Global number, shape, pattern and global localization of EnABL dots are the same as in the patent. Sorry, it is clearly the case here and it is "blind following" for me.I can't honestly say that sounds like 'blind following' to me, since that normally implies total acceptance of everything, without question or variation, which clearly isn't the case here.

Decreasing cone resonance is what is wanted. If the applied dots are too small in area/mass, they will not change anything.Yes. But that is assuming it's actually wanted / required.

I agree. But how will we know when the optimum is reached? You have to apply more and more, to the point where it is clear that anything more is harmful. Do you really think that EnABL dots are the optimum?From a practical POV also, when making permanent mechanical modifications, it's usually better to start with, or simply use, less rather than an excess.

But what if those dots are not enough and defeating the cone resonance require more? Maybe conventional "ring" applied to the cone with diluted PVA (or something else) close to the cone surround is just enough?you may not require more [more not necessarily always being 'better' or beneficial, especially in these cases]

Or, to take it to a silly extreme in other direction - we'd all be painting those silly EnABL dots to the cone.Otherwise, to take it to a silly extreme, we'd all be nailing sheet lead to the cone.

Last edited:

So the additional rings Dave regularly added, the unit-specific positioning etc. [which you've already accepted] now don't exist and are 'blind following'. We obviously have rather different definitions. 😉Global number, shape, pattern and global localization of EnABL dots are the same as in the patent. Sorry, it is clearly the case here and it is "blind following" for me.

According to whom, in the first case [since it may or may not be]. And nobody appears to disagree in the second [for practical purposes: since they exist, they will make a difference, period, although whether it's within audibility threshold is another question]. But the location, position, mass and stiffening requirements vary on a case-by-case basis, so blanket statements that 'it doesn't do anything' are twaddle in the same way that any other dodgy physics are.Decreasing cone resonance is what is wanted. If the applied dots are too small in area/mass, they will not change anything.

They may be. They may not [assuming you're after damping in the first place]. But this 'what if' business is pure speculation on ephemerals, and back to a case of condeming something simply because you think something else might be more effective, without knowing the conditions. And it might. Or it might not. Equally, people may care. Or they may not.But what if those dots are not enough and defeating the cone resonance require more? Maybe conventional "ring" applied to the cone with diluted PVA (or something else) close to the cone surround is just enough?

Which is just mud-slinging without an engineering argument.Or, to take it to a silly extreme in other direction - we'd all be painting those silly EnABL dots to the cone.

You don't like it. Fair enough. That's your right. I'm ambivalent myself, for the reasons above & others -from my POV the original speculated mode of operation is wrong, and the entirely generic positioning unlikely to yeild much of value except in some very specific cases. In its adapted form, with unit-specific positioning & additional rings & other blocks etc., then it's rather more likely to have some form of effect, subtle or otherwise. That's just basic physics, mechanical engineering & acoustics, like it or not. People can debate whether something might, possibly, perhaps, maybe more effective in a given situation or in general, but it's castles in the air, since unless they're going to do a comparative test, they don't actually know, and the can't generalise from that any more than the reverse is the case. If they care enough, they can try. I don't. So I haven't. And I'm not going to either.

EnABL dots on the enclosure!? I think this qualifies as "blind following":

Cosmetic.

dave

and global localization of EnABL dots are the same as in the patent

Not in EnABL2. The ringsets take the same form, their placement is quite different. And one often finds addition places to put the rings. The midcone ring on FE126/127 was a first application of that, and the new pattern on the FFxx5wk dustcaps shows the power of getting feedback from the actual cone in order to placew the spots.

Current EnABL looks visually somewhat like what is in the patent, but better ring placement is a big step forward. At this point patent is only of acedemic interest.

dave

Last edited:

They do exist, but "unit -specific positioning" still is under the description of the patent, including the patent claim 1: "the features in the pattern extending along and adjacent to at least a substantial portion of said discontinuity". The term "discontinuity" is defined in the page column 1, rows 37-39, and is place where the discontinuity is formed, and of course, the place where the dots are most effective. I know thing or two about patenting - pictures are for illustration only, wording in the patent claims is everything.So the additional rings Dave regularly added, the unit-specific positioning etc. [which you've already accepted] now don't exist and are 'blind following'. We obviously have rather different definitions.

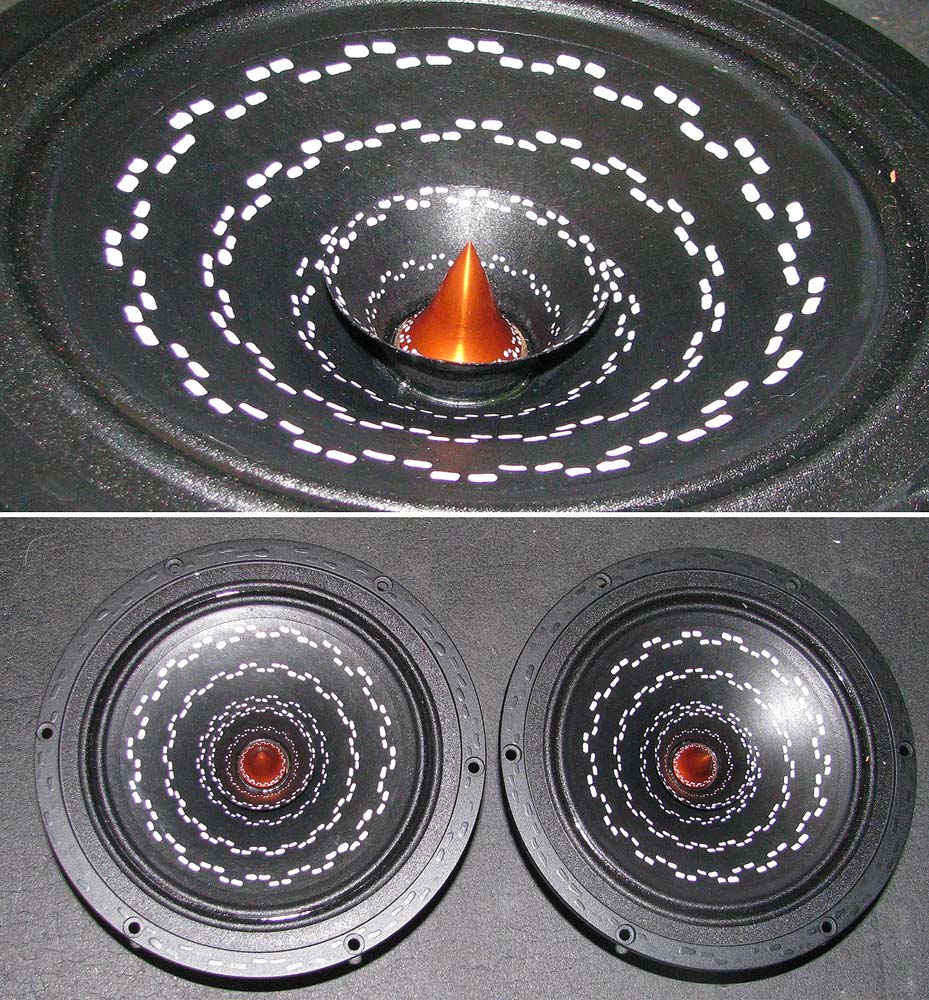

Description "regularly added additional rings" means that there are cases where there are no additional rings, like this Dave's example of "improved" EnABL v2 :

We can see that the number of double rings on the cone is the same as in the patent: four. No additional rings! Also, there are EnABL dots on the driver mounting plate/flange - are this for "cosmetic purposes" also, or according to the patent claims?EnABL v2

-

Maybe we have different definitions for "blind following", but we must have same definition for the number 4.

the number of double rings on the cone is the same as in the patent: four. No additional rings!

That is all that cone needs. You will note that the rings are not in the same place. This is a particulr 4” cone.

The similar 5.25” has an extra set of rings, so do the dustcaos — as do the 4”.

These 4.5” Fostex:

And a different 4.5 Fostex. It has an extra ½ ring at the surround as well, and the different dustcap.:

And a Dayton with 4 ringsets;

If you looks at the Mar-Kel70T i posted you can aldo see a 3rd ringlet.

Every driver is a little different,

dave

According to everyone, including the author of the patent in the first place.According to whom, in the first case [since it may or may not be].

Until there are measurements (or double blind listening tests) to prove effectiveness of the EnABL dots, they doesn't do anything. For now, we have only blanket statements that EnABL dots do something - a "twaddle in the same way that any other dodgy physics are."But the location, position, mass and stiffening requirements vary on a case-by-case basis, so blanket statements that 'it doesn't do anything' are twaddle in the same way that any other dodgy physics are.

Coating the whole cone, or part of it, with materials like diluted PVA, varnish, ModPodge, WetLook etc. in order to change the mechanical behavior of the speaker cone is proven with numerous measurements, and there are no measurements for EnABL dots to prove they are more effective. Even without knowing the conditions, physics teach us that there must be some minimal/critical amount of something (EnABL dots area and/or mass) on the cone, to have any audible difference above the hearing threshold.But this 'what if' business is pure speculation on ephemerals, and back to a case of condeming something simply because you think something else might be more effective, without knowing the conditions.

There is a engineering argument - there must be some minimal/critical amount of something (EnABL dots area and/or mass) on the cone, to have any audible difference above the hearing threshold. Until that, it is a castle in the air....without an engineering argument.

Last edited:

OK, but I was discussing the wording "regularly" in the Scottmoose post, using your picture as evidence. I really don't know the percentage of drivers you threated with more than 4 pairs of doted rings. If that number is substantially larger than the number of drivers with 4 pairs of rings, then the word "regularly" is justified and I owe apology to you and to Scottmoose.That is all that cone needs.

Last edited:

Right, I'm finding this difficult to follow since it seems to be leaping about in different posts, but it's certainly starting to get silly.

We're really not, you know. 😉

We're really not, you know. 😉

Yes. There must. I've made this point repeatedly myself, so implying otherwise or trying to find some wording in a patent you've already been told I think is wrong to claim otherwise won't fly I'm afraid

Come on, me old mucker -we're all friends here & we get on well. It's really not difficult to accept that on a fundamental level any variation does something [that's just basic mechanical engineering] because by definition a change has been made. It's also not difficult to accept that the practical audibility [or lack of] will vary on a case by case basis, i.e. depending on the driver and the specific details of what's been done, although from my POV, it's unlikely to be dramatic in the great scheme of things. It isn't difficult to accept either [you already have above] that the application has sometimes varied away from the claims made in the original patent [which even people like Dave, and certainly ambivalent people like myself consider to be wrong in terms of the proposed operating physics], & on current evidence, nobody seems to see it as a competition with other well-known mechanical modifications. The fact that it is / has often been applied in combination with them seems to underline that. Dave for e.g. was modifying drivers for decades before he started applying his own variations in conjunction with those changes he'd already been using -attached are two examples showing the fronts; the second more clearly shows one part of the stiffening that was applied.

Frankly, I don't see what the issue is. I never have done, in any of these debates. Overblown claims are rubbish, unqualified statements that it does 'nothing' are equally rubbish since both defy the laws of physics, and ifs, buts & maybes get nobody anywhere without very specific criteria being set out -and making sure in advance that whatever is compared was meant to address those criteria in the first place, otherwise, it's apples / oranges. I can certainly understand why people criticise it, but if they're that bothered, then they're free to make whatever tests they want. Since I don't care, other than pointing out some claims in its favour seem titanically overblown, and many arguments used against it are actually rather flawed, I've zero interest in doing so. If you do & want to spend the time / money -crack on! Nobody's stopping you.

Shall we all of us draw a line under this? We all know what the result will be otherwise, and what's the point? Words on the internet. The Earth still spins. I've just lost a remarkable elderly relative who took up acting age 80 and spent 14 years performing in plays until the last few months when his health took a downturn. That counts. DIY driver modifications? Not so much. In fact, 'nothing'.

I think Bernard would have liked that bit of humour.

Who is 'everyone'? Since that isn't the case with Dave or myself [to give the two obvious examples from this thread] you appear to be claiming we don't exist. Which I accept is a novel take on Schrodinger, but I was never into that kind of philosophy myself. 😉According to everyone, including the author of the patent in the first place.

So you are actually stating that adding mass [along with changing the rigidity / bending ratio of the substrate] at those points does nothing. Okay -it's not possible to have any kind of sensible conversation then, because that is contrary to every law of physics and engineering in this universe. However small it is, it is an addition, and therefore has an effect. Period. The difference may, and in many cases will, be small, as I've repeatedly said. But it exists. Audibility [or lack thereof] will vary on a case by case basis. As I've also repeatedly said.Until there are measurements (or double blind listening tests) to prove effectiveness of the EnABL dots, they doesn't do anything. For now, we have only blanket statements that EnABL dots do something - a "twaddle in the same way that any other dodgy physics are."

Yes. Who has been claiming otherwise, and where did they learn their physics? Many on this forum have been doing variations on that for years / decades. You're talking as if we're unaware of it.Coating the whole cone, or part of it, with materials like diluted PVA, varnish, ModPodge, WetLook etc. in order to change the mechanical behavior of the speaker cone is proven with numerous measurements,

We're really not, you know. 😉

We're really not, you know. 😉I've given a hint above -perhaps I was a little too subtle [which must be a first!]. So to be polite: will you please stop this strawman nonsense. I have not claimed [and everybody can check this by simply reading the posts] they are 'more effective' than anything. As far as I can see, neither has anybody else. I haven't, in fact, made any claims for it at all, other than stating the well-known and unremarkable fact that if you add something, you've added something, and it therefore a/ has mass [since we live in a universe governed by basic laws of nature] and b/ will effect mechanical changes at those points. What you appear to be moaning about is that in your opinion other things might have more effect on a given behaviour. And they might. Or might not, depending on what it is. Or it may simply produce a different set of results [ditto].and there are no measurements for EnABL dots to prove they are more effective.

Ah! So nowThere is a engineering argument - there must be some minimal/critical amount of something (EnABL dots area and/or mass) on the cone, to have any audible difference above the hearing threshold. Until that, it is a castle in the air.

Is an engineering argument [forgive me, but I don't see the physics] and stating 'they don't do anything' has become 'audible differences above the hearing threshold'....we'd all be painting those silly EnABL dots to the cone

Yes. There must. I've made this point repeatedly myself, so implying otherwise or trying to find some wording in a patent you've already been told I think is wrong to claim otherwise won't fly I'm afraid

No apologies necessary; I don't think Dave or I are that thin-skinned. 😉OK, but I was discussing the wording "regularly" in the Scottmoose post, using your picture as evidence. I really don't know the percentage of drivers you threated with more than 4 pairs of doted rings. If that number is substantially larger than the number of drivers with 4 pairs of rings, then the word "regularly" is justified and I owe apology to you and to Scottmoose

Come on, me old mucker -we're all friends here & we get on well. It's really not difficult to accept that on a fundamental level any variation does something [that's just basic mechanical engineering] because by definition a change has been made. It's also not difficult to accept that the practical audibility [or lack of] will vary on a case by case basis, i.e. depending on the driver and the specific details of what's been done, although from my POV, it's unlikely to be dramatic in the great scheme of things. It isn't difficult to accept either [you already have above] that the application has sometimes varied away from the claims made in the original patent [which even people like Dave, and certainly ambivalent people like myself consider to be wrong in terms of the proposed operating physics], & on current evidence, nobody seems to see it as a competition with other well-known mechanical modifications. The fact that it is / has often been applied in combination with them seems to underline that. Dave for e.g. was modifying drivers for decades before he started applying his own variations in conjunction with those changes he'd already been using -attached are two examples showing the fronts; the second more clearly shows one part of the stiffening that was applied.

Frankly, I don't see what the issue is. I never have done, in any of these debates. Overblown claims are rubbish, unqualified statements that it does 'nothing' are equally rubbish since both defy the laws of physics, and ifs, buts & maybes get nobody anywhere without very specific criteria being set out -and making sure in advance that whatever is compared was meant to address those criteria in the first place, otherwise, it's apples / oranges. I can certainly understand why people criticise it, but if they're that bothered, then they're free to make whatever tests they want. Since I don't care, other than pointing out some claims in its favour seem titanically overblown, and many arguments used against it are actually rather flawed, I've zero interest in doing so. If you do & want to spend the time / money -crack on! Nobody's stopping you.

Shall we all of us draw a line under this? We all know what the result will be otherwise, and what's the point? Words on the internet. The Earth still spins. I've just lost a remarkable elderly relative who took up acting age 80 and spent 14 years performing in plays until the last few months when his health took a downturn. That counts. DIY driver modifications? Not so much. In fact, 'nothing'.

I think Bernard would have liked that bit of humour.

Attachments

Last edited:

OK, these are my final thoughts/summary about the EnABL dots, and I am out of this.Right, I'm finding this difficult to follow since it seems to be leaping about in different posts, but it's certainly starting to get silly.

1. Principle of operation of the EnABL dots as described in the patent is wrong. Beyond wrong. It is an insult for any educated person.

2. EnABL dots painted on the driver frame/flange/plate and/or on the speaker enclosure (as in the patent) can not possibly bring any meaningful difference. It is an insult for any educated or uneducated person. A dry leaf blown by the wind and accidentally landed on the speaker enclosure will have greater impact on the sound than those EnABL dots painted on the enclosure or driver frame. Basic physics.

3. EnABL doted rings painted on the driver cone may bring improvement, but only if their mass and/or area are sufficiently large, to be able to change the mechanical properties of the cone above the hearing/measurement threshold. Of course, even single EnABL dot, or single speck of dust accidentally landed on the cone - for that matter, will change something on the nanoscale (pico/femto/atto scale), but it can not be the "argument" because the crucial point is missing: is it enough to be measurable/hearable? The same for the effectiveness of EnABL dots.

If there are no differences above the hearing threshold, for all practical purposes it is the same as "there is no difference at all" and "they doesn't do anything" - that is what I wrote and I stand by it.

4. There is plenty of evidence (measurements) for effectiveness of older techniques of coating cones with layers of diluted PVA, varnish, ModPodge or WetLook, but those coats are applied to cones in a substantial area (and in several coatings), in the shape of wide rings (especially close to the surround), radial stripes, or other shapes. Area and mass of applied EnABL dots are substantially smaller, so my doubts about their effectiveness is justified - until some measurements emerge to prove otherwise.

Because area and mass of EnABL dots with more than 4 pairs of dotted ring (as per Dave/planet10 technique) are larger, they may be more effective. But, measurements (as evidence) are missing, so far. So my doubts are still unchanged.

5. Part of the EnABL patent are the shape of dots and alternating pattern of voids and dots in the rings - that is unchanged in the Dave/planet10 technique. I am just stating the fact. Is that "blind following"? If there is some evidence that those EnABL shapes applied with calligraphic pen are better than simple segmented (or full) rings applied with simple brush, then it is not "blind following" but use of the best technique. Until then...

6. "Tapping technique" by Dave/planet10 looks logical to me and looks like it may discover the best possible places to apply coatings, but there are no evidence (measurements) so far to prove it. The best places for applying dots is skillfully worded in the patent claims, so it includes all 4 areas where Dave/planet10 is placing dots, although they are different from illustrations in the patent. To remind you - patent claims are everything, illustrations in the patent are not.

My knowledge of English language is limited and in my previous posts I may inadvertently wrote something different from what I really meant, or maybe I understood something wrong from what was written by others so far. If that was the case, I apologize.

Over and out.

the second more clearly shows one part of the stiffening that was applied

Damar. Love the smell (in small quantities). Mike MacKenzie gets credit for figuring out/inspiring the pattern to help curb HF resonances.

A much more recently the use of ZIG 2-way on the back at bthe surround cone overlap also helps (FE/FF)

dave

… their mass and/or area are sufficiently large,

Don’t forget that they have a height. And that might well have an effect on the behaviour of the air/waveform at/near the air/cone interface.

… the shape of dots and alternating pattern of voids and dots in the rings - that is unchanged …

Bud tried many patterns and numbers of spots. At least a decade went into figuring out what to put in the patent. And the patent had nearly expired when Bud laid it all out here.

I was skeptical at first, but a set of FE127e that Bud EnABLed changed my mind.

since Sonce has finally signed off, i’ll finish with this recent Martin Collums quote:

it is a matter of optimizing the transmission of the more subtle information that describes recorded acoustic, instrumental detail, the performers, and, not least, dynamics and rhythm: Are your feet tapping unconsciously in time to the performance?

And that closely mirrors a lesson from Julian Vereker in the late ‘70s (over a beer at CES Chicago): A hifi is an information processing system: you want to startb with as much information as possible and then lose as little as possible getting out to your ears.

Even with the best systems there are manynplaces to lose information, particularly the small bits.

And why don’t we throw in some Floyd Toole:

Two ears and a brain are massively more analytical and adaptable than an omnidirectional microphone and an analyzer.

dave

Last edited:

I believe that EnABL patterns disrupt standing waves by creating new distributed and discontinuous reflecting boundaries in addition to those created by major boundary reflections from cone-surround, cone-VC, and cone-dust cap boundaries. Local reflections from pattern elements are out of phase with major boundary reflections, so they sort of "de-tune" the standing waves.

Micro Gloss coating disrupts standing waves by different principle. Because speed of sound is different in the paper layer and the Micro Gloss layer, the standing waves in the two layers would be at different frequencies, so in the sandwich they interfere with each other. I guess BudP empirically determined that effects of pattern and coating are additive.

There was a body of research about visualizing standing waves on speaker cones. They found complex patterns of radial and tangential SW at frequency multiples. I did my best trying to find it on the web but failed.

A simple way to visualize standing waves is to use light particles, e.g. sand or sawdust. If there are standing waves, the particles will clear from humps and collect in the nodes. This cannot be done directly with a typical speaker, but a test speaker with flat radiator can be constructed specially for this purpose. If EnABL changes standing waves, that would be a proof that can be extrapolated to regular speakers. I am going to do it sometime this year, but now I am too busy with more urgent things.

Micro Gloss coating disrupts standing waves by different principle. Because speed of sound is different in the paper layer and the Micro Gloss layer, the standing waves in the two layers would be at different frequencies, so in the sandwich they interfere with each other. I guess BudP empirically determined that effects of pattern and coating are additive.

There was a body of research about visualizing standing waves on speaker cones. They found complex patterns of radial and tangential SW at frequency multiples. I did my best trying to find it on the web but failed.

A simple way to visualize standing waves is to use light particles, e.g. sand or sawdust. If there are standing waves, the particles will clear from humps and collect in the nodes. This cannot be done directly with a typical speaker, but a test speaker with flat radiator can be constructed specially for this purpose. If EnABL changes standing waves, that would be a proof that can be extrapolated to regular speakers. I am going to do it sometime this year, but now I am too busy with more urgent things.

a 4" midrange with a flared Bextrene (a modified Polystyrene IIRC) cone. The hole positions were determined using Laser Holography, but to eliminate 'Bextrene Breath' completely, the back of the cone was painted with Plastiflex 1200, a PVA glue which never really hardened and to seal the holes. The surround was nasty flat thin PVC.

All this is (except for the holes) was 1970s BBC tech by Harwood and the Spendor BC1. We later went onto various filled Homo & Co Polymers of Polypropylene, and all this early stuff went into the Don't Recycle Bin.

That's not to say, the Jurassic Bextrene/Plastiflex tech made bad speakers. Indeed a very early Spendor BC1 (with the milky white PVC surround which fell off if you looked at it) was our standard for midrange accuracy for nearly a decade and would still be considered excellent today. But consistency was poor and you were limited to quite a small (and low) sensitivity range.

We developed much better tools, SCAnned Laser Plots and BEA/FEA later. But the most important tool was in fact 'waterfalls'. At that time only we and KEF could do them sensibly. These confirmed the 'nicer' breakup patterns actually resulted in better sound ... as did our DBLTs.

So I'm open to the effect of EnABL magic dots affecting the sound. But I expected to see MUCH more improvement in the 'waterfalls' if they made things sound better.

Last edited:

Waterfall and standing waves are different things, and ways of countering them are different. In your case it is damping local resonances to improve the waterfall. Scan Speak used tools similar to yours, but instead of rows of dots they used slits, as in the picture. EnABL doesn't dampen local resonances, it creates local reflecting borders. The mass of EnABL dots doesn't matter; what matters their anisotropy and geometry.

Announcement - I will not discuss further anything about the "the name that shall not be spoken", as I promised in my post #91. But I may discuss about something much more interesting which I found here:

This is one of the better techniques to fight with the problems of cone breakups, resonances and standing waves - holes make dramatic change in the cone material continuum, changing by that its mechanical properties (among other things - creating local reflecting borders) resulting in reducing the aforementioned problems. Painting the whole back area of the cone (and filling holes) with PVA also make big change in cone damping.

I remember those midranges - my friend had Wharfedale speakers with them, I forgot the model, maybe Linton something. Many, many years ago.a 4" midrange with a flared Bextrene (a modified Polystyrene IIRC) cone. The hole positions were determined using Laser Holography, but to eliminate 'Bextrene Breath' completely, the back of the cone was painted with Plastiflex 1200, a PVA glue which never really hardened and to seal the holes.

This is one of the better techniques to fight with the problems of cone breakups, resonances and standing waves - holes make dramatic change in the cone material continuum, changing by that its mechanical properties (among other things - creating local reflecting borders) resulting in reducing the aforementioned problems. Painting the whole back area of the cone (and filling holes) with PVA also make big change in cone damping.

Err..rh! The ONLY reason we damp local resonances bla bla is cos we believe this IMPROVES THE SOUND. Nice 'waterfalls' are probably still the best indication of 'better sound'.Waterfall and standing waves are different things, and ways of countering them are different. In your case it is damping local resonances to improve the waterfall.

Deleted 9 pages of rant as to why even waterfalls & other juju from da false prophets Toole & Olive don't really address the Room Interface Profile which is the TRUE indicator of why a speaker sounds like it does. But they quote us so some of their stuff must be pukka bla bla ....

More rants about the interpretation of waterfalls bla bla deleted.

If your magic holes, dots, slits, gunk don't improve the 'waterfall', it is unlikely you will get 'better sound'.

BTW, the breakup behaviour of a 'good sounding' paper cone is very different from that of a 'good sounding' metal or plastic cone. A 'good sounding' paper cone shows very random chaotic behaviour when it breaks up compared to the very symmetrical breakup of a 'good sounding' plastic cone. But the onset & growth of this 'random' behaviour is still well controlled.

? Standing waves are cause, waterfall is effect! You can't counter the effect, you can counter the cause only!Waterfall and standing waves are different things, and ways of countering them are different.

Holes and slits are not just damping local resonances, they also are creating local reflecting borders in the cone material by their anisotropy and geometry - which is logical, because holes and slits are strategically placed on the best places on the cone and are filled with different material than the cone.In your case it is damping local resonances to improve the waterfall. Scan Speak used tools similar to yours, but instead of rows of dots they used slits, as in the picture

Last edited:

- Home

- Loudspeakers

- Full Range

- EnABL-ing MAOP7