CNC Winding Machine

Facebook group: Arduino CNC Winding Machine

Arduino Project Hub: CNC Arduino Winding Machine

*Updated Codes download below updated 5th August 2022

Facebook group: Arduino CNC Winding Machine

Arduino Project Hub: CNC Arduino Winding Machine

*Updated Codes download below updated 5th August 2022

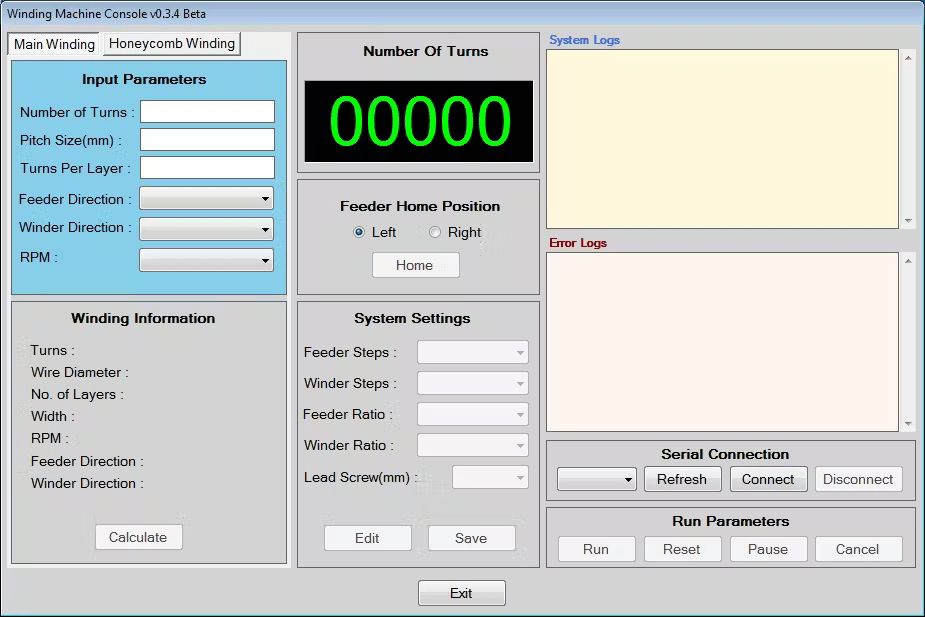

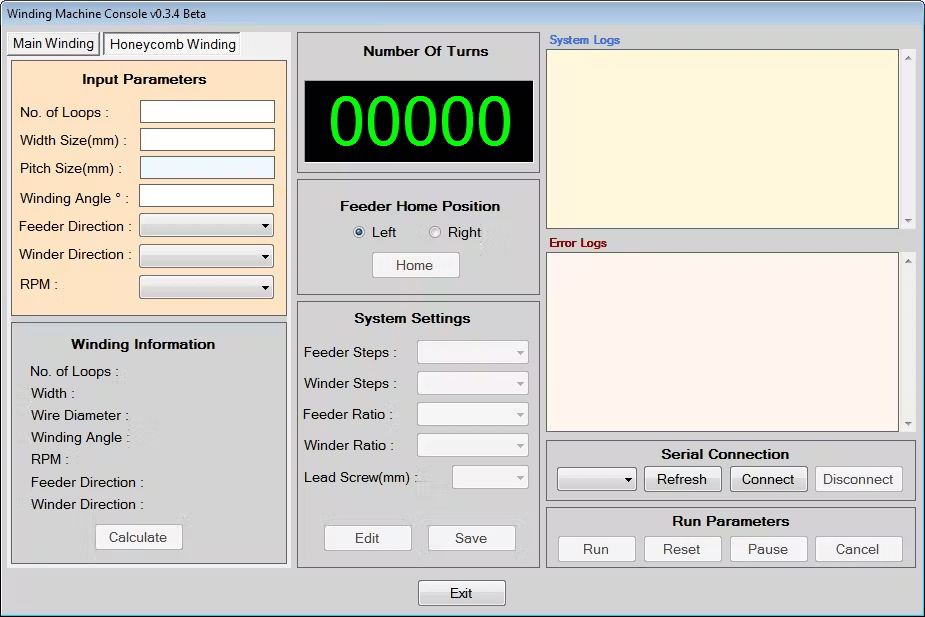

- Winding Machine GUI v0.3.4 Beta.zip - Visual Basic Source Code(Required Microsoft Visual Studio)

- Winding Machine GUI v0.3.4 Beta.exe - Winding Machine GUI exe file

- Winder_Shield_v0.3.1.8.zip - Arduino Firmware

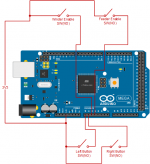

- Wiring Diagram(Due) v0.3.zip - Arduino Due Wiring Diagram in Microsoft Visio

Attachments

-

Control Buttons.png15.7 KB · Views: 580

Control Buttons.png15.7 KB · Views: 580 -

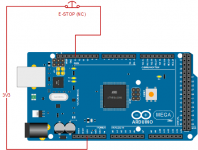

E-Stop.png13.1 KB · Views: 534

E-Stop.png13.1 KB · Views: 534 -

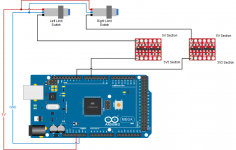

Limit Switch.png27.4 KB · Views: 548

Limit Switch.png27.4 KB · Views: 548 -

Logic Leveler.png26.8 KB · Views: 522

Logic Leveler.png26.8 KB · Views: 522 -

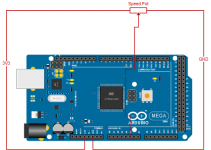

Speed Pot.png13.5 KB · Views: 540

Speed Pot.png13.5 KB · Views: 540 -

Stepper Motor Controller.png81.2 KB · Views: 548

Stepper Motor Controller.png81.2 KB · Views: 548 -

Toggle Switch.png12.9 KB · Views: 555

Toggle Switch.png12.9 KB · Views: 555 -

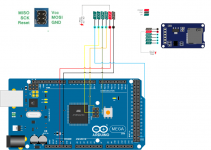

SD Card Connection.png44.6 KB · Views: 560

SD Card Connection.png44.6 KB · Views: 560

Last edited:

Nice i got some broken hard to get drivers hows need repair, I see in the link it need some nozzels here, in fly tying are some tools you can convert, See my link Fly Tying Bobbin / Super-Smooth Bobbins -- Orvis there are cheaper to buy

Anders

Anders

Last edited:

Normally to get a good wind you want the wire feed tension point to be thirty times the wind diameter away from the coil form edge or more.

Nice i got some broken hard to get drivers hows need repair, I see in the link it need some nozzels here, in fly tying are some tools you can convert, See my link Fly Tying Bobbin / Super-Smooth Bobbins -- Orvis there are cheaper to buy

Anders

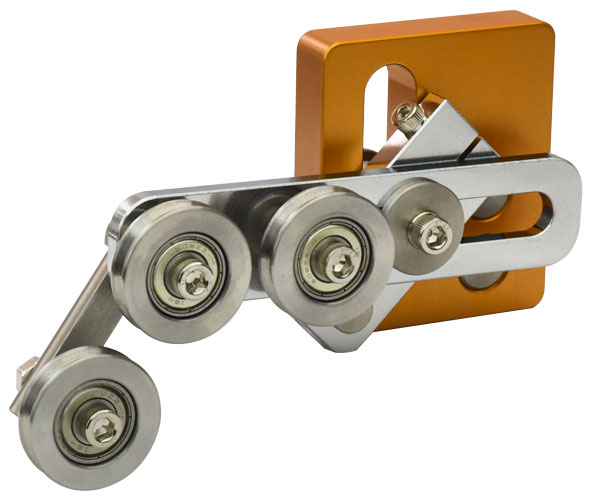

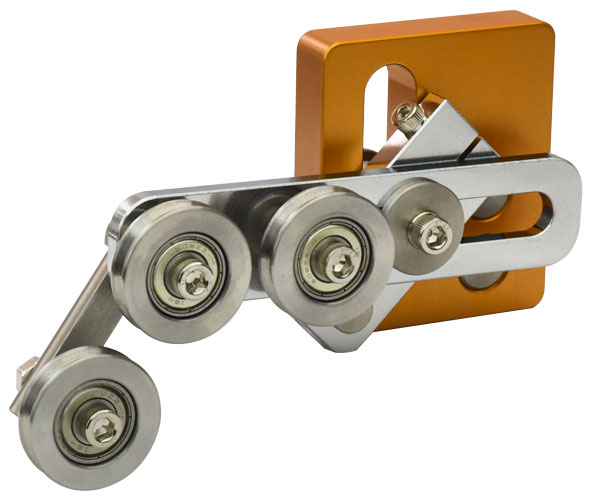

Looks interesting, worth a try since they are not super expensive, and I also found this while doing some research online

Low cost mechanical wire tensioners for coil winding machines

Normally to get a good wind you want the wire feed tension point to be thirty times the wind diameter away from the coil form edge or more.

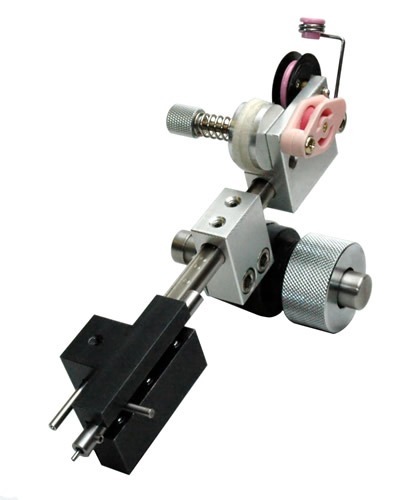

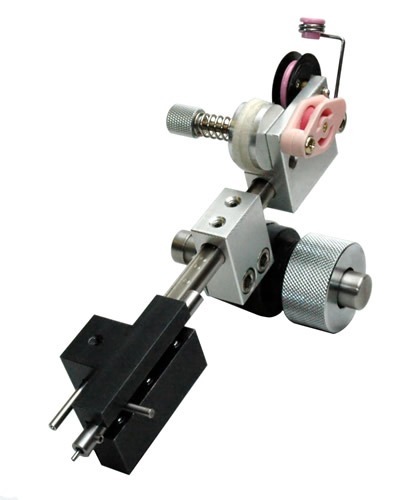

Yeah, will keep that in mind making the wire guide adjustable. And as for the wire tension, I planning to use this as a solution:

MTB-03 Wire Coiling Binding Machine Torque Controller Mechanical Tension | eBay

I did bought some 10mm and 22mm V-Grove pulley for the feeder

Last edited:

Some ideas I been exploring to make the wire guide modular, like interchangeable for thicker wire gauge

Thin wire 0.05 to 0.5

1mm and above(Mainly for winding electromagnet)

Thin wire 0.05 to 0.5

1mm and above(Mainly for winding electromagnet)

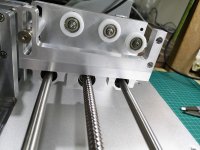

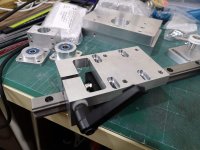

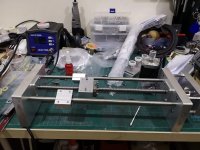

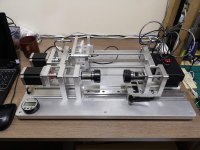

Some updates on the winding machine clone built.

Still have quite a few stuff still pending fabrication. But the mind winder is completed, but need to cut down the linear shaft to a proper length.

Still have quite a few stuff still pending fabrication. But the mind winder is completed, but need to cut down the linear shaft to a proper length.

Attachments

I wind my own voice coils and built a dedicated variable diameter bobbin former holder which I insert in my regular transformer winding machine, but since voice coils are just 2 layers and typically around 100 turns only, I just hand guide and tension them.

Way faster than you imagine and very precise, because I guide wire from far away, as suggested above, and just provide some sideways tension, no need for an advance screw since wire "self accomodates" against the previously wound one.

Just be careful on the first turn and then it self guides.

Winding machine itself is only half the problem, you need variable diameter/expansible form holders or you will never be able to pull the wound coil smoothly out of it.

You will also need to solve the wire adhesive problem.

Nowadays you have many solutions, usually dry adhesive precoated wire, which you either activate with heat or wiping it with a mild solvent (alcohol), I have been doing this for decades and still use the messy old "wet wire winding" system, since precoated wires simply did not exist and today getting them into Argentina is a mess, so .....

Way faster than you imagine and very precise, because I guide wire from far away, as suggested above, and just provide some sideways tension, no need for an advance screw since wire "self accomodates" against the previously wound one.

Just be careful on the first turn and then it self guides.

Winding machine itself is only half the problem, you need variable diameter/expansible form holders or you will never be able to pull the wound coil smoothly out of it.

You will also need to solve the wire adhesive problem.

Nowadays you have many solutions, usually dry adhesive precoated wire, which you either activate with heat or wiping it with a mild solvent (alcohol), I have been doing this for decades and still use the messy old "wet wire winding" system, since precoated wires simply did not exist and today getting them into Argentina is a mess, so .....

I using self-bonding enamel wire with a Nichrome wire are heating agent, then pre-coated again

Off shelf winding machine doesn't suits my need which I need easy changing from voice coil winding to field coil winding.

It is more fun to design and build your own, give me more flexibility in capability expansion for future.

Off shelf winding machine doesn't suits my need which I need easy changing from voice coil winding to field coil winding.

It is more fun to design and build your own, give me more flexibility in capability expansion for future.

Attachments

-

IMG_20181016_145140.jpg186.2 KB · Views: 631

IMG_20181016_145140.jpg186.2 KB · Views: 631 -

IMG_20181016_145132.jpg119.8 KB · Views: 527

IMG_20181016_145132.jpg119.8 KB · Views: 527 -

IMG_20181016_145216.jpg150 KB · Views: 506

IMG_20181016_145216.jpg150 KB · Views: 506 -

IMG_20181016_145604.jpg157.4 KB · Views: 466

IMG_20181016_145604.jpg157.4 KB · Views: 466 -

IMG_20181016_145609.jpg109.4 KB · Views: 458

IMG_20181016_145609.jpg109.4 KB · Views: 458 -

IMG_20181016_201300.jpg172.4 KB · Views: 453

IMG_20181016_201300.jpg172.4 KB · Views: 453 -

IMG_20181016_214226.jpg146.3 KB · Views: 506

IMG_20181016_214226.jpg146.3 KB · Views: 506 -

IMG_20181016_214400.jpg125.3 KB · Views: 487

IMG_20181016_214400.jpg125.3 KB · Views: 487 -

IMG_20181016_201303.jpg118.5 KB · Views: 464

IMG_20181016_201303.jpg118.5 KB · Views: 464

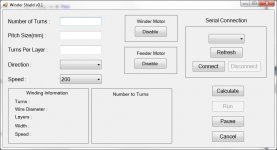

Some updates to the winding machine that I building

Attachments

Attachments

-

GUI.jpg71.5 KB · Views: 992

GUI.jpg71.5 KB · Views: 992 -

IMG_20190227_233017.jpg170.9 KB · Views: 979

IMG_20190227_233017.jpg170.9 KB · Views: 979 -

IMG_20190227_233108.jpg161.9 KB · Views: 429

IMG_20190227_233108.jpg161.9 KB · Views: 429 -

IMG_20190227_233050.jpg172.8 KB · Views: 871

IMG_20190227_233050.jpg172.8 KB · Views: 871 -

IMG_20190227_233057.jpg101.6 KB · Views: 942

IMG_20190227_233057.jpg101.6 KB · Views: 942 -

IMG_20190306_175102.jpg139.2 KB · Views: 903

IMG_20190306_175102.jpg139.2 KB · Views: 903 -

IMG_20190201_162958.jpg123.2 KB · Views: 531

IMG_20190201_162958.jpg123.2 KB · Views: 531 -

IMG_20190305_224613.jpg186.5 KB · Views: 552

IMG_20190305_224613.jpg186.5 KB · Views: 552

Anyone interested in the coding for both Visual Basic and Arduino? Though it still need polishing.

Uploaded the source code to my share drive. Coding still need bit of polishing

I will do u the schematics later, but if u can understand arduino. The pin assignments are on the code

CNC Winding Machine Shield - Google Drive

I will do u the schematics later, but if u can understand arduino. The pin assignments are on the code

CNC Winding Machine Shield - Google Drive

Last edited:

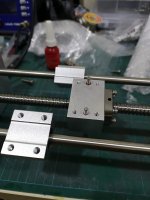

Parts:

-Arduino Mega

-NC proximity limit switch

-Nema 23 1.8 degree stepper motor

-TMC2208 or DRV8825 set at 2x microstepping

- Ball screw pitch 4mm travel per round

Some of the outstanding issues to resolve:

- Need a better stepper motor driver that can achieve 600rpm

- Need to calibrate and calculate the acceleration for more accurate Winder and Feeder speed synchronization.

- Noise related during stepping of the motor which needed to be tone down(Driver related?)

- Stepper torque to allow larger gauge wires

- Increasing Arduino PWM frequency to test on maximum rpm reachable.

-Arduino Mega

-NC proximity limit switch

-Nema 23 1.8 degree stepper motor

-TMC2208 or DRV8825 set at 2x microstepping

- Ball screw pitch 4mm travel per round

Some of the outstanding issues to resolve:

- Need a better stepper motor driver that can achieve 600rpm

- Need to calibrate and calculate the acceleration for more accurate Winder and Feeder speed synchronization.

- Noise related during stepping of the motor which needed to be tone down(Driver related?)

- Stepper torque to allow larger gauge wires

- Increasing Arduino PWM frequency to test on maximum rpm reachable.

Last edited:

Thanks

I thinking of getting a closed loop servo or stepper motor, to make sure speed synchronization.

I thinking of getting a closed loop servo or stepper motor, to make sure speed synchronization.

Your winding machine is definitely a masterpiece, a sample of technical porn. I'm impressed!!!

I also made a winding machine, it is much more modest than yours. It is made of bent sheet steel. Unfortunately winding machine is already sold. They were made to order for the company as a winding machine for one operation.

I will allow myself to share my experience:

-For the main engine, it is better to use a manifold motor with a reducer and an optical encoder.

-Ball screw is better to use increments of 2mm.

-The power of the engine layout a bit redundant, it is enough NEMA17

- In practical work, the number of turns and step layout is more convenient to set the decade switches.

- For counting turns it is convenient to use high-speed ICM7217. It has a limit of 9999 turns, but 90% of practical work is enough.

There's no Arduino in my winding machine. Everything was done on a simple elementary logic 74 series. I wanted to make a computer-independent machine.

I also made a winding machine, it is much more modest than yours. It is made of bent sheet steel. Unfortunately winding machine is already sold. They were made to order for the company as a winding machine for one operation.

I will allow myself to share my experience:

-For the main engine, it is better to use a manifold motor with a reducer and an optical encoder.

-Ball screw is better to use increments of 2mm.

-The power of the engine layout a bit redundant, it is enough NEMA17

- In practical work, the number of turns and step layout is more convenient to set the decade switches.

- For counting turns it is convenient to use high-speed ICM7217. It has a limit of 9999 turns, but 90% of practical work is enough.

There's no Arduino in my winding machine. Everything was done on a simple elementary logic 74 series. I wanted to make a computer-independent machine.

Last edited:

- Home

- Design & Build

- Equipment & Tools

- DIY Voice Coil Winding Machine