I should add that Hans/Bill/Dagfinn's recent paper showed how little of the energy is converted to electricity - less than a percent max.

Chris

Chris

Oh yeah, it works all right, definitely a good product. I have LPs I treated over 30 years ago with it, much played, and they are still in mint condition. It does what it says on the tin.BTW, it actually does something

Yes I think you are right.It sounds like LAST.

Why apply for a Patent and not disclose the product name ?

It’s a well kept but very expensive secret.

Hans

Attachments

They are talking about Shockwaves while playing, what might that be ?

Does it alter the Young modulus, does it substantially lower the friction coefficient or what ?

I don’t want to ridicule the product, but their description is not very encouraging to me.

If this where all true, like lowering IM distortion by at least 10dB, why isn’t the product already applied to the surface by LP producers ?

And why aren’t their magazine test to show this all ?

Hans

LAST Record Preservative chemically enhances the molecular stability, and therefore the cohesiveness of the groove surface so that it completely resists the effects of stylus shock waves. The 30-second treatment affects the vinyl to a depth of about ten molecular layers and becomes part of the grove wall. It leaves no surface residues for the stylus to collect. In fact, overuse is harmless.

Does it alter the Young modulus, does it substantially lower the friction coefficient or what ?

I don’t want to ridicule the product, but their description is not very encouraging to me.

If this where all true, like lowering IM distortion by at least 10dB, why isn’t the product already applied to the surface by LP producers ?

And why aren’t their magazine test to show this all ?

Hans

LAST Record Preservative chemically enhances the molecular stability, and therefore the cohesiveness of the groove surface so that it completely resists the effects of stylus shock waves. The 30-second treatment affects the vinyl to a depth of about ten molecular layers and becomes part of the grove wall. It leaves no surface residues for the stylus to collect. In fact, overuse is harmless.

It's a secret recipie that has a clinical effect but is benign too. So benign you can't overdose. You see this a lot on internet miracle cures.And why aren’t their magazine test to show this all ?

So colour me sceptical. Not saying it doesn't work, but...

I can't wholeheartedly endorse the record preservative because it MAY be contributing to-difficult-to remove buildup on the stylus (or it may be caused by SoundGuard, which was a disaster that even my old Keith Monks machine can't remove). Never or rarely used either, but I'm the repository of my friend Jerry's records (and Dr. Ann Chotard's vocal records, and.. about 50 linear feet of records), so grain of salt, but it does preserve records. Who knows how or why.

Can enthusiastically endorse StyLAST. If even I can hear it, it must work! How can it last to the end of a side of an LP record? Yeah, that's a difficult question. Dunno, works, cheap enough - a tiny bottle lasts forever. Nuf said.

All good fortune,

Chris

Can enthusiastically endorse StyLAST. If even I can hear it, it must work! How can it last to the end of a side of an LP record? Yeah, that's a difficult question. Dunno, works, cheap enough - a tiny bottle lasts forever. Nuf said.

All good fortune,

Chris

Chris,

What’s the shape of your stylus tip.

Round, eliptical, line contact ?

Is your positive experience limited to one and the same stylus ?

I’m going to send an email to Last, hoping to get some more technical based answers.

Hans

What’s the shape of your stylus tip.

Round, eliptical, line contact ?

Is your positive experience limited to one and the same stylus ?

I’m going to send an email to Last, hoping to get some more technical based answers.

Hans

For many decades I used a collection of Denon DL160s, which when still available Denon would exchange when worn for about US$60, but the last of them are now all used up. They had an elliptical stylus on a stepped-diameter aluminum cantilever. Nothing fancy, but I could afford to keep them fairly fresh. All my experience is with these.

Now have a Shure Ultra500 (like Type V) with a fancy Jico line-contact stylus on Ruby cantilever. Not nearly as fancy as the Shure original, but those aren't (actually can't be! Beryllium) made any more. Working on a new phono stage to minimize loading C.

Magic potions have large Venn diagram overlap with regular old audiophoole snake extractions, and advertising puffery is offensive to any sensible person, so your reticence is only proper. You'll probably need to try one or the other for yourself, if you have a friend who can hook you up with a tiny taste. Arf!

As always,

Chris

Now have a Shure Ultra500 (like Type V) with a fancy Jico line-contact stylus on Ruby cantilever. Not nearly as fancy as the Shure original, but those aren't (actually can't be! Beryllium) made any more. Working on a new phono stage to minimize loading C.

Magic potions have large Venn diagram overlap with regular old audiophoole snake extractions, and advertising puffery is offensive to any sensible person, so your reticence is only proper. You'll probably need to try one or the other for yourself, if you have a friend who can hook you up with a tiny taste. Arf!

As always,

Chris

The bit that scares me is the stuff about it bonding with the surface of the LP. It's not going to come off, and while I probably don't need to worry about what happens to my LPs in 40 years time I can't shake the habit of a lifetime 🙂You'll probably need to try one or the other for yourself, if you have a friend who can hook you up with a tiny taste. Arf!

This has been a fascinating discussion. For a thing that dominated music for so long, it's hard to credit how little solid fact there is when it comes to the physics of stylus in groove behaviour.

Comming back to the initial question why it's almost impossible to play a steel record.

What about damping? Vinyl has a very high inner damping compared to steel which is very low. Steel has a crystalline structure while vinyl is composed of long polymer strings like a bowl of spaghetti resulting in a quite high damping.

When dropping a steel ball onto a block of steel, it bounces back while on a block of vinyl, the effect is much much lower

What about damping? Vinyl has a very high inner damping compared to steel which is very low. Steel has a crystalline structure while vinyl is composed of long polymer strings like a bowl of spaghetti resulting in a quite high damping.

When dropping a steel ball onto a block of steel, it bounces back while on a block of vinyl, the effect is much much lower

Aboos,

There is not that much difference in damping, steel with 0.01 and plastic between 0.02 and 0.04.

However steel has a 100 times higher Young modulus, so the spring function is much stronger.

Steel has a crystaline structure and vinylite, the material used for LP's, has for 20% a crystaline structure and 80% amorph.

Hans

There is not that much difference in damping, steel with 0.01 and plastic between 0.02 and 0.04.

However steel has a 100 times higher Young modulus, so the spring function is much stronger.

Steel has a crystaline structure and vinylite, the material used for LP's, has for 20% a crystaline structure and 80% amorph.

Hans

IMHO Because it would be too complicated, because it would be surprisingly expensive and because not only audiophiles buy LPs, but also quite "normal" people, and possibly not everyone would like to buy a non-virgin LP.why isn’t the product already applied to the surface by LP producers ?

Furthermore the commercial agreements between companies with totally different business structures would be difficult, I guess. 🙂

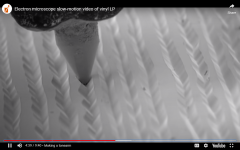

I really liked the video you posted (thank you!), from which I made this screenshot (related to vinyl).Not deeply related, but fun, a look at practical scanning electron microscopy:

I can easily be wrong, but that image made me think that it's possibly not a matter of the difference in the elasticity or damping of the different materials (steel and vinyl) that change the sound quality, but just the different ability to make the grooves of the engraving lathe relative to the material itself.

Are we sure that the grooves engraved in the steel by the lathe are micrometrically exactly identical to those in the vinyl under the electron microscope?

I'm not sure at all about this because the chemical structure of the two materials is too different and also their ability to be machined is. IMHO

Hans,Aboos,

There is not that much difference in damping, steel with 0.01 and plastic between 0.02 and 0.04.

However steel has a 100 times higher Young modulus, so the spring function is much stronger.

Steel has a crystaline structure and vinylite, the material used for LP's, has for 20% a crystaline structure and 80% amorph.

Hans

vinylite is a vinylchloride-vinylacetate copolymer (called PVCA, this is not a blend which is simply a mixture of two different plastic materials!) which is an amorphous plastic material. What is the 20% crystalline component?

The damping properties you mention are hard to believe (if they are coefficients for acoustic damping): if you hit a steel plate with a hammer, it rings like a bell. If you do the same with a plastic sheet, you only get a short and highly damped 'tock'

Plastic materials also differ significantly from steel by showing a time delayed relaxation. If you slighetly bend a stell rod, it returns to its original state almost immediately. If you do the same with a plastic rod, the following will happen: it returns back to its original shape but not completely. Depending on the plastic material, this initial 'fast return' is followed by slow 'crawling' back phase which can take seconds up to days

Sorry, I completely misunderstood the issue: please ignore what I posted, thank you all.I can easily be wrong...

As I mentioned, yesterday I wrote an email to Jeff, the owner of LAST, and received in return an email today.

Here it is.

Hello Hans,

These are some great comments and questions! Let me take a swing at them.

Regarding tip temperature, I have looked for the documentation of Van den Hul's temperature measurements and I can not find his original research. However I see his work referred to in various places and they say he measured the temperature at 160C. Our own work (4 decades ago) showed temperature at the contact point of 300F, so while ours was cooler, those are at least in the same range. Differences in tracking force, vinyl, measurement techniques and other things will vary the results, so I'm pleased to see that the two are fairly close. Other references suggest that Tremaine put the temperature at much higher, but his work would have been with earlier equipment. Interestingly, Shure seems to have no temp data: https://service.shure.com/s/article/temperature-of-stylus?language=en_US It is a very technically difficult measurement to make.

A writer on VinylEngine https://www.vinylengine.com/turntable_forum/viewtopic.php?t=27421 takes this to the next step and with the difference in thermal conductivity as you mention, suggests a temperature increase in the vinyl of about 10C. Which is still well below melting the vinyl.

I agree that the stylus heating is not raising the temperature of the solid vinyl groove by a significant amount, whether it is 1C or 10C. The stylus temperature is actually much more important to the stylus life. (I should put in an advertisement for our Stylus Treatment here, but that isn't what you asked!)

So the statement in the patent that the vinyl may be heated to "near the melting point" sounds suspicious. However, the combination of a hot stylus and a contact pressure of 10,000 - 50,000 PSI is quite similar to the forces and temperature used to press records. Record vinyl is not heated to melting temperature during manufacture, rather the vinyl is softened and then forced under very high pressure into the stamper. Those conditions are similar to what a small particle of loose vinyl, caught between the stylus and the vinyl, might experience. And while that isn't really described in the patent, that is one of the damage mechanisms that we believe does relate to the pressure/temp of the stylus. As you think about the pressure created by the stylus, make sure to account for the dynamic nature of a traveling stylus. The static pressure numbers are just the beginning.

[You will see record stamping pressures reported as anything from a few thousand PSI up to 70,000 PSI. Sometimes they say something like "110 Tonnes" but that is total pressure, you have to divide by surface area. Temperature is generally listed as somewhere between 160C and 200C].

So while it may not make sense to say that the stylus is melting the vinyl, it is certainly still the case that the stylus can deform the vinyl, and in the presence of particles, those particles may become pressed into the vinyl as the stylus passes.

We do still have the SEM images - some are in our product listings - but I do not know the stylus used to make those photos.

Your questions about friction and steel make sense, but friction isn't really a chemical property, it is a combination of physical characteristics that result in a mechanical property of measured friction. Surface finish, pressure, processing, all can affect the friction of a given material. I don't know how a steel record would sound, but I imagine it would be hard to get a surface with a smooth enough microstructure. Electroplated nickel is used in the process of making records, and according to some record manufacturing companies, you can play the nickel "mother" with excellent sound reproduction.

So that leaves us with what our preservative actually does. I had not thought about it in terms of Young's modulus, though it may have some slight effect. But the preservative only affects the surface to within the top molecular layers (we say 10 molecular layers, but of course that is approximate). The preservative will continue to be diffused/absorbed into the vinyl if applied excessively. The effect in that shallow domain is to reduce the surface free energy, which is roughly the equivalent of surface tension in a liquid. The effect is to reduce friction. But it does not do this by introducing a lubricant, but rather by this reduction in surface energy. It is that reduced friction that reduces the shock wave created by the stylus, and that, in turn reduces the damage caused to the record. As a side effect it also means the stylus has an easier time following the groove. So although we sell our Record Preservative to reduce record damage in the long term, it also can give immediate playing improvement.

I hope that generally answers your questions. I'm typing this up late at night (actually, very early in the morning). I have tried to make good sense of this, but if I see a grave error sometime during the day I will send a note! I do appreciate your interest and I hope you will consider our products. Our value is simple - a clean, undamaged record sounds better. The most expensive cables in the world or the finest preamp won't fix a worn stylus or a noisy album. We are probably the least expensive but most important thing that can be done to make a system sound great.

Most importantly, go enjoy your music!

Jeff Kaskey

Owner, The Last Factory

Here it is.

Hello Hans,

These are some great comments and questions! Let me take a swing at them.

Regarding tip temperature, I have looked for the documentation of Van den Hul's temperature measurements and I can not find his original research. However I see his work referred to in various places and they say he measured the temperature at 160C. Our own work (4 decades ago) showed temperature at the contact point of 300F, so while ours was cooler, those are at least in the same range. Differences in tracking force, vinyl, measurement techniques and other things will vary the results, so I'm pleased to see that the two are fairly close. Other references suggest that Tremaine put the temperature at much higher, but his work would have been with earlier equipment. Interestingly, Shure seems to have no temp data: https://service.shure.com/s/article/temperature-of-stylus?language=en_US It is a very technically difficult measurement to make.

A writer on VinylEngine https://www.vinylengine.com/turntable_forum/viewtopic.php?t=27421 takes this to the next step and with the difference in thermal conductivity as you mention, suggests a temperature increase in the vinyl of about 10C. Which is still well below melting the vinyl.

I agree that the stylus heating is not raising the temperature of the solid vinyl groove by a significant amount, whether it is 1C or 10C. The stylus temperature is actually much more important to the stylus life. (I should put in an advertisement for our Stylus Treatment here, but that isn't what you asked!)

So the statement in the patent that the vinyl may be heated to "near the melting point" sounds suspicious. However, the combination of a hot stylus and a contact pressure of 10,000 - 50,000 PSI is quite similar to the forces and temperature used to press records. Record vinyl is not heated to melting temperature during manufacture, rather the vinyl is softened and then forced under very high pressure into the stamper. Those conditions are similar to what a small particle of loose vinyl, caught between the stylus and the vinyl, might experience. And while that isn't really described in the patent, that is one of the damage mechanisms that we believe does relate to the pressure/temp of the stylus. As you think about the pressure created by the stylus, make sure to account for the dynamic nature of a traveling stylus. The static pressure numbers are just the beginning.

[You will see record stamping pressures reported as anything from a few thousand PSI up to 70,000 PSI. Sometimes they say something like "110 Tonnes" but that is total pressure, you have to divide by surface area. Temperature is generally listed as somewhere between 160C and 200C].

So while it may not make sense to say that the stylus is melting the vinyl, it is certainly still the case that the stylus can deform the vinyl, and in the presence of particles, those particles may become pressed into the vinyl as the stylus passes.

We do still have the SEM images - some are in our product listings - but I do not know the stylus used to make those photos.

Your questions about friction and steel make sense, but friction isn't really a chemical property, it is a combination of physical characteristics that result in a mechanical property of measured friction. Surface finish, pressure, processing, all can affect the friction of a given material. I don't know how a steel record would sound, but I imagine it would be hard to get a surface with a smooth enough microstructure. Electroplated nickel is used in the process of making records, and according to some record manufacturing companies, you can play the nickel "mother" with excellent sound reproduction.

So that leaves us with what our preservative actually does. I had not thought about it in terms of Young's modulus, though it may have some slight effect. But the preservative only affects the surface to within the top molecular layers (we say 10 molecular layers, but of course that is approximate). The preservative will continue to be diffused/absorbed into the vinyl if applied excessively. The effect in that shallow domain is to reduce the surface free energy, which is roughly the equivalent of surface tension in a liquid. The effect is to reduce friction. But it does not do this by introducing a lubricant, but rather by this reduction in surface energy. It is that reduced friction that reduces the shock wave created by the stylus, and that, in turn reduces the damage caused to the record. As a side effect it also means the stylus has an easier time following the groove. So although we sell our Record Preservative to reduce record damage in the long term, it also can give immediate playing improvement.

I hope that generally answers your questions. I'm typing this up late at night (actually, very early in the morning). I have tried to make good sense of this, but if I see a grave error sometime during the day I will send a note! I do appreciate your interest and I hope you will consider our products. Our value is simple - a clean, undamaged record sounds better. The most expensive cables in the world or the finest preamp won't fix a worn stylus or a noisy album. We are probably the least expensive but most important thing that can be done to make a system sound great.

Most importantly, go enjoy your music!

Jeff Kaskey

Owner, The Last Factory

Last edited:

And this was my reply to him

Hello Jeff,

Thx for your immediate and extensive reply, I really appreciate it.

I can´t resist to give a short comment on the links that you gave, because there is so much non validated hear-say info on the subject.

Kindest Regards

Hans

Hello Jeff,

Thx for your immediate and extensive reply, I really appreciate it.

I can´t resist to give a short comment on the links that you gave, because there is so much non validated hear-say info on the subject.

- Shure mentioning 30 to 60.000psi, I’m amazed they gave this answer.

The yield point of PVC being at 14.500psi will change from solid into fluid (plastic state) and more pressure will hardly be possible.

Bastiaans (see attachment) has done very thorough calculations AND measurements to compare theory versus real life measurements.

The best document I’ve come across so far. - About van den Hull, he wrote that others had measured tip temps of 160C but with his own carts the maximum he could measure was 60C.

But anyhow, as you also mentioned, even this will have little effect on vinyl temp.

Good to know is that although the PVC’s melting point is at ca 215C, but as from between 70C and 80C the PVC will start evaporating chlorine, start weakening and will change properties.

A 160C tip could potentially harm the LP when the LP coming to a halt, not to speak what would happen when playing a 78rpm record generating more than 2 times heat flow by friction.

So I could live with 60C, but 160C really seems beyond reality. - Your second link starts with mentioning that, according to G.Alexandrovich, when the vinyl melts under pressure, it must be at its melting point.

That’s a very big misunderstanding in physics.

Under pressure the boiling point reduces, and at the yield point of PVC under high pressure there is hardly any temp rise. - A 0.5mg tip, accelerating at 2000m/sec while playing, is facing a pressure of 1mN or 0,1 gram. Compare this to the 2 gram stylus pressure and it becomes clear that Static pressure is by far the dominant pressure.

Kindest Regards

Hans

Ah, I'd always heard not to play an album more than once in a short period of time. That would make sense in the context of the time delayed relaxation.Hans,

vinylite is a vinylchloride-vinylacetate copolymer (called PVCA, this is not a blend which is simply a mixture of two different plastic materials!) which is an amorphous plastic material. What is the 20% crystalline component?

The damping properties you mention are hard to believe (if they are coefficients for acoustic damping): if you hit a steel plate with a hammer, it rings like a bell. If you do the same with a plastic sheet, you only get a short and highly damped 'tock'

Plastic materials also differ significantly from steel by showing a time delayed relaxation. If you slighetly bend a stell rod, it returns to its original state almost immediately. If you do the same with a plastic rod, the following will happen: it returns back to its original shape but not completely. Depending on the plastic material, this initial 'fast return' is followed by slow 'crawling' back phase which can take seconds up to days

According to the link Composition of Vinyl Records that Alighiszem gave, PVC has a 10% to 20% crystalline content.Hans,

vinylite is a vinylchloride-vinylacetate copolymer (called PVCA, this is not a blend which is simply a mixture of two different plastic materials!) which is an amorphous plastic material. What is the 20% crystalline component?

The damping properties you mention are hard to believe (if they are coefficients for acoustic damping): if you hit a steel plate with a hammer, it rings like a bell. If you do the same with a plastic sheet, you only get a short and highly damped 'tock'

Plastic materials also differ significantly from steel by showing a time delayed relaxation. If you slighetly bend a stell rod, it returns to its original state almost immediately. If you do the same with a plastic rod, the following will happen: it returns back to its original shape but not completely. Depending on the plastic material, this initial 'fast return' is followed by slow 'crawling' back phase which can take seconds up to days

Damping figures providesd according to

https://www.jpe-innovations.com/precision-point/structural-damping-properties-mechanical-systems/

Hans

Thank you Hans for providing the sources.

For me, the article 'Composition of Vinyl Records' is a little bit shaky. It is desribed that the raw material is a blend of PVC and PVA. I read at various sources (datasheets from raw material vendors claiming 'vinyl records' as one field of application for the material) that the basic material for vinyl discs is PVCA which is a copolymer. In a copolymer, the two monomers (VinylChloride and VinylAcetate) form one chain with part of the pure PVC chain substituted with VinylAcetate molecules. During synthesis, the amount of each monomer can be set to various ratios allowing to set certain parameters like melting point, elasticity and many others for the resulting material. And this material is a single plastic material and not a mixture of two. And in this case, it can only be amorphous or crystalline - not 80% amorphous and 20% crystalline.

Furthermore, the article states that usually carbon black was used as an additive. This is true and carbon black provides stability against light, it is cheap, gives a nice surface and can serve as an embedded lubricant in the polymer mix. But, the article also states that this carbon black in modern records often is replaced by other color pigments and that titanium dioxide is in use. This would be a very bad choice as titanium dioxide is a very hard crystalline material (Hardness of 6.5 Mohs, silicondioxide/quartz has a hardness of 7) that would lead to very significant diamond wear shortening the tip life. And it would produce high surface noise as small crystals sticking out from the surface will behave like embedded bricks on a road hammering your tires when driving.

Yes, there might be other color pigments used but certainly not titanium doxide (which is a bright white powder!)

For me, the article 'Composition of Vinyl Records' is a little bit shaky. It is desribed that the raw material is a blend of PVC and PVA. I read at various sources (datasheets from raw material vendors claiming 'vinyl records' as one field of application for the material) that the basic material for vinyl discs is PVCA which is a copolymer. In a copolymer, the two monomers (VinylChloride and VinylAcetate) form one chain with part of the pure PVC chain substituted with VinylAcetate molecules. During synthesis, the amount of each monomer can be set to various ratios allowing to set certain parameters like melting point, elasticity and many others for the resulting material. And this material is a single plastic material and not a mixture of two. And in this case, it can only be amorphous or crystalline - not 80% amorphous and 20% crystalline.

Furthermore, the article states that usually carbon black was used as an additive. This is true and carbon black provides stability against light, it is cheap, gives a nice surface and can serve as an embedded lubricant in the polymer mix. But, the article also states that this carbon black in modern records often is replaced by other color pigments and that titanium dioxide is in use. This would be a very bad choice as titanium dioxide is a very hard crystalline material (Hardness of 6.5 Mohs, silicondioxide/quartz has a hardness of 7) that would lead to very significant diamond wear shortening the tip life. And it would produce high surface noise as small crystals sticking out from the surface will behave like embedded bricks on a road hammering your tires when driving.

Yes, there might be other color pigments used but certainly not titanium doxide (which is a bright white powder!)

- Home

- Source & Line

- Analogue Source

- Effect of Stylus friction on LP