IMO, if you are serious, you run a three-way. 😎

It just all works better:

SP38/13

SEAS-3-Way-Classic

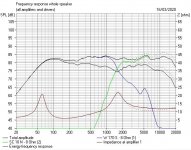

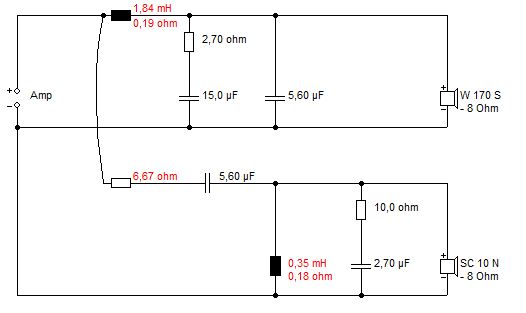

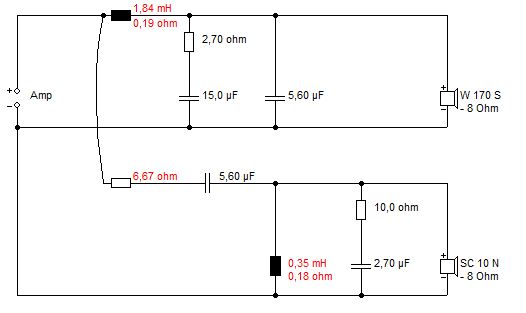

But you can see most of what's going on with some modelling:

Software | Visaton

Just import this design into the projekte folder and play around with values and add bits:

CT 142 mod – Boxsim Projektdatenbank

Paper drivers are not so easy as polycones, because they have more bumps in the response being less damped, but you get a feel for what does what.

Boxsim, like most simulators, can optimise parts for particular circumstances. The ones you mark in red.

You then just modify for convenient preferred values. 10% here or there makes little difference.

It just all works better:

SP38/13

SEAS-3-Way-Classic

But you can see most of what's going on with some modelling:

Software | Visaton

Just import this design into the projekte folder and play around with values and add bits:

CT 142 mod – Boxsim Projektdatenbank

Paper drivers are not so easy as polycones, because they have more bumps in the response being less damped, but you get a feel for what does what.

Boxsim, like most simulators, can optimise parts for particular circumstances. The ones you mark in red.

You then just modify for convenient preferred values. 10% here or there makes little difference.

Last edited:

Dear Steve,

With my wild idea to disconnect the HF correction I forgot that it might affect the crossover frequency!

Is this so?

Best regards, Veeren

With my wild idea to disconnect the HF correction I forgot that it might affect the crossover frequency!

Is this so?

Best regards, Veeren

Dear Steve,

With my wild idea to disconnect the HF correction I forgot that it might affect the crossover frequency!

Is this so?

Best regards, Veeren

Consider removing the fast-on connectors from the equation. That may solve a lot of normally unexplainable dips and general strangeness in the sound.

In my opinion these have no place in audio, as they are designed to carry high current and thus do not have the consistent pressure on the contact surfaces necessary for stable connections at lower currents

Regards, Tjeerd

Thanks Tjeerd,

Yes they are kind of loose as they can move sideways😀

Probably will start with the input terminals as they don't serve any funktion really.

Hartelijke groet, Veeren

Yes they are kind of loose as they can move sideways😀

Probably will start with the input terminals as they don't serve any funktion really.

Hartelijke groet, Veeren

I am not too sure what a fast-on connection is.

More certain is the effect of crossover components if you model them:

What happens if you take out the 10R plus 2.7uF Zobel?

A raise in high frequencies. Simple as that. The dotted line. 🙂

More certain is the effect of crossover components if you model them:

What happens if you take out the 10R plus 2.7uF Zobel?

A raise in high frequencies. Simple as that. The dotted line. 🙂

Attachments

No!A faston connector ...

I thought it would change the crossover frequency

But make sure they have tight connection. If not, squeeze a little the fast-on connector with pliers and than connect to woofer terminals.

Thanks Sonce!

Hello Macedonia!

Will check tightness on the fastons and resistance.

What I just realised is that the bare copper wire that is squished in the faston

can oxidise to , this has noting to do with tightness of connection but could lead

to a bad connection.

Will check that also.

Best regards, Veeren

Hello Macedonia!

Will check tightness on the fastons and resistance.

What I just realised is that the bare copper wire that is squished in the faston

can oxidise to , this has noting to do with tightness of connection but could lead

to a bad connection.

Will check that also.

Best regards, Veeren

Cheers!

Yes, copper oxidation can be a big problem, but usually it is quite visible. If in doubt, cut the wire a few centimeters above the old fast-on connector, inspect the naked wire (copper) if it is good and install a new fast-on connector. Or use a new wire.

Yes, copper oxidation can be a big problem, but usually it is quite visible. If in doubt, cut the wire a few centimeters above the old fast-on connector, inspect the naked wire (copper) if it is good and install a new fast-on connector. Or use a new wire.

I am not too sure what a fast-on connection is.

Those are the push on connectors they use instead of good practices like soldering. Basically they provide a good mechanical connection, in that they won't fall off, but a lousy electrical connectin since there's no pressure or bonding at the contact point.

Laughably solder would be both more economical and more reliable, even on the production line, as a good solder joint takes no more time than push-ons.

Yes they are kind of loose as they can move sideways😀

If there is any play at all, it is very likely there are at least a couple of spots where you're getting a high resistance connection. As I mentioned in my previous post, these things provide a good mechanical connection but not a very good electrical one. My common practice when working on speakers is to remove them and solder everything.

Yes, the bare copper where they crimped the connectors onto the wire can and does oxidise, but that isn't their biggest drawback.

Thanks every one,

Soldering connections to speakers has been a good practise for decades

wonder why the manufacturers have abandoned them😕

There exist gold plated fastons that might be better but I wont crimp them

without a professional crimping tool.

It seems that only Dynaudio`s top of the range loudspeakers use soldering to

all connections.

Did they run out of skilled solder iron wielders?

I bet the whole crossover board is assembled in Taiwan or China and them shipped to Denmark for assembly.

The quality of the board and the soldering is good, well made.

Best regards, Veeren

Soldering connections to speakers has been a good practise for decades

wonder why the manufacturers have abandoned them😕

There exist gold plated fastons that might be better but I wont crimp them

without a professional crimping tool.

It seems that only Dynaudio`s top of the range loudspeakers use soldering to

all connections.

Did they run out of skilled solder iron wielders?

I bet the whole crossover board is assembled in Taiwan or China and them shipped to Denmark for assembly.

The quality of the board and the soldering is good, well made.

Best regards, Veeren

Soldering connections to speakers has been a good practise for decades

wonder why the manufacturers have abandoned them😕

Beacause they had justifying reasons to do so, and it has to do with labours costs and practicality.

my DM 2/7 experience...

Hello Guys,

nice to see this post live...

2 days ago I made a last xover update to my DM 2/7...

Before 3 years I decised to open my Dynaudios to see what is inside. What a disappointment ! Bennic, MKP´s and fastons ! UGH 😱

So I decised buy a Jantzen Audio caps (8,2uF Superior Z-Cap for higs and 1uF to change one small MKP + 15uF Standart Z-cap for mids). Also I changed a new Kimber Kable 8PR to all wired connections + direct soldering.

1st I installed Kimber Kable 8PR + faston OFF and listened the change ... nice, bass were more rigid, more solid and less muddy and highs were more airy and opened.

2nd I installed caps...and then started 3 years of re-possitioning speakers, 5x of damping foam reducing in thousant steps... yes there were more colours to recognize - amazing but there was also bad mid + tweeter connection... so after one year I decided to put back that 1uF MKP because I understand that it could be a original one... and really mid+highs were nicely connected again so I just listened.

I found them very demanding for Amps but after a change it was worse and worse with possitioning... bass were slow in some freqs and I used and changed lot of amps to provide best damping factor values + Kenwood KA-1100D, DPA 222SE dual mono, everything less powered were slow. In 50Hz were a massive drop, I never knew why it is strong under 48hz and at 50Hz its so weak and then make it strong again in 53Hz+... oh dear... possitioning never ends !

And the same it was with sound source, LP, CD, MC... same all interconnets changed to SUPRA EF-1 and this all sorted this DM 2/7 setup. Well I got also some other speakers too, but Dynaudios were always best in terms of vocal and instrument colours, clarity and bit real feel. So I always do everything to make sound them perfect.

But there were another issue too, in space were often a hole in a center... so never-ending re-possitioning to make them enough close because of center space and enough away because of wide space and ideal from back side because of bass delay 😡 ... well it was really good test to me, what I am able to do for the sound, lot of personal energy.

So as I mentioned after 3 years of this (changed 2 rooms because of moving to another flats) I realised, that when is speaker sucks in phase, that you have to correct everything others or easily said, they are not able to sound correct in phase in some real conditions. I made a decision to try put the original bennic 15uF there (real value on both is 16,15uF not a 15,1 as is Jantzen) and see what happen... with this all damping foam is back inside as original - 3% from back sides foams but this is OK it gave them a very small amount of hardness which I overal missed.

So what happened after put back old bennic´s ? Oh sh1t they have so smooth and quick bass... and space is so perfect, wide, deep but with full center mass as I always wish... I told to myself, that I am so stupid... but this is very good experience to me.

So now Dynaudios have:

- 8,2uF Jantzen Superior Z-Cap for higs (this not influence to any previous issue)

- Original 1uF MKP and 15uF Bennic

- Kimber Kable 8PR freshly on tweeter I used only two wires from 8PR cable to connect a tweeter... This solutions has a smaller capacity as standart 8PR cable and power ablitiy for tweeter is still very good...

Iam lucky man now... And I am happy to saw on start of this thread - just change a tweeter cap and everything leave original ! Yes this is very safe solution !

I know that all this is because I never measured it, never calculated and completely fail myself to see, that only consider capacity is not enough.

I hope it will help to somebody...

PS: I am not native speaker, sorry for my Englis... 😱

Hello Guys,

nice to see this post live...

2 days ago I made a last xover update to my DM 2/7...

Before 3 years I decised to open my Dynaudios to see what is inside. What a disappointment ! Bennic, MKP´s and fastons ! UGH 😱

So I decised buy a Jantzen Audio caps (8,2uF Superior Z-Cap for higs and 1uF to change one small MKP + 15uF Standart Z-cap for mids). Also I changed a new Kimber Kable 8PR to all wired connections + direct soldering.

1st I installed Kimber Kable 8PR + faston OFF and listened the change ... nice, bass were more rigid, more solid and less muddy and highs were more airy and opened.

2nd I installed caps...and then started 3 years of re-possitioning speakers, 5x of damping foam reducing in thousant steps... yes there were more colours to recognize - amazing but there was also bad mid + tweeter connection... so after one year I decided to put back that 1uF MKP because I understand that it could be a original one... and really mid+highs were nicely connected again so I just listened.

I found them very demanding for Amps but after a change it was worse and worse with possitioning... bass were slow in some freqs and I used and changed lot of amps to provide best damping factor values + Kenwood KA-1100D, DPA 222SE dual mono, everything less powered were slow. In 50Hz were a massive drop, I never knew why it is strong under 48hz and at 50Hz its so weak and then make it strong again in 53Hz+... oh dear... possitioning never ends !

And the same it was with sound source, LP, CD, MC... same all interconnets changed to SUPRA EF-1 and this all sorted this DM 2/7 setup. Well I got also some other speakers too, but Dynaudios were always best in terms of vocal and instrument colours, clarity and bit real feel. So I always do everything to make sound them perfect.

But there were another issue too, in space were often a hole in a center... so never-ending re-possitioning to make them enough close because of center space and enough away because of wide space and ideal from back side because of bass delay 😡 ... well it was really good test to me, what I am able to do for the sound, lot of personal energy.

So as I mentioned after 3 years of this (changed 2 rooms because of moving to another flats) I realised, that when is speaker sucks in phase, that you have to correct everything others or easily said, they are not able to sound correct in phase in some real conditions. I made a decision to try put the original bennic 15uF there (real value on both is 16,15uF not a 15,1 as is Jantzen) and see what happen... with this all damping foam is back inside as original - 3% from back sides foams but this is OK it gave them a very small amount of hardness which I overal missed.

So what happened after put back old bennic´s ? Oh sh1t they have so smooth and quick bass... and space is so perfect, wide, deep but with full center mass as I always wish... I told to myself, that I am so stupid... but this is very good experience to me.

So now Dynaudios have:

- 8,2uF Jantzen Superior Z-Cap for higs (this not influence to any previous issue)

- Original 1uF MKP and 15uF Bennic

- Kimber Kable 8PR freshly on tweeter I used only two wires from 8PR cable to connect a tweeter... This solutions has a smaller capacity as standart 8PR cable and power ablitiy for tweeter is still very good...

Iam lucky man now... And I am happy to saw on start of this thread - just change a tweeter cap and everything leave original ! Yes this is very safe solution !

I know that all this is because I never measured it, never calculated and completely fail myself to see, that only consider capacity is not enough.

I hope it will help to somebody...

PS: I am not native speaker, sorry for my Englis... 😱

Attachments

Does anyone know the schematics of BM6? Looks like they share the same units with different crossover for professional environment. I happened to get X18, but the midrange is definitely scooped (BBC dip), and a little too much bass.

Dynaudio Acoustics BM6 - 2-way passive monitor system

BM6A is "4th order phase-aligned crossover with a crossover point at 2.2kHz", so I guessed it is similar to that, but BM6's crossover is 3.3k. hmm.

Dynaudio Acoustics BM6 - 2-way passive monitor system

BM6A is "4th order phase-aligned crossover with a crossover point at 2.2kHz", so I guessed it is similar to that, but BM6's crossover is 3.3k. hmm.

Last edited:

Dear Plasnu,

As you have the x18 you can probably see that the drive units are not the same.

The BM6`s drive units are many generations back and are probably the 17w75 and d28.

What you hear as a midrange scoop I seem to perceive as lack of lower treble.

Too much bass I cannot detect even in a very small room close to the wall.

The x18 are very responsive to what you feed them and it is a refined loudspeaker deserving a good amp and source.

Best regards,

Veeren

As you have the x18 you can probably see that the drive units are not the same.

The BM6`s drive units are many generations back and are probably the 17w75 and d28.

What you hear as a midrange scoop I seem to perceive as lack of lower treble.

Too much bass I cannot detect even in a very small room close to the wall.

The x18 are very responsive to what you feed them and it is a refined loudspeaker deserving a good amp and source.

Best regards,

Veeren

Does anyone know the schematics of BM6?... I happened to get X18, but the midrange is definitely scooped (BBC dip), and a little too much bass...

Sorry, haven't got a schematic for bm6, but perhaps we could do something to improve the X18's x/o?

Dear Plasnu,

As you have the x18 you can probably see that the drive units are not the same.

The BM6`s drive units are many generations back and are probably the 17w75 and d28.

I see now that the D28 is actually a Esotec tweeter the woofer is still an unknown.

I cant tell from the frame whether it is a die cast or stamped frame.

What you hear as a midrange scoop I seem to perceive as lack of lower treble.

Too much bass I cannot detect even in a very small room close to the wall.

The x18 are very responsive to what you feed them and it is a refined loudspeaker deserving a good amp and source.

Best regards,

Veeren

- Home

- Loudspeakers

- Multi-Way

- Dynaudio X18 good cabinet and drivers lousy crossover?