What does the measurement gizmo look like?Yes you can measure for DC on the mains. A good digital scope will show it. You can build a gizmo to show it on a meter.

If the hum is due to saturating magnetising current at 50Hz, as it seems, hum should reduce with mains voltage at a 'knee' - so for test purposes you might try it on a Variac and see...... but if so there's no easy answer, unfortunately.

Had a bit more "fun" with the transformer overnight...

I re-wired it for 120V input and used the variac to see how the hum levels were.

Interesting that under load it still hummed at 50Hz operation, not quite as loud, but still annoying.

So, I took off the bell covers, opened it up and found that it is very solidly constructed, nothing loose whatsoever. I had some spare thick insulating pad left over from another project (similar to the rubber pads which sit between a toroidal transformer and the chassis - but made of a black foam with an adhesive on one side). I put some under the core of the transformer, between the chassis and transformer. Then I also put three pieces on each of the inside sections of the bell cover.

Sealed it shut tight again, re-wired it back for 240v and hey presto the buzzing has been reduced by about 50%. It's tolerable now. I have no idea about the heat tolerance of the foam adhesive I've use to dampen the sound....but it will have to do!

Thanks again for all the help - and a word of warning, it's probably best to get transformers custom made for your local frequency requirements!

I re-wired it for 120V input and used the variac to see how the hum levels were.

Interesting that under load it still hummed at 50Hz operation, not quite as loud, but still annoying.

So, I took off the bell covers, opened it up and found that it is very solidly constructed, nothing loose whatsoever. I had some spare thick insulating pad left over from another project (similar to the rubber pads which sit between a toroidal transformer and the chassis - but made of a black foam with an adhesive on one side). I put some under the core of the transformer, between the chassis and transformer. Then I also put three pieces on each of the inside sections of the bell cover.

Sealed it shut tight again, re-wired it back for 240v and hey presto the buzzing has been reduced by about 50%. It's tolerable now. I have no idea about the heat tolerance of the foam adhesive I've use to dampen the sound....but it will have to do!

Thanks again for all the help - and a word of warning, it's probably best to get transformers custom made for your local frequency requirements!

Last edited:

how hot does it become and how long before it gets hot?

if temperature is not that high, then most likely it is mechanical

and not electrical, so a dip in varnish helps more...

if temperature is not that high, then most likely it is mechanical

and not electrical, so a dip in varnish helps more...

What does the measurement gizmo look like?

Classic FM discriminator circuit. Use a center tapped transformer, diodes and resistors. When at my computer will try to post circuit.

how hot does it become and how long before it gets hot?

if temperature is not that high, then most likely it is mechanical

and not electrical, so a dip in varnish helps more...

It gets to about 35 degrees (centigrade) after an hour of driving speakers.....if driving headphones it is merely slightly warm to touch.

What sort of varnish? Do you mean simply dip the whole transformer in varnish and wait for it to dry?

that is not so bad at all...

dipping in electrical grade polyurethane air drying varnish,

take out the endbells and dip the whole traffo in a can of

varnish so that it is fully submerged, then hang out to dry

take the traffo out only when the bubbling stops..

do this process about three times....submerge, drip, and then dry...

do not throw away used varnish, you can still use it for other traffos,

or perhaps your friends'....

dipping in electrical grade polyurethane air drying varnish,

take out the endbells and dip the whole traffo in a can of

varnish so that it is fully submerged, then hang out to dry

take the traffo out only when the bubbling stops..

do this process about three times....submerge, drip, and then dry...

do not throw away used varnish, you can still use it for other traffos,

or perhaps your friends'....

Before dropping it into the varnish bucket, I think I would try to eliminate DC on the power line, and determine whether it is from magnetic saturation.

If it saturates at 240V on 50 Hz, it will also saturate at 288 V on 60 Hz.

Even on the 240V/50 Hz, one should establish the voltage of obvious buzzing onset using the variac. Then try 1.2X that voltage, using 60 Hz, to see if it starts there too. If these ratios don't hold up, then it must be some loose lamination resonance at 50 Hz.

If there is a loose lamination deep inside the core, it may be impossible to get it fixed with just varnish. The xfmr manufacturers use a vacuum varnishing techique to pull the air out first, and then absorb the varnish in to the deepest recesses when the vacuum is released. One would need a pressure cooker pot with an overpressure port for a hose connection and a vacuum pump to pull that off.

I know Edcor designs their SE OTs close to the saturation limit. And while they probably design 60 Hz power xfmrs with adequate core flux margin, they may have designed for miniscule 50 Hz margin. While 50 Hz xfmrs domestically designed probably have ample flux reserve for line voltage variation. So just because the domestic 50 Hz xfmrs are not buzzing from saturation or DC on the line, may not be sufficient to eliminate that as the cause here.

If it saturates at 240V on 50 Hz, it will also saturate at 288 V on 60 Hz.

Even on the 240V/50 Hz, one should establish the voltage of obvious buzzing onset using the variac. Then try 1.2X that voltage, using 60 Hz, to see if it starts there too. If these ratios don't hold up, then it must be some loose lamination resonance at 50 Hz.

If there is a loose lamination deep inside the core, it may be impossible to get it fixed with just varnish. The xfmr manufacturers use a vacuum varnishing techique to pull the air out first, and then absorb the varnish in to the deepest recesses when the vacuum is released. One would need a pressure cooker pot with an overpressure port for a hose connection and a vacuum pump to pull that off.

I know Edcor designs their SE OTs close to the saturation limit. And while they probably design 60 Hz power xfmrs with adequate core flux margin, they may have designed for miniscule 50 Hz margin. While 50 Hz xfmrs domestically designed probably have ample flux reserve for line voltage variation. So just because the domestic 50 Hz xfmrs are not buzzing from saturation or DC on the line, may not be sufficient to eliminate that as the cause here.

Last edited:

dipping in electrical grade polyurethane air drying varnish,

thanks - any particular brand/make you can recommend?

Before dropping it into the varnish bucket, I think I would try to eliminate DC on the power line

Is there any way to do this using a multimeter to measure off the mains?

I'd have thought that isolating the xfmr with a step-down xfmr should have eliminated any DC?

Even on the 240V/50 Hz, one should establish the voltage of obvious buzzing onset using the variac. Then try 1.2X that voltage, using 60 Hz, to see if it starts there too. If these ratios don't hold up, then it must be some loose lamination resonance at 50 Hz.

The ratio definitely doesn't hold up.

Whilst I can't measure above 240v using the variac (no boost mode), I can measure 200v 50hz unloaded, and at 240v 60hz there is no buzzing. May simply be a lack of testing in the Edcor lab at 50hz (unless it's DC on the mains).

Last edited:

Yes, a step down xfmr should eliminate any DC, although an autoformer would not do so well.

If there is something in the house pulling DC off the power line, it would be useful to find out what it is besides. Not good for anything else with xfmrs in it including the outside pole xfmr. The cheapo DC thingies should really be prohibited. Typically something like a clock or LED light, but could be a PC or TV or something with warm start, battery charging, remote start up, low power idle mode. Bread maker, microwave....in fact just about anything nowadays that is electronic instead of resistive. And then there are switching power supplies that can put noise on the line from spiked current pull at voltage peaks.

You might try an OLD half worn out 1.5V D cell battery briefly in series with the buzzing xfmr, in both series polarities, to see if there is any difference in the xfmr buzzing. Don't expect the battery to work well afterwards.

If there is something in the house pulling DC off the power line, it would be useful to find out what it is besides. Not good for anything else with xfmrs in it including the outside pole xfmr. The cheapo DC thingies should really be prohibited. Typically something like a clock or LED light, but could be a PC or TV or something with warm start, battery charging, remote start up, low power idle mode. Bread maker, microwave....in fact just about anything nowadays that is electronic instead of resistive. And then there are switching power supplies that can put noise on the line from spiked current pull at voltage peaks.

You might try an OLD half worn out 1.5V D cell battery briefly in series with the buzzing xfmr, in both series polarities, to see if there is any difference in the xfmr buzzing. Don't expect the battery to work well afterwards.

Last edited:

thanks - any particular brand/make you can recommend?

i use "Remington" brand, but not sure what is available to you locally, you may want to check out your local stores...

By way of an update - I've received this response from Edcor:

"The photo show a peace of steel call a keeper. That is correct. The transformers that we have at 120V are 60Hz. Our 240V transformers run at 50Hz. Yes, a 120V 60Hz. transformer could hum at 50Hz. because the flux is so high. I am sorry, it is very hard to keep up with all voltages and frequencies of counties.

Thank you"

"The photo show a peace of steel call a keeper. That is correct. The transformers that we have at 120V are 60Hz. Our 240V transformers run at 50Hz. Yes, a 120V 60Hz. transformer could hum at 50Hz. because the flux is so high. I am sorry, it is very hard to keep up with all voltages and frequencies of counties.

Thank you"

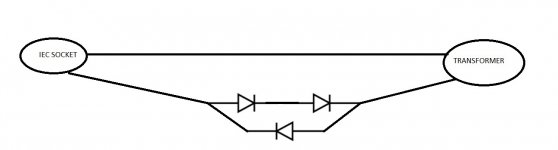

Wire two diodes in series and a third across the first two going the other way. Place this in series with the AC line feeding the transformer. See how that affects the buzz.

By way of an update - I've received this response from Edcor:

"The photo show a peace of steel call a keeper. That is correct. The transformers that we have at 120V are 60Hz. Our 240V transformers run at 50Hz. Yes, a 120V 60Hz. transformer could hum at 50Hz. because the flux is so high. I am sorry, it is very hard to keep up with all voltages and frequencies of counties.

Thank you"

we knew this all along, in my traffo builds i now use 260+ volts as design reference for traffos that will run at 240 volts....

Certainly can try that - how will it stop the buzz?

Is the diagram I have attached correct & what are the best diodes to use?

You got it right. Almost any rectifier diode will work. PIV doesn't matter only current rating does. As there will be less than an amp you would be had pressed to find one that won't work.

Wire two diodes in series and a third across the first two going the other way. Place this in series with the AC line feeding the transformer. See how that affects the buzz.

Ok I tested it this evening, seems to have reduced the buzz a little. How does it do this? Is it simply dropping the voltage a little, or also blocking DC in some way?

At least the hum is at tolerable levels now!

It is providing a DC offset around .6 volts to cancel a bit of what is on the line. The next thing to try is three or four diodes each way and a 1000 uF 16 volt bipolar capacitor across the diodes. You can actually use just about any value of capacitor above a few hundred uF and if you don't have a bipolar a pair of normal ones also in parallel back to back.

- Status

- Not open for further replies.

- Home

- Amplifiers

- Tubes / Valves

- Edcor 240V primary 50hz humming