😀 And I will throw it right back at you with a bass guitar truss rod embedded in a panel!I am going throw something out here that I has crossed my mind. A tunable enclosure using a bolt mounted internally to a cabinet wall. This same bolt protrudes to the other opposing cabinet wall allowing outward pressure (adjustable by an external knob, hence the tuning). This would look most acceptable from the inside of the baffle with the bolt exiting the rear of the cabinet. I admit this is a pretty strange idea.

The cabinet walls could be then, thinner?

Randy,

The first time that I saw this sort of thinking was with a KEF, although the rod connected two drivers rather than the cabinet. I like the idea of a rod connected to the rear of a driver, that is for sure, but what I am trying to explain is the tension of the rod could be adjustable for DIY people like me.

In a sort of related example of attachment of the rear of the driver. There was a sub that I built in which the magnet of the driver was close enough to a brace in the cabinet that I was able to secure it with silicone adhesive. The thinking in that case was to minimize/dissipate the vibration of the driver itself.

The first time that I saw this sort of thinking was with a KEF, although the rod connected two drivers rather than the cabinet. I like the idea of a rod connected to the rear of a driver, that is for sure, but what I am trying to explain is the tension of the rod could be adjustable for DIY people like me.

In a sort of related example of attachment of the rear of the driver. There was a sub that I built in which the magnet of the driver was close enough to a brace in the cabinet that I was able to secure it with silicone adhesive. The thinking in that case was to minimize/dissipate the vibration of the driver itself.

Yeah, this is an interesting area which for me has appeal when considered for bass amp for an electric double that I am working on for my daughter. I have tried both booker and truss rods. There is a very fine line between horrible vibration sounds and good warm output, especially with the booker rod. I tried various washers and nothing really worked. Then I thought to glass on a truss rod on the panel and ordered a short one, but haven't tried it yet as all projects came to a halt. My proposition is that the truss will twist the panel into stiffness and can be dialled in. I am leaning more towards a sound box under the bridge and piezo pickup and keeping the amp/cab hi-fi. DSP should let me tune that sound box output better than mech tuning the cabRandy,

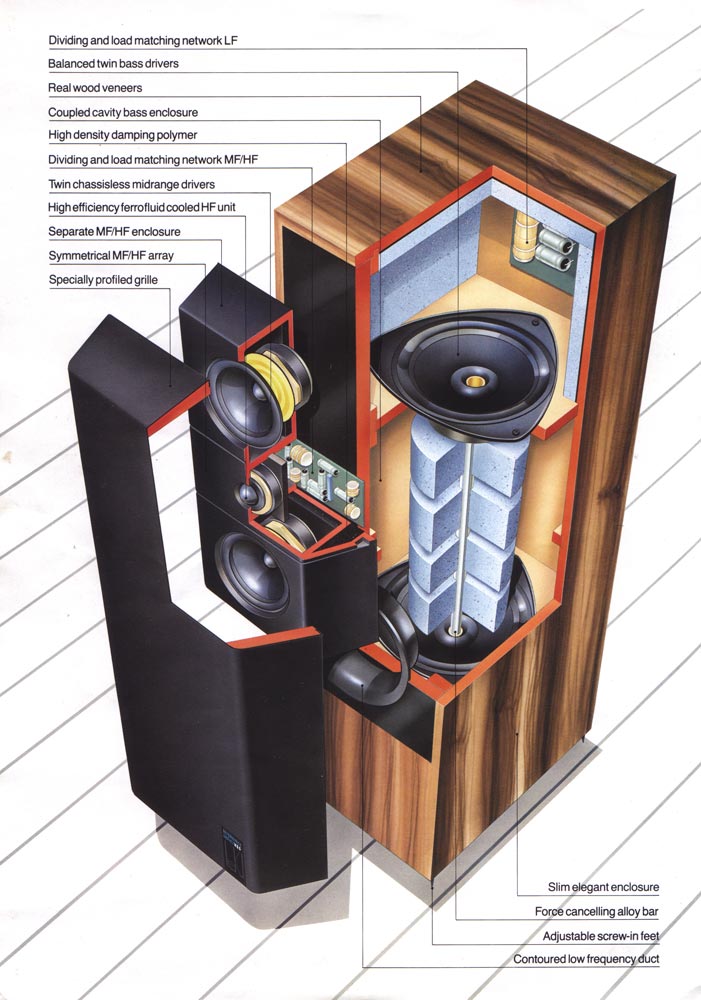

The first time that I saw this sort of thinking was with a KEF, although the rod connected two drivers rather than the cabinet. I like the idea of a rod connected to the rear of a driver, that is for sure, but what I am trying to explain is the tension of the rod could be adjustable for DIY people like me.

In a sort of related example of attachment of the rear of the driver. There was a sub that I built in which the magnet of the driver was close enough to a brace in the cabinet that I was able to secure it with silicone adhesive. The thinking in that case was to minimize/dissipate the vibration of the driver itself.

Some result I can confirm. Works well when the baffle is the vibe panel and the cab is solid. HDPE (blue transport drums) sounds better than wood when excited by driver vibration. Buzz is hard to control over a range in wood but less in HDPE. The base cutout from a drum makes for a good, strong but movable baffle material. Need to use Nylocks otherwise driver will come loose and fall off! Ask me how I know 😀

EF, although the rod connected two drivers rather than the cabinet. I like the idea of a rod connected to the rear of a driver

KEF 104 II

dave

Or, are those really two woofers with bipole cones?

In the LS60 they are, not sure in the blades, but they are very tightly coupled. A stiff cabinet and a brace in beween does pretty well.

dave

Something which I have found to work well is to not build enclosures the worst shape possible - a cuboid - in the first place and then try to correct its many inherent flaws.

Six-sided boxes are popular because they are profitable for manufacturers, something which does not concern us DIYers.

Think outside the box, if you'll pardon the pun, and thinner material suddenly becomes considerably more useable.

Six-sided boxes are popular because they are profitable for manufacturers, something which does not concern us DIYers.

Think outside the box, if you'll pardon the pun, and thinner material suddenly becomes considerably more useable.

Ideal for a transportable box. Nice work.

Today polypropylene boxes do it for PA systems

https://www.diyaudio.com/community/threads/tuning-tweaking-of-bp-115-a.375464/

Today polypropylene boxes do it for PA systems

https://www.diyaudio.com/community/threads/tuning-tweaking-of-bp-115-a.375464/

Current project under way, 3.6mm ply walls, comprehensively braced (about 50 bits of wood in each cabinet).

Creative, but i am not sure how effectivve some of those braces are. Be very interetsed inthe results.

dave

- Home

- Loudspeakers

- Full Range

- Does the sheet thickness for the enclosure matters?