At the end of the day, the ultimate test is to balance the tonearm and fine tune the leveling until there's no tendency to spin in any direction. A few years ago I made an air bearing based tangential tonearm and believe me, I know very well what leveling means 🙂 If it wasn't for the fish tank air pump buzz and the tiniest grain of dust making the tonearm skip the groove, I would have never give it up. It sounded fantastic!

The levels at the top of these arms are useless, because it cannot take the setting of the stylus setting into account. Which has the primary requirement to perpendicular to the LP. Although most styli are set correctly, not all are.

Cheers

Cheers

In my post #1548 I said it's almost impossible to replicate Frank's LT TA. I said "almost" because I had a hint it's doable even without high-tech tools and the original blueprints. After analyzing and mathematically replicating its geometry, I'm sure it is!

After all, we DIY-ers should never say never and at all times, think out of the box 🙂

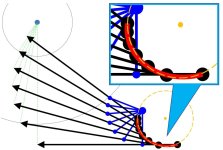

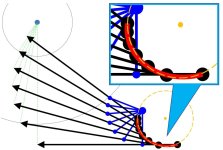

Have a look at the attached image. It's obvious the red path is anything close to a circle, but using a technique widely applied in digital 3D animation and robotics, called inverse kinematics, it's rather easy to get it right.

This image also highlights some interesting facts:

1) No Birch-type TA, using a variable shape quadrilateral, will ever be able to obtain perfect tracking. Not even Thales Statement or Reed 5A can do it. The initial Thales model probably did, but it was so cumbersome that Micha Huber eventually gave it up.

2) Frank's genius made it possible to do it reducing at the same time from four to two the number of vertical bearings needed. With the added bonus of the damping provided by the magnetic coupling.

After all, we DIY-ers should never say never and at all times, think out of the box 🙂

Have a look at the attached image. It's obvious the red path is anything close to a circle, but using a technique widely applied in digital 3D animation and robotics, called inverse kinematics, it's rather easy to get it right.

This image also highlights some interesting facts:

1) No Birch-type TA, using a variable shape quadrilateral, will ever be able to obtain perfect tracking. Not even Thales Statement or Reed 5A can do it. The initial Thales model probably did, but it was so cumbersome that Micha Huber eventually gave it up.

2) Frank's genius made it possible to do it reducing at the same time from four to two the number of vertical bearings needed. With the added bonus of the damping provided by the magnetic coupling.

I think it may be off the topic to talk about Birch-style tonearm here.In my post #1548 I said it's almost impossible to replicate Frank's LT TA. I said "almost" because I had a hint it's doable even without high-tech tools and the original blueprints. After analyzing and mathematically replicating its geometry, I'm sure it is!

I would say it is possible to replicate if you are willing to pay for the magnetic rail at any cost. My question is do you need to?

This topic had been covered in DD's excellent thread, Angling for 90° - tangential pivot tonearms.Have a look at the attached image. It's obvious the red path is anything close to a circle, but using a technique widely applied in digital 3D animation and robotics, called inverse kinematics, it's rather easy to get it right.

This image also highlights some interesting facts:

1) No Birch-type TA, using a variable shape quadrilateral, will ever be able to obtain perfect tracking. Not even Thales Statement or Reed 5A can do it. The initial Thales model probably did, but it was so cumbersome that Micha Huber eventually gave it up.

In my thread, Building a Tuthill/Reed 5A Tangential Tracking Pivot Tonearm, the maximum tracking error for my 6B is only less than 0.1 degrees, which may be smaller than the construction tolerance for DIYers. For 6C, its tracking error is even smaller. Old Thales tonearm should have no tracking errors in theory, but not Reed 5A. Frank's LT and Reed 5A should have similar tracking errors. I am pretty sure that my 6B has less tracking errors than Frank's LT and Reed 5A in theory, not to mention my 6C. My 6C has the smallest tracking errors. However, small tracking error is not the only factor for performance.

In my post #1548 I said it's almost impossible to replicate Frank's LT TA. I said "almost" because I had a hint it's doable even without high-tech tools and the original blueprints. After analyzing and mathematically replicating its geometry, I'm sure it is!

After all, we DIY-ers should never say never and at all times, think out of the box 🙂

Have a look at the attached image. It's obvious the red path is anything close to a circle, but using a technique widely applied in digital 3D animation and robotics, called inverse kinematics, it's rather easy to get it right.

This image also highlights some interesting facts:

1) No Birch-type TA, using a variable shape quadrilateral, will ever be able to obtain perfect tracking. Not even Thales Statement or Reed 5A can do it. The initial Thales model probably did, but it was so cumbersome that Micha Huber eventually gave it up.

2) Frank's genius made it possible to do it reducing at the same time from four to two the number of vertical bearings needed. With the added bonus of the damping provided by the magnetic coupling.

View attachment 1191524

Hi,

Agree, the Frank s execution is really genius as technical solution and also as design and minimalist good look.

Rgds

Adelmo

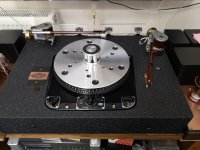

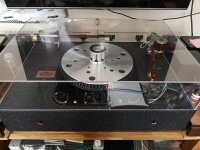

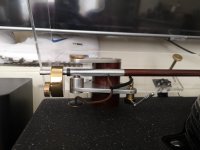

Very nice work....more pictures would be lovely.I have been following this forum for a long time and the result of many hours of my work is the long-awaited turntable with two arms.

Of course, more pictures.

Attachments

-

IMG_20240322_124030.jpg465.1 KB · Views: 202

IMG_20240322_124030.jpg465.1 KB · Views: 202 -

IMG_20240322_124042.jpg522.8 KB · Views: 221

IMG_20240322_124042.jpg522.8 KB · Views: 221 -

IMG_20240322_124059.jpg304.3 KB · Views: 221

IMG_20240322_124059.jpg304.3 KB · Views: 221 -

IMG_20240322_124107.jpg255 KB · Views: 219

IMG_20240322_124107.jpg255 KB · Views: 219 -

IMG_20240322_124111.jpg238.9 KB · Views: 201

IMG_20240322_124111.jpg238.9 KB · Views: 201 -

IMG_20240322_124121.jpg333.9 KB · Views: 195

IMG_20240322_124121.jpg333.9 KB · Views: 195 -

IMG_20240322_124127.jpg300.2 KB · Views: 201

IMG_20240322_124127.jpg300.2 KB · Views: 201 -

IMG_20240322_124135.jpg340.6 KB · Views: 224

IMG_20240322_124135.jpg340.6 KB · Views: 224 -

IMG_20240322_124151.jpg443.6 KB · Views: 226

IMG_20240322_124151.jpg443.6 KB · Views: 226 -

IMG_20240322_124201.jpg522.2 KB · Views: 218

IMG_20240322_124201.jpg522.2 KB · Views: 218 -

IMG_20240322_124223.jpg242.3 KB · Views: 213

IMG_20240322_124223.jpg242.3 KB · Views: 213

I also thought about making an LT arm, but it is a very difficult task, it seems even impossible without very precise machines and, above all great knowledge.

It plays very well, I had several good turntables and none of them played so well. There are silver VDH cables in the arms and they are connected to WBT-0210Ag RCA Sockets. Only now you can really hear the differences between the gramophone cartridges, so I'm still looking for better ones and these are a lot of money. I dream of a Lyra Etna, but £10,000 is out of my reach.

But if I were to build a turntable tonearm again, I would use Audio Note silver Tonearm wires are the best I have ever seen, of course they are difficult to solder, but the effect is great. I replaced them with Linn Ekos and the change in sound quality was shocking.

The drill in wood has a tendency to run away and at such a length it will never be perfectly straight, so it is best to cut a square or several, for example 25 mm x 25 mm, and only after drilling, mount it in the centers of a wood lathe and then after turning you will have a hole in the middle.

Of course, you may need a few tries and good quality drill bits of different lengths, my arms are 12" long.

Drilling in a lathe is more accurate (but even so its a big ask), I wonder if a pilot hole can be laser-drilled? (Not with a CO2 laser for a hole that deep, note, the fumes absorb the beam completely).

One approach is take a thicker stock, lathe-drill the hole, then use the hole as centres for turning down the tube, but then you have the problem of needing centre-rests and great care not to ruin it.

Pencils are made by gluing two half-tube sections together - this is probably the best approach.

One approach is take a thicker stock, lathe-drill the hole, then use the hole as centres for turning down the tube, but then you have the problem of needing centre-rests and great care not to ruin it.

Pencils are made by gluing two half-tube sections together - this is probably the best approach.

I did it on a lathe, I'm sure there are other better ways. I did it all myself without any help at home on a mini lathe.

If it doesn't have to be round all the way along, then perhaps it could be made of wooden strips, stuck together with superglue - leaving a path for the wire in the middle!

Then you need to experiment yourself. For me, drilling in wood was not a big problem. If someone trying to make a maple magnetic arm manages to find a way to make a properly functioning magnetic bearing {and that's not easy!!!}, the rest of the work shouldn't pose any problem.

Hi Mark,Pencils are made by gluing two half-tube sections together - this is probably the best approach.

A variation of that would be to use a straight grained piece of wood and split it lengthwise, mill a groove into each half and glue it back together.

I have not tried that method but it might work. If done correctly, one should not be able to see how it was done.

Sincerely,

Ralf

- Home

- Source & Line

- Analogue Source

- DIY Schroeder Tonearm?