Competent subwoofer cabinets will be stiff and fairly heavy but not damped.

One can eliminate the need for a heavy cabinet to keep the box from walking by using 2 drivers push-push (balanced drive to actively cancel the majority of the reactive force. One also gets dramatically less energy into the box.

Elegance as opposed to brute force.

And your back will tahnk you.

dave

PS: i did mention outside shape vrs inside shape. It is important as frequencies increase

The best thing you can do for accuracy is to model the correct thing to begin with, isolate the issues effectively and to interpret the results properly.

I guess what I was referring to the simulations ability to give you realistic results. No point interpreting results which aren't realistic. But I dont know what type of simulations the free or paid software for speaker design use. What exactly do you mean by model the correct thing, have an accurate representation of your enclosure to start with?

One can eliminate the need for a heavy cabinet to keep the box from walking by using 2 drivers push-push (balanced drive to actively cancel the majority of the reactive force. One also gets dramatically less energy into the box.

Thats an interesting idea but then that increases the pressure differential inside the cabinet, does that not present its own problems? Is the cabinet moving the only issue which mass addresses? The energy to vibrate a larger mass is also large which I imagine is an advantage too.

3D printing is definitly on my mind.

I'm sad to say my old lecturer got back to me and said its very unlikely I'll get on the additive manufacturing machine. I'll hold out in the small hope work will let me use ours but it seems even less likely. W"hat I was thinking is that I could use 3d printing to create a mould for composites though, that is definitely alot more doable and my cousin works in the composites section of the university, I can see carbon fiber reinforced epoxy being a good material for speaker enclosures as its very stiff and highly damped and you can optimise the stiffness for different directions depending on the direction you layer the fibers.

A practical problem with simulating the acoustics of porous media is being able to specify the required empirical constants

That makes sense, but then are these not already calculated? Have you tried using websites like the engineering toolbox? I used that all the time at university. It won't have the more exotic materials on there though. Try get hold of some material datasheets maybe? I imagine if you're using standard acoustic absorbing materials someone has already calculated material constants. Interesting way to measure them empirically, although its not much of a controlled study if you dont know how much energy was absorbed by the material enclosing it.

but a stiff cabinet will offer poor performance.

Why are you saying a stiff cabinet will offer poor performance? I understand why you're saying its less important, but then a stiff cabinet is still harder to move and therefore to vibrate, it requires a large input force to deflect it.

I am familiar with the concept. My question was more about which interfaces were causing issues that required addressing.

Well my understanding, which I admit is limited in this area, I'm not an acoustic engineer, is that sound reflecting around inside the cabinet is not good. Sound travels as a pressure wave, if its reflecting around the cabinet, constructively and destructively interfering with itself. This would then create an inconsistent pressure within the cabinet which isn't something desirable when aiming to create a flat frequency response, a frequency response which is inconsistent is surely even worse. The other thing was the possibility of standing waves. Surely a less reflective material, a material with a more similar acoustic impedance to air, is a good thing? But as I say I'm trying to apply hazy concepts learned at university to a field I'm absolutely no expert in.

My expertise is more within the manufacturing industry and ultrasonics. My aim here is to build up a conclusive set of requirements for an enclosure, given that I believe I can build a pretty good enclosure.

Why are you saying a stiff cabinet will offer poor performance?

You will find that there is a disagreement among the people on this website regarding the proper design philosophy for a cabinet. Some believe that structural damping is critical, and these folks propose various strategies of damping coatings and constrained layers. Others believe that if a cabinet is stiff enough, the spectral content of music and video soundtracks will not be able to excite the structural resonances. These folks propose high stiffness cabinet construction. Planet10 and I are believers in the second approach.

Both styles of cabinet construction have been used to achieve very excellent results. It is my belief that the high-stiffness approach is easier and lower risk for the average DIY speaker builder.

Youngs modulas of the material is important, but in practice it is only a part of structural stiffness. Structural stiffness is largely dominated by geometry. For example a truss made of pine can be much stiffer than a beam made of steel, even though steel is about 15 times more stiff than pine.

Common Baltic birch plywood can make an excellent cabinet, world class even. Bracing is the key. I recently completed a build where I followed Planet10's guidelines and I am very happy with the result.

Last edited:

Yes it changes the motion of the cone but far from making things more difficult it can extend the low frequency response, raise the output, lower distortion by limiting deflection, etc... depending on the frequency and type of rear loading. So if you opt to drop all these quantitatively significant benefits how large would the benefit be from a theoretically perfect rear acoustical impedance presumably to match that of the front?

Why does it extend the low frequency response? It seems odd to me as I've also heard creating an isobaric chamber doubles the low frequency response which would be the opposite of what we're talking about. Do you know the name of the theories here so I can read about them?

Might have read completely over it, but I see nobody mentioning the following. The outside (shape) of an enclosure is at least as important as is the inside shape and construction. That is, if the desired frequency range corresponds with wavelengths that are relatively small in comparison with the size of the enclosure. No news though.

So what is the desired shape of the outside of a cabinet? What is goal intended here?

This was a trend some decades back. Floor tiles were recommended.

It makes sense, of course. The thing is that damping material is fairly good at managing response variations from internal standing waves. Of the handful of different cabinet noise methods this one is fairly easy to fix

But damping material isn't as effective in the low frequency ranges I believe, so this is only a fairly easy fix in the mid/high frequencies right?

You speak of impedance, it is worth seeing the modal nature of these standing waves, so that basic discussion of the fundamental box function and rolloff has its own considerations.

Sorry I'm not entirely sure what you mean here

You will find that there is a disagreement among the people on this website regarding the proper design philosophy for a cabinet. Some believe that structural damping is critical, and these folks propose various strategies of damping coatings and constrained layers. Others believe that if a cabinet is stiff enough, the spectral content of music and video soundtracks will not be able to excite the structural resonances. These folks propose high stiffness cabinet construction. Planet10 and I are believers in the second approach.

I see both arguments but why would stiffer be worse? Why not just do both and get the both worlds? I dont see a compromise here as both can be acheived surely?

Youngs modulas of the material is important, but in practice it is only a part of structural stiffness. Structural stiffness is largely dominated by geometry. For example a truss made of pine can be much stiffer than a beam made of steel, even though steel is about 15 times more stiff than pine.

Common Baltic birch plywood can make an excellent cabinet, world class even. Bracing is the key. I recently completed a build where I followed Planet10's guidelines and I am very happy with the result.

I get your point there, its a combination of the two. Its also important to think about which direction you want the stiffness in. Stiffness doesnt work in all directions. Take a piece of paper, you cant bend it in the plane of the paper it will just tear. However bending it perpendicular to that plane and thats easy.

That is what is call the second moment of area. I thought I'd written that alongside the young's modulus comment. I apologise if I didnt.

Thats an interesting idea but then that increases the pressure differential inside the cabinet

It does not. Of course the enclosure needs to be 2x as big as for one woofer, but typically, more due to budget, one would choose 2x10 instead of 1x12, etc. I have had superb results with 2 x SDX10 in an enclosure made of 15mm BB, one could pick the cabinet up with a couple finger sin the driver cutout, add the drivers and it is pretty much a 2 man lift. I could get the top panel to move but i had to turn off the mains amplifier and turn things up about 10dB highe rthan i would ever use them. SInce the boxes needed finishing a piece of solid surface material such as corian or stone on top with a compliant layer holding it down solves any issues.

...and you can optimise the stiffness for different directions depending on the direction you layer the fibers.

Like plywood.

dave

...as I've also heard creating an isobaric chamber doubles the low frequency response…

A VERY misleading statement with a grain of truth.

If you use am isobarik enclosure with the same volume as for a single driver you are effectively doubling the size of the box, that is what gives the (potential) bass extention.

So what is the desired shape of the outside of a cabinet? What is goal intended here?

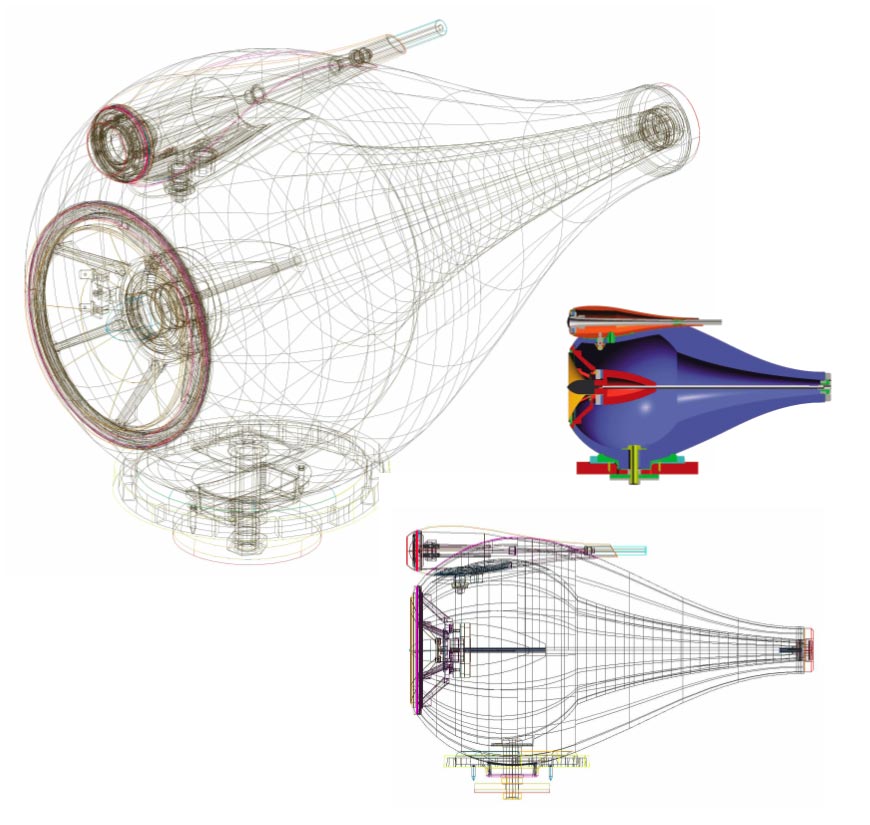

Depends on the frequency. As i suggested in my first post the mid enclosure in the esser Nautilus speakers is a good example. Something shaped like a teardrop.

In the plan view our trapezoid miniOnkens resemble a teardrop and they do have an audiably lower diffraction signature than the rectangular ones or the Classic Golden Rario variations:

And while i am digging out pictures, here is a DM302 cutaway:

But damping material isn't as effective in the low frequency ranges I believe, so this is only a fairly easy fix in the mid/high frequencies right?

But it doesn’t matter as long as any enclosure dimension is smaller than the higest frequecies the enclosure is reproducing. In things like TLs, where this is not the case, the amount (length) of damping is effective at removing unwanted harmonics.

dave

I see both arguments but why would stiffer be worse? Why not just do both and get the both worlds? I dont see a compromise here as both can be acheived surely?

The goal with maximum stiffness is to move potential resonances high enuff that they will not be excited. Adding damping measn more mass with no gain in stiffness, so resonances fall in frequency so they are more easily excited, so to counter that even more stiffness would be required.

zTo be effective it only needs to be good enuff and in practice, even with the FRs i often use, one can achieve the goals without the extra complexity and cost of adding panel damping.

Stiffness doesnt work in all directions.

One of the reasons plywood works so well, Alternating orientations of plies gives stiffness that is close to the same in each (orthogal) direction. One can screw that up by doing a translam build, where the 3rd orientation is used and walls need to be much thicker to regain the stiffness you have thrown away.

dave

I'm sad to say my old lecturer got back to me and said its very unlikely I'll get on the additive manufacturing machine. I'll hold out in the small hope work will let me use ours but it seems even less likely.

In my day when I was a youngster at Royce's I was unaware of any of my peers getting access to production machines. In fact, I was once officially reprimanded for simply talking to machine operators. However, access and help on the machines at the training school in Mickleover at the old Nestles factory was quite different. The foreman would leap at working on anything that was "real" rather than an exercise. I recall they helped save the aluminium head of my Hillman Imp when I had unwisely given it to the commercial machine shop that advertised on the side of the buses at the time to skim. Don't know where the training centre is these days google maps shows a housing estate which seems to have been the fate for many of Royce's satellite sites.

Another option might be Nottingham hackspace in the centre of the city. When I visited they had a couple of basic 3d printers and some limited in terms of axes CNC machining capability. If you live close enough it is likely worth a visit if you haven't already done so.

Interesting way to measure them empirically, although its not much of a controlled study if you dont know how much energy was absorbed by the material enclosing it.

It is a common way to measure absorption coefficients using a plane wave of known magnitude. If interested one can also get at things like the speed of sound which changes in a porous media and is usually relevant to the tuning of lines. The absorption is determined by measuring with and without the stuffing.

Why are you saying a stiff cabinet will offer poor performance? I understand why you're saying its less important, but then a stiff cabinet is still harder to move and therefore to vibrate, it requires a large input force to deflect it.

Indeed stiffness will make a cabinet deform less but it generally won't reduce the level of unwanted radiated sound despite most speaker DIY folk believing it will. The reason is that stiffness raises the frequency of the resonances and at higher frequency a cabinet needs to deflect less to be equally as loud compared to a lower frequency. Think how small a tweeter cone is and how little it deflects at high frequency in order to be equally as loud as a large woofer cone at low frequency. There is an old paper on the BBC website somewhere showing this for different cabinet wall thicknesses.

In addition, if you want high damping this will be at the expense of stiffness and/or thicker walls. It is also likely to be significantly more expensive than mdf or plywood.

The other thing was the possibility of standing waves.

Internal cabinet resonances are indeed undesirable but the wavelength needs to be small relative to the cavity dimensions in order to resonate. Generally under such conditions a bit of stuffing will damp the resonances sufficiently to be inaudible. Some DIY folk will enthuse about golden ratios and non-parallel internal walls but it all becomes irrelevant if you add a bit of stuffing (which of course you should). Similarly DIY enthusiasts will often carefully cut up and stick stuffing to the internal walls where it will be least effective (particle velocity zero at the wall) whereas an engineer from a commercial company is more likely to simply fold a bit of stuffing in the centre (particle velocity at maximum for lowest mode shapes) where it will be more effective.

So what is the desired shape of the outside of a cabinet? What is goal intended here?

The goal is a preferably predictable only slowly changing relation between sound power output and sound pressure at listening distance. Or a gradually changing directivity index if you like. A second goal is minimizing diffraction effects along sharp corners of the enclosure, although some argue that diffraction alone is hardly noticeable.

Why does it extend the low frequency response? It seems odd to me as I've also heard creating an isobaric chamber doubles the low frequency response which would be the opposite of what we're talking about. Do you know the name of the theories here so I can read about them?

Yes it is resonance. A sealed cabinet uses the mass of the cone and suspension stiffness (and cavity stiffness if not negligible). A ported cabinet uses this resonance plus the Helmholtz resonance of the mass of the incompressible slug of air in the port and the stiffness of cavity. Other types of loading use other types of physics.

So what is the desired shape of the outside of a cabinet? What is goal intended here?

The goal is to smoothly control the radiated directivity/beamwidth with frequency. The desired beamwidth and how it changes with frequency is a function of both the properties of the room and to a fair extent the type of music. The optimum for orchestral music and studio recorded music tends to be significantly different. Again you will find enthusiasts that claim one approach (e.g. constant directivity) is correct but this is not supported by either the physics of how we perceive sound or listening tests. It is by far the most challenging aspect of speaker design because there isn't a correct way only good ways with caveats.

But damping material isn't as effective in the low frequency ranges I believe, so this is only a fairly easy fix in the mid/high frequencies right?

Not really. We are less able to perceive resonances at low frequencies and so one popular approach that is still around in some ye olde worlde speakers was to make floppy cabinets which placed the lowest resonances containing most energy low in frequencies with simple extensional damping (less effective than constrained layer or fibres in resin). This did little to damp the lowest frequencies but at higher frequencies where the ear is more sensitive the limited damping was effective at reducing the higher less energetic modes. A stiffer cabinet with the same damping would have the more energetic lowest modes higher in frequency where the ear is more sensitive and the mode shapes will deform the damping less.

Today it is easier to introduce more effective damping (fibres, CLD,...) particularly if you simulate the speaker to determine which few modes are the ones that radiate most to the ear and target damping at them (e.g. damping panels). (And stiffness in some circumstances).

Indeed stiffness will make a cabinet deform less but it generally won't reduce the level of unwanted radiated sound despite most speaker DIY folk believing it will.

This is what I meant when I said there is a disagreement among the people on this website regarding the proper design philosophy for a cabinet. It has been hashed out over and over going back a number of years. I think we have all agreed to disagree...

Michael5039 - As a fellow aerospace engineer, I recommend you read as much of these old threads as you can, then make up your own mind.

Is MDF or plywood better for speaker cabinets?

Discussion on what materials to build speakers out of

You will find interesting threads if you search for "constrained layer", "Baltic", and "bitumen"

What I'm saying is that precision means nothing if you don't use the tool correctly. Part of doing so involves understanding exactly what the tool does. Also, precision isn't necessary to the level you are talking about.I guess what I was referring to the simulations ability to give you realistic results. No point interpreting results which aren't realistic. But I dont know what type of simulations the free or paid software for speaker design use. What exactly do you mean by model the correct thing, have an accurate representation of your enclosure to start with?

Why does it matter what happens at the lowest frequencies? Your cabinet is supposed to augment the bass resonance.But damping material isn't as effective in the low frequency ranges I believe,

You mentioned acoustic impedance, maybe I misunderstood you. What did you mean?Sorry I'm not entirely sure what you mean here

All this convo and not one mention of transmission line, tisk tisk, the study of transmission line enclosures covers resonance, bracing, and its potentials...the “aperiodic” constant CSA TL being the epitome of the box less sound (with a box 😉. I’m not saying to build a TL but rather to see what the constant CSA fully stuffed TL is capable of and use these aspects to tune your own design. For example, the idea that internal bracing can be used to create stiffness as well as raising the resonate notes caused by internal reflections, at the same time. Or the idea that the only way to kill the backwave involves channeling the wave through a line, folded or not, sealed or vented, in unison with heavy damping material....

Somehow I am saying to build TL....a sealed one...and it doesn’t have to be 1/2 wavelength, the length of the sealed TL is somewhat a non issue....or if going vented, figure out how resonant you want it to be, and build something with a decent amount of folds or at least using the knowledge to create your bracing scheme. Damping material supporting your resonance goal.....

Just in case there’s some more learning for me? Did we figure out some other way to kill the backwave....making TL obsolete?

Somehow I am saying to build TL....a sealed one...and it doesn’t have to be 1/2 wavelength, the length of the sealed TL is somewhat a non issue....or if going vented, figure out how resonant you want it to be, and build something with a decent amount of folds or at least using the knowledge to create your bracing scheme. Damping material supporting your resonance goal.....

Just in case there’s some more learning for me? Did we figure out some other way to kill the backwave....making TL obsolete?

Last edited:

Whereas I would suggest you refer to reliable rather than unreliable sources. Lookup what resonance is in an engineering text book and understand why stiffness is wholly irrelevant to the magnitude of the motion at resonance and why damping determines it. Measurements are few and far between because of the difficulty of separating the sound radiated by the cabinet from that from the drivers but there are some and they are usually informative. But by far the most useful source of understanding is to simulate the motion of the cabinet+drivers and the sound radiated using normal BEM/FEM engineering software. This will quantitatively show you what is going on everywhere and why.Michael5039 - As a fellow aerospace engineer, I recommend you read as much of these old threads as you can, then make up your own mind.

The mechanical design of a cabinet is a straightforward engineering task requiring little more than the application of conventional engineering principles (which obviously need to be known) in order to push down the level of radiated sound below audibility. Little-to-nothing is required in terms of innovation but there are the usual trade-offs in terms cost, complexity, size, weight, etc... On the other hand if a cabinet radiates audible resonances it is unlikely to be strikingly obvious except in the more extreme cases. It is unlikely to be a significant factor in the overall sound quality of any reasonably competent speaker.

All this convo and not one mention of transmission line

Not three, i have mentioned them

And please, you sow half-truths that are misleading. I like TLs, but alignments are not the subject of this thread.

Most TLs (almost none that are intended to do bass) are aperiodic. Most are intended to use th fundamental quarter-wave resonance to augment the bass.

A half-wave line has to support a half-wave. If it is tapered down as it is further away from the driver it can be shorter than a 1/2 wave but it still needs to be the same volume.

dave

... stiffness is wholly irrelevant to the magnitude of the motion at resonance and why damping determines it...

Andy, you are missing the point, the idea is not to kill the resonance (potential) — everything will resonate — the idea is to move it up in frequency and in Q so that it is never (or extremely unlikely) to be excited by the music playing. If it is not excited is as if it never existed.

dave

Linkwitz figured out how to let it live instead....Just in case there’s some more learning for me? Did we figure out some other way to kill the backwave....making TL obsolete?

Andy, you are missing the point, the idea is not to kill the resonance (potential) — everything will resonate — the idea is to move it up in frequency and in Q so that it is never (or extremely unlikely) to be excited by the music playing. If it is not excited is as if it never existed.

dave

This only applies to woofers and then only if the cabinet is well designed to be stiff and light. A midrange will have resonances present in the passband and if the cabinet is stiff with little damping they will be loud.

A high Q resonance can approach the level of the wanted signal in magnitude whereas a low Q resonance can be below the threshold of audibility with some thought. A high Q resonance will continue long after the signal has stopped whereas a low Q resonance will stop quickly. Simply hoping a high Q resonance doesn't get driven by the signal is foolish when by the application of a bit of engineering knowledge it can be made inaudible regardless of the signal.

This has of course all been said before and it is down to the individual to decide whether to follow conventional engineering practises based on the physics or set them aside and place faith in something else or perhaps simply have a go at something else without any faith and see what happens. It is a hobby and one or two designs I would judge as excessively expensive and completely incompetent as designs with obvious audible failings are actually liked by some. Conventional engineering isn't the be all and end all but it can be a useful benchmark.

Not three, i have mentioned them

And please, you sow half-truths that are misleading. I like TLs, but alignments are not the subject of this thread.

Most TLs (almost none that are intended to do bass) are aperiodic. Most are intended to use th fundamental quarter-wave resonance to augment the bass.

A half-wave line has to support a half-wave. If it is tapered down as it is further away from the driver it can be shorter than a 1/2 wave but it still needs to be the same volume.

dave

I think you miss my point. The study of transmission line enclosures gives one insight on the manipulation of several core enclosure aspects (resonance, dampening, bracing)....

A sealed TL doesn’t have to be 1/2wl....take your internal volume and make a line, fully dampen it, and the tuning note will be lower and the resonance will be lower than a basic sealed, stuffed box...the length isn’t detrimental to a usable response like with vented

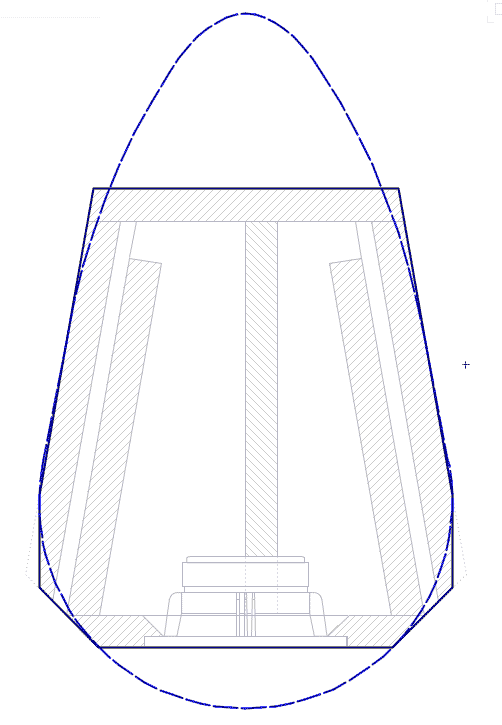

If you take a constant csa tl and folded it into a monkey coffin of sorts....the bracing is mostly taken care of. This shows the designer what that might look like...one could take that knowledge and create bracing that doesn't exactly form a line use the idea of using flat panels inside the enclosure to break up the internal dimensions thus raising the reflective resonances out of the pass band. For example;

Attachments

Last edited:

- Home

- Loudspeakers

- Multi-Way

- Enclosure design - Exactly what is required?