Hi Woneill,

thanks for your explanation and the link, usefull information about fresnel,

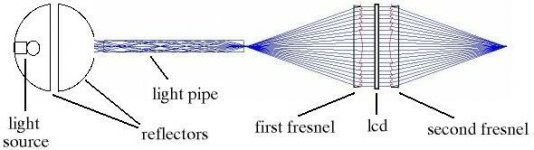

Since OHP fresnel used as collector and collimator, I wonder if we can split it up into two individual fresnel and placing the LCD in between them, what do you think?

Hi Daveb,

First try to figure out what type of reflector you have. My suggestion works for parabolic reflector only.

You can't produce good projection without reflector.

If you satisfied with your projected image size, then keep your objective lens.

Below is my rough suggestion, just for testing:

try placing the fresnel between 5.5" and no longer than 11" in front of the "point" light source.

With 5.5" you get parallel light output,

with 11" you get condensed light output.

I think 9" is the optimum distance and you get the whole obj. lens covered with light beam, just try it...

Please have a look at fresnel link that Woneill found below, to know what type of fresnel you have.

http://www.fresneltech.com/pdf/FresnelLenses.pdf

My diagram is not to scale, it just showing how to use almost all of light from the lamp, it depends on 4 factors: reflector size, bulb size, lens size and lens fl.

see you.

thanks for your explanation and the link, usefull information about fresnel,

Since OHP fresnel used as collector and collimator, I wonder if we can split it up into two individual fresnel and placing the LCD in between them, what do you think?

Hi Daveb,

First try to figure out what type of reflector you have. My suggestion works for parabolic reflector only.

You can't produce good projection without reflector.

If you satisfied with your projected image size, then keep your objective lens.

Below is my rough suggestion, just for testing:

try placing the fresnel between 5.5" and no longer than 11" in front of the "point" light source.

With 5.5" you get parallel light output,

with 11" you get condensed light output.

I think 9" is the optimum distance and you get the whole obj. lens covered with light beam, just try it...

Please have a look at fresnel link that Woneill found below, to know what type of fresnel you have.

http://www.fresneltech.com/pdf/FresnelLenses.pdf

My diagram is not to scale, it just showing how to use almost all of light from the lamp, it depends on 4 factors: reflector size, bulb size, lens size and lens fl.

see you.

Check this link out.

"LCD Projector plans...EASY "

http://cgi.ebay.com/ws/eBayISAPI.dll?ViewItem&item=1372662084

"LCD Projector plans...EASY "

http://cgi.ebay.com/ws/eBayISAPI.dll?ViewItem&item=1372662084

Gunawan W

in an earlier post you talked about a 150 watt MH floodlight that could be purchased for 30$, do you have any other info?

in an earlier post you talked about a 150 watt MH floodlight that could be purchased for 30$, do you have any other info?

Plans

Hey ap0the0sis, the plans they are selling on Ebay can be found for free at:

http://www.audiovisualizers.com/madlab/lcd_proj.htm

I was thinking of building the reflective one from the scanned sheets. But have been told that the lights wont be bright enough.

-BD

Hey ap0the0sis, the plans they are selling on Ebay can be found for free at:

http://www.audiovisualizers.com/madlab/lcd_proj.htm

I was thinking of building the reflective one from the scanned sheets. But have been told that the lights wont be bright enough.

-BD

Video PCB

Just wondering, can any video pcb be used with any screen or would I need a PCB that is designed to work with a specific LCD?

Just wondering, can any video pcb be used with any screen or would I need a PCB that is designed to work with a specific LCD?

what exactly do you mean by "pcb" all lcd's require a controller. While some controllers will work with multiple lcd displays, I'm not aware of any 1 controller that will handle them all. This is where the problem is....we can find cheap high quality lcd's on ebay, but finding a cheap controller is out of the question. Good luck. Also you need to be carefull in your choice of lcd's because some have components on the back that simply can't be removed no matter how hard you try

well in a previous post I had wrote how I screwed on a bid on an lcd screen. That was quite cheap but then noticed it said no video PCB included which I assumed is the controler I had already bid on the item...ebayscrewed again...

I emailed them telling them I refuse to pay for something that is such a horrendous ripe off. Thanks for the information...

Well whatever, I feel thats its unfair to hide something like that...so he can complain to ebay all he wants he was purposely trying to deceive people.

Hi Guys,

This is going to sound whacky, but it might not be too difficult to build an LCD controller.

From the adverts I have seen recently, and the few data sheets posted on the LCDs, it would appear that there are generic LCD controller chips, usually from Chips & Technologies (remember them???) that can be programmed with the characteristics of the LCD via a ROM.

It is probably not beyond some of the people who frequent this thread (or maybe the other electronics oriented threads) to put something together that would interface to a computer (digitally).

Analogue would be much more difficult, but could probably be done too.

Bill.

(Of course such a project would be more complicated than building the projector itself...)

This is going to sound whacky, but it might not be too difficult to build an LCD controller.

From the adverts I have seen recently, and the few data sheets posted on the LCDs, it would appear that there are generic LCD controller chips, usually from Chips & Technologies (remember them???) that can be programmed with the characteristics of the LCD via a ROM.

It is probably not beyond some of the people who frequent this thread (or maybe the other electronics oriented threads) to put something together that would interface to a computer (digitally).

Analogue would be much more difficult, but could probably be done too.

Bill.

(Of course such a project would be more complicated than building the projector itself...)

While I have noticed the increase of sellers just selling raw lcd panels and making it seem like they will work with a video source they always seem to put in their in fine print needs a driver board to work Or something to that effect. While I do not agree with the way they are selling it it's not a scam but pretty darn close to it. If anyone has any questions about any lcd panel they are planning on buying ask here first before making a mistake.

If you bid on something on ebay you can just retract your bid (as long as you do it 12 hours before the auction closes). I know its not the best method but it gets you out of buying it. No big deal....

As for my above post. I was showing you that someone on ebay is selling plans to build a DIY Projector. I had a feeling it was gonna happend any day now. I have no intention on buying these plans as I know where to get them for free. HERE!

For all we know it's someone from this forum 😱)

As for building your own controller, I think it would be virtually impossible since you would have to get schematics of the LCD panel and find all the necessary parts to build the controller. The effort alone wouldnt be worth it. to much work and trial and error to end up with something that might not work correctly or at all.

Just dish out the $200.00+ for a controller. Look at it this way, once you make that purchase you will have a controller that you can use on other LCD panels as well. (if your lucky)

ap0the0sis

As for my above post. I was showing you that someone on ebay is selling plans to build a DIY Projector. I had a feeling it was gonna happend any day now. I have no intention on buying these plans as I know where to get them for free. HERE!

For all we know it's someone from this forum 😱)

As for building your own controller, I think it would be virtually impossible since you would have to get schematics of the LCD panel and find all the necessary parts to build the controller. The effort alone wouldnt be worth it. to much work and trial and error to end up with something that might not work correctly or at all.

Just dish out the $200.00+ for a controller. Look at it this way, once you make that purchase you will have a controller that you can use on other LCD panels as well. (if your lucky)

ap0the0sis

Hi guys,

Most OHP setup is like my drawing 1 below, using small spherical reflector to focus light beam into small point close to lamp spark/filament.

With this setup there are lot of waste direct light (light blue color area).

I think using a long-narrow elliptical reflector can avoid this problem (see drawing 2).

What do you think?

Also I correct my previous post that said: most OHP fresnel panel has focal point=12", wrong, actually is between 5" to 6".

Hi eebasist,

sorry not answering your email about 150W MH for $30, I confused, I though, you sent email at the wrong guy or I forgot, may I know at what page I wrote it?

Anyway, my choice of MH lamp is like this:

Double ended MHN-TD 150 W, 12.100 lumens, CRI 85, 4200 K

http://www.gelighting.com/india/metal_halide.htm

http://www.dealec.co.uk/acatalog/Deal_Electrical__Hitlite_Double_Ended_Metal_Halide_Lamps_344.html

Most OHP setup is like my drawing 1 below, using small spherical reflector to focus light beam into small point close to lamp spark/filament.

With this setup there are lot of waste direct light (light blue color area).

I think using a long-narrow elliptical reflector can avoid this problem (see drawing 2).

What do you think?

Also I correct my previous post that said: most OHP fresnel panel has focal point=12", wrong, actually is between 5" to 6".

Hi eebasist,

sorry not answering your email about 150W MH for $30, I confused, I though, you sent email at the wrong guy or I forgot, may I know at what page I wrote it?

Anyway, my choice of MH lamp is like this:

Double ended MHN-TD 150 W, 12.100 lumens, CRI 85, 4200 K

http://www.gelighting.com/india/metal_halide.htm

http://www.dealec.co.uk/acatalog/Deal_Electrical__Hitlite_Double_Ended_Metal_Halide_Lamps_344.html

Attachments

Hey all. Long time no see.

I may have been silent, but my diy projection hasnt been at a total standstill. it's been slow going - 18 yr old splitting time between friends women school work and thirty some odd pet projects - but its been moving.

spending most of my time doing number crunching now. optimizing lens equations, reducing aberations, trying to get a decent range of distrotions across zoom, all sorts of "fun". *cough* shoot me now *cough*

i think i've arrived at one final piece though, and thats the reflector.

first off, for reflectors: ellipsoidal. keeps me from having to use a fresnel. sends a constant-light-density beam (no faded edges or center hotspots) to a single point, perfect for being thrown through a series of optics to be displayed. no large lenses required. just one big freaking reflector, gathering and focusing the light.

building it large. i've only got a 15 inch panel, but if the reflector works as planned, i will be purchasing a (significantly larger) panel capable of at least 1280 x 1024. plus if i make the mold larger, i can always just cut down the final panel.

not entirely sure how i'm going to build the final mold. previous efforts involved crude plastor molds, wooden braced frames, anything i could do to get something vaguely ellipsoidal. proof of concept work. i'm thinking perhaps a male mold, wood underneath covered by plastor. then heat a large aluminum sheet (i'm going to have to build a custom oven to do so) and bend it over.

the problem is, as Gunawan W illustrated, a good ellipsodial is deep. very deep. i'm going to have over a two foot diameter openning aperature, but that's going to be nothing compared to the nearly three feet of depth i'm building this reflector to.

aluminum really isnt going to like stretching that much. the mold might break. the aluminum might not bend appropriately. i dont know if it will work. i'm skeptical.

probably going to end up throwing a big wad of cash at the problem sometime. get a real metal mold made on a CNC machine. then try some homebrew electro-deposition / electroforming. then ship the resultant reflector off for vaccum deposition. the whole thing reeks of effort.

anyone have suggestions for where to get a gargantuan reflector mold made? my dad's work's CNC machines wont work with things that big, i'm pretty sure.

btw, gunawan, you showed one light path a while back which gathered the light coming from the center of the projector. it wont work, rather, it will, but there'd be a really bright circle in the center of the image. let that unreflected undirected light just diffuse. it wont hurt pq, esp if the reflectors deep enough.

400 w mh is still the way to go. there's also 600 watts available too, if you want something between 1000 (soo much light) and 400 w (a mere metric buttload).

peace + good luck

myren

I may have been silent, but my diy projection hasnt been at a total standstill. it's been slow going - 18 yr old splitting time between friends women school work and thirty some odd pet projects - but its been moving.

spending most of my time doing number crunching now. optimizing lens equations, reducing aberations, trying to get a decent range of distrotions across zoom, all sorts of "fun". *cough* shoot me now *cough*

i think i've arrived at one final piece though, and thats the reflector.

first off, for reflectors: ellipsoidal. keeps me from having to use a fresnel. sends a constant-light-density beam (no faded edges or center hotspots) to a single point, perfect for being thrown through a series of optics to be displayed. no large lenses required. just one big freaking reflector, gathering and focusing the light.

building it large. i've only got a 15 inch panel, but if the reflector works as planned, i will be purchasing a (significantly larger) panel capable of at least 1280 x 1024. plus if i make the mold larger, i can always just cut down the final panel.

not entirely sure how i'm going to build the final mold. previous efforts involved crude plastor molds, wooden braced frames, anything i could do to get something vaguely ellipsoidal. proof of concept work. i'm thinking perhaps a male mold, wood underneath covered by plastor. then heat a large aluminum sheet (i'm going to have to build a custom oven to do so) and bend it over.

the problem is, as Gunawan W illustrated, a good ellipsodial is deep. very deep. i'm going to have over a two foot diameter openning aperature, but that's going to be nothing compared to the nearly three feet of depth i'm building this reflector to.

aluminum really isnt going to like stretching that much. the mold might break. the aluminum might not bend appropriately. i dont know if it will work. i'm skeptical.

probably going to end up throwing a big wad of cash at the problem sometime. get a real metal mold made on a CNC machine. then try some homebrew electro-deposition / electroforming. then ship the resultant reflector off for vaccum deposition. the whole thing reeks of effort.

anyone have suggestions for where to get a gargantuan reflector mold made? my dad's work's CNC machines wont work with things that big, i'm pretty sure.

btw, gunawan, you showed one light path a while back which gathered the light coming from the center of the projector. it wont work, rather, it will, but there'd be a really bright circle in the center of the image. let that unreflected undirected light just diffuse. it wont hurt pq, esp if the reflectors deep enough.

400 w mh is still the way to go. there's also 600 watts available too, if you want something between 1000 (soo much light) and 400 w (a mere metric buttload).

peace + good luck

myren

Myren

**************

anyone have suggestions for where to get a gargantuan reflector mold made? my dad's work's CNC machines wont work with things that big, i'm pretty sure.

**************

For cheap interim test reflector suggest use lot of strips of material. Pop rivet or PK screw together. I have seen similar fold up reflectors for solar cookers where pieces open out like a giant curved fan.

Stainless steel often avaliable as long thin offcuts for free from metal shops.

SS has good reflective properties. Stainflex is one SS type. Need good drill. Aluminium needs polished and can loose reflectivity over time due to oxidisation. Either one not bad for test setup. I use offcut SS for solar parabolic collector.

**************

anyone have suggestions for where to get a gargantuan reflector mold made? my dad's work's CNC machines wont work with things that big, i'm pretty sure.

**************

For cheap interim test reflector suggest use lot of strips of material. Pop rivet or PK screw together. I have seen similar fold up reflectors for solar cookers where pieces open out like a giant curved fan.

Stainless steel often avaliable as long thin offcuts for free from metal shops.

SS has good reflective properties. Stainflex is one SS type. Need good drill. Aluminium needs polished and can loose reflectivity over time due to oxidisation. Either one not bad for test setup. I use offcut SS for solar parabolic collector.

Hello Everyone,

I’m Gustavo from Argentina, I been reading all the post for 3 days now, I’m very interested on making a projector myself, first of all I want to tell you that’s great all the effort and all your achievements, I hope I can be able to do it since it’s impossible for me to buy one real projector, we jump from a 1-1 dollar to 1-4 dollar exchange rate (only in my country).

Well here I go, I’m not use to work whit lens but I’m a very understanding man, but I need a little help from you, hope you agree on that.

I’ll go whit a 12.1 inch lcd tft 1024x768 CT:150 from NEC, that’s becouse I can get a Daewoo monitor that comes whit it inside, and I’ll not need to buy the controller board, besides from NEC pdf it seems not to be trouble to take apart the electronics from the lcd, I’ll try to get it for U$s200 in a local auction (it’s U$s260).

Since I don’t know much about optics my first question is about the fresnels,

I found those links and I need to chose one of them

http://www.ec-securehost.com/ila/Hand_Held_Magnifiers.html

Full-Page Magnifier (10” x 12”) $34.95

http://www.officedepot.com/shop/catalog/sku.asp?ID=327016&LEVEL=SK

Apollo Full Page Magnifier, 8 1/2" x 11" $6.99

From my calculations either one should work but I’m aware that you are more qualified to opine on that, could be a big quality difference? Should it affect the prject that much?

For start I would choose RedEvil design for light source, I think the lens he is using is a standard round magnifier, easy to get for cheap. I’ll be wasting a lot of light whit this?

My setup will be: 400w MH - round glass magnifier close to bulb – fresnel – lcd – fresnel – plano convex.\

About the page magnifier, do they all have about the same focal length? 6inch+-, if it so my plano convex should be the same FL? In a local optics, they are able to make me one of them for about 2 dollars whit any specs I want but whit a diameter max of 6cm, I guess for all I read that’s too little, more for 12.1 tft, but I guess I could find it somewere.

Last inquire for now, since some of you have done one of this, whit my setup, witch could be the lumen comparison whit the branded ones? Since I have some frined that have infocus 1000 lumens projectors I could have an idea this way how close can I be.

Thank you and I apologies if my thread is too large.

I ask for excuses if any word or redaction is wrong, but my natural born language is Spanish.

Thanks again.

Gustavo

I’m Gustavo from Argentina, I been reading all the post for 3 days now, I’m very interested on making a projector myself, first of all I want to tell you that’s great all the effort and all your achievements, I hope I can be able to do it since it’s impossible for me to buy one real projector, we jump from a 1-1 dollar to 1-4 dollar exchange rate (only in my country).

Well here I go, I’m not use to work whit lens but I’m a very understanding man, but I need a little help from you, hope you agree on that.

I’ll go whit a 12.1 inch lcd tft 1024x768 CT:150 from NEC, that’s becouse I can get a Daewoo monitor that comes whit it inside, and I’ll not need to buy the controller board, besides from NEC pdf it seems not to be trouble to take apart the electronics from the lcd, I’ll try to get it for U$s200 in a local auction (it’s U$s260).

Since I don’t know much about optics my first question is about the fresnels,

I found those links and I need to chose one of them

http://www.ec-securehost.com/ila/Hand_Held_Magnifiers.html

Full-Page Magnifier (10” x 12”) $34.95

http://www.officedepot.com/shop/catalog/sku.asp?ID=327016&LEVEL=SK

Apollo Full Page Magnifier, 8 1/2" x 11" $6.99

From my calculations either one should work but I’m aware that you are more qualified to opine on that, could be a big quality difference? Should it affect the prject that much?

For start I would choose RedEvil design for light source, I think the lens he is using is a standard round magnifier, easy to get for cheap. I’ll be wasting a lot of light whit this?

My setup will be: 400w MH - round glass magnifier close to bulb – fresnel – lcd – fresnel – plano convex.\

About the page magnifier, do they all have about the same focal length? 6inch+-, if it so my plano convex should be the same FL? In a local optics, they are able to make me one of them for about 2 dollars whit any specs I want but whit a diameter max of 6cm, I guess for all I read that’s too little, more for 12.1 tft, but I guess I could find it somewere.

Last inquire for now, since some of you have done one of this, whit my setup, witch could be the lumen comparison whit the branded ones? Since I have some frined that have infocus 1000 lumens projectors I could have an idea this way how close can I be.

Thank you and I apologies if my thread is too large.

I ask for excuses if any word or redaction is wrong, but my natural born language is Spanish.

Thanks again.

Gustavo

Gustavo

Good choice.

I put the 2nd fresnel after the pannel, but you can see the circular

linese on the screen. Therefore in my case, putting 2 fresnels after

the magnifying glass reduced the circular lines.

And yes it was cheap for the magnifying glass.

It is about 4 1/2 inch diameter.

Your not going to believe this, but yesterday I picked up a metal halide lamp (400watt 3.4K at 65CRI) and ballast for $80.00.

Couldnt refuse that deal.

Tried it today and man did it ever look good. I would say about

40% brighter. Now I can watch it with lights on. But after a

1/2 hour the case was super hot. Like holy crap man.

Did not have re adjust anything either. This bulb was much larger.

Took it out until I can put more fans in.

It would be much better to use a bulb that is 400w 5Kcolor and at least 75CRI or higher.

If any knows where I can find one, can you please post it.

Make sure you can buy seperate. Most places want you to buy 6 or more

Later

Good choice.

I put the 2nd fresnel after the pannel, but you can see the circular

linese on the screen. Therefore in my case, putting 2 fresnels after

the magnifying glass reduced the circular lines.

And yes it was cheap for the magnifying glass.

It is about 4 1/2 inch diameter.

Your not going to believe this, but yesterday I picked up a metal halide lamp (400watt 3.4K at 65CRI) and ballast for $80.00.

Couldnt refuse that deal.

Tried it today and man did it ever look good. I would say about

40% brighter. Now I can watch it with lights on. But after a

1/2 hour the case was super hot. Like holy crap man.

Did not have re adjust anything either. This bulb was much larger.

Took it out until I can put more fans in.

It would be much better to use a bulb that is 400w 5Kcolor and at least 75CRI or higher.

If any knows where I can find one, can you please post it.

Make sure you can buy seperate. Most places want you to buy 6 or more

Later

- Home

- General Interest

- Everything Else

- The Moving Image

- DIY Projectors

- DIY Video Projector Part II