I wish I have the tools to finish my suspension

I will use metal arrow shaft, I have most of the parts but with out precision tools I can not do these.. With a power drill not possible..

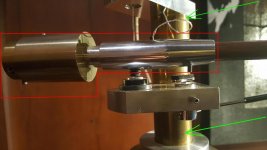

I made the support marked GREN but I can't do these part marked RED

It would be nice of someone could help, I'm willing to pay reasonable price

Greetings

I will use metal arrow shaft, I have most of the parts but with out precision tools I can not do these.. With a power drill not possible..

I made the support marked GREN but I can't do these part marked RED

It would be nice of someone could help, I'm willing to pay reasonable price

Greetings

Attachments

It would be nice of someone could help, I'm willing to pay reasonable price

I'd like to help but I'm far away.

I had to use steel ball pivot to clamp the string with a bolt.

to a position above, I give a small bearing to prevent twist of string. quite helpful.

The string should twist, it's a part of anti-skating mec.

What is the diameter of a string?

I have made three or four unipivot and a dual pivot arm in the past. Subjectively two have been on a par (if slightly more detailed) with my favourite, the FR64S.🙂. These had ceramic arm-wands and were high mass designs for a Kondo Io cartridge. Correspondence shortly before Kondo San's sad demise suggested that Frank's arm had become his reference.

Having lurked on this thread since its beginning I would now like to attempt an arm-build and, like Gabor above, I not only have no power tools other than a hand drill or two. However I have successfully 'briefed-out' quite complicated designs for fly-fishing reels (based on those of the late Stan Bogdan).

Being a very keen fisherman I have a variety of broken fly-rods. Amongst these bits I have a butt section of a built-bamboo rod. This is made from six strips of bamboo which has been hardened by heat; each strip is planed to 60degree angles and six strips glued and cured under pressure give a hexagonal cross section which is stiffer than raw bamboo of similar dimensions. My mind tells me that this piece may make a superb arm-wand.

Any comments? [the metal work would be put out to a machine shop.]

Many Thanks

Having lurked on this thread since its beginning I would now like to attempt an arm-build and, like Gabor above, I not only have no power tools other than a hand drill or two. However I have successfully 'briefed-out' quite complicated designs for fly-fishing reels (based on those of the late Stan Bogdan).

Being a very keen fisherman I have a variety of broken fly-rods. Amongst these bits I have a butt section of a built-bamboo rod. This is made from six strips of bamboo which has been hardened by heat; each strip is planed to 60degree angles and six strips glued and cured under pressure give a hexagonal cross section which is stiffer than raw bamboo of similar dimensions. My mind tells me that this piece may make a superb arm-wand.

Any comments? [the metal work would be put out to a machine shop.]

Many Thanks

hi.

i seen in post by Zoen / stoN_cold. very nice and perfect.

I am not an expert. The project for the hobby and just corious.

i have not made that perfect, as in say ugly .. lol .... thanks Zeon ..

at Last about the string problem I have tried replaced with the small diameter of 0.45mm, but a hole in the pivot quite large 1.00 mm .in the vertical position occurs oblique. Therefore, I still try to use the diameter as yesterday but in the auxiliary bearings to avoid twisting. to create a New pivot again was difficult. but this is enough for me ... but this is enough for me ... thanks Zoen.

i seen in post by Zoen / stoN_cold. very nice and perfect.

I am not an expert. The project for the hobby and just corious.

i have not made that perfect, as in say ugly .. lol .... thanks Zeon ..

at Last about the string problem I have tried replaced with the small diameter of 0.45mm, but a hole in the pivot quite large 1.00 mm .in the vertical position occurs oblique. Therefore, I still try to use the diameter as yesterday but in the auxiliary bearings to avoid twisting. to create a New pivot again was difficult. but this is enough for me ... but this is enough for me ... thanks Zoen.

thanks Zoen.

I am not Zoen, stoN_Cold!

Use some small plastic tubing or insulation from the wire as the difference in diameter from 0,45 to 1mm.

Fugly 🙄

Hi guys,

Yes, one should incorporate a provision for twisting the thread as this is indeed what excerts the necessary skating compensation force.

I've used bamboo to build armwands many times,- natural(just heat-treated), layered and split cane types(I built a few fly fishing rods in my teens...). An old spinning or fly fishing split cane handle piece will make an excellent blank for an armwand. Just don't slaughter an otherwise fine rod for that purpose, please... 🙂

Also remember that it isn't easy to come up with a mechanically sound connection/transition from a hexagonal wand to either headshell and/or bearing end stub.

Good luck with your project!

Frank

Yes, one should incorporate a provision for twisting the thread as this is indeed what excerts the necessary skating compensation force.

I've used bamboo to build armwands many times,- natural(just heat-treated), layered and split cane types(I built a few fly fishing rods in my teens...). An old spinning or fly fishing split cane handle piece will make an excellent blank for an armwand. Just don't slaughter an otherwise fine rod for that purpose, please... 🙂

Also remember that it isn't easy to come up with a mechanically sound connection/transition from a hexagonal wand to either headshell and/or bearing end stub.

Good luck with your project!

Frank

For my next project I planing to use : Bass Fishing Rod Reviews | BASStardFishing.com

Мммммммммм carrot.

Мммммммммм carrot.

For my next project I planing to use : Bass Fishing Rod Reviews | BASStardFishing.com

Мммммммммм carrot.

the 'carrot stick' (Curran) was designed and invented about 10 miles away from me in a town i used to stay in. i think they are still in business there but i'm not sure. i've often thought about popping my head round the door for a chat.

The pic shows two of the built cane/bamboo shafts (these are hexagonal cross section). The white one is silicon carbide (makes a very 'fast' unipivot arm) and the green piece is from the butt of a light salmon flyrod.....graphite tube - [which would need some internal damping and mass for my purposes.]

Any comments on suitability welcomed.🙂

Many thanks.

Bibio: your name suggests that you know a bit about rods!😉

Any comments on suitability welcomed.🙂

Many thanks.

Bibio: your name suggests that you know a bit about rods!😉

Attachments

I am not Zoen, stoN_Cold!

sorry, I may be wrong when you change the name. i mean and know Zeonrider

very happy if you can share with your system that would sound very nice.

regards

fugly 😀

https://youtu.be/9d-_s_aa-yc

The pic shows two of the built cane/bamboo shafts (these are hexagonal cross section). The white one is silicon carbide (makes a very 'fast' unipivot arm) and the green piece is from the butt of a light salmon flyrod.....graphite tube - [which would need some internal damping and mass for my purposes.]

Any comments on suitability welcomed.🙂

Many thanks.

Bibio: your name suggests that you know a bit about rods!😉

got me.. my first love in life was fly fishing on the Tweed and Galla Water. i started at the age of 8 and also started fly tying at the same time at around the age of 10 i built my first fly rod which was multi section due to having to use the bus to go fishing as i stayed in Edinburgh. my local fishing shop was Simpsons in east preston street, very knowledgable people who used to take time to teach me more complicated fly tying techniques and rod building.

I may be wrong when you change the name. i mean and know Zeonrider

New year, new nickname 🙂

Hey guys! Sorry for posting back in may and just vanishing. In that time so much has been happening lol. I bought a house got engaged... ya know the spiel. And Herr Schröder I apologize for coming out so blut and asking for dimensions. I should have thought more before a blurted out. I never meant any harm. But anyway in the mean time I have been going nuts designing and have built a few pieces of my arm base and wand! I will be using carbon fiber for my first wand but designed thr main arm to allow easy removal of the wand to accept another, which may be mahogany.

An externally hosted image should be here but it was not working when we last tested it.

here are some of the party's I have made soo far. The brass headshell id's actually for another build im doing where the wand is based of the looks of the pete riggle "woody" both will be 12" armsFinally, I have almost everything 🙂

Next step is to connect cable to cartridge pins in headshell and connectors on the back, to modify a lift and to finalize a headshell to accept a cartridge, more pictures will follow (once it is done).

Next step is to connect cable to cartridge pins in headshell and connectors on the back, to modify a lift and to finalize a headshell to accept a cartridge, more pictures will follow (once it is done).

Attachments

Finally, I have almost everything 🙂

Next step is to connect cable to cartridge pins in headshell and connectors on the back, to modify a lift and to finalize a headshell to accept a cartridge, more pictures will follow (once it is done).

Nice, change four screws on the top now are fugly.

Nice, change four screws on the top now are fugly.

🙂 they are already ordered

- Home

- Source & Line

- Analogue Source

- DIY Schroeder Tonearm?