what are some of the downsides to unipivots? I mean, why aren't they more popular? And are there any real downsides to the air bearings?

unipivots are popular....

er have been, er will be again!

the quality of the pivot bearing is less of an issue than with other types, even a knitting needles can be used as the pivot....so for a given price "point" (sorry for the pun) the bearing can be made to be virtually frictionless.

If the counter weight is in the same plane as the record when played, stability is not much of an issue. Also, "hanging" the arm mass, as long as the centre of gravity is lower than the pivot, creates a stable platform for a cartridge.

Adjusting azimuth can be a pain, but if properly designed , can be easy. Sometimes with an "outrigger" weight , and sometimes with an adjustable section on the end of the arm tube itself (my preferred method).

The other pro point, specific to this message board is that they can be very easy to DIY.

are there some problems? Yes, of course, but there are problems in other "good" arms as well. The key to stopping the worst of these problems is to ensure that the pivot point is physically as high as possible in the tube, and the counterweight is as low as possible. Also the bearing that it rides on should be of good quality, and needs to index to a specific location in the cup and not jump out of it. And you can easily knock the arms off of the bearing, so they can take on a feeling of fragility.

However using 90ksi aluminum tubing for the arm tube itself pretty much takes care of that. I've had cats knock the arm off of my turntable and not do any damage to the arm. Thankfully no damage occurred to the cartridge either.

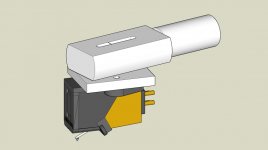

One of the biggest challenges with a DIY unipivot is making a headshell.

With the advent of suspended decks, unipivots fell out of grace. But my DIY arm has worked great on my Oracle Alex (suspended). Unipivots work very well on solid plinth or non-suspended turntables, as there is less to upset them.

er have been, er will be again!

the quality of the pivot bearing is less of an issue than with other types, even a knitting needles can be used as the pivot....so for a given price "point" (sorry for the pun) the bearing can be made to be virtually frictionless.

If the counter weight is in the same plane as the record when played, stability is not much of an issue. Also, "hanging" the arm mass, as long as the centre of gravity is lower than the pivot, creates a stable platform for a cartridge.

Adjusting azimuth can be a pain, but if properly designed , can be easy. Sometimes with an "outrigger" weight , and sometimes with an adjustable section on the end of the arm tube itself (my preferred method).

The other pro point, specific to this message board is that they can be very easy to DIY.

are there some problems? Yes, of course, but there are problems in other "good" arms as well. The key to stopping the worst of these problems is to ensure that the pivot point is physically as high as possible in the tube, and the counterweight is as low as possible. Also the bearing that it rides on should be of good quality, and needs to index to a specific location in the cup and not jump out of it. And you can easily knock the arms off of the bearing, so they can take on a feeling of fragility.

However using 90ksi aluminum tubing for the arm tube itself pretty much takes care of that. I've had cats knock the arm off of my turntable and not do any damage to the arm. Thankfully no damage occurred to the cartridge either.

One of the biggest challenges with a DIY unipivot is making a headshell.

With the advent of suspended decks, unipivots fell out of grace. But my DIY arm has worked great on my Oracle Alex (suspended). Unipivots work very well on solid plinth or non-suspended turntables, as there is less to upset them.

Graeme,

I built a Ladegaard arm a while ago, and I really like it. There was a thread somewhere on the virtues of the upside-down model, and seeing this thread has renewed my interest in building one. Do you happen to remember such an article or thread and if so, do you remember where?

Thanks

I built a Ladegaard arm a while ago, and I really like it. There was a thread somewhere on the virtues of the upside-down model, and seeing this thread has renewed my interest in building one. Do you happen to remember such an article or thread and if so, do you remember where?

Thanks

I'm not sure if my arm will outperform a Rega (I never had one), but it certainly is much better than a Thorens TP16.

It is also very easy to make (including a headshell).

You can find some details here. I'm working on model two with some minor revisions (easier tracking force adjustment and easier VTA adjustment).

You can find some details here ...

http://www.diyaudio.com/forums/showthread.php?s=&threadid=109696

greetings, MArco

It is also very easy to make (including a headshell).

You can find some details here. I'm working on model two with some minor revisions (easier tracking force adjustment and easier VTA adjustment).

You can find some details here ...

http://www.diyaudio.com/forums/showthread.php?s=&threadid=109696

greetings, MArco

Marco, headshell and badminton racket...

it seems we may have come from different sides to a similar result. The carbon fibre racket pieces are very cool, and it seems that mounting a plate for a headshell ids pretty easy too. Very creative (I had posted in that thread some time ago).

I think what I may end up doing is something si,olar to the Clearaudio style headshell, but (perhaps) out of wood. I like the idea of low mass. If I need some mass, I can always deface an American penny (mainly because to deface Canadian money in Canada is a crime, as is defacing American money in the US is there). That way I could increase the mass a bit.

I prototyped a new style headshell as well. Just not sure if suitable...

it seems we may have come from different sides to a similar result. The carbon fibre racket pieces are very cool, and it seems that mounting a plate for a headshell ids pretty easy too. Very creative (I had posted in that thread some time ago).

I think what I may end up doing is something si,olar to the Clearaudio style headshell, but (perhaps) out of wood. I like the idea of low mass. If I need some mass, I can always deface an American penny (mainly because to deface Canadian money in Canada is a crime, as is defacing American money in the US is there). That way I could increase the mass a bit.

I prototyped a new style headshell as well. Just not sure if suitable...

deduikertjes ,

Saw the pictures you made for your arm. Nice. What was the concept behind the azimuth adjustment? What was the the three screws (squared boxed) on the counterbalance? What about the screw like item (encilcled) behind the counterbalance, what is it for?

Saw the pictures you made for your arm. Nice. What was the concept behind the azimuth adjustment? What was the the three screws (squared boxed) on the counterbalance? What about the screw like item (encilcled) behind the counterbalance, what is it for?

Attachments

Rotate the counterweight around the arm; fine adjustment by the large screw in the middle of your rectangleWhat was the concept behind the azimuth adjustment?

The counterweight is made of two strips of brass with a round longitudinal recess to accommodate the arm. The three screws in the box you've drawn clamp these strips firmly on the arm. There is some heat shrink tubing in between the arm and the counterweight to provide some damping.

The screw in the ellipse provides some fine adjustment of the tracking force. In model 2 a larger screw is sitting in the end of the arm. I expect this to give me a larger (more usable adjustment range).

MArco

Lenco

Stew,

Sorry to jack this thread again fellas but I'm a fairly new member still under moderation so I can't mail Nanook direct.

Shipping costs are $172 Canadian by Data Post/$156 Air Mail/$125 Slow Boat (about 3 weeks). As it stands the TT weighs about 8Kgs not including packing but the plinth, as I said, isn't too hot, so the possibility of dismantling is there if these costs are too high.

Ron

Stew,

Sorry to jack this thread again fellas but I'm a fairly new member still under moderation so I can't mail Nanook direct.

Shipping costs are $172 Canadian by Data Post/$156 Air Mail/$125 Slow Boat (about 3 weeks). As it stands the TT weighs about 8Kgs not including packing but the plinth, as I said, isn't too hot, so the possibility of dismantling is there if these costs are too high.

Ron

KIndwolf...

a little on the rich side. Basically All I'd need are the "guts, no plinth, no arm, no cover....

If at all possible slow boat could be considered. Air mail might be an option though if it can get a little cheaper...

you can email me directly at nellsk@hotmail.com if you like.

thanks,

stew

a little on the rich side. Basically All I'd need are the "guts, no plinth, no arm, no cover....

If at all possible slow boat could be considered. Air mail might be an option though if it can get a little cheaper...

you can email me directly at nellsk@hotmail.com if you like.

thanks,

stew

hold on....... I think that there is a difference in the motors for the lenco in the US and europe, ie 50Hz vs 60HZ. I'm nearly certain that there are different motors in both.

If you are going to fit something else to drive it, fair enough, but if you were planning on using the motor, you may need to think again.

BTW, I have one of these, modded and in a heavy plinth. Sounds great, very good bass impact and slam. I'm using a DIY unipivot, but I think it lacks a little that my modded RB300 has. Don't hink its the TT though....

just a heads up is all....

Fran

EDIT: I think the motor can be wired for 110 as well as 230 so maybe its the nose cone thats different?

lenco lovers is what you need to have a look at.

If you are going to fit something else to drive it, fair enough, but if you were planning on using the motor, you may need to think again.

BTW, I have one of these, modded and in a heavy plinth. Sounds great, very good bass impact and slam. I'm using a DIY unipivot, but I think it lacks a little that my modded RB300 has. Don't hink its the TT though....

just a heads up is all....

Fran

EDIT: I think the motor can be wired for 110 as well as 230 so maybe its the nose cone thats different?

lenco lovers is what you need to have a look at.

Generally, in most turntables, the m0tors are the same for 50 hz and 60hz , they just have different diameter pulleys on the motor shaft , to drive the belt or the idler wheel..

woodturner-fran said:hold on....... I think that there is a difference in the motors for the lenco in the US and europe, ie 50Hz vs 60HZ. I'm nearly certain that there are different motors in both.

If you are going to fit something else to drive it, fair enough, but if you were planning on using the motor, you may need to think again.

BTW, I have one of these, modded and in a heavy plinth. Sounds great, very good bass impact and slam. I'm using a DIY unipivot, but I think it lacks a little that my modded RB300 has. Don't hink its the TT though....

just a heads up is all....

Fran

EDIT: I think the motor can be wired for 110 as well as 230 so maybe its the nose cone thats different?

lenco lovers is what you need to have a look at.

Fran,

On the question of 50 vs. 60 Hz, I think it only makes a difference if you're using Metric RPM, instead of Imperial RPM.

Best Regards,

TerryO

hey TerryO, how you doing?

One of the 5 or so tonearms I am currently making, one is slated for you. I ended up with 5 different sized shafts, so it's been a PITA, so tomorrow I think I'll go get 5 of the same size.

Any suggestions for headshells? I'm thinking about a Clearaudio style, but made of wood (dowel) and acrylic ("cartridge plate").

stew

One of the 5 or so tonearms I am currently making, one is slated for you. I ended up with 5 different sized shafts, so it's been a PITA, so tomorrow I think I'll go get 5 of the same size.

Any suggestions for headshells? I'm thinking about a Clearaudio style, but made of wood (dowel) and acrylic ("cartridge plate").

stew

Attachments

On the question of 50 vs. 60 Hz, I think it only makes a difference if you're using Metric RPM, instead of Imperial RPM.

Ha - I like that.

No, these motors are different, its not a case of simple AC synchronous mtors where you just have the same motor but a different pulley (eg linn etc).

The problem here is that the nose cone (ie that which drives teh idler wheel) is different.

I seem to remember over on lenco lovers guys selling and looking for US motors and a post about someone modding a euro motor to suit Us frequency - it involved mounting the nose cone (which is the motor armature) all in a lathe and cutting a new taper on the cone.

Look, all I'm saying is to Nanook just to check it out before you layout a fortune on shipping (even if the the TT is free). Just something to be aware of is all.

Of course I could be wrong - verify for yourself, I won't mind if I'm wrong!

Fran

metric RPM 🙂

works in metric, and Canada uses metric (has been used here for the last 30 years or so!).. Ya, obviously. I think I'd bow out graciously of kindwolf's generous offer, unless freight can be reduced by shipping only the guts of the table, and metal top plate.

Speed can be controlled with other means. I do know there are methods for controlling the Airpax motors, etc using different schemes, so it seems there must be a scheme for the Lencos.

stew

works in metric, and Canada uses metric (has been used here for the last 30 years or so!).. Ya, obviously. I think I'd bow out graciously of kindwolf's generous offer, unless freight can be reduced by shipping only the guts of the table, and metal top plate.

Speed can be controlled with other means. I do know there are methods for controlling the Airpax motors, etc using different schemes, so it seems there must be a scheme for the Lencos.

stew

Stew,

As far as headshells, I'm fine with whatever you deem to be best. You've obviously delved deeply into the arcane aspects of Turntable Design and I'm certainly comfortable with any decisions that you make. My only concern is that I can mount a variety of cartridges and that it can be adjusted.

On a more important topic, how's your wife doing? Hopefully she's doing much better and is recovering rapidly.

Best Regards,

TerryO

As far as headshells, I'm fine with whatever you deem to be best. You've obviously delved deeply into the arcane aspects of Turntable Design and I'm certainly comfortable with any decisions that you make. My only concern is that I can mount a variety of cartridges and that it can be adjusted.

On a more important topic, how's your wife doing? Hopefully she's doing much better and is recovering rapidly.

Best Regards,

TerryO

mounting cartridges, and adjustments...

Terry,

as the tonearm sits on it's own base (in this case I think l I'll use good old Viceroy 'ockey pucks), the tonearm can be moved around on top of the turntable plinth to get a good alignment. Also the headshell will have a lot of adjustment (rotationally, and longitudinally). The only adjustment that will not be very easy to do is any VTA. If I know what the measurement from the top of your platter to the top of your plinth is, I can cut the "precision bearing holder and ball assembly" to a suitable length.

The pucks are cheap and made of some good," high carbon black" rubber. It should not allow too much noise to be transfered from the plinth to the arm.

stew

Terry,

as the tonearm sits on it's own base (in this case I think l I'll use good old Viceroy 'ockey pucks), the tonearm can be moved around on top of the turntable plinth to get a good alignment. Also the headshell will have a lot of adjustment (rotationally, and longitudinally). The only adjustment that will not be very easy to do is any VTA. If I know what the measurement from the top of your platter to the top of your plinth is, I can cut the "precision bearing holder and ball assembly" to a suitable length.

The pucks are cheap and made of some good," high carbon black" rubber. It should not allow too much noise to be transfered from the plinth to the arm.

stew

Re: mounting cartridges, and adjustments...

Stew,

I really haven't made any decisions as to the TT. My old Rega will be Table of Choice, but I'm debating what to do with a plinth. Outboard addition to the "stock" unit, or a whole new, bigger build out of stacked Baltic Birch or laminated MDF/Aluminum/Cork all done with "Green Glue" or what? I'm certainly open to ideas.

It's kinda scary when you're on the verge of departing forever from the comforts of Mid-Fi and about to enter the cutting edge of the Outer Limits of SOTA.

BTW, My mouse died this last weekend, so I now have a source of "Nanook Approved Hi-End Cartridge/Arm Wire."

Another Note: I'm depending on my Canadian Cousins to recommend the appropriate Hockey Puck. As an American from the West Coast, I humblely bow to our Northern Neighbor's acknowledged superiority in all matters involving, or pertaining to ice, sleet and snow😉

I do feel, OTOH, that our rain is a match for any in the Northern Hemisphere!

Best Regards,

TerryO

Nanook said:Terry,

as the tonearm sits on it's own base (in this case I think l I'll use good old Viceroy 'ockey pucks), the tonearm can be moved around on top of the turntable plinth to get a good alignment. Also the headshell will have a lot of adjustment (rotationally, and longitudinally). The only adjustment that will not be very easy to do is any VTA. If I know what the measurement from the top of your platter to the top of your plinth is, I can cut the "precision bearing holder and ball assembly" to a suitable length.

The pucks are cheap and made of some good," high carbon black" rubber. It should not allow too much noise to be transfered from the plinth to the arm.

stew

Stew,

I really haven't made any decisions as to the TT. My old Rega will be Table of Choice, but I'm debating what to do with a plinth. Outboard addition to the "stock" unit, or a whole new, bigger build out of stacked Baltic Birch or laminated MDF/Aluminum/Cork all done with "Green Glue" or what? I'm certainly open to ideas.

It's kinda scary when you're on the verge of departing forever from the comforts of Mid-Fi and about to enter the cutting edge of the Outer Limits of SOTA.

BTW, My mouse died this last weekend, so I now have a source of "Nanook Approved Hi-End Cartridge/Arm Wire."

Another Note: I'm depending on my Canadian Cousins to recommend the appropriate Hockey Puck. As an American from the West Coast, I humblely bow to our Northern Neighbor's acknowledged superiority in all matters involving, or pertaining to ice, sleet and snow😉

I do feel, OTOH, that our rain is a match for any in the Northern Hemisphere!

Best Regards,

TerryO

- Status

- Not open for further replies.

- Home

- Source & Line

- Analogue Source

- DIY tone arm vs rega?