Variac...

unfortunately "No"

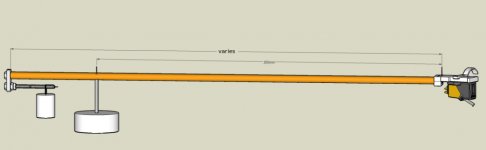

Basically it is an adaptation of the Altmann DIY tonearm , but using an aluminum arrow shaft as the major component, a ball point pen refill (for the "bearing" pivot) and a brass or steel pipe plug for the bearing "cup".

I'm putting together some examples for a trial run and sending them off to a few who had shown some interest previously ,for their input on the sound and for a critique of the arms. Everyone who has heard it loves it.

If you do a search for "Nanook's $2.19 " tonearm here on diyAudio, there is enough to get an idea. It really is very self interpretive. toughest part is attaching the counter-weight in an adjustable manner, making or adapting a headshell, and doing some fine adjustment to the length of the rear overhang to allow a standard weight to provide enough adjustment.

stew

unfortunately "No"

Basically it is an adaptation of the Altmann DIY tonearm , but using an aluminum arrow shaft as the major component, a ball point pen refill (for the "bearing" pivot) and a brass or steel pipe plug for the bearing "cup".

I'm putting together some examples for a trial run and sending them off to a few who had shown some interest previously ,for their input on the sound and for a critique of the arms. Everyone who has heard it loves it.

If you do a search for "Nanook's $2.19 " tonearm here on diyAudio, there is enough to get an idea. It really is very self interpretive. toughest part is attaching the counter-weight in an adjustable manner, making or adapting a headshell, and doing some fine adjustment to the length of the rear overhang to allow a standard weight to provide enough adjustment.

stew

webby said:

Thanks for the info Graeme, I will have to have a play. Do you have any other pictures, a thousand word and all that?

I live down sauf, south east London

cheers

Ian

From east london myself but living in sheffield.

I can take more pics if you like but im deliberately being a little coy. I'd rather you worked it out for yourself, purely because you'll get more out of the project and you'll understand the arm more. Im sure you'll also work out your own ways of doing things too.

Having said that, ill answer any questions you have gladly🙂

Stuey said:Howdy Graeme,

What type of pump is used? I can't see any mention of it on the site - apologies if I'm a bit of a blind git...

Cheers

Stuey

Any fish tank type air pump will do, mine puts out 550lph, it was about £15.

I dont need to run it on full though.

Ive just swapped for a vintage piston pump though just because there cool!

some instructions

I hadn't written up instructions as I thought it is pretty intuitive, but perhaps not (maybe I "see" things in my head a little easier than some)

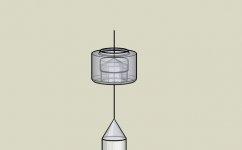

Basically the tonearm is a Altmann DIY tonearm, but using a brass or steel "cup" and a 1mm (or smaller), high precision ball bearing inserted into a steel carry device (a discarded ball point pen refill).

As the headshell mass plays a large role, and I haven't made what many might consider one, the rear overhang can vary from 2"-3" , while the arm tube itself is essentially 12". Add an inch or so for a headshell, and you end up with something approximately 13" effective length. Use whatever alignment gauge you want. a 1 point or 2, and whatever "flavour"...

One must use something to hold the "high precision bearing" holder, a piece of wood or whatever. But don't secure it to anything until you align the cartridge satisfactorily, as there is not a lot of adjustment available. Obviously an adjustable headshell needs to be made or devised and I have a very simple one in mind.

And all who have heard it are completely in awe (sorry, my head is swelling just a bit). As stated though I have merely innovated an existing design to use a little more precision compared to others of this type.

The ones I am sending off are in direct response to some in-person enquiries. I may further develop this into a kit or commercial design. I have been in direct contact with Mr. Altmann to ensure that there is no infringement on his intellectual property. He is a very gracious man.

stew

I hadn't written up instructions as I thought it is pretty intuitive, but perhaps not (maybe I "see" things in my head a little easier than some)

Basically the tonearm is a Altmann DIY tonearm, but using a brass or steel "cup" and a 1mm (or smaller), high precision ball bearing inserted into a steel carry device (a discarded ball point pen refill).

As the headshell mass plays a large role, and I haven't made what many might consider one, the rear overhang can vary from 2"-3" , while the arm tube itself is essentially 12". Add an inch or so for a headshell, and you end up with something approximately 13" effective length. Use whatever alignment gauge you want. a 1 point or 2, and whatever "flavour"...

One must use something to hold the "high precision bearing" holder, a piece of wood or whatever. But don't secure it to anything until you align the cartridge satisfactorily, as there is not a lot of adjustment available. Obviously an adjustable headshell needs to be made or devised and I have a very simple one in mind.

And all who have heard it are completely in awe (sorry, my head is swelling just a bit). As stated though I have merely innovated an existing design to use a little more precision compared to others of this type.

The ones I am sending off are in direct response to some in-person enquiries. I may further develop this into a kit or commercial design. I have been in direct contact with Mr. Altmann to ensure that there is no infringement on his intellectual property. He is a very gracious man.

stew

Attachments

graeme uk said:

Any fish tank type air pump will do, mine puts out 550lph, it was about £15.

I dont need to run it on full though.

Ive just swapped for a vintage piston pump though just because there cool!

Thanks. I assume then that the pump is placed away from the listening area, or is it in a sound proofed box?

Cheers

Stu

Re: some instructions

Stew,

The sketch of the arm looks excellent! I plan on giving it a go once I find something worth putting it on. There have been some advancements in that area, and hopefully I can make it down to that shop next week (they have really short daily hours). I've also been working on my own sketches, one for my own version of the Altmann turntable, and one for a tonearm. I throw some sketches your way once I get past the ugly planning stages.

-Justin

Nanook said:I hadn't written up instructions as I thought it is pretty intuitive, but perhaps not (maybe I "see" things in my head a little easier than some)

Basically the tonearm is a Altmann DIY tonearm, but using a brass or steel "cup" and a 1mm (or smaller), high precision ball bearing inserted into a steel carry device (a discarded ball point pen refill).

As the headshell mass plays a large role, and I haven't made what many might consider one, the rear overhang can vary from 2"-3" , while the arm tube itself is essentially 12". Add an inch or so for a headshell, and you end up with something approximately 13" effective length. Use whatever alignment gauge you want. a 1 point or 2, and whatever "flavour"...

One must use something to hold the "high precision bearing" holder, a piece of wood or whatever. But don't secure it to anything until you align the cartridge satisfactorily, as there is not a lot of adjustment available. Obviously an adjustable headshell needs to be made or devised and I have a very simple one in mind.

And all who have heard it are completely in awe (sorry, my head is swelling just a bit). As stated though I have merely innovated an existing design to use a little more precision compared to others of this type.

The ones I am sending off are in direct response to some in-person enquiries. I may further develop this into a kit or commercial design. I have been in direct contact with Mr. Altmann to ensure that there is no infringement on his intellectual property. He is a very gracious man.

stew

Stew,

The sketch of the arm looks excellent! I plan on giving it a go once I find something worth putting it on. There have been some advancements in that area, and hopefully I can make it down to that shop next week (they have really short daily hours). I've also been working on my own sketches, one for my own version of the Altmann turntable, and one for a tonearm. I throw some sketches your way once I get past the ugly planning stages.

-Justin

instead of air, could you use magnets (reversed)?

http://www.diyaudio.com/forums/showthread.php?s=&postid=1610742#post1610742

http://www.diyaudio.com/forums/showthread.php?s=&postid=1610742#post1610742

despotic931, tonearm stuff

it really is very easy. (the tonearm)

and is just a continuation of the Altmann design. Google sketchup is what I use for the "drawing", it's free, multi-platform and easy to use (but the learning curve is a little steep to start).

I have a few photos posted on diyAudio, just do the search.

stew

it really is very easy. (the tonearm)

and is just a continuation of the Altmann design. Google sketchup is what I use for the "drawing", it's free, multi-platform and easy to use (but the learning curve is a little steep to start).

I have a few photos posted on diyAudio, just do the search.

stew

Re: despotic931, tonearm stuff

I've played with sketchup a bit, heres my humble first attempts. I've actually read through this thread multiple times, and I like what you've done with the counter weight in its newest form.

And now for a question that is back on topic. Doesn't the escaping are produce noise? It's just that I often listen at low levels and I fear this would be the equivalent of a hissing amp.

-Justin

Nanook said:it really is very easy. (the tonearm)

and is just a continuation of the Altmann design. Google sketchup is what I use for the "drawing", it's free, multi-platform and easy to use (but the learning curve is a little steep to start).

I have a few photos posted on diyAudio, just do the search.

stew

I've played with sketchup a bit, heres my humble first attempts. I've actually read through this thread multiple times, and I like what you've done with the counter weight in its newest form.

And now for a question that is back on topic. Doesn't the escaping are produce noise? It's just that I often listen at low levels and I fear this would be the equivalent of a hissing amp.

-Justin

Re: Re: despotic931, tonearm stuff

just turn the music up, there will be no hissing audible🙂

There is a lot that can be done to reduce pump noise, etc---that is usually the biggest "noise maker" with air bearing tonearms. The amount of air escaping and floating the arm is pretty minimal. I have never heard a "hissing" air bearing and have listened to a few.

stew

despotic931 said:

And now for a question that is back on topic. Doesn't the escaping are produce noise? It's just that I often listen at low levels and I fear this would be the equivalent of a hissing amp.

-Justin

just turn the music up, there will be no hissing audible🙂

There is a lot that can be done to reduce pump noise, etc---that is usually the biggest "noise maker" with air bearing tonearms. The amount of air escaping and floating the arm is pretty minimal. I have never heard a "hissing" air bearing and have listened to a few.

stew

Pump can be in a box or another room, the manifold is silent, no hissing at all.

As for magnets, i thought about that but discussions elsewhere have already explained why that wont work. It wont be stable enough, the air gap is very thin!

As for magnets, i thought about that but discussions elsewhere have already explained why that wont work. It wont be stable enough, the air gap is very thin!

Hi Nanook,

I have an L75 for free if you want to pay for the shipping. It looks a little rough, as I moved out of a house for a couple of years and when I returned I found that the TT had been put in the garden shed. The bottom cover and some of the other soft parts are not too hot but the fundamentals are sound. I got it at a boot sale about five years ago and paid the grand sum of £8.00 for it. I'm looking at building a TT from the ground up and thought about using the idler but decided to go DC in the end, so it's up for grabs if you want it?

I have an L75 for free if you want to pay for the shipping. It looks a little rough, as I moved out of a house for a couple of years and when I returned I found that the TT had been put in the garden shed. The bottom cover and some of the other soft parts are not too hot but the fundamentals are sound. I got it at a boot sale about five years ago and paid the grand sum of £8.00 for it. I'm looking at building a TT from the ground up and thought about using the idler but decided to go DC in the end, so it's up for grabs if you want it?

kindwolf....

very generous! Is it all there? I live in Canada, so it's a ways off, but I'm game as long as the shipping isn't too expensive...don't really need the tonearm though. Then I'd have to do a transformer I think (unless someone for sure f I'd need to, or I coul regenerate ac frequency for it...

thanks for the generous offer.

I live at postal code T1H 4V7. If you could get a shipping estimate from your end, if I can afford the shipping, I'd Paypal you or similar.

stew

very generous! Is it all there? I live in Canada, so it's a ways off, but I'm game as long as the shipping isn't too expensive...don't really need the tonearm though. Then I'd have to do a transformer I think (unless someone for sure f I'd need to, or I coul regenerate ac frequency for it...

thanks for the generous offer.

I live at postal code T1H 4V7. If you could get a shipping estimate from your end, if I can afford the shipping, I'd Paypal you or similar.

stew

This is fascinating! Here I was rueing even the price of an RB250 for my Planar 2 table (as an upgrade from the stock R200 - the S shaped one) let alone something like an SME. But now I've been inspired...

Thanks!

Stuey

Thanks!

Stuey

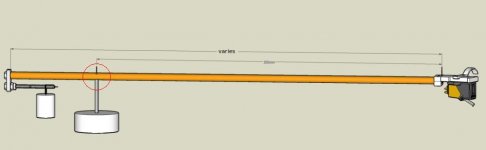

sorry for the bit of a thread "hijack"...

the encircled portion of the drawing is a ball point pen refill, and an Allen head cap screw or similar (trimmed up centre punched and glued into the arm tube), or pipe plug. Both pieces become the bearing for the arm pivot. The vertical line in the complete arm view is just there to ensure alignment of all the pieces in the sketchup.

stew

the encircled portion of the drawing is a ball point pen refill, and an Allen head cap screw or similar (trimmed up centre punched and glued into the arm tube), or pipe plug. Both pieces become the bearing for the arm pivot. The vertical line in the complete arm view is just there to ensure alignment of all the pieces in the sketchup.

stew

Attachments

How do you keep the allen head cap screw vertically plump in line with the vertical line? The glue will take some time to harden and I don't know how to keep the allen screw vertically plump in relation to the arm also?

By the way, I remember reading from somewhere that a unipivot needs a lot of attention when choosing a cartridge. Any comments on this? How do you solve the skating of the arm?

- Status

- Not open for further replies.

- Home

- Source & Line

- Analogue Source

- DIY tone arm vs rega?