Uriah's Lighter note. It is the solder side. No pads were lifted its just the black ring surrounding wiper got missing.

I ll try to scrap , otherwise order replacement pcb. Only few components been soldered so damage is not that big... the learning curve !

Can you post a picture?

OK - Good luck.

BTW - Could you be soldering a bit to hot? I try to do most work at 330C. Just a thought...

Ken

BTW - Could you be soldering a bit to hot? I try to do most work at 330C. Just a thought...

Ken

Dear experts 🙂

Which bit to buy for a Subbu dac soldering works?

I am using xs25 iron from antex.

Would you please advice :

List of bits

Ivan

You should get the 5060 or 5160, the sharp tip would not give you enough metal to reach the melting point fast enough.

That's hard to see exactly what's happening there, but the darkness/dullness of the other solder points suggests you may not be using the best solder. Are you using liquid or paste flux in your work? Is there still copper under the grey on those open pads?

I must admit I stopped all soldering works because of this BAD solder. I ll get suggested rosin 37/63 solder and continue.

I do flux.

There is a thick copper pad in place , sort of copper bridge from wiper to the right pad.

I should listen to advise and buy good solder right away 🙁

I do flux.

There is a thick copper pad in place , sort of copper bridge from wiper to the right pad.

I should listen to advise and buy good solder right away 🙁

You can use rubbing alcohol or fingernail polish remover with an old toothbrush to clean things up before your next attempt. The investment in a good liquid flux used in addition to the flux that may be in the solder is well worth the cost. It cleans up easily as suggested above.

Mine aren't perfect but the end result should be closer to shiny bright.

I like this shape for scraping pads when necessary.

Radio Shack has a 62/36/2 silver solder that is decent and doesn't cost much.

Good Luck !

Mine aren't perfect but the end result should be closer to shiny bright.

I like this shape for scraping pads when necessary.

Radio Shack has a 62/36/2 silver solder that is decent and doesn't cost much.

Good Luck !

Attachments

Last edited:

ChipQuick in the syringe is my favorite. Other brands are available but the syringe is very useful. My second choice is liquid with a brush.

Whatever you use don't be afraid to use more rather than less. It all cleans up well. My work looks horrible till I do the final clean up with alcohol/toothbrush. 😱

BTW, Dow Bathroom Cleaner (Scrubbing Bubbles) works great to remove any flux residue after the alcohol pass.

Whatever you use don't be afraid to use more rather than less. It all cleans up well. My work looks horrible till I do the final clean up with alcohol/toothbrush. 😱

BTW, Dow Bathroom Cleaner (Scrubbing Bubbles) works great to remove any flux residue after the alcohol pass.

Last edited:

- Status

- Not open for further replies.

- Home

- Group Buys

- ES9023 / WM8804 S/PDIF "Subbu DAC V3" GB Interest