"...don't use...single tone signals this risks creating a memory patten(sic) in the outer 7-10 micron cone substrate".

In plain English, does this mean it will develop a weak point in the structure of the cone in a specific place within the cone?

_________________________________________________Rick............

Hi Rick,

Your welcome to seek clarification should I (or other members) become too technical for your level of understanding. Regarding your other remarks, now deleted, leave them out of this forum.

Forum rules are here: http://www.diyaudio.com/forums/markaudio/196919-markaudio-forum-guide.html

Mark

In plain English, does this mean it will develop a weak point in the structure of the cone in a specific place within the cone?

_________________________________________________Rick............

Hi Rick,

Your welcome to seek clarification should I (or other members) become too technical for your level of understanding. Regarding your other remarks, now deleted, leave them out of this forum.

Forum rules are here: http://www.diyaudio.com/forums/markaudio/196919-markaudio-forum-guide.html

Mark

Last edited by a moderator:

".... a pair of maracas", and the following rhyme get me every time 😀

"don't you boys know any Nice songs?"

It'd have been fun to hear Frank, George Carlin & young Richard Pryor riff, but I digress

yup the simple 1st order PLLXO are darn simple & cheap - if you want to get fancy with a small separate project box, that and the requisite RCA connectors can cost more than the passive components

If there's room, you could add a second pair of input connectors and toggle switch and insert the PLLXO in the amps' chassis - I did that a few years ago with a pair of Decware Zen amps. They were actually quite well suited for this as they came with 2 pairs of inputs and a top mounted toggle switch for adjusting input tube bias that was easily repurposed when the owner decided which bias setting he preferred.

"don't you boys know any Nice songs?"

It'd have been fun to hear Frank, George Carlin & young Richard Pryor riff, but I digress

yup the simple 1st order PLLXO are darn simple & cheap - if you want to get fancy with a small separate project box, that and the requisite RCA connectors can cost more than the passive components

If there's room, you could add a second pair of input connectors and toggle switch and insert the PLLXO in the amps' chassis - I did that a few years ago with a pair of Decware Zen amps. They were actually quite well suited for this as they came with 2 pairs of inputs and a top mounted toggle switch for adjusting input tube bias that was easily repurposed when the owner decided which bias setting he preferred.

Being confused and confounded is no reason for rudeness.

I'm often in that state as I learn how to build things, and there is nothing but patience kindness and assistance here if your willing to ask for it.

I'm often in that state as I learn how to build things, and there is nothing but patience kindness and assistance here if your willing to ask for it.

That's the next project, after the twin driver studio monitors (4x7.3)

Lorien,

Sounds exciting - what plans are you using - any of Dave's designs or an updated rev of Scott's box for 2 x Alpair 7 (first gen, different from Alpair 7.3)?

Or something different altogether? 🙂

- Zia

p.s. sorry Mark for going OT! Please feel free to clean up the thread after a few exchanges (hopefully), or make a new thread of it if some good discussion happens.

Revised monitor by Scott (thanks again) I will be posting some build pics and impressions. Idea is for a near/mid field audiophile level monitor. Stage 2 build, give it one 7.3 and some serious muscle underneath. But one step at a time.

Also sorry for wandering off the path.

PM me if you'd like to share ideas.

Also sorry for wandering off the path.

PM me if you'd like to share ideas.

Attachments

Hi Guys,

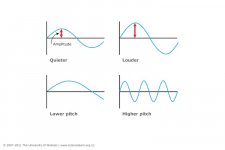

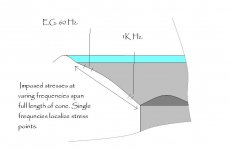

Member Rick seeks clarification (I think) on what happens to a driver when its subjected to a constant artificially generated signal, such as test tone and/or a single amplitude signal (see 1-kHz pic). Much depends on the type of driver being tested or run-in but for light-mass Full-Rangers, there's a risk of creating a "memory" affect within its moving parts, especially its cone when using signals of these types.

Perhaps the best way to imagine this effect is by looking at the 1-kHz pic and visualising that when a low-mass cone is subjected to such a constant signal, this single patten begins to burn its way onto the top layers of its surface. The effect can be further exaggerated if a light-mass driver is subjected to heavier constant signal loads early in its life (see sound-waves pic). Also, depending on the design of the drivers suspensions, their compliance may become more limited to the specific cycle generated by the particular fixed signal.

Hence the recommendation is to use general/popular/easy listening music to run-in most any Full-Range driver, these loads are variable and mostly non-linear.

Hope this helps.

Thanks

Mark.

(pics courtesy of:The University of Waikato - copyright acknowledged)

Member Rick seeks clarification (I think) on what happens to a driver when its subjected to a constant artificially generated signal, such as test tone and/or a single amplitude signal (see 1-kHz pic). Much depends on the type of driver being tested or run-in but for light-mass Full-Rangers, there's a risk of creating a "memory" affect within its moving parts, especially its cone when using signals of these types.

Perhaps the best way to imagine this effect is by looking at the 1-kHz pic and visualising that when a low-mass cone is subjected to such a constant signal, this single patten begins to burn its way onto the top layers of its surface. The effect can be further exaggerated if a light-mass driver is subjected to heavier constant signal loads early in its life (see sound-waves pic). Also, depending on the design of the drivers suspensions, their compliance may become more limited to the specific cycle generated by the particular fixed signal.

Hence the recommendation is to use general/popular/easy listening music to run-in most any Full-Range driver, these loads are variable and mostly non-linear.

Hope this helps.

Thanks

Mark.

(pics courtesy of:The University of Waikato - copyright acknowledged)

Attachments

Last edited:

Pallas,

Your comments in this post are deleted.

You're not a driver designer/maker, neither is Floyd.

Mark.

I know you're tired of me raining on this "break-in" scam you have going, but please answer one question: how is whether or not Dr. Floyd Toole is a "driver designer/maker" relevant to the listening test he described, and the results obtained?

Is a listening test of amps invalid if it's done by a speaker maker rather than an amp maker?

Last edited:

To clarify:

Please run in the latest Markaudio drivers:

1 - First 100 hours - low volume music only.

Uh-oh. 😉

Pallas, it would be more productive if you took these comments/suggestions/iterations to the full range forum area, rather than here.

No Mark, I'm not trying to rain on your parade. There obviously is some degradation, changing of parameters going on here, I just have issue with them audibly changing.

Some double-blind experiments are in order to confirm your hypothesis, broken-in vs. New. If this is indeed the case, I contend that changes of enclosure alignments are also in order.

Since you are so concerned with this break-in issue, why don't you break-in each driver before you release it for sale? Being as you "know" what's best & the best way & method to "pre-condition" your drivers, it seems the logical thing to do?

This is my take on the cone stress issue, am I on the right track here?

__________________________________________________________________Rick........

Some double-blind experiments are in order to confirm your hypothesis, broken-in vs. New. If this is indeed the case, I contend that changes of enclosure alignments are also in order.

Since you are so concerned with this break-in issue, why don't you break-in each driver before you release it for sale? Being as you "know" what's best & the best way & method to "pre-condition" your drivers, it seems the logical thing to do?

This is my take on the cone stress issue, am I on the right track here?

__________________________________________________________________Rick........

Attachments

Last edited:

I know you're tired of me raining on this "break-in" scam you have going, but please answer one question: how is whether or not Dr. Floyd Toole is a "driver designer/maker" relevant to the listening test he described, and the results obtained?

Is a listening test of amps invalid if it's done by a speaker maker rather than an amp maker?

Pallas,

The nature and tone of your comments is designed to insult. Regular reference directed at me (scam) is now well beyond reasonable behaviour and is a breach the rules of this section of the forum and the rules of Diyaudio.com.

I'm not sure why you've become obsessed with Floyd in this particular regard. Likely His work relates to limited range drivers of a more general design. As yet I've seen nothing from Floyd that specifically relates to the operation of the class of driver I design and make. I can't see any publication from him specifically relating to changes in micro-resonant behaviour in low-mass emitters designed for single-point-source operation; Nor in specific changes to the compliance of light-load, low mass long throw compliant suspensions used specifically in Markaudio drivers.

There's plenty of posts where I've talked much about the function and operation of Full-Range Low-Mass drivers. I'v spent several thousand hours designing and testing drivers. Last November, we passed the 1/4 million driver production mark, a more than adequate demonstration of my driver knowledge.

I'm very tired of expending my time and health (both in limited supply) having to deal with these sorts of posts. Genuine members and end-users need my time/energy to help them enjoy this hobby. Make a decision, choose who you wish to respect, those that make or those that don't.

Move on the open sections of Diyaudio to peddle your particular beliefs.

Mark

Last edited:

No Mark, I'm not trying to rain on your parade. There obviously is some degradation, changing of parameters going on here, I just have issue with them audibly changing.

Some double-blind experiments are in order to confirm your hypothesis, broken-in vs. New. If this is indeed the case, I contend that changes of enclosure alignments are also in order.

Since you are so concerned with this break-in issue, why don't you break-in each driver before you release it for sale? Being as you "know" what's best & the best way & method to "pre-condition" your drivers, it seems the logical thing to do?

This is my take on the cone stress issue, am I on the right track here?

__________________________________________________________________Rick........

Hi Rick,

I welcome debate provided its done with respect, without resorting to negatively personalising anyone's integrity, including mine.

Many members report audible changes in drivers during the earlier hours of operation. Its more likely to relate to low-mass light load Full-Range drivers due to their particular design and function characteristics. The micro-resonant function of low mass cones is complex and challenging to measure. I'm one of a few with the necessary lab equipment capable of analysis of these properties. I know that such cones are capable of audible state change, a factor often noted by many members who's hearing is of sufficient sensitivity to notice these events. For heavier mass, higher load drivers, it may be less of an issue but I can't speak for every driver maker, they may have their own operational requirements.

Your drawing is very interesting but not accurate. To produce the effect you describe, the indicated likely amplitude on your drawing given its relative proportion would be < 10 to 20 Hz. At 1-kHz, there's no prospect of producing the effect you describe in your drawing from typical service loads.

But I appreciate what you're trying to imagine. For me personally, I'm always wrestling with competing design factors, especially those where I'm asked by members to increase the operational performance of drivers, but at the same time, produce a reliable product. I have some sympathy with your thinking that there are "limits" to can can be achieved and what should be expected from a Full-Range driver. Stress loadings on Full-Range drivers are more critical. In the latest models, I've introduced the Arrestor to help eliminate the worst of excess loading, short of "suicidal" operation, there's little danger of breaking a cone.

To date we're running 4 X Alpair 7's and 8 X Alpair 10's (late Gen 1's and early Gen 2's) on ultra long life tests, each with 42,000 hours (rounded) and 41,000 hours (rounded) on non-linear loads (general music) in the low 80dB's (peak90dB)in 8 and 12.5 litre BR boxes respectively. I tested the resonance frequency of 2 Alp 7's and found a 0.7 and a 0.81 < Hz change from their state at the 150 hour point of their operation. No signs of damage, all sounding nice. Pretty good in any makers book and well inside any box design tolerances.

As for running in each driver at the factory, that would be commercial suicide. Think of the shear scale of such an operation!

(apologies chaps. I mistakenly used the wrong figures from the test sheets - please see corrected run time data - blue text in above post)

Hope this helps

Mark

Last edited:

You mean I have to break in my own speakers because you couldn't be bothered to spend 75,000,000 hours (to date)breaking in your product before shipping!

That's only 8,500 years worth of putting on music, sounds like heaven to me.

Pull your socks up 🙂

That's only 8,500 years worth of putting on music, sounds like heaven to me.

Pull your socks up 🙂

You mean I have to break in my own speakers because you couldn't be bothered to spend 75,000,000 hours (to date)breaking in your product before shipping!

That's only 8,500 years worth of putting on music, sounds like heaven to me.

Pull your socks up 🙂

Back to the workhouse!😉

You mean I have to break in my own speakers because you couldn't be bothered to spend 75,000,000 hours (to date)breaking in your product before shipping!

That's only 8,500 years worth of putting on music, sounds like heaven to me.

Pull your socks up 🙂

i just dont get the negitiveity around marks recommendations to break in the drivers gently, what is the big deal guys? SCAM? ONG! how is it a scam to run a driver in there is no miney exchanged to run in. come on get a grip guy's

" opinions are like *********, everybody has one"

but come on who needs another ********? 🙂

well whatever way you read it Bob. 🙂 🙂

dont think some of the inapproriate comments on Scamming are a joke though! but then thats only my opinion or is that ********, lost my train of thought there. 🙂

dont think some of the inapproriate comments on Scamming are a joke though! but then thats only my opinion or is that ********, lost my train of thought there. 🙂

Last edited:

The post you quoted was in fact a humourous one supporting Mark. With that said, I concur with the point made: there are a lot of people who like to pontificate their great knowledge, nay, wisdom, and are pleased to inform people who design and build drive units how wrong they are, how they know more about the driver than the designer / manufacturer does, and that the designer / manufacturer is an evil, lying toad out to destroy civilisation as we know it. Because it is obvious that they know better than the designer / manufacturer what materials are used, the exact tolerances in both manufacturing and load terms that are involved in the function of the components & end-driver, that they have tested these over thousands of hours under a wide variety of conditions (unlike the manufacturer), and have a deep, even a profound knowledge of the optimal operating conditions / window and how to bring the driver into this.

It is of course, most interesting that the people who think this have never designed nor built a loudspeaker drive unit.

Question: who would flog the bollocks off a car straight out of the showroom? Only a yoghurt. Same for drivers. A little common sense is necessary: not all drive units are created equal, and not all are designed for the same thing. You want to hammer the daylights out of a heavy-duty pro-audio woofer? Fine. That's what it's designed for. An extremely low mass wideband drive unit with an extremely long-throw suspension is another proposition entirely, and the need for a degree of mechanical sympathy straight out of the box is hardly a matter that requires deep contemplation. The designer / manufacturer might also know how best to bring his products through the initial loosening up stages. Why this should be such a big deal for some people is most odd. We are dealing with precision mechanical components built to very specific tolerances for crying out loud. Live with it.

It is of course, most interesting that the people who think this have never designed nor built a loudspeaker drive unit.

Question: who would flog the bollocks off a car straight out of the showroom? Only a yoghurt. Same for drivers. A little common sense is necessary: not all drive units are created equal, and not all are designed for the same thing. You want to hammer the daylights out of a heavy-duty pro-audio woofer? Fine. That's what it's designed for. An extremely low mass wideband drive unit with an extremely long-throw suspension is another proposition entirely, and the need for a degree of mechanical sympathy straight out of the box is hardly a matter that requires deep contemplation. The designer / manufacturer might also know how best to bring his products through the initial loosening up stages. Why this should be such a big deal for some people is most odd. We are dealing with precision mechanical components built to very specific tolerances for crying out loud. Live with it.

Last edited:

The post you quoted was in fact a humourous one supporting Mark. With that said, I concur with the point made: there are a lot of people who like to pontificate their great knowledge, nay, wisdom, and are pleased to inform people who design and build drive units how wrong they are, how they know more about the driver than the designer / manufacturer does, and that the designer / manufacturer is an evil, lying toad out to destroy civilisation as we know it. Because it is obvious that they know better than the designer / manufacturer what materials are used, the exact tolerances in both manufacturing and load terms that are involved in the function of the components & end-driver, that they have tested these over thousands of hours under a wide variety of conditions (unlike the manufacturer), and have a deep, even a profound knowledge of the optimal operating conditions / window and how to bring the driver into this.

It is of course, most interesting that the people who think this have never designed nor built a loudspeaker drive unit.

Question: who would flog the bollocks off a car straight out of the showroom? Only a yoghurt. Same for drivers. A little common sense is necessary: not all drive units are created equal, and not all are designed for the same thing. You want to hammer the daylights out of a heavy-duty pro-audio woofer? Fine. That's what it's designed for. An extremely low mass wideband drive unit with an extremely long-throw suspension is another proposition entirely, and the need for a degree of mechanical sympathy straight out of the box is hardly a matter that requires deep contemplation. The designer / manufacturer might also know how best to bring his products through the initial loosening up stages. Why this should be such a big deal for some people is most odd. We are dealing with precision mechanical components built to very specific tolerances for crying out loud. Live with it.

WELL SAID!

yeah the quote i highlighted was in humour i know, it was the nay sayers i was jabbing at not lorienblack,

Sorry my poor attempt at Tongue in cheek 🙂

Just because these are the most expensive drivers ever made at $2.5 trillion dosent mean they dont need a bit of respect when new, tish some people eh! 🙄

Last edited:

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Full Range

- Driver Break in Questions